Assignment 14

3.5.2017

Topic: Composites

Read the material safety data sheet (MSDS) and technical data sheet

(TDS) for the resins that you're using.

Design and make a 3D mould (~ft2 /30x30cm), and produce a fibre

composite part in it.

Learning outcomes:

- Demonstrate workflows used in

mould design and construction.

- Select and apply suitable

materials and processes to create a composite part.

Have you:

- Shown how you made your mould

and created the composite.

- Described problems and how you

fixed them.

- Included your design files and

‘hero shot’ photos of the mould and the final part.

- Read and linked to the

material safety data sheet (MSDS) and technical data sheet (TDS)

for the resins that you're using.

New deck

What I found from garden? What a makers, my kids. I want help and do

a new deck.

A composite mould

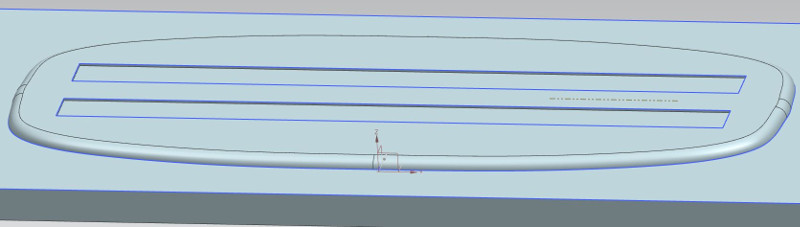

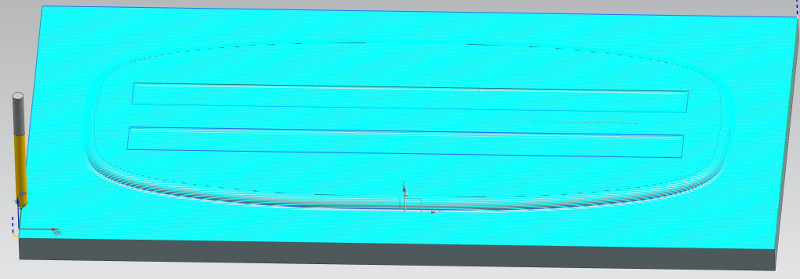

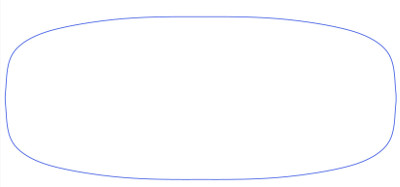

I modeled a mould by NX11 as earlier in Assignment 12, for

example. The first task was outlines, what a form it would have. I

extruded it upward 5 mm and blended the edges 5 mm. I have idea to

bend plies down and then up to the top of deck. Also, I want put

jute wires to the edges to strengthen them. As well as, I strengthen

the deck adding two bands to the middle of the mould. Deck size

is 350 x 150 mm. Thickness would be 6 mm, therefore I need

about 9 layers of plies.

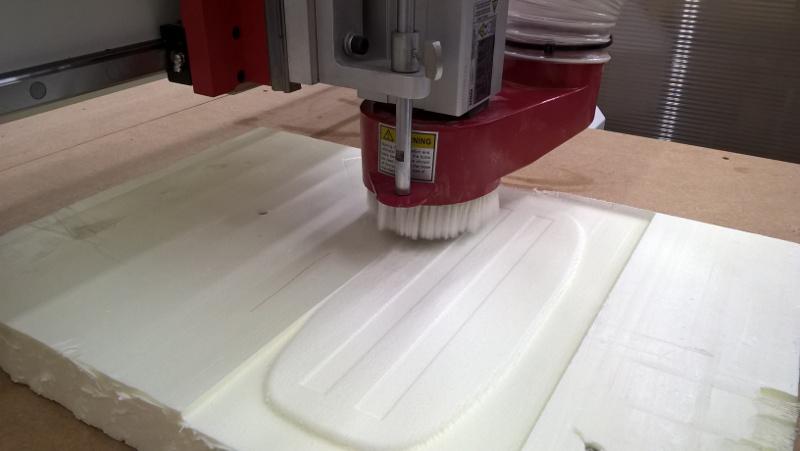

Then, I done plan for milling the mould by Ø6 mm ball head

mill. Operation was Fixed contour, drive method as Area

milling and quality as Mill finish. Designed feed rate

was 2.000 mm/min. and spindle speed 10.000 r/min. Depth of mould is

5 mm and I want mill it by one drive of tracks, but stepover

as only 20%.

