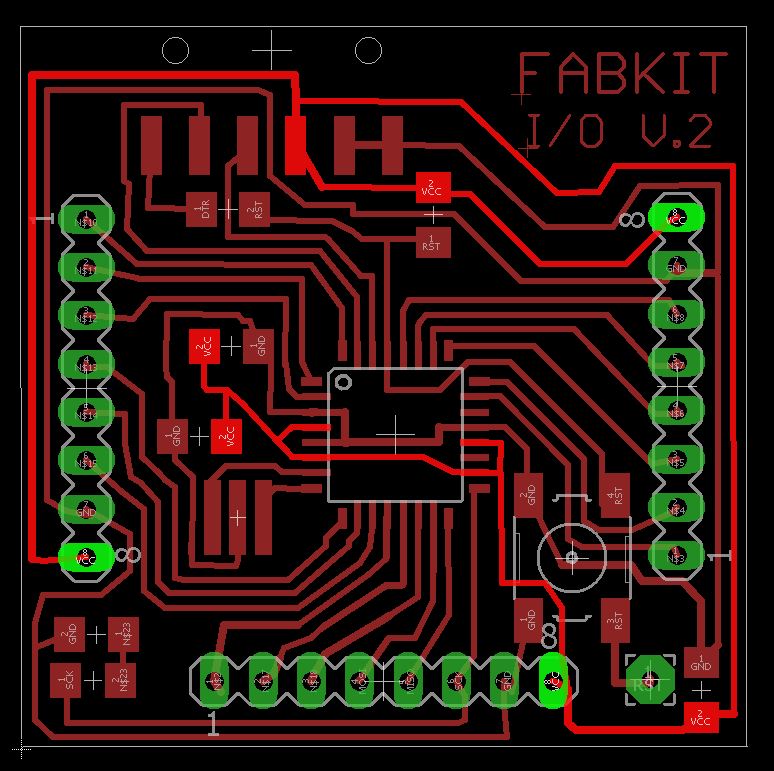

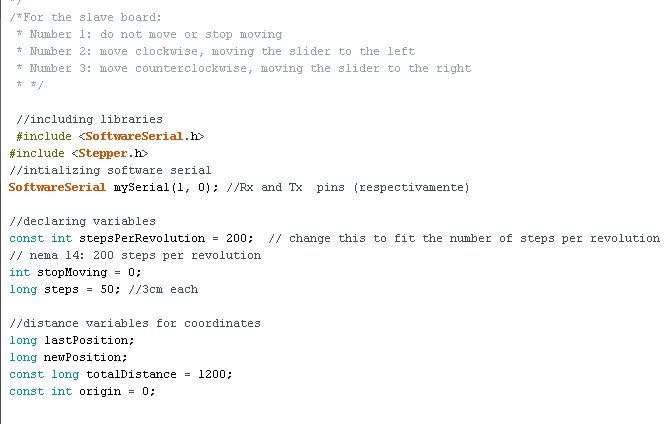

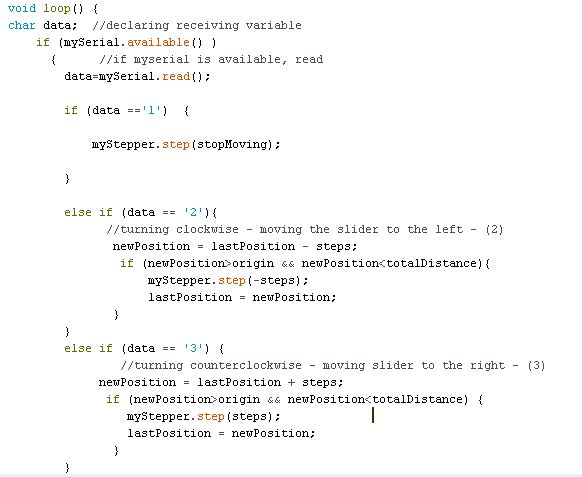

1. Strategy

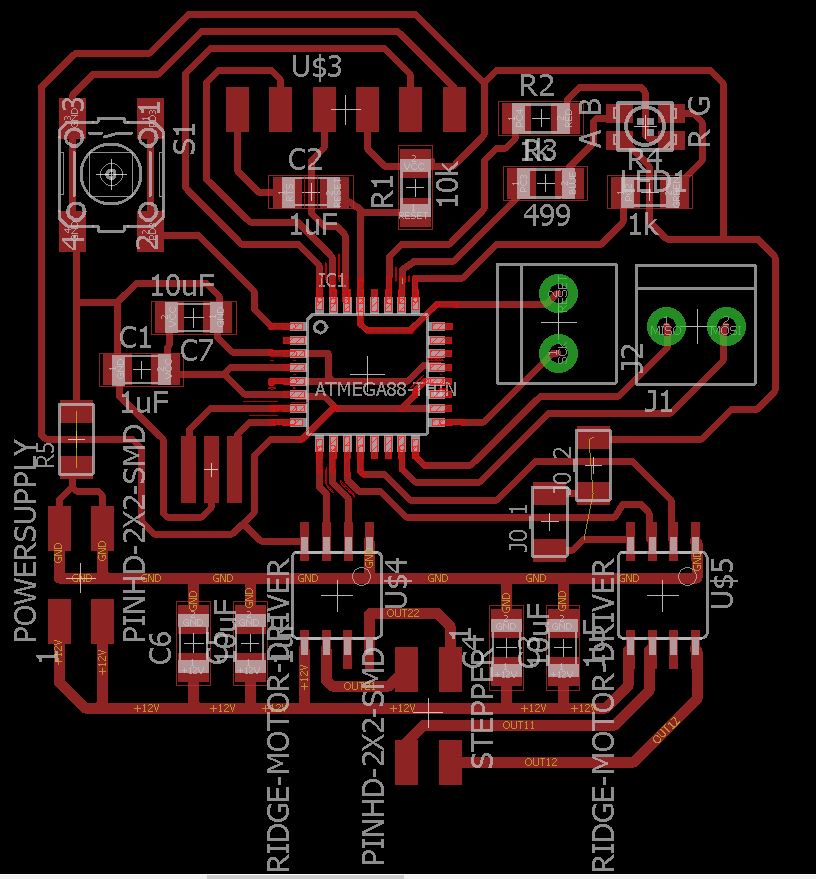

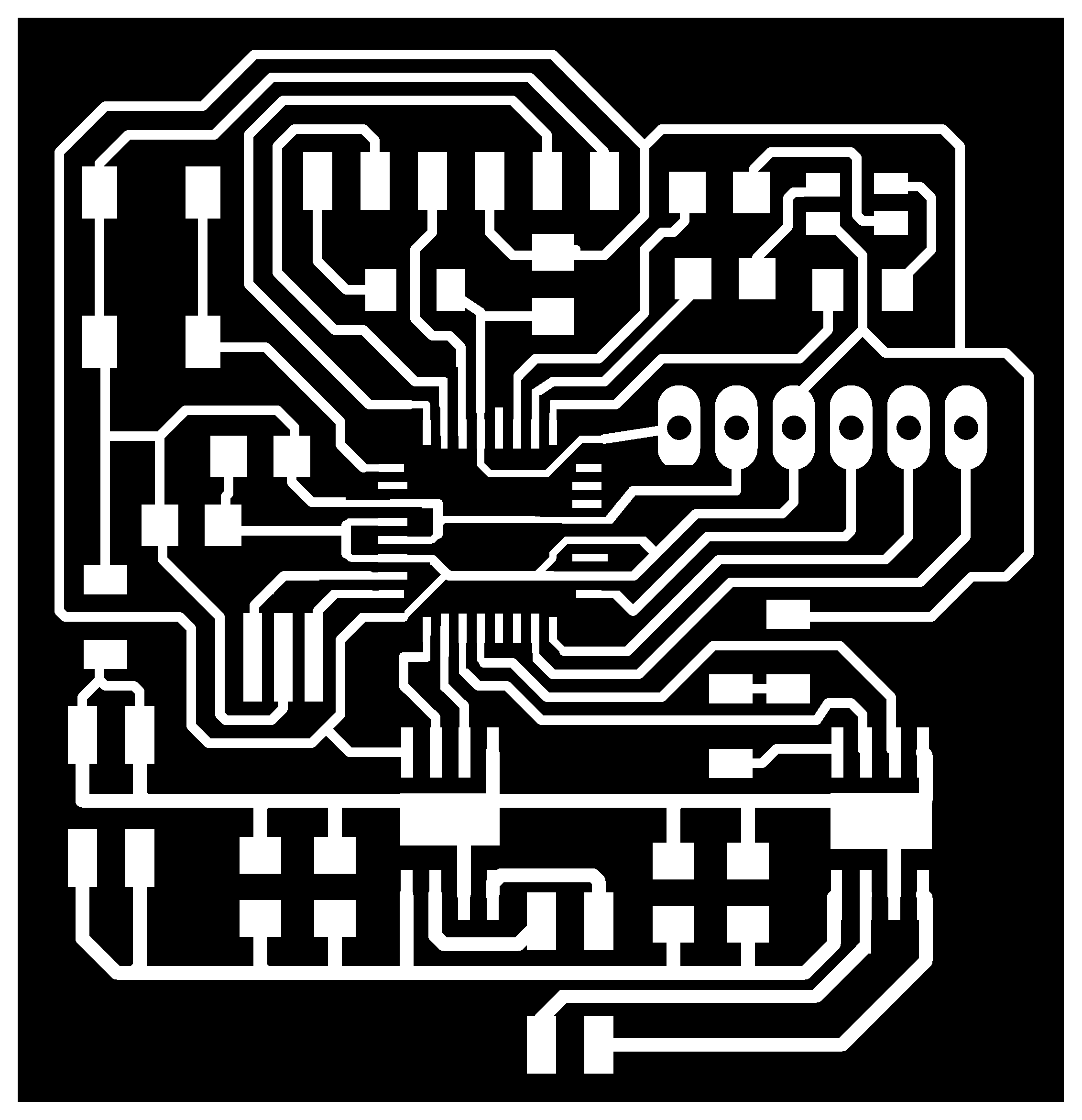

