Until 26 April 2017

KURIchoco molding and casting

Contents

- 'KURIchoco' Design

- Mill Mold

- Make Mold

- Casting KURIchoco

'KURIchoco' Design

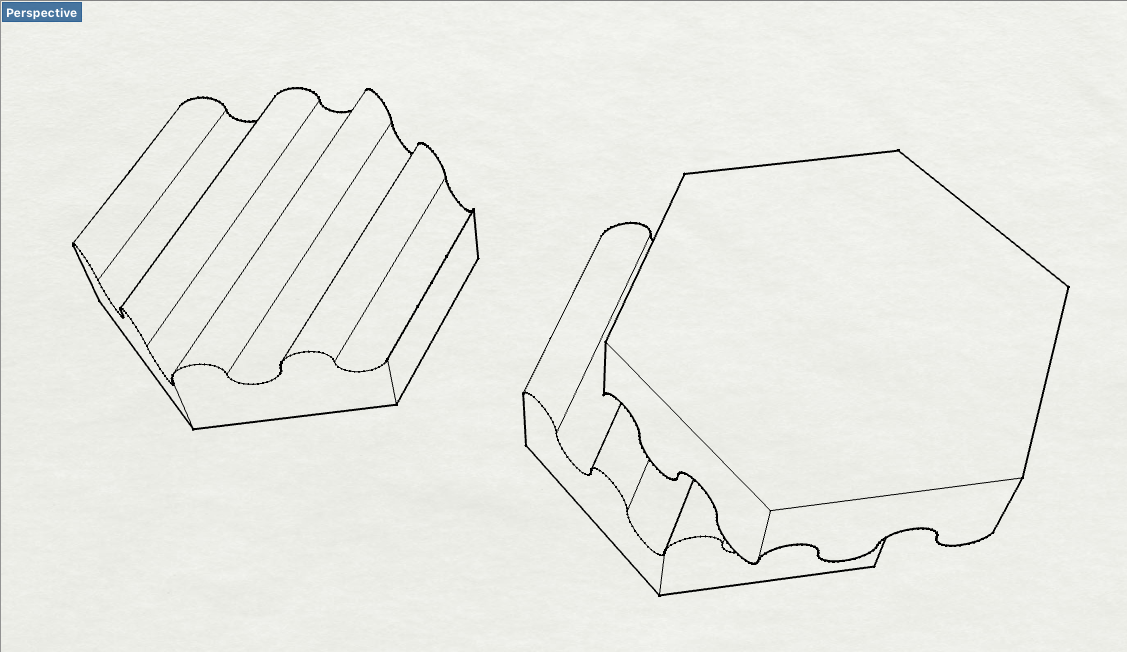

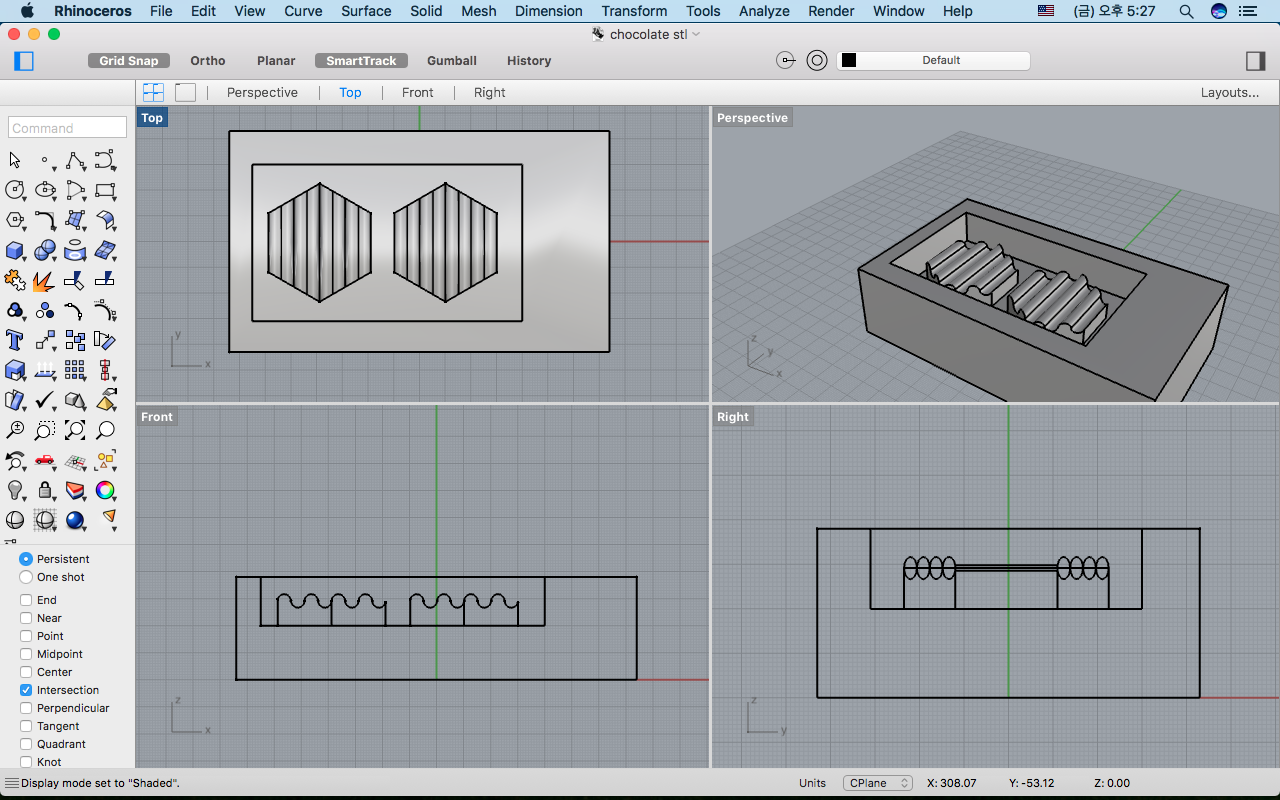

Modeling chocolate in Rhino

Modeling Mold in Rhino (stl file)