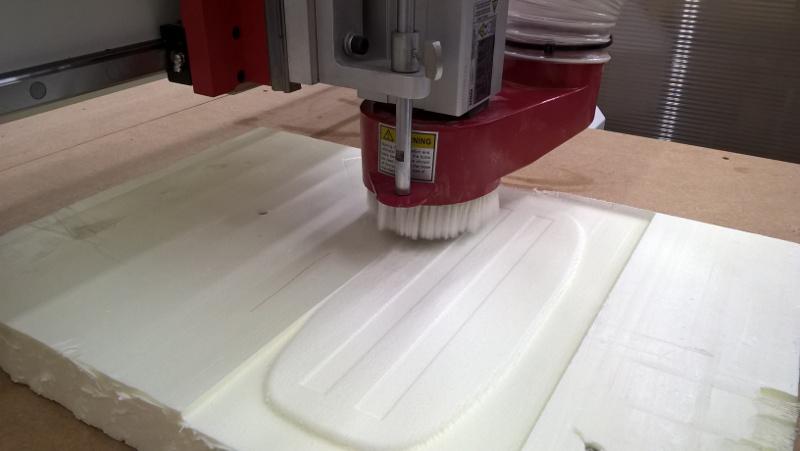

Again, I used our CNC router machine Eidtech E2-1325 for

milling. The material is XPS polystyrene and I fixed it by screws.

Materials

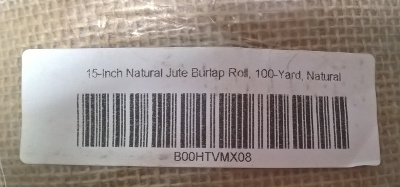

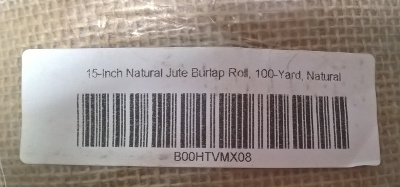

I must study also my composite materials: natural jute burlap as

well as Super Sap epoxy resin and hardener

(www.pecepoxy.co.uk) properties. Tehnical data sheet is here: https://entropyresins.com/wp-content/uploads/2014/03/ONE-TDS.pdf

and material safety data sheet of epoxy is here: https://entropyresins.com/wp-content/uploads/2014/03/Super-Sap-ONE-SDS-NAM-English.pdf

and hardener here: https://entropyresins.com/wp-content/uploads/2014/03/Super-Sap-ONF-SDS-NAM-English.pdf

Plant based

natural fibres can be used as reinforcement in polymer composites.

The maximum tensile, impact and flexural strengths for natural

fibre reinforced plastic (NFRP) composites reported so far are 104.0

MN/m2 (Jute - Epoxy), http://www.indiantextilejournal.com/articles/FAdetails.asp?id=3732.

The load to my deck might be F=500 N at maximum. Thus, the maximum

bending moment might be M=500 N x175 mm = 88 kNmm. Further, flexural

tensity might be σ=My/I = 98 N/mm2 = 98 MN/m2,

where y= 3 mm and I = 2700 mm4. Therefore, two bands in

the middle are needed.