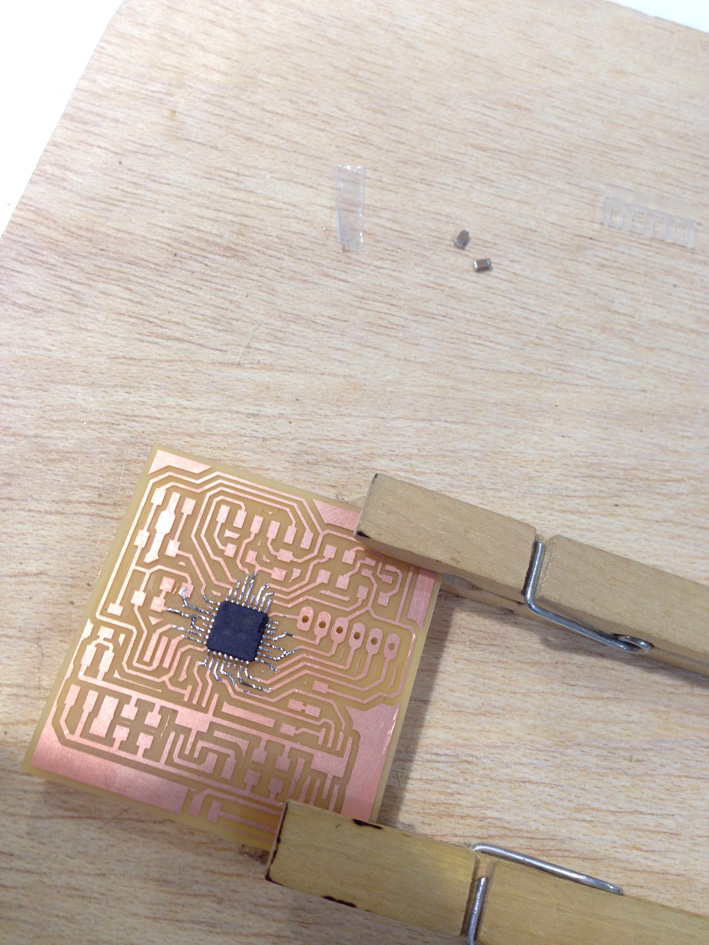

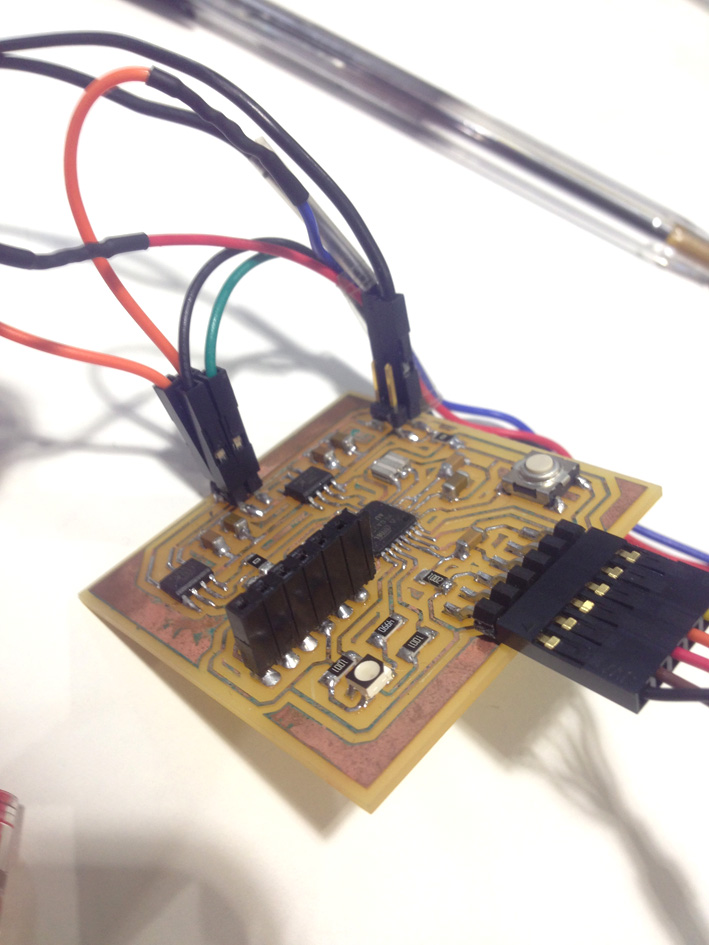

The goal this week is to continue developing my final project. As the project is to create a lightning device that can be moved without being touched, my idea is to create a new board connected to a stepper motor.

The reason I chose a stepper motor is because I can have a controlled movement, giving me the opportunity to measure distance (the axis I am using) with steps.

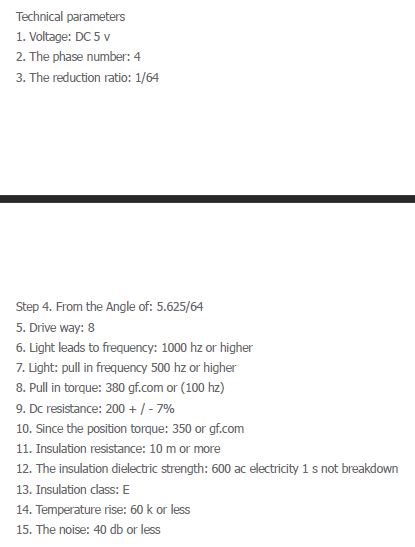

The motor I will be using is

'Stepper - 28BYJ-48':

Check Stepper Motor - Data Sheet:

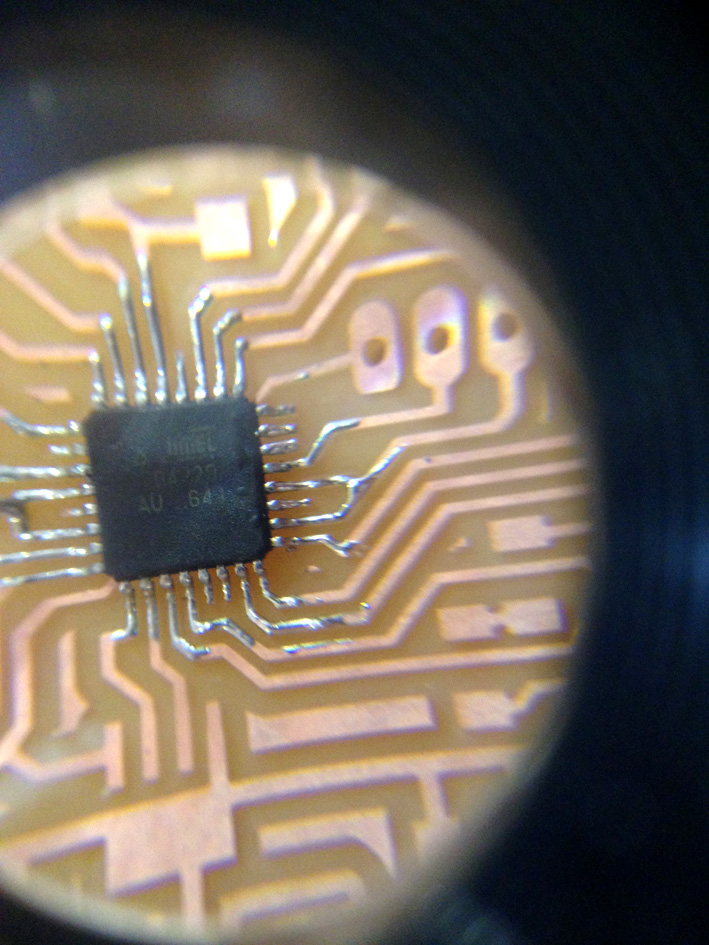

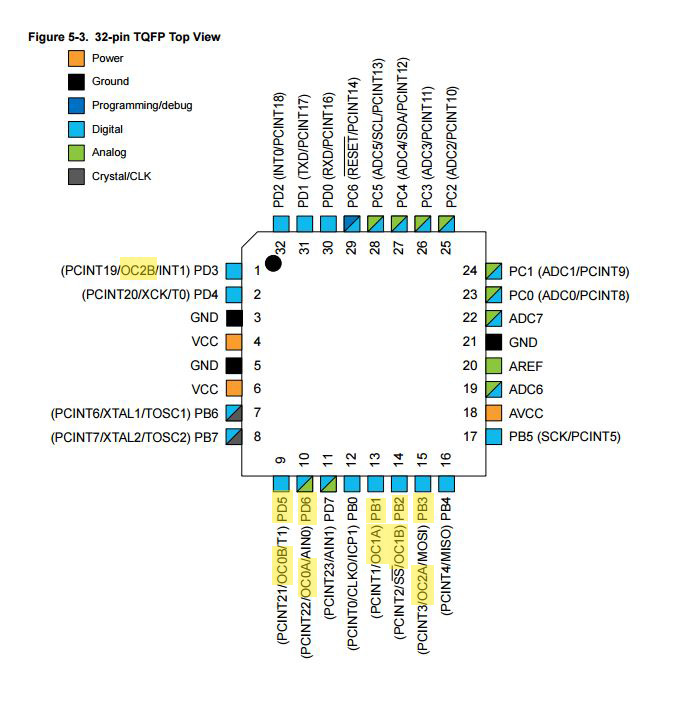

MCU I am going to use:

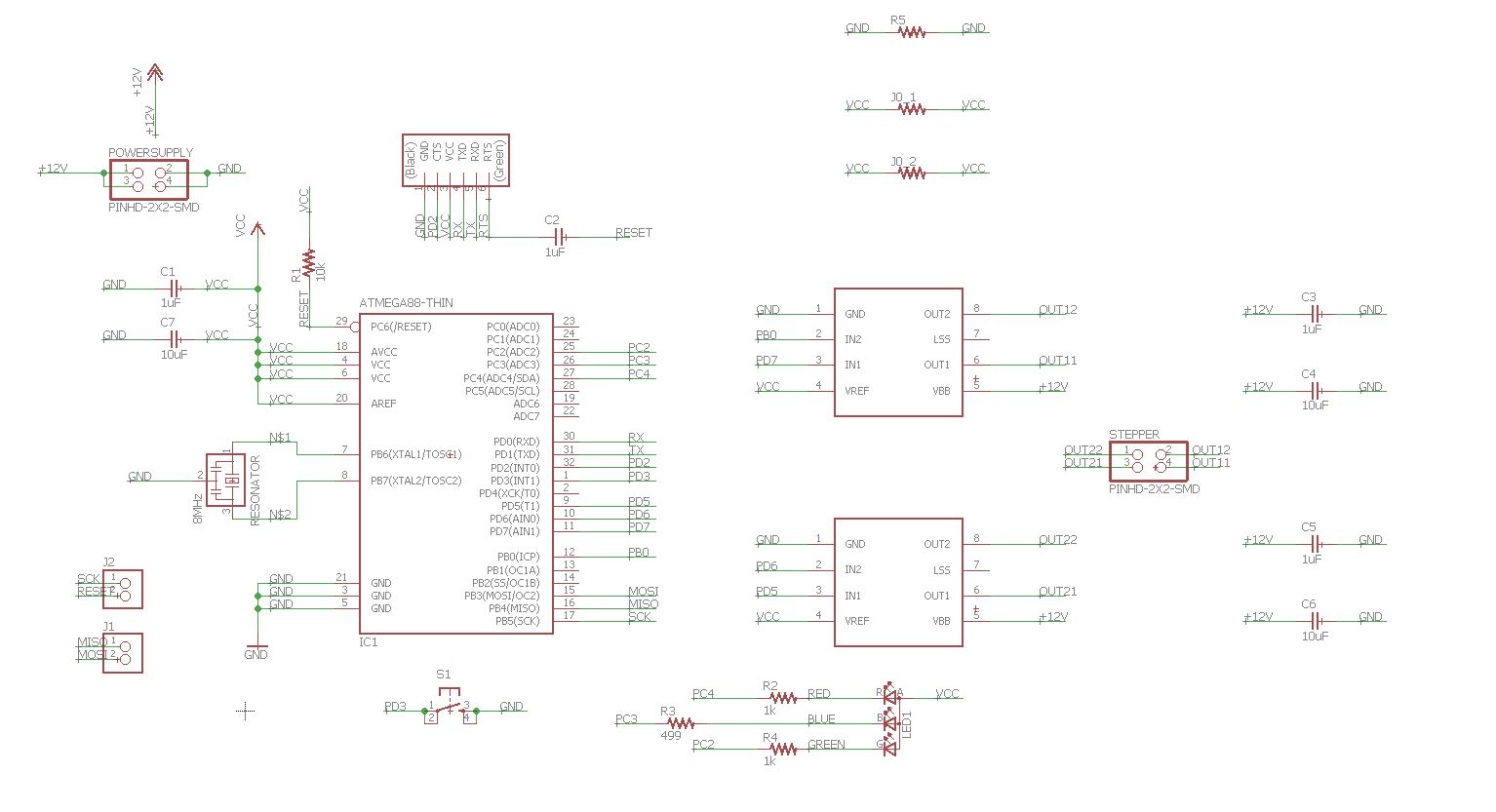

I will be using a Atmel AtMega 328 P with 32 pins. The reason I chose this one is because it has more memory than the ATiny 44 that Neil uses. Plus, in order to have as well a RGB led, I need more pins to connect the led.

Here is the reference with arduino pins:

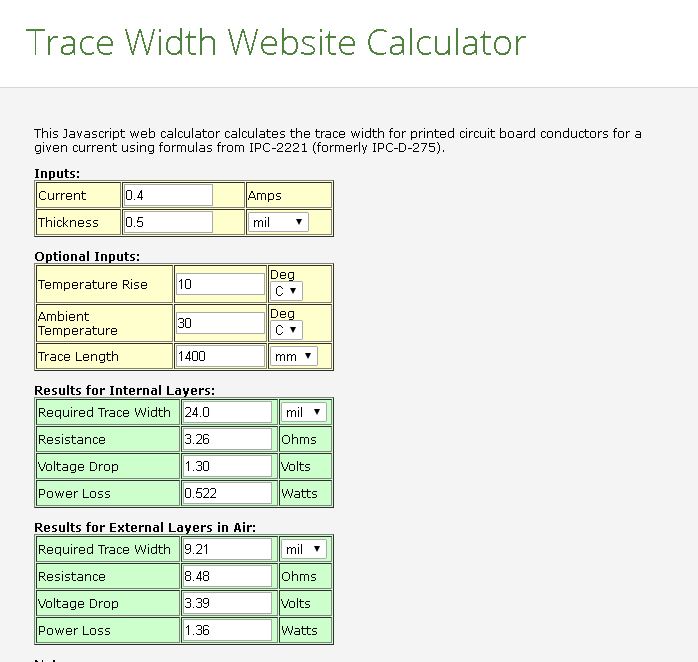

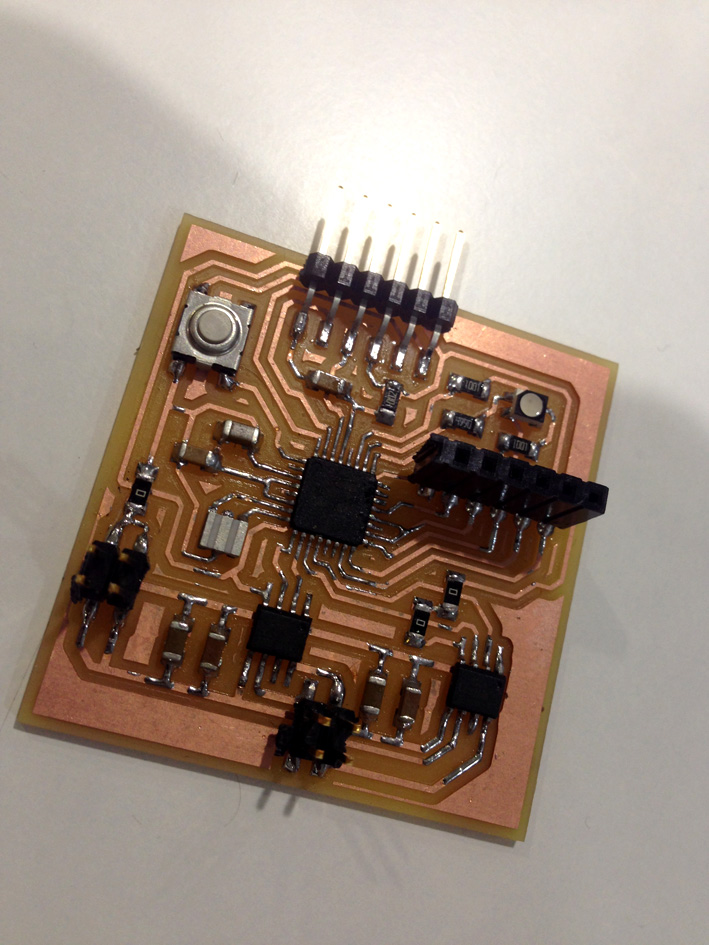

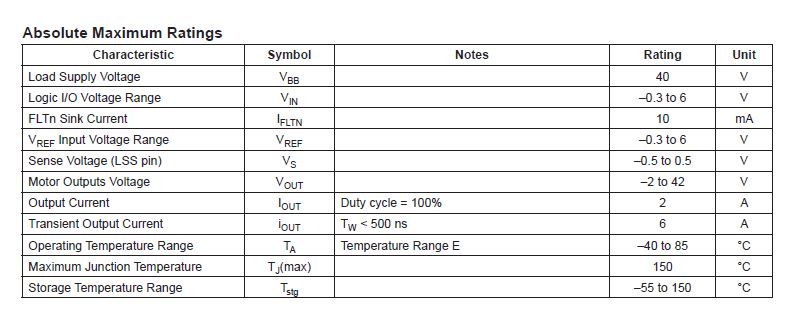

To work with a Stepper Motor, I need to H-Bridge to change the currents direction. I selected H-Bridge A4953 for my board:

Making sure it can support the 12 Volts that will be supplied to the stepper motor:

