I was very excited for this specific project, but I was falling behind on other projects, and thus had to keep it simple. I wanted to come up with a construction component/bracket, but I couldn't come up with anything that isn't already made from sheet metal.

So, I kept it simple: a dome.

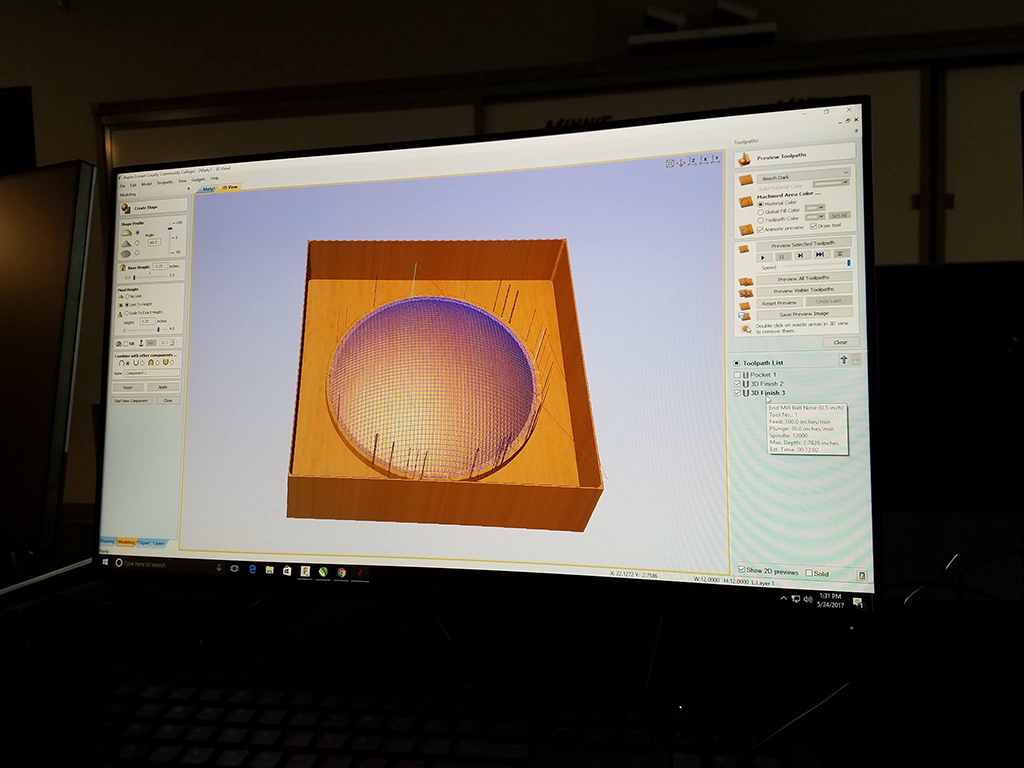

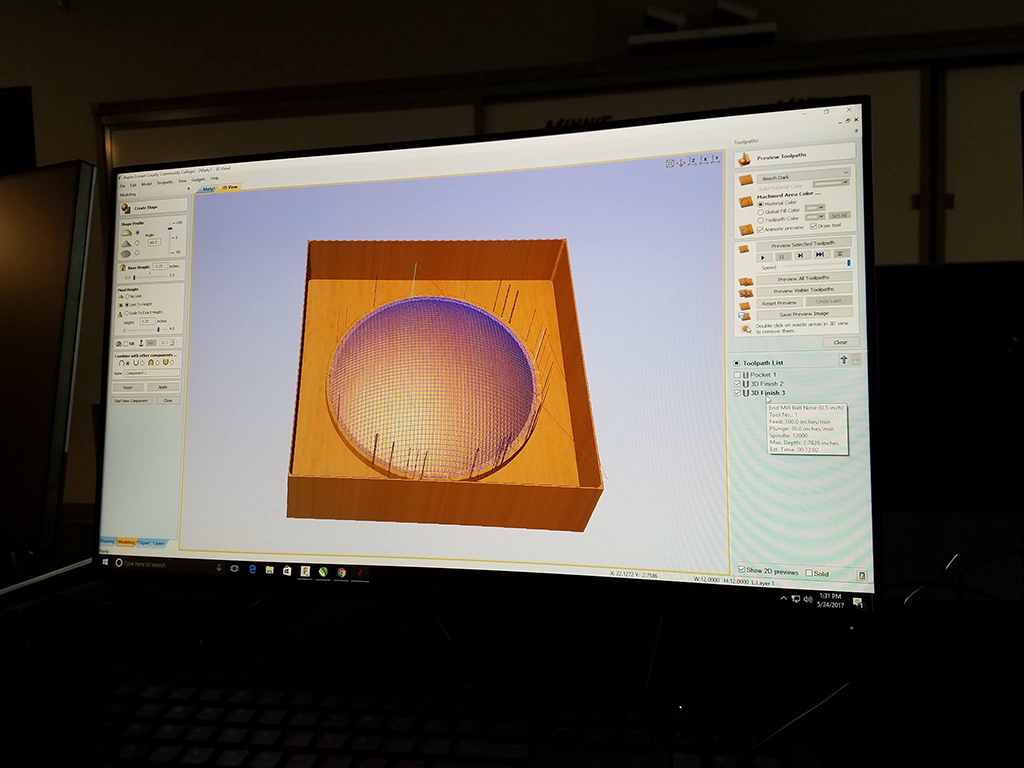

I first started out with making the design and toolpaths in Aspire

Getting the foam setup on the CNC router and Zero-ing it out.