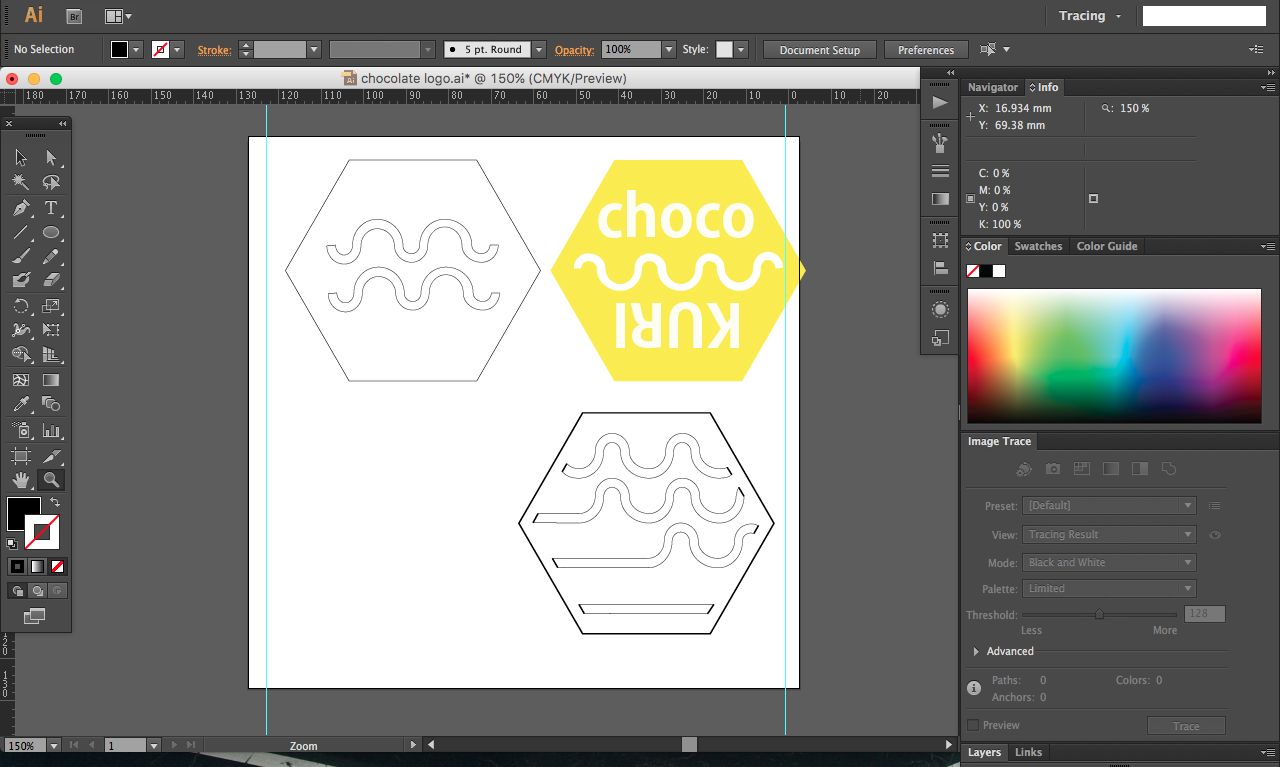

Branding & KURIchoco Logo

Layout and vinyl cutout

Mill 3D Mold

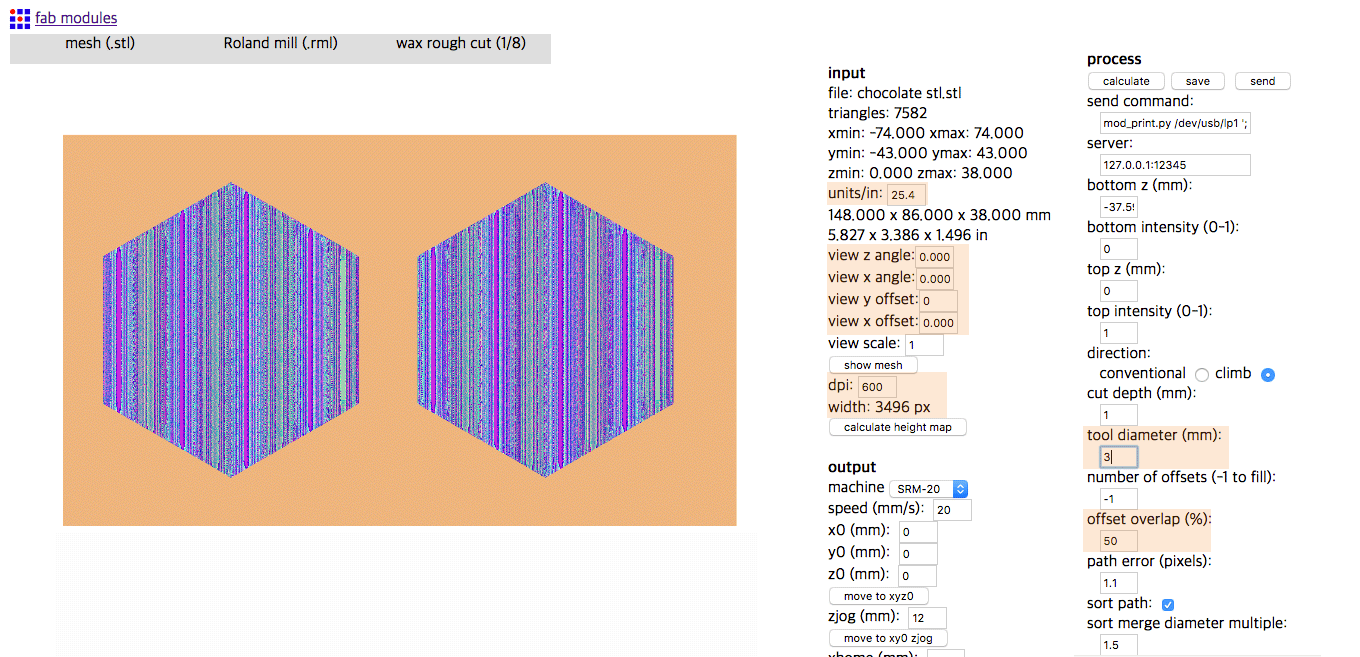

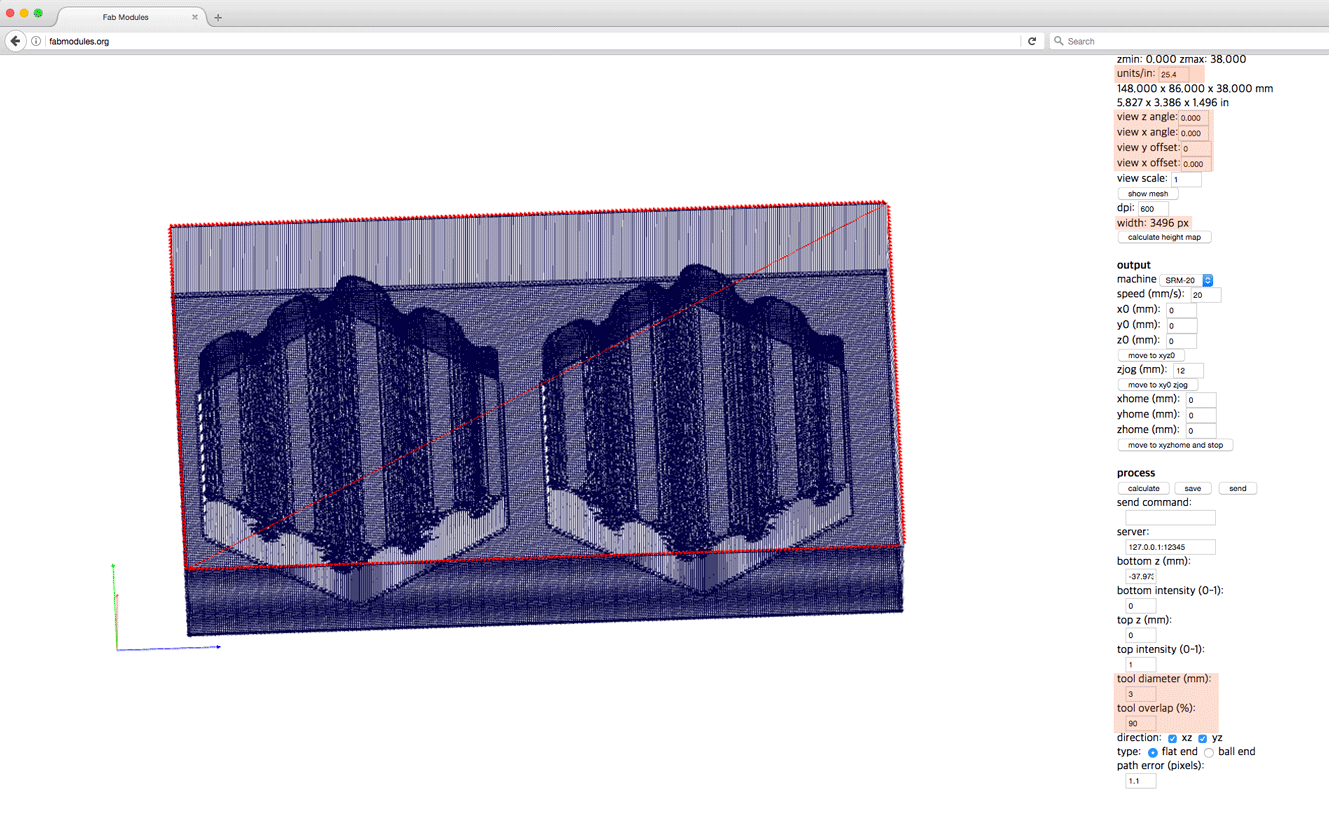

Fabmodule

Wax Rough Cut

Wax Finish Cut

For this mold, I used Roland SRM-20 and blue Ferris: File-A-Wax(Carving & Milling Wax).