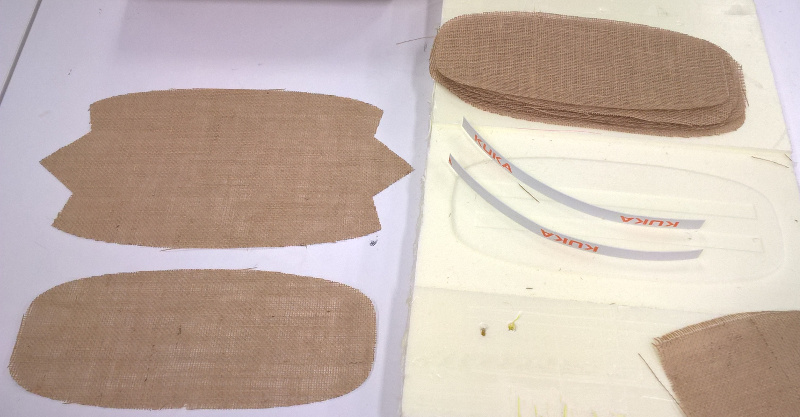

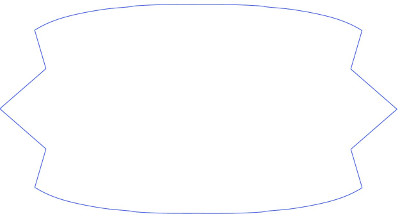

I needed also outlines for my plies. I designed outlines that the

edges of left one can be bent to the bottom of the mould. And, the

right one can be bent to the top middle of the mould. Both I

exported from my CAD model similarly as in Assignment 2.

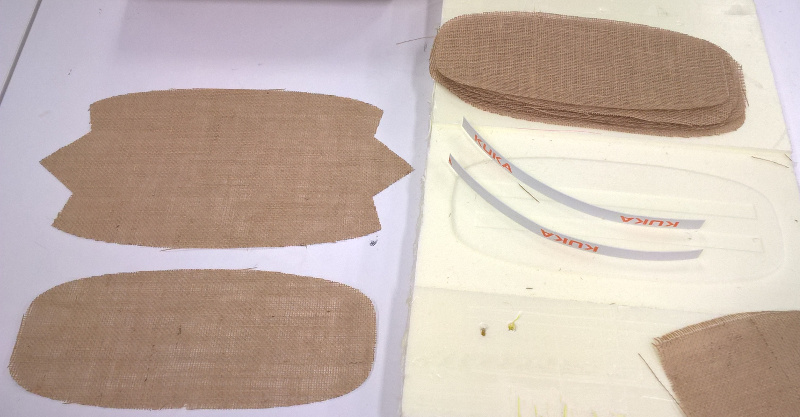

I cut plies by laser using speed 40%, power 50% and frequency 50% of

maximum. I cut 1 big and 11 small ones. KUKA bands may be used to

strengthen the deck. Size of them is 18x294x1 mm.

