06 COMPUTER CONTROL MACHINE

Index

WEEK 7

MY IDEAS

For this week´s assignment, the goal is to MAKE "Something Big" for learn the use of CNC Routers Machines and knows the design rules for works with them.

I haven´t previous experience with this machine or others so this assignment it´s really interesting for learn a lot new things. This is the unique experience i have, tiny works with my grandfather when i was a child, fabricating boats :

I loved pass the time doing tiny things i have little hands and he used them for help in task hahaha and this was my first handmade mechanism design, a box for store mini-mills, was a present that i made for him when i was 7.

Mechanisms, Tiny, Mills from Pilu Caballero on Vimeo.

I found a beautyful documentary about PlyWood on vimeo so i decided to share because it learned me a lot things for start with the material which i will use at the practice. I recommended to see it to all beginners like me.

Love Letter to Plywood. By Tom Sachs from Tom Sachs on Vimeo.

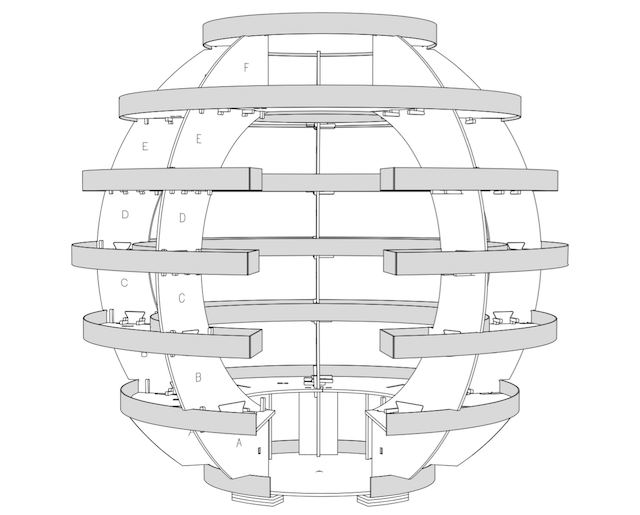

The first idea i had for make something BIG was readapt a design from Sine Lindholm and Mads-Ulrik Husum, the GrowRoom, a lovely concept which i would like to build some day. We just have a panel for work on it, i haven´t space in my house and discart it for future.

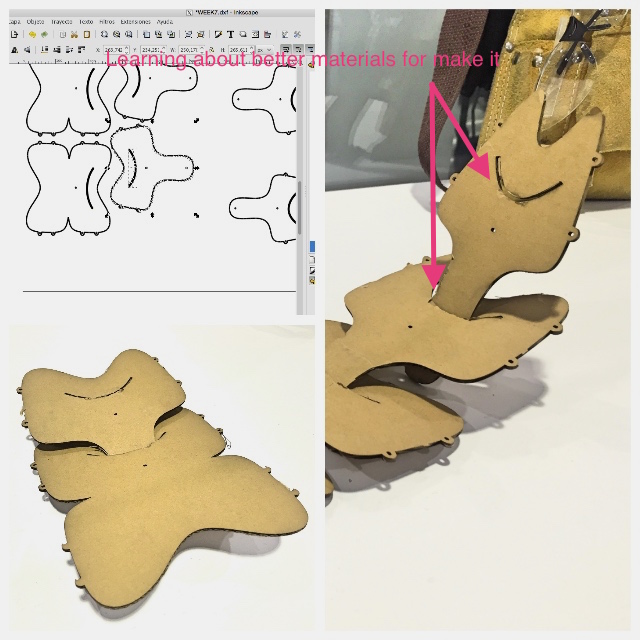

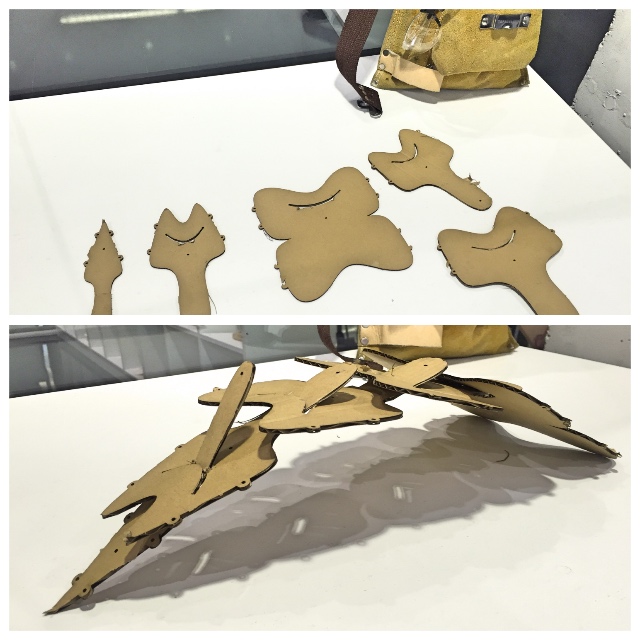

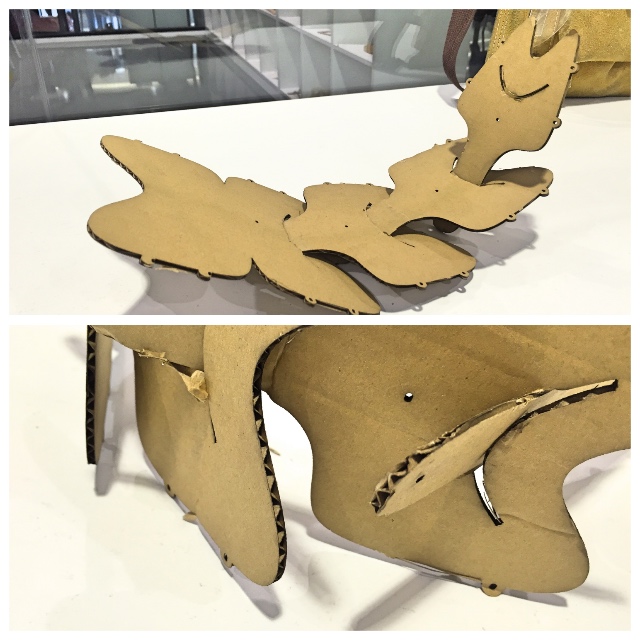

The second idea is based at the moments i spent with my dog at the beach and was thinnking about to make something for stop the sun. For this I drew basic shapes at AutoCad, making joints with the idea to practice stitches technniques.