Error: at the fab module(wax finish), I didn't select [type: ball end], so I didn't get smooth result.

Make Mold

Link to instructions: Smooth-Sil 940 'FOOD SAFE: Platinum Silicones cure at room temperature with negligible shrinkage.'

Molding and Casting Tips / Using Fab Modules: tutorial from Fab Modules, CNC milling to finished mold.

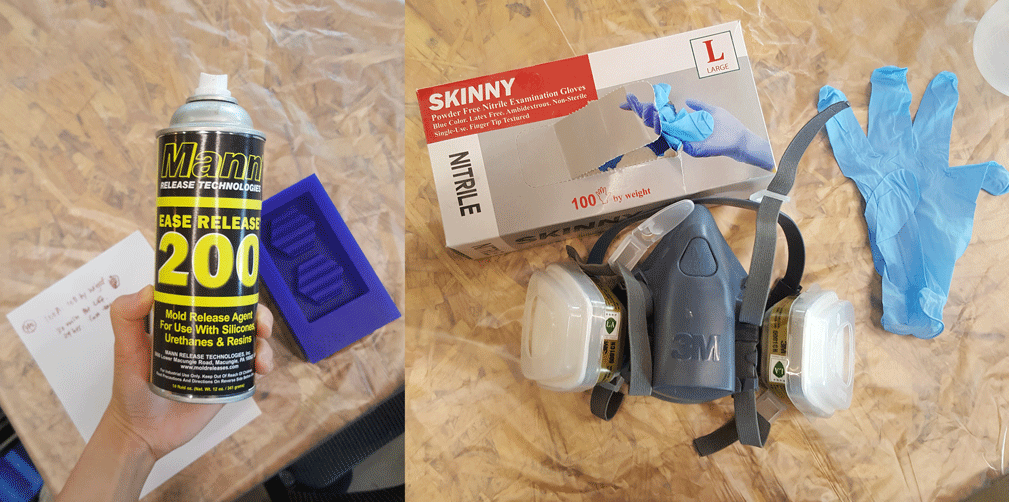

Mann's Ease Relese 200 wax-base non silicone liquid release agent. WEAR MASK + gloves! Spray from angle so it doesn't leave any blind spots.