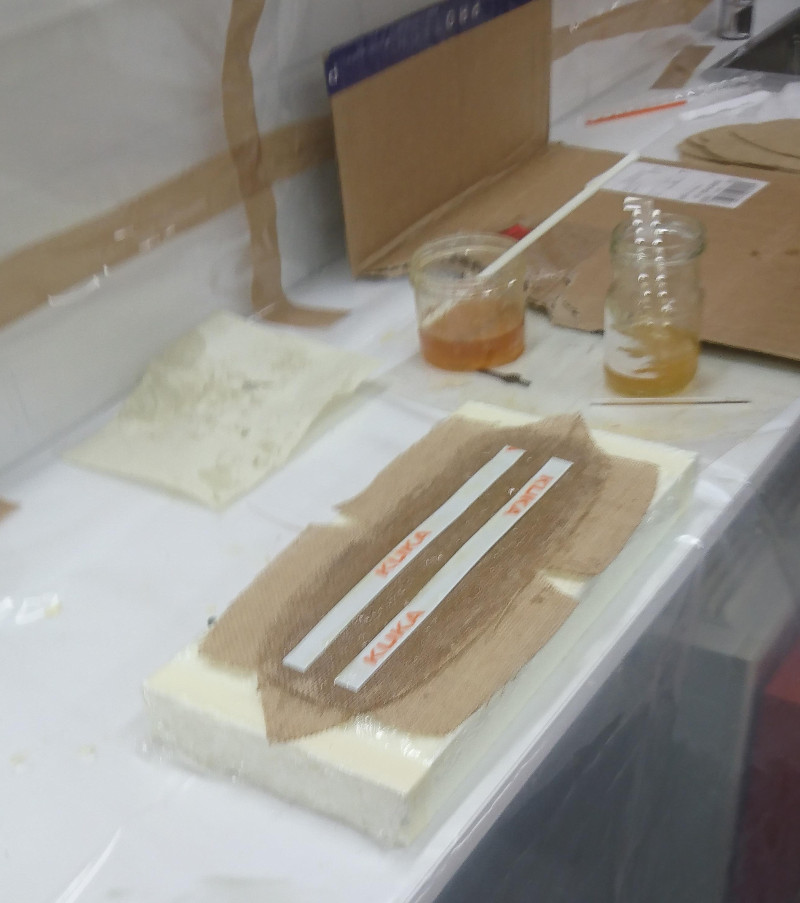

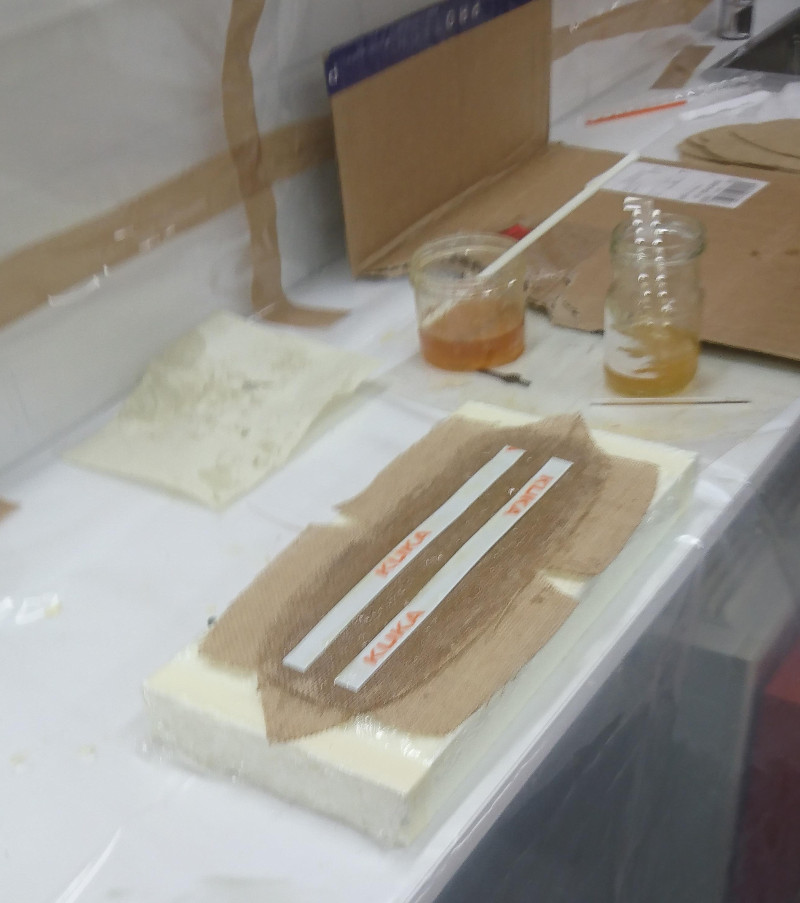

I prepared me first, vinyl gloves and safety clothing. Then, I

prepared on top of the mold two sheets of plastics for releasing the

deck from mould. Then, I prepared epoxy resin-hardener mix. Mixing

ratio was 2:1 of resin and hardener, but I used 2:1 measuring

pumps, Then, one depression of each pump needed, 6 depressions from

each pump was enough for me.

I started apply epoxy mix to plies and stacked them. I added bands

after two plies. Finally, I found the big ply was too small. I

couldn't bend it enough and it didn't stay in place. I took it out

and stacked 9 similar plies together. Then, I added punched plastic

sheet and absorbing cotton to take all the excess resin out.

Finally, two plastic sheet to close the mould.

Here is my composite deck under vacuum. I checked vacuum every half

hour at the beginning. I used industrial vacuum cleaner Kärcher WD 4

Premium, 1000W, for this purposes.

My new deck is ready. It needs only some rough around the edges.

And, here we go. It is strong enough for my use, maybe.

Included original design files:

My NX CAD file is here: 3D model.

This also in DXF format is here: 3D model.

This also in stl format: fab_deck2.stl.