As you can see at the pic bellow the "Faito´s Parasol" is an interesting design which play with the sun lights producing changes at the shapes shadows remembering you the sleeves moves.

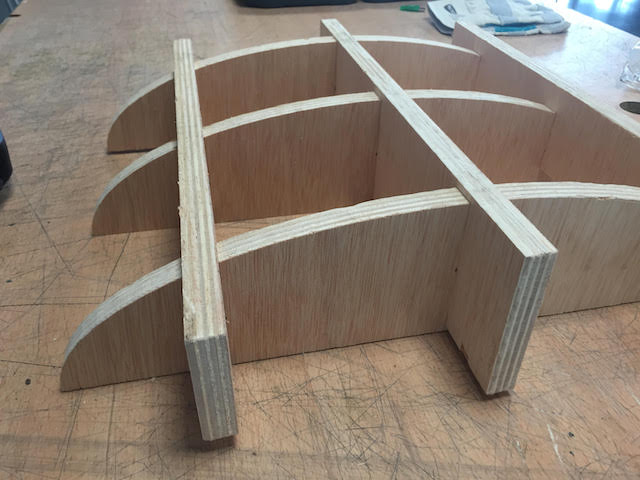

For test the design and decided about joints i made it at the Laser Cut Machine. The results open my mind in differents ways :

DESIGN TIME

1st ATTEMP

The next i designed was a house for my Dog, but i discart the idea later because at the night i dreamed tha i was fabricating the his last box and wake crying. But here are the things i made :