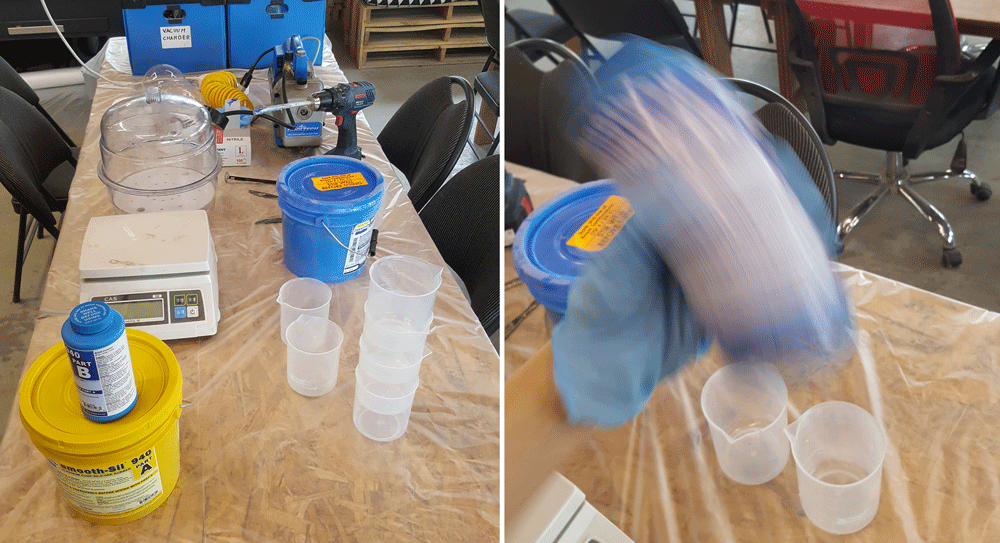

After reading the website and MSDS, I prepared all the materials and put all the mold related materials on top of cover.