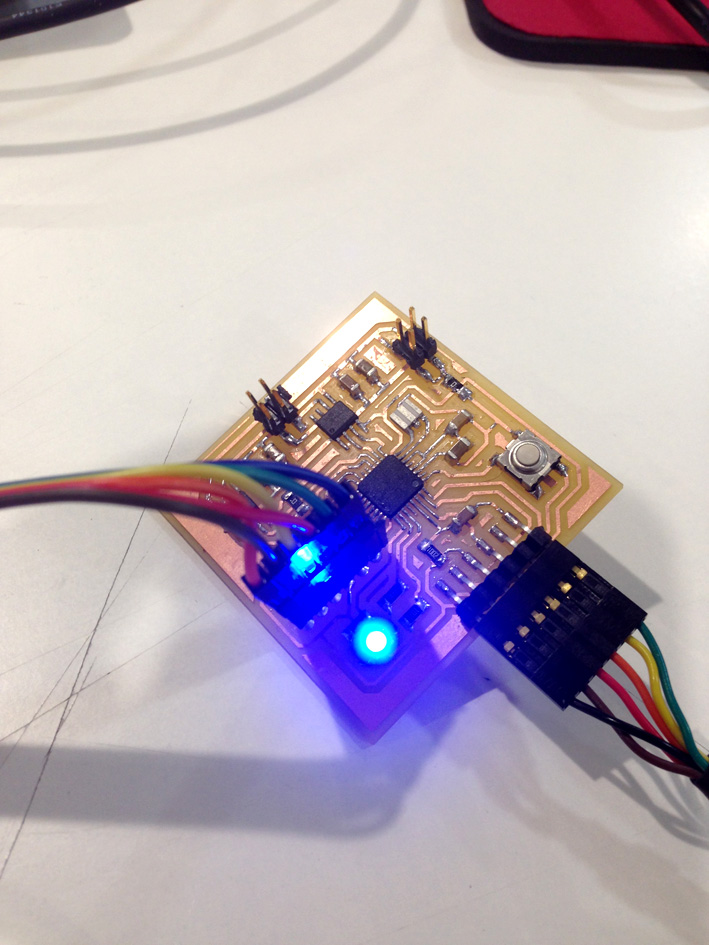

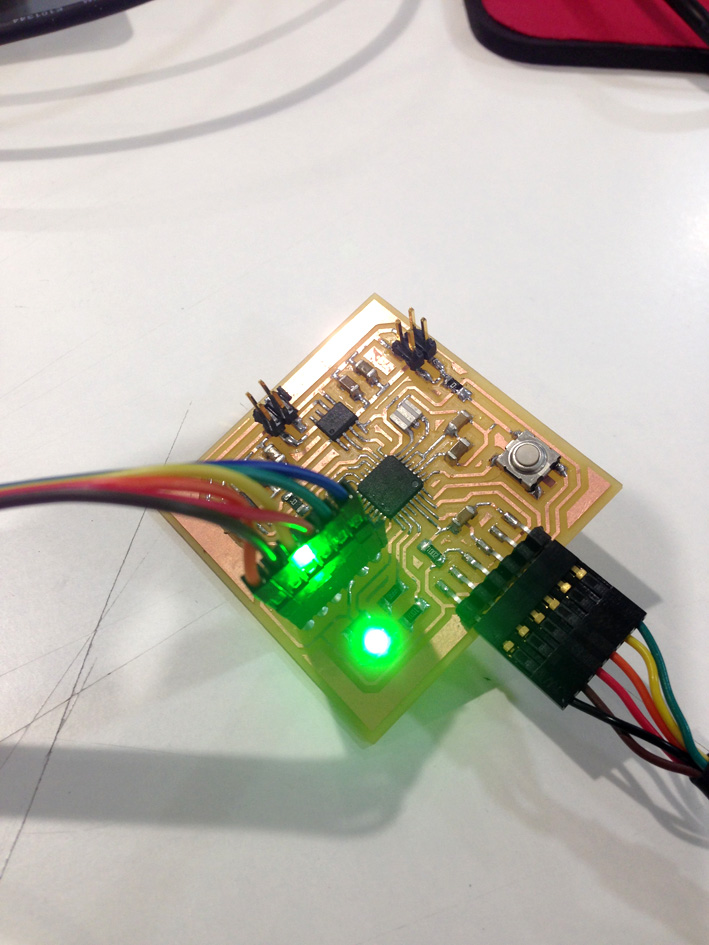

As well, it is highly recommended to have a led incorporated to the board, especially to make sure it works correctly first.

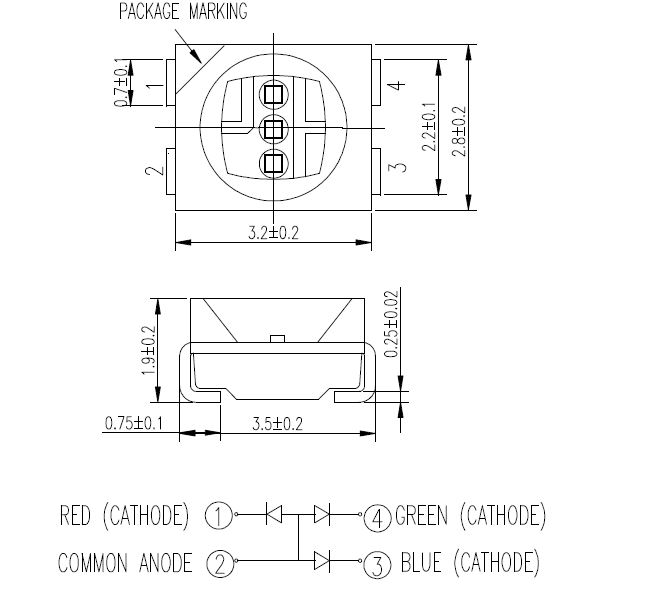

As the last 2 boards I have had an included different colour leds, this time I wanted to use a RGB led (RGB Led CLV1A-FKB)

Technical information