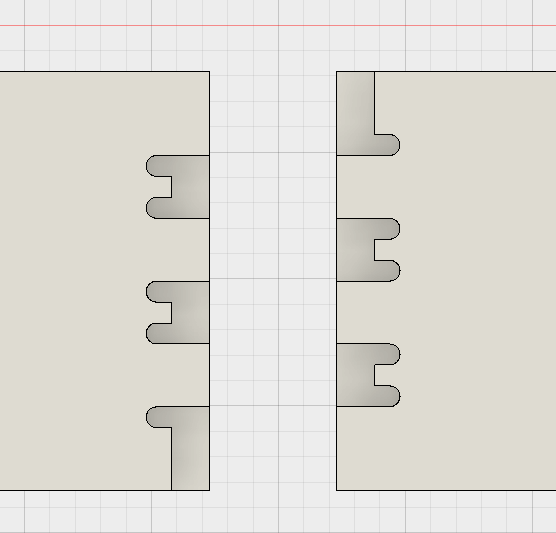

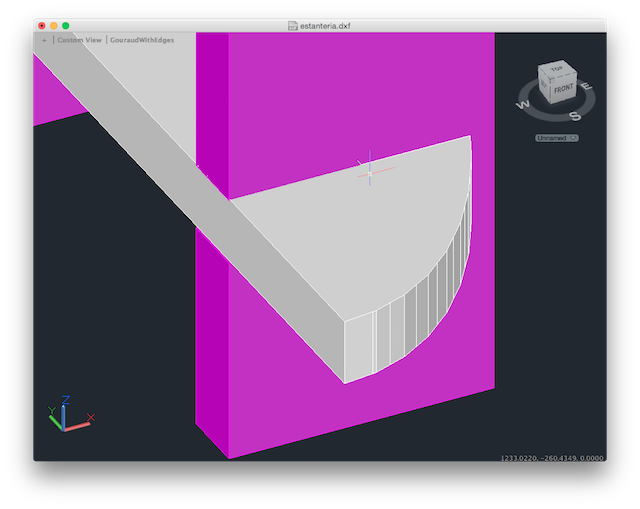

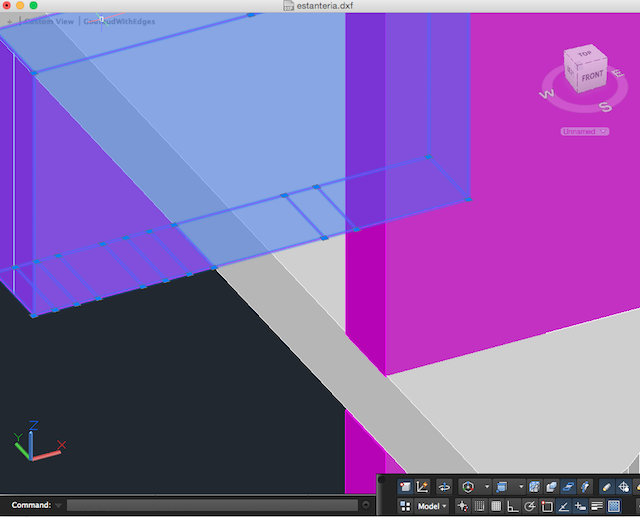

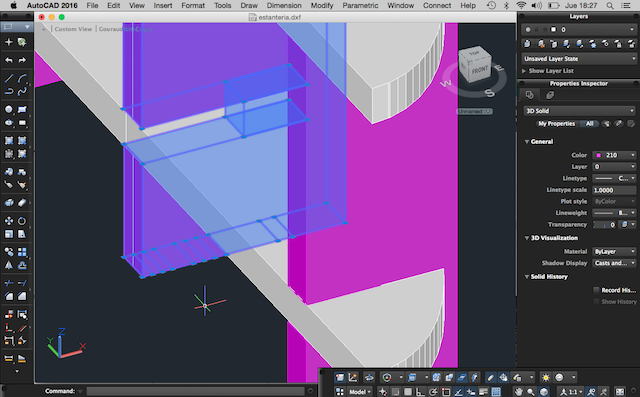

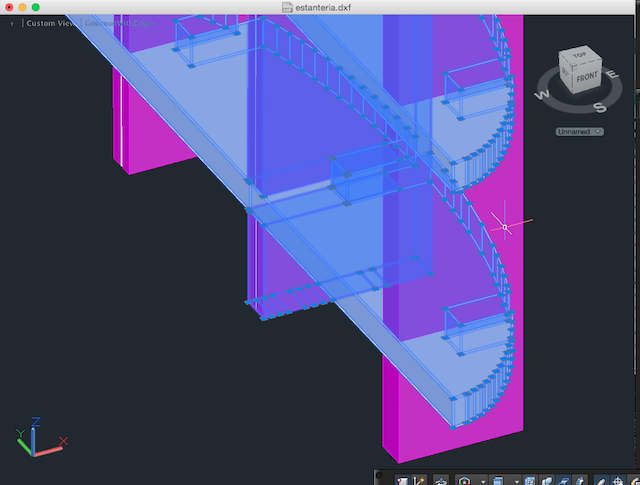

1. I used Rhino for the 2D and 3D design first a tolerance tester with the joint selected and later the house.

MY DOG DIED 4 DAYS LATER, SO FINNISH THIS ASSIGNMENT WAS A TASK BETWEEN TEARS....

2nd ATTEMP

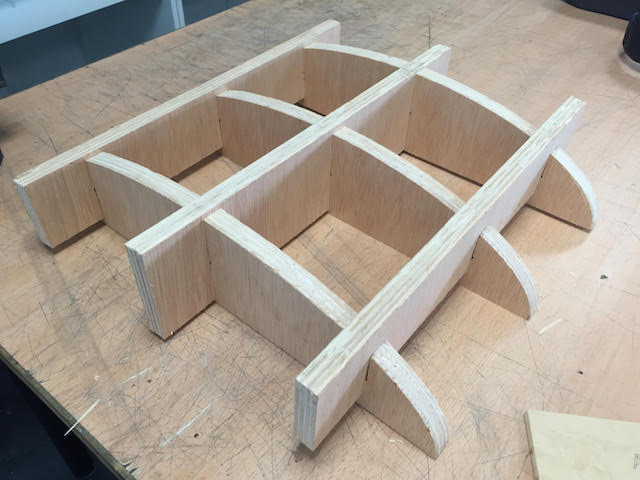

TEST TOLERANCES

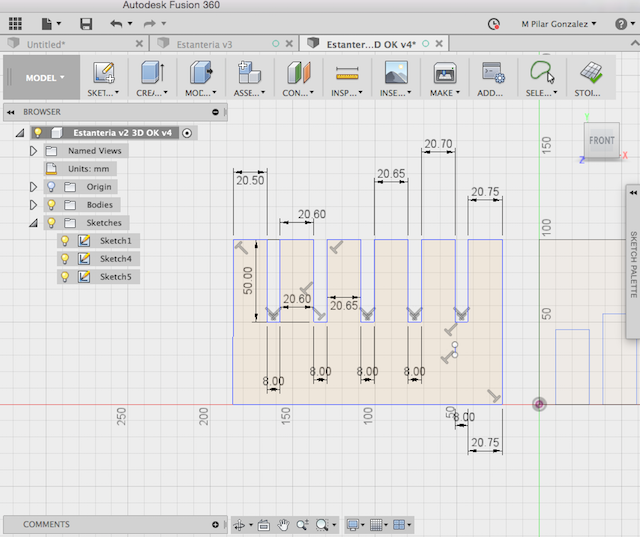

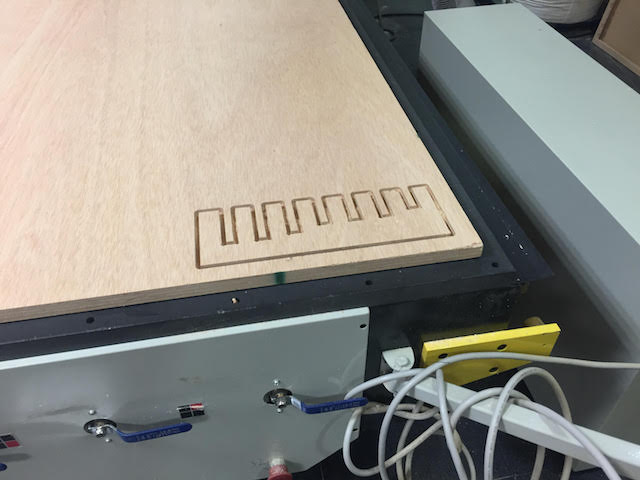

1. First i made was measure my plywood panel 2440x1500x I noticed differents weight along the panel, so i decided to use the medium in my case 20.50mm. The Test tolerances is for learn how to design correctly for make joints.