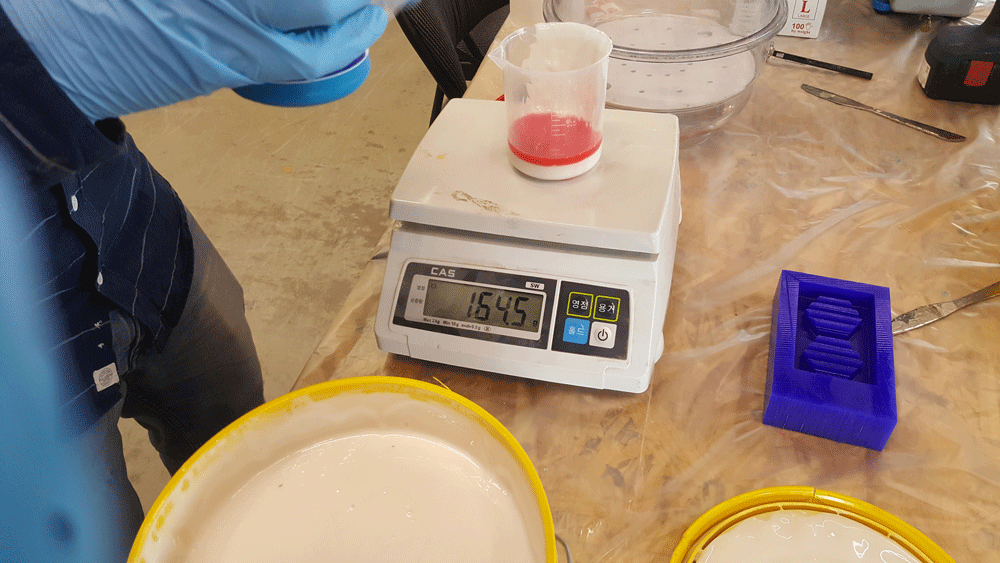

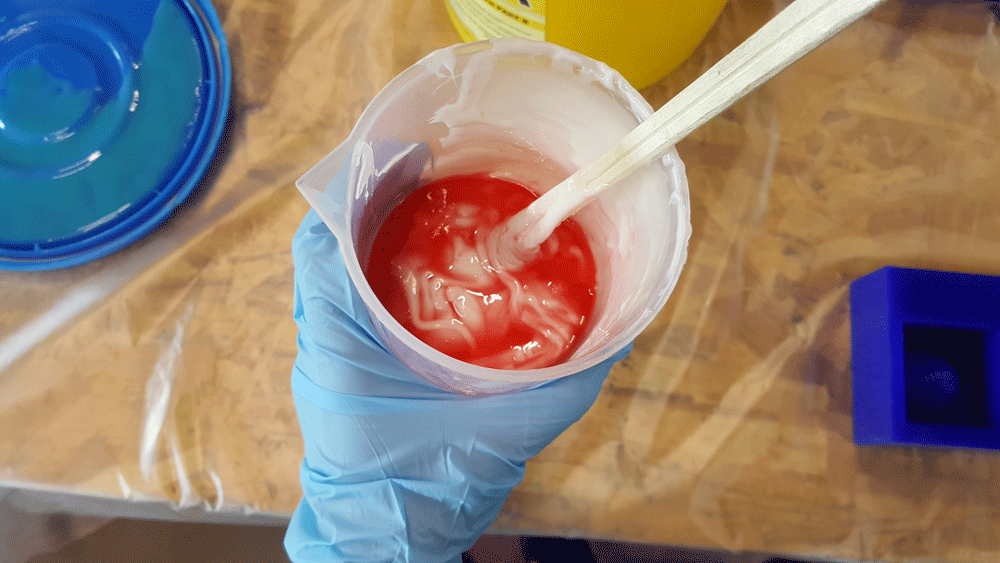

Best way for getting the volume of the mold, add water and measure. I used 100A:10B ratio so 15:150gram. 30 minutes pot life.

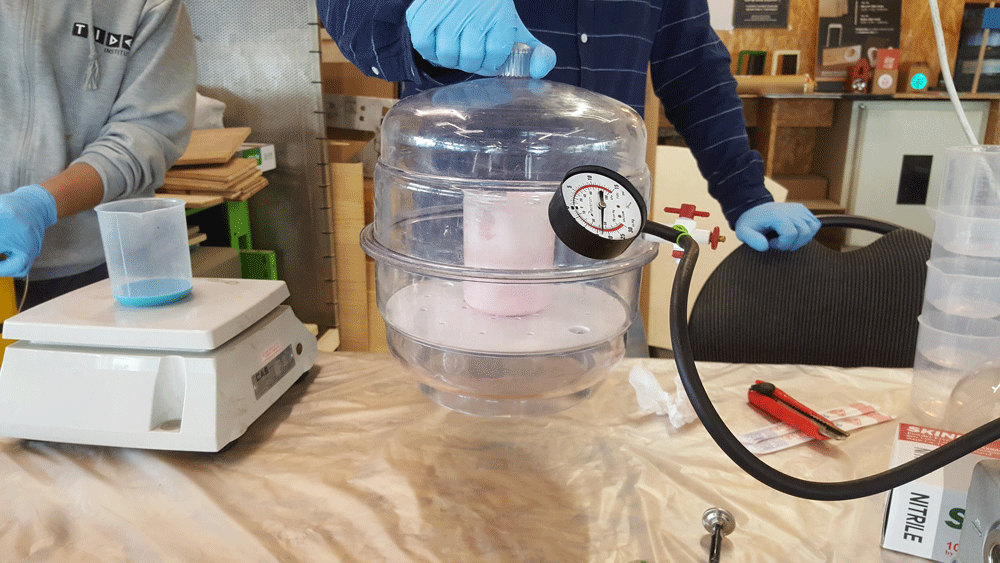

After Mixing parts A and B, vacuum degassing was used to eliminate any entrapped air. On and off puttons were open and close.

