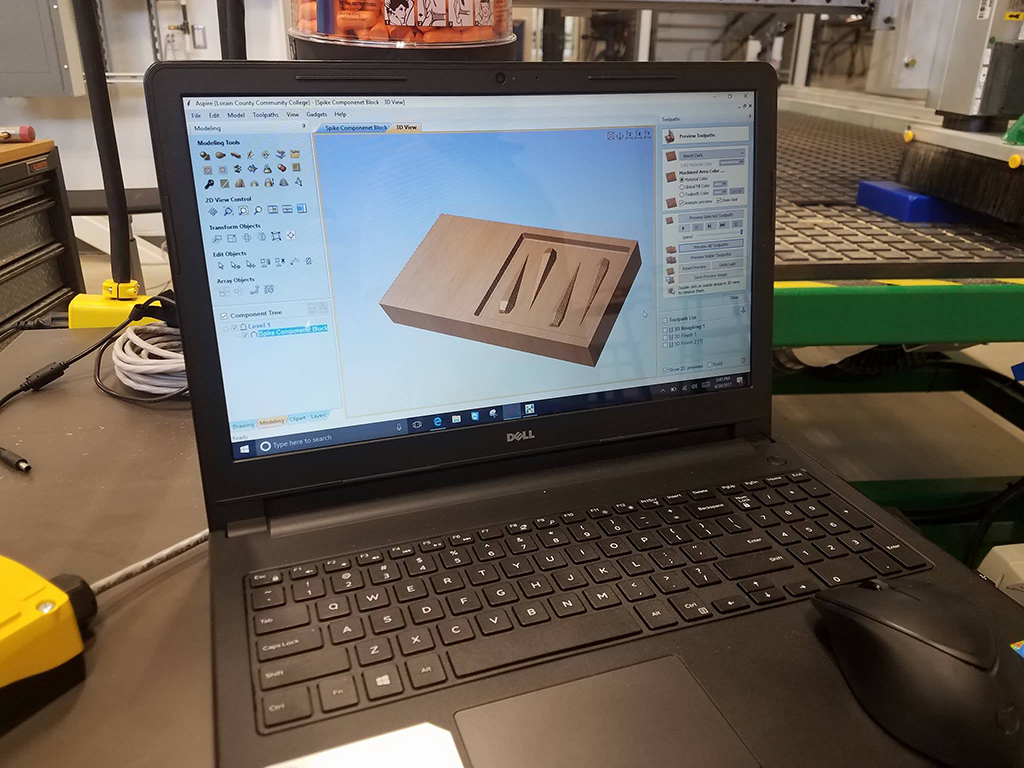

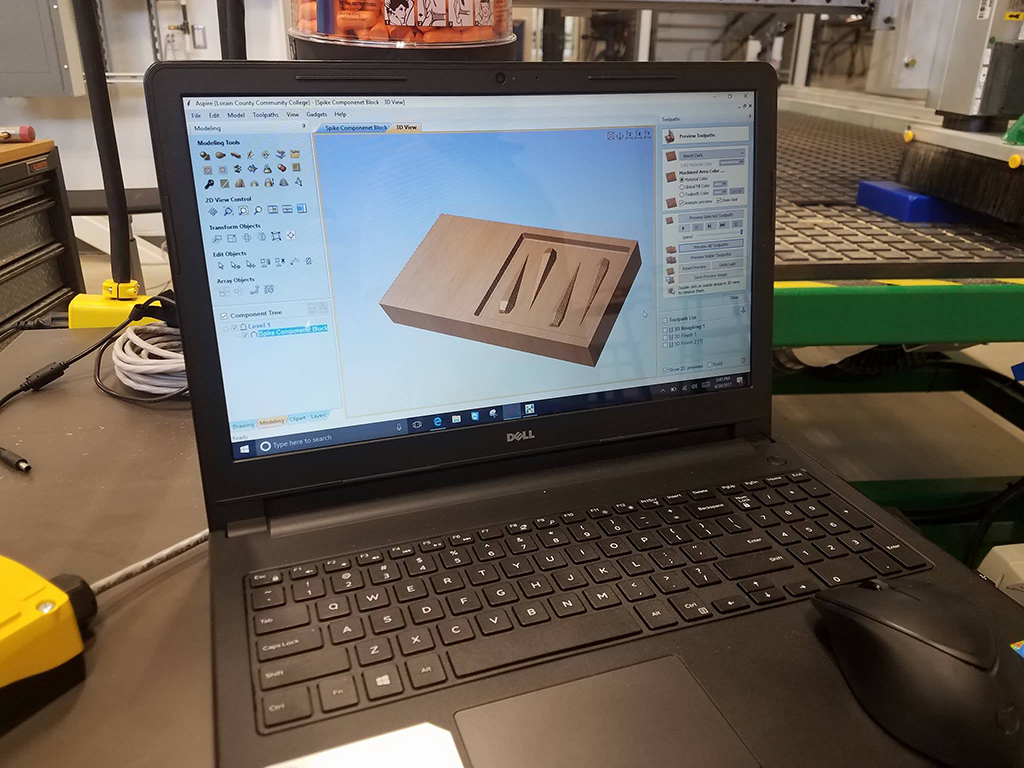

Back again to a skill set I already have and am comfortable with, we begin making molds and casting from them. Unfortunately, as I was working with an instructor on the wax positive that was going to be carved out on the CNC, we got the scaling and depths all wrong and I basically scrapped that project.

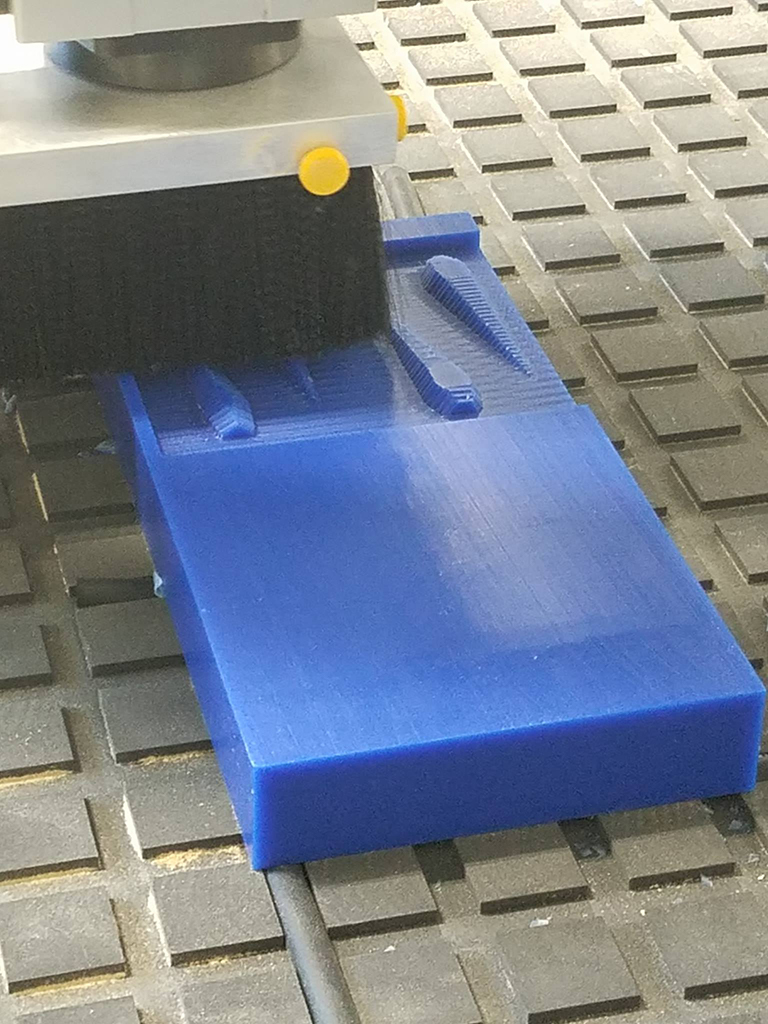

I then made a quick rubber mold of the downspout caps I had printed for the "tubes" that were lasercut during week 3. They were very thin, and the hydrostone is obviously not meat to cast things with such thin areas. A few turned out though.

In reference to the Prosthetic Prototype I had designed, I took a mold of a model's leg, and then cast it out in hydrocal. I then took the hydrocal leg and scanned it into a digital form to create the prosthetic.