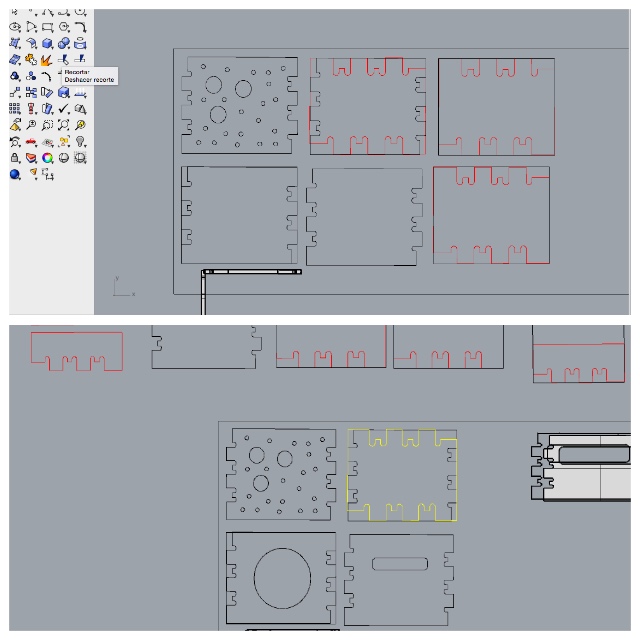

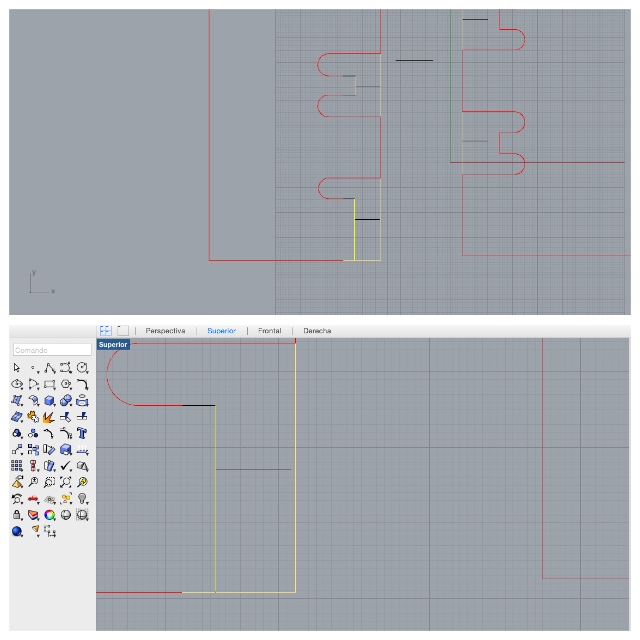

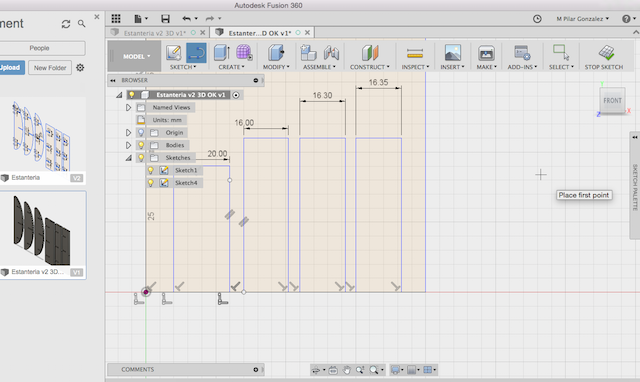

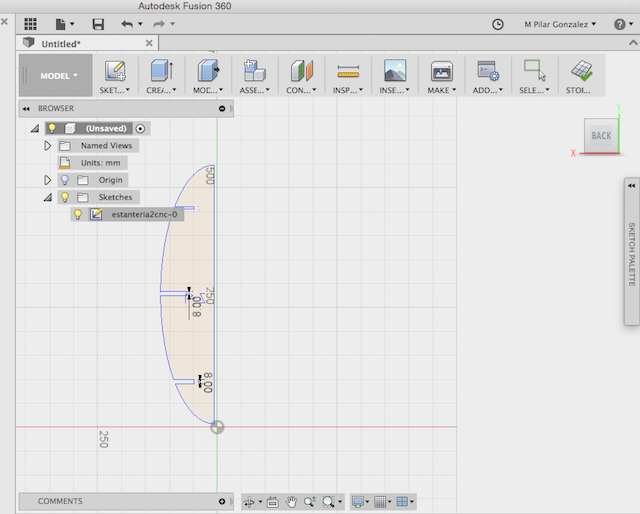

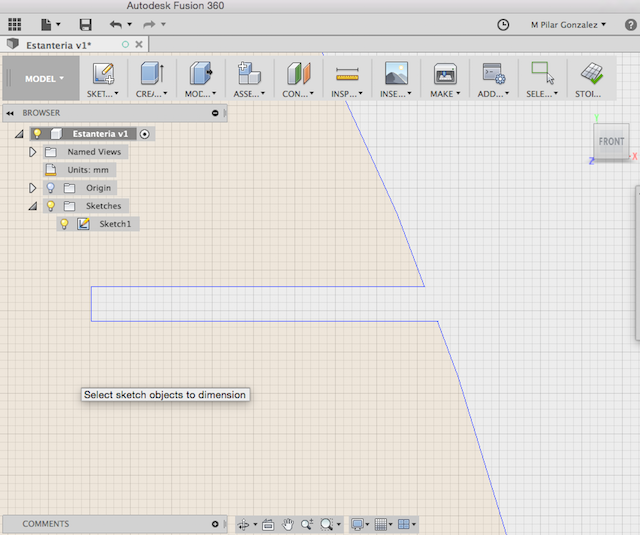

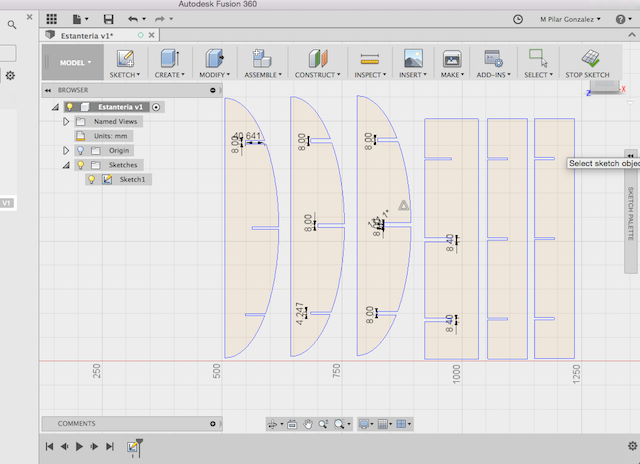

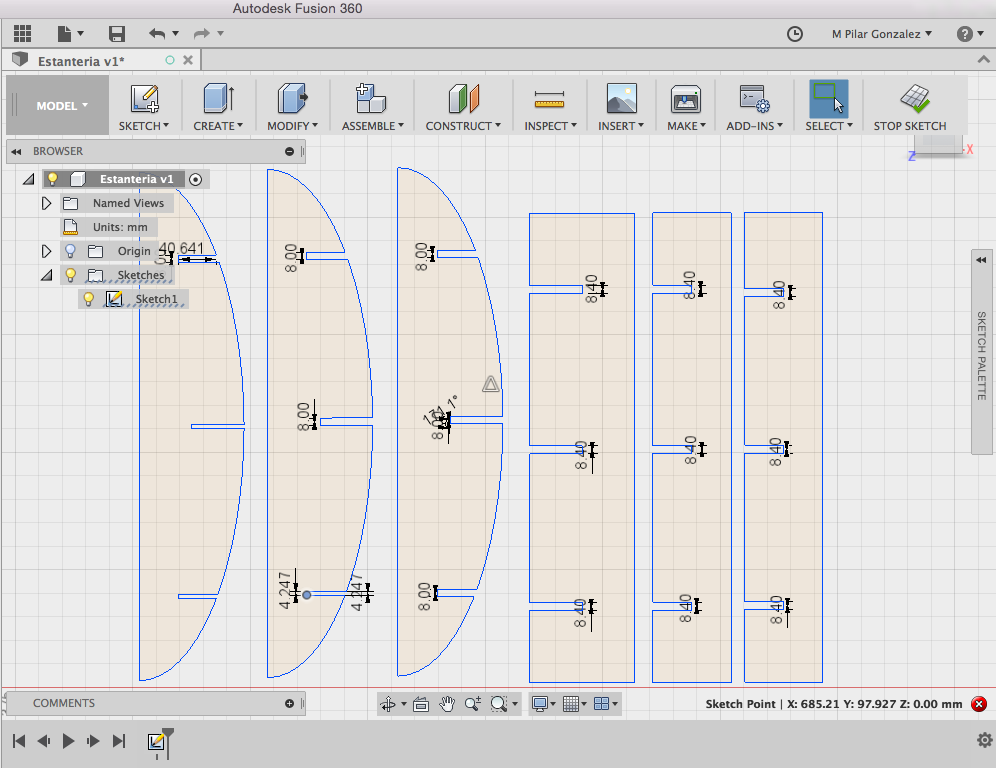