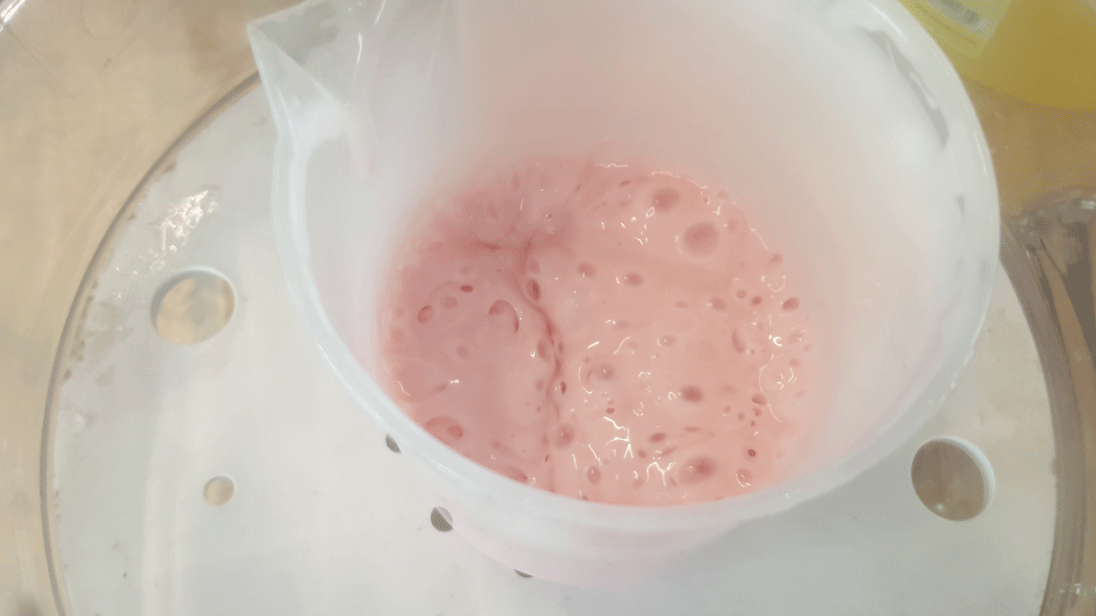

We can lift the vacuum to make sure that vacuum works.

After few minutes, bubble started to raise.

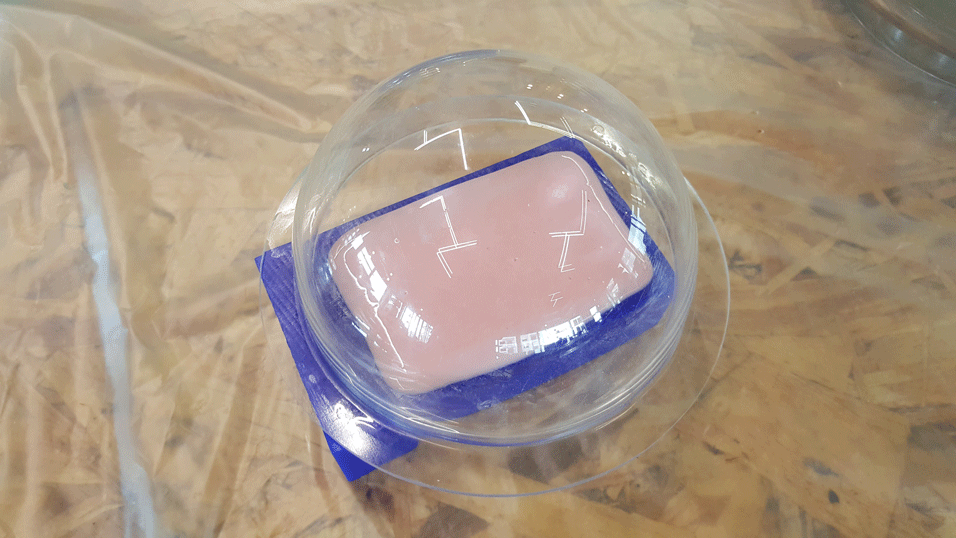

Pore silicone to the mold with thin line of silicone in angle.

Let if cure for 24 hours.