Starting the rough cut

Tool change to ball nose

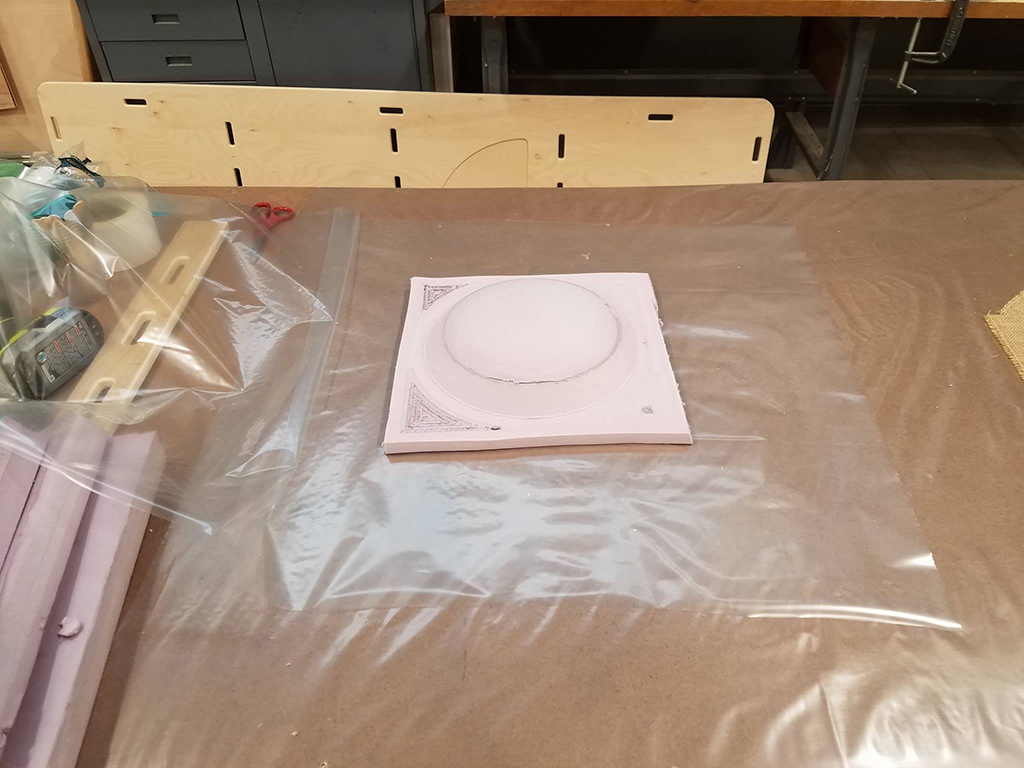

All finished. Now I am building the composites vacuum bag

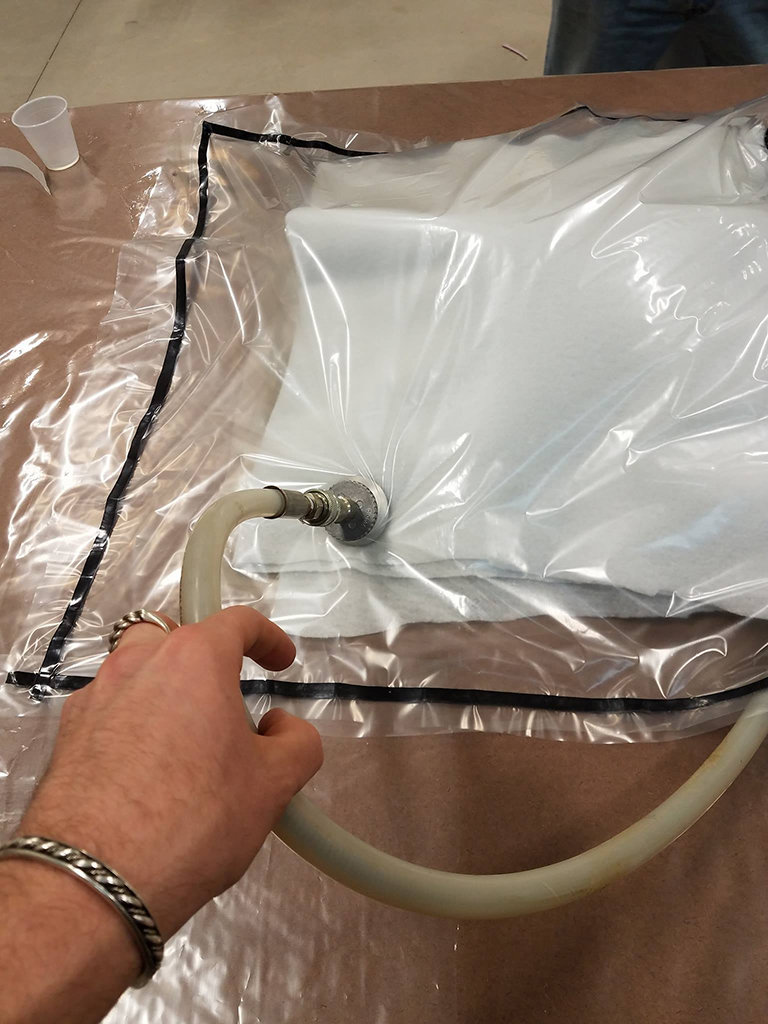

A couple more layers

All the layers are built, folded over and sealed together. Added the vacuum nozzel; Time to turn on the pump. I couldn't take any photos of me building the epoxy empregnated burlap sheets atop the cut dome form, due to being covered in resin. I ended up having 4 layer overlap around the outer rim, and about 12 in the center.

24hrs later (with the pump on): The epoxy is all set up

Pulling the form from the mold was a little nerve wracking; I had no idea how strong it would end up being and it required A LOT of force to demold.

Got it out in one piece

It seemed to be very strong, so I decided to stress test my new dome. It easily handeled my full weight and then some

Im also sporting the tshirt I made from week 2's assignment

Trimmed the edges with a bandsaw, and now it sits lovely on my bar as a bowl