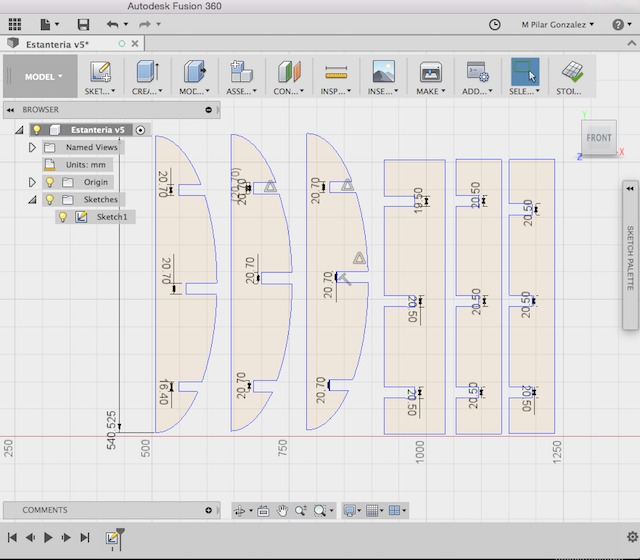

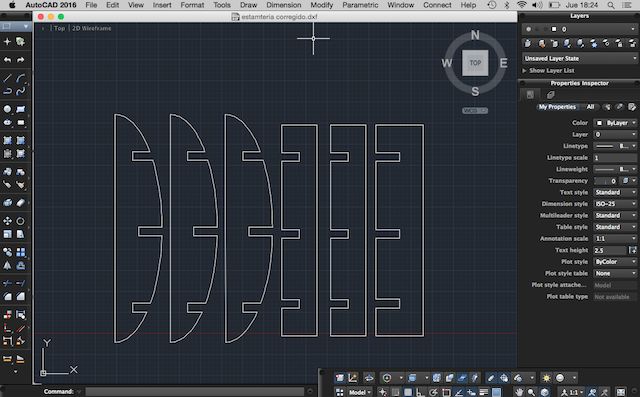

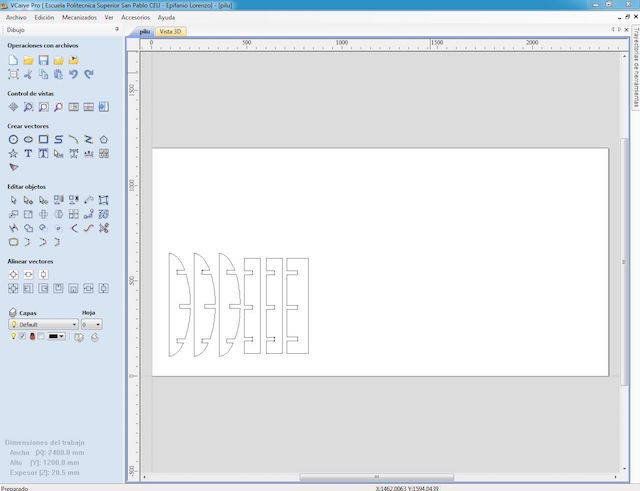

I designed a Piece with fusion 360º, but as always, Fusion miss some polylines when i exported the model to .dxf and we was correcting at Vcarve.