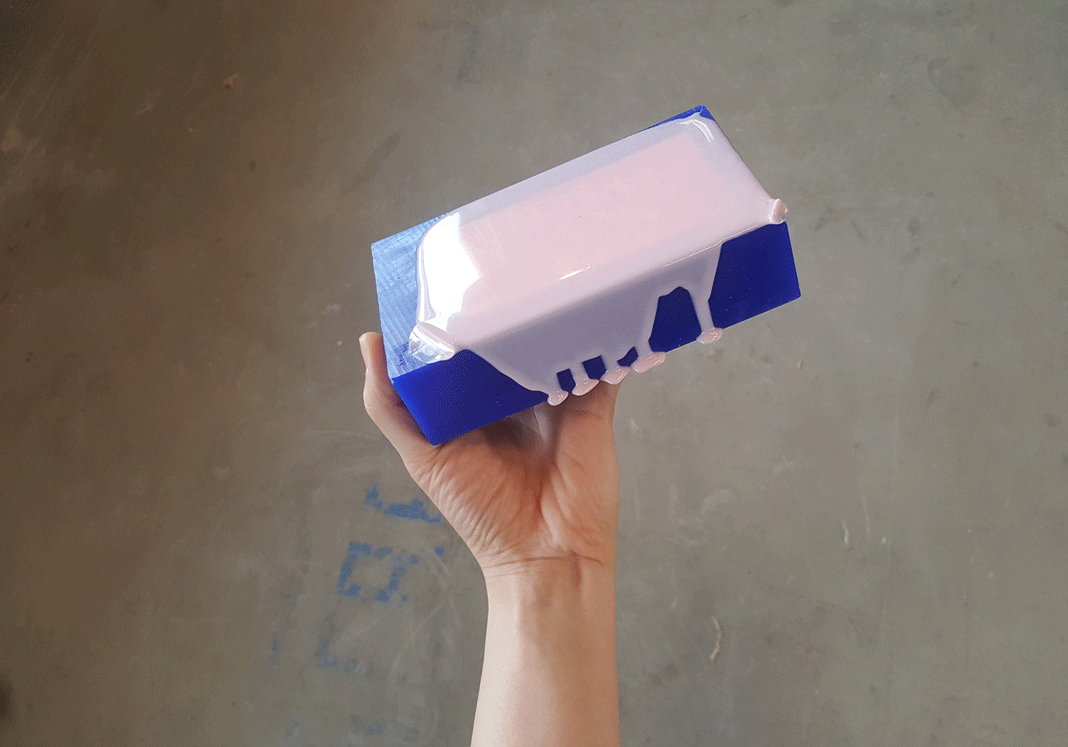

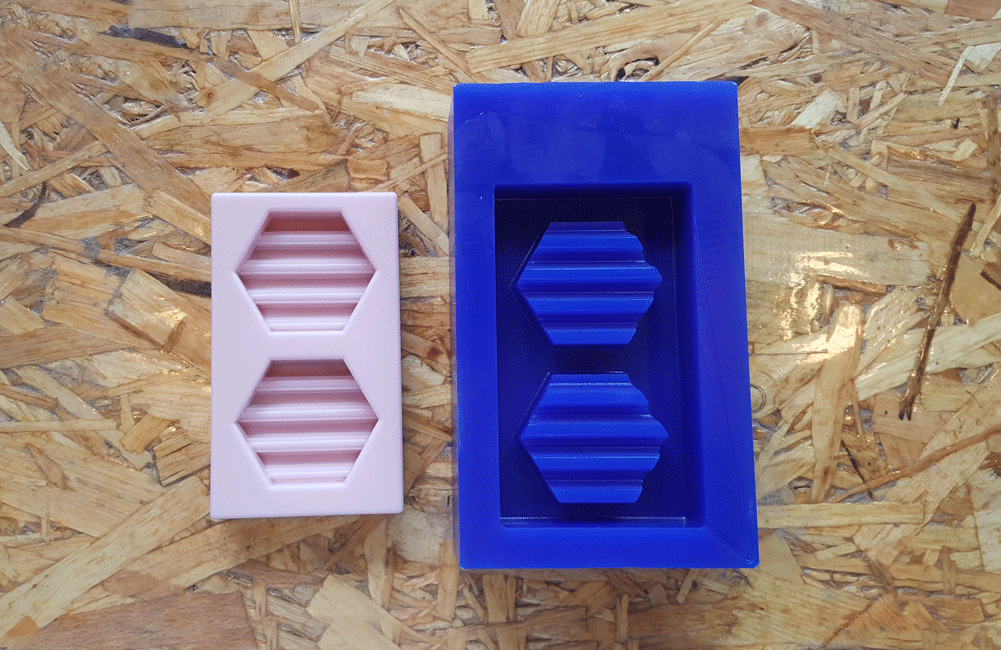

Best way of taking silicone out from the mold is to use air compressor.

Casting KURIchoco

For maximum physical and performance curing the silicone, expose the rubber to 176°F/80°C for 2 hours and 212°F/100°C for one hour. I didn't have oven at home, so I boiled for a while.

Chocolate Recipe(Korean)

After poring, for fast curing, I've put my chocolate mold in to a refrigerator for a hour.

Finished, I gave away my chocolate that I took 25+ hours to make. It's not toxic but I hope they don't feel sick.(I didn't eat it)

12th Meeting:

molding and casting 19 April, 2017 10pm~1am(Seoul)

Homework

o - Design appropriate objects within the limitations of 3 axis machining

o - Explained how you made the files for machining

o - Show how you made your mold and cast the parts

o - Read the MSDS and datasheet of you products and understood how to use, how to mix, etc

o - Described your problems and how you fixed

o - Cast you final part and repeat the process at least once

o - Include your design files and photos