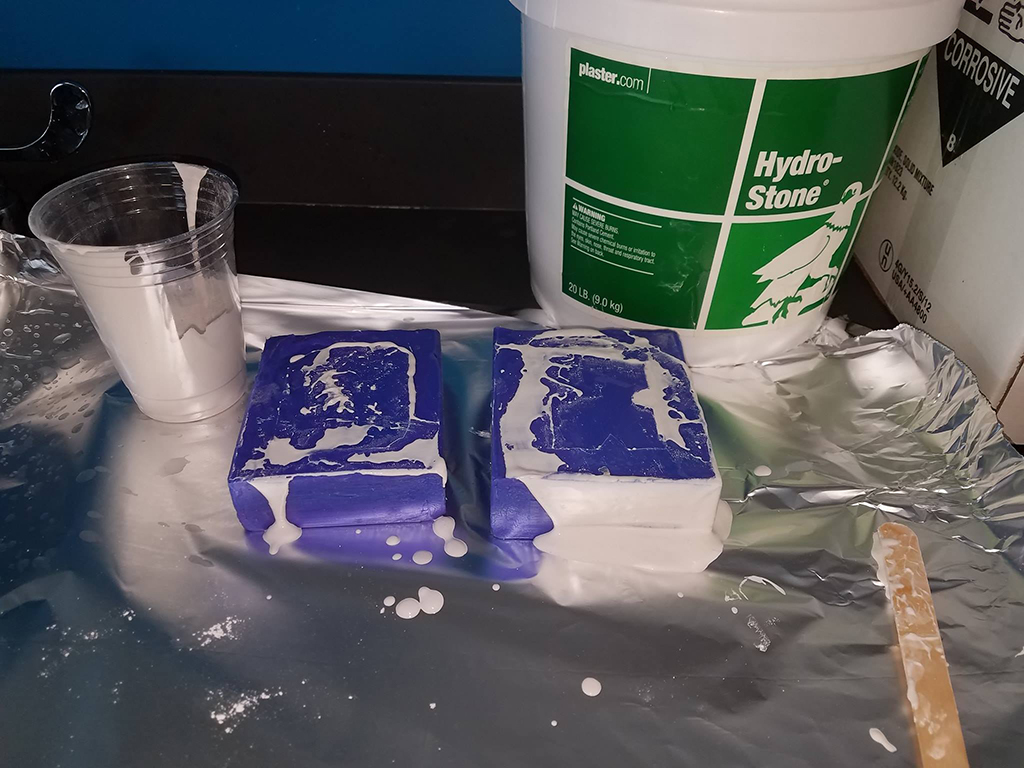

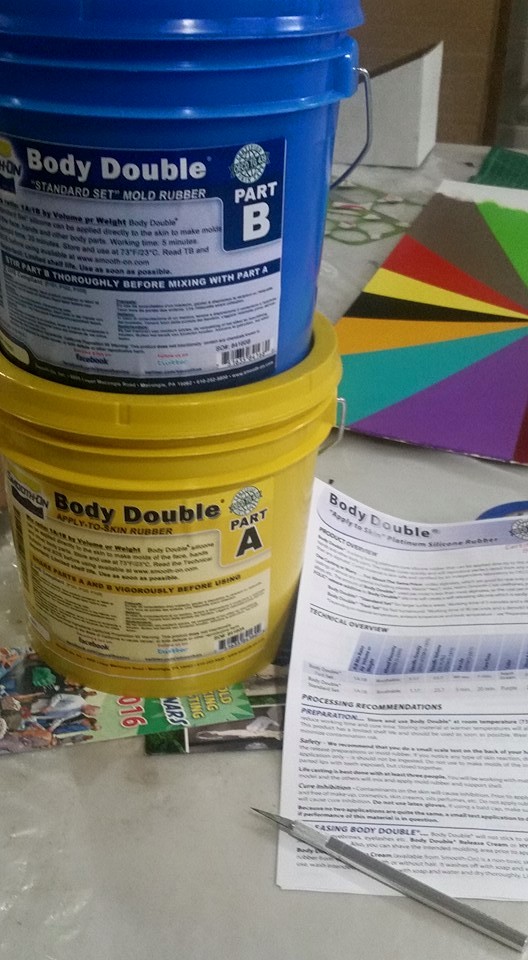

Here is the mold material I used to life cast from my model

I built the top of the mold first with the model laying on her back. Then, I had her roll on her stomach, with her leg still in the mold, and then began building the other half.

I built a hard shell of hydroCal over the soft rubber shell for both halves, with buttons so that they key back together in the same way every time.