When test with the panel and as i was the last in the assignment, always i ´m present and participated in my classmates assignments so i learn the tolerance previously for that reason i decided test first the correct, 20.80mm and tell to my instructor but he suggested me to try in others and finally use 20.70mm.After this, i began with the design but during the night i was thinking in how hard or difficult can to be assembled the parts if the measures is wrong... As i explained i was working a lot in the rest classmates tolerance´s mistakes.

MY DESIGN

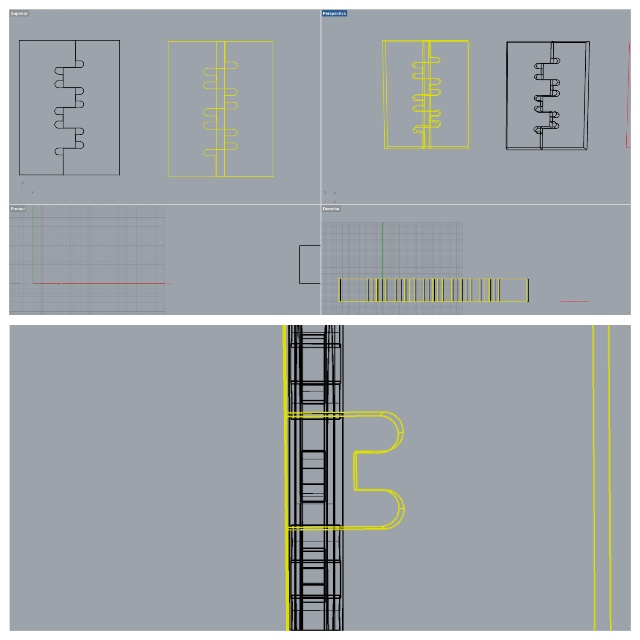

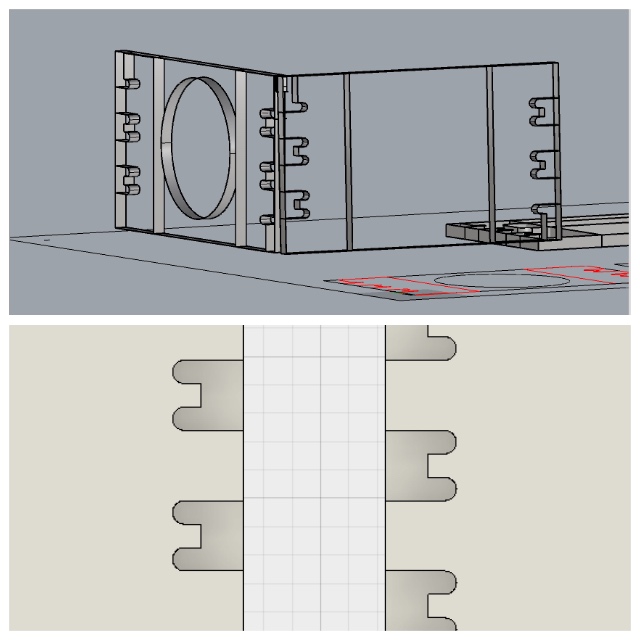

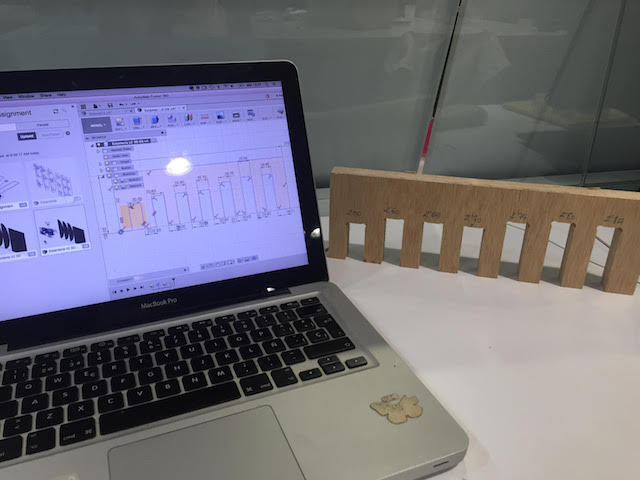

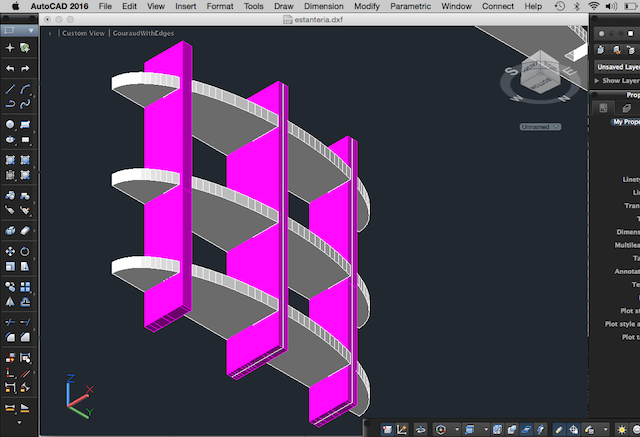

I decided to made a always useful for store things, so i use Fusion 360º for that :

As you can see at the picture below, first i decided made something light.

I wont to make to 16mm but my instructor suggested me adjust the design to the measures of plywood so i redesigned measures for don´t spent all day.

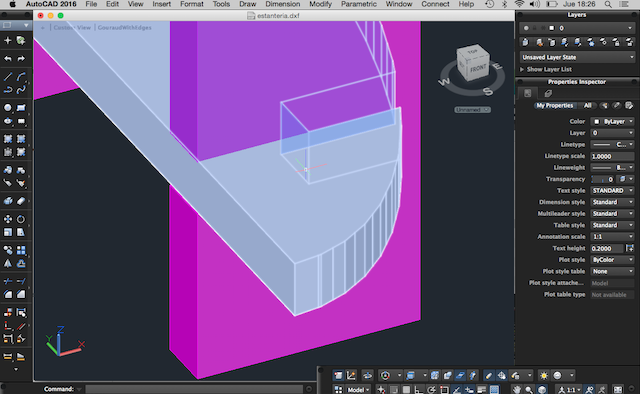

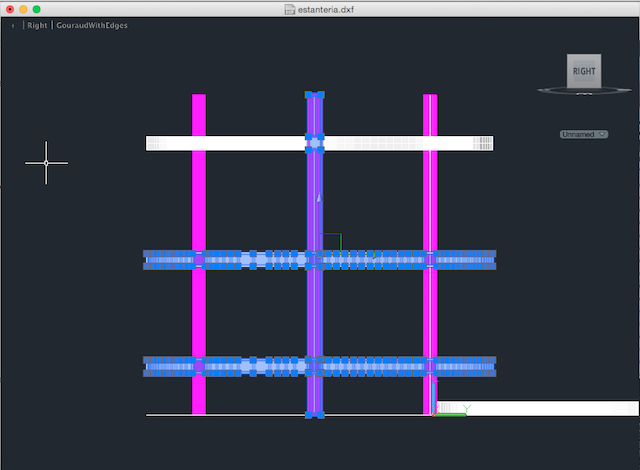

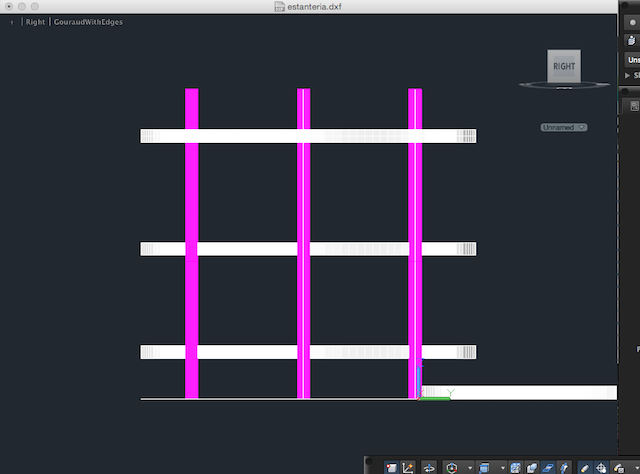

After i had the draw extude first each layer for rotate and traslate with the idea to made the joint coincides:

FABRICATION PROCESSES

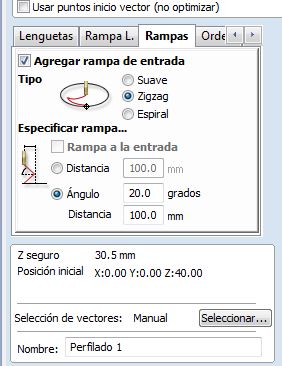

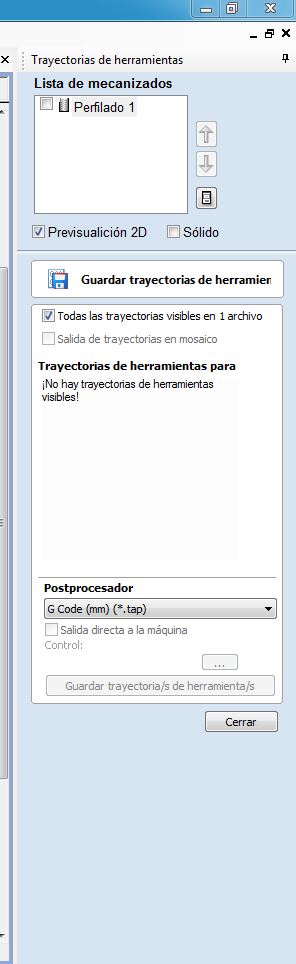

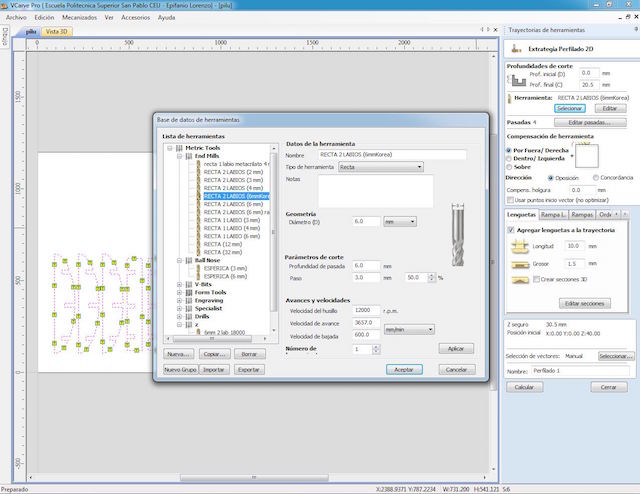

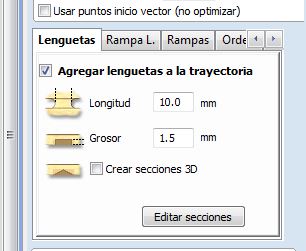

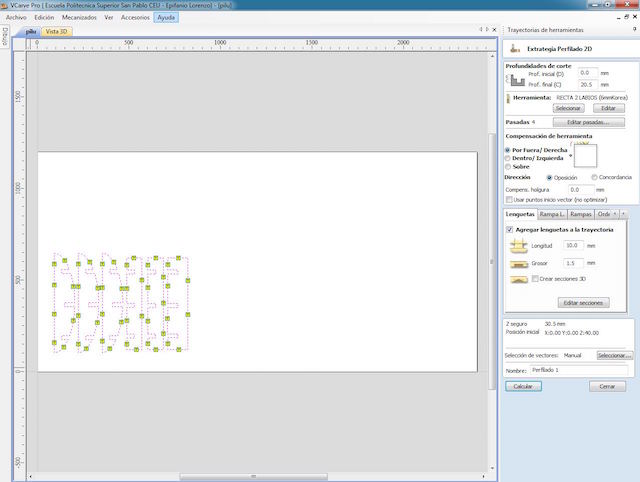

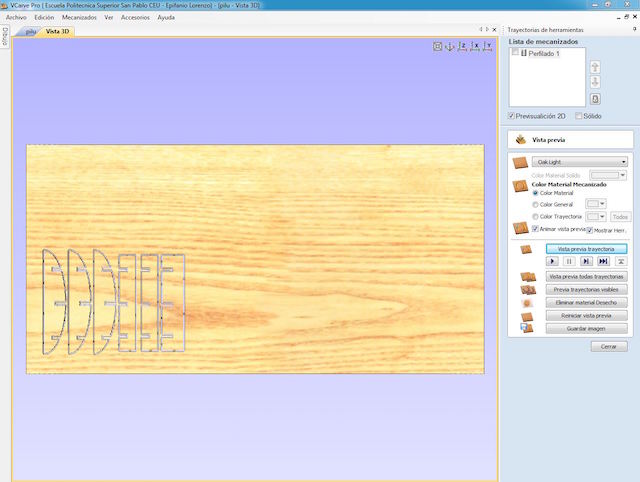

This was the proccesses followed at Vcarve in our CNC Room :

Bits and Settings

| FLUTES | RPM | FEED RATE | PLUG RATE |

|---|---|---|---|

| "6 mm 2lips | 12.000 | 3657.00 | 600.00 |

Make Something Big with CNC Router Machine from Pilu Caballero on Vimeo.

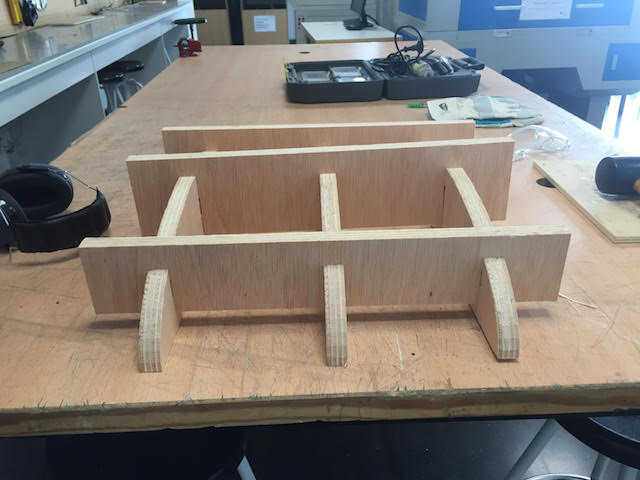

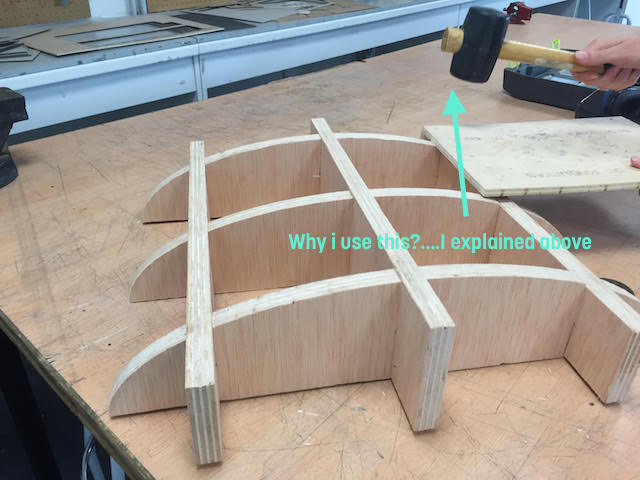

ASSEMBLED TIME

The assembled was not easy, why? as i was thinking by the experience lived, the idea that my instructor suggested me not work and i don´t know why if he made 3 times the same suggested me the measure...but doesn´t matter, i love work with plynwood...

WEEK PROBLEMS

This assignment cost me a lot tears, why? during the first week our instructor suggested us an interminable book of joints really interesting for learn but hard for study about my experience. I decided made something for my dog, but during the 2nd night i dream what i was fabricating the final box for him. This week my pet died....AFTER 14 YEARS WITH ME!

WEEK FILES

WEEK´s LEARNED

All was new for me during the process so i learned how to design, how to mill, how to use CNC, How to prepare files there with Vcarve, how to assembled... and of course this week i learned why my instructor like that i have problems.