Back to my comofort zone.

I have had lots of success 3d printing and scanning since I have first gotten into it a year ago. One of my larger, more complicated projects was a prosthetic design prototype with internal lighting and fiberoptic cable

Some Examples of Solidworks work, and objects being printed in different ways

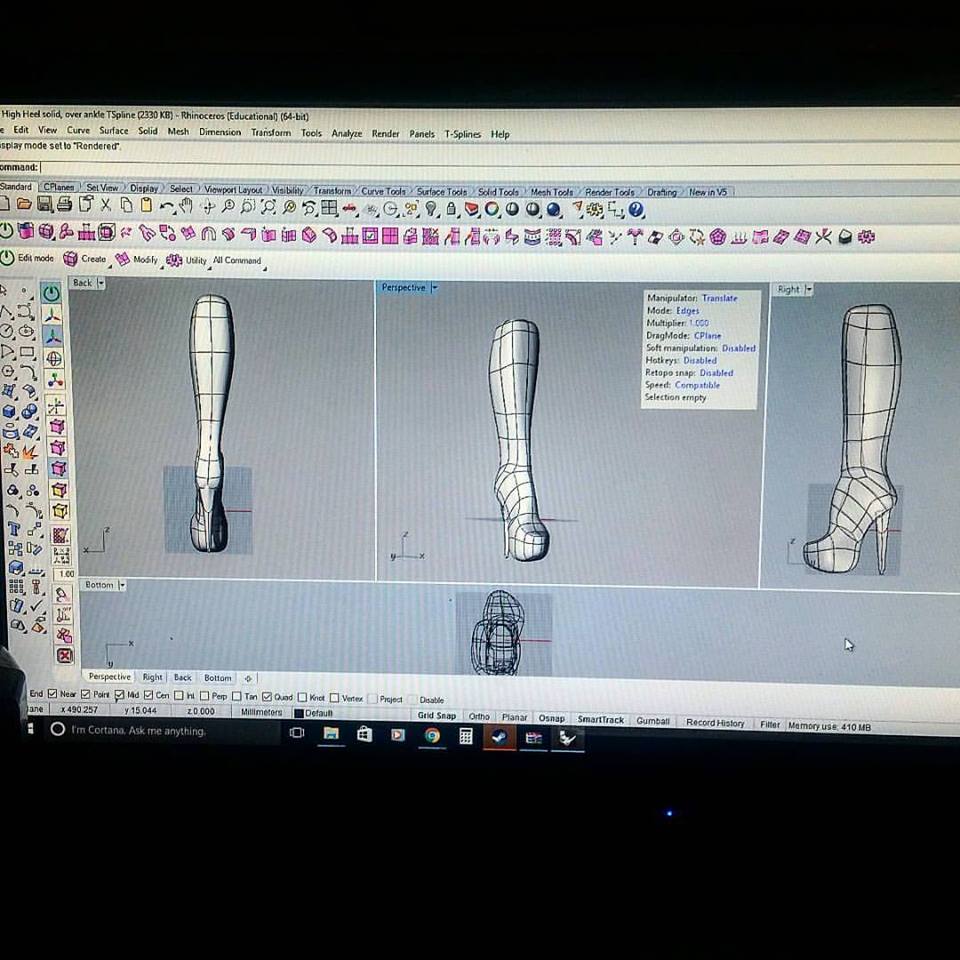

After I created and stitched together the scan files as best I could, I began making shapes using T-splines (in Rhino) inside of the scan shape, using the scan almost as a digital mould. Using the scan left out any guesswork on anatomic preportions of a leg, and from there I augmented and stylized it a little further past "natural" preportions.

From that initial leg form, I carved out an interior pocket and pathways for the electronics, wiring, and fiber opitc cables. I Then Printed the new design out on a Fortus Sm. 400 in 3 seperate parts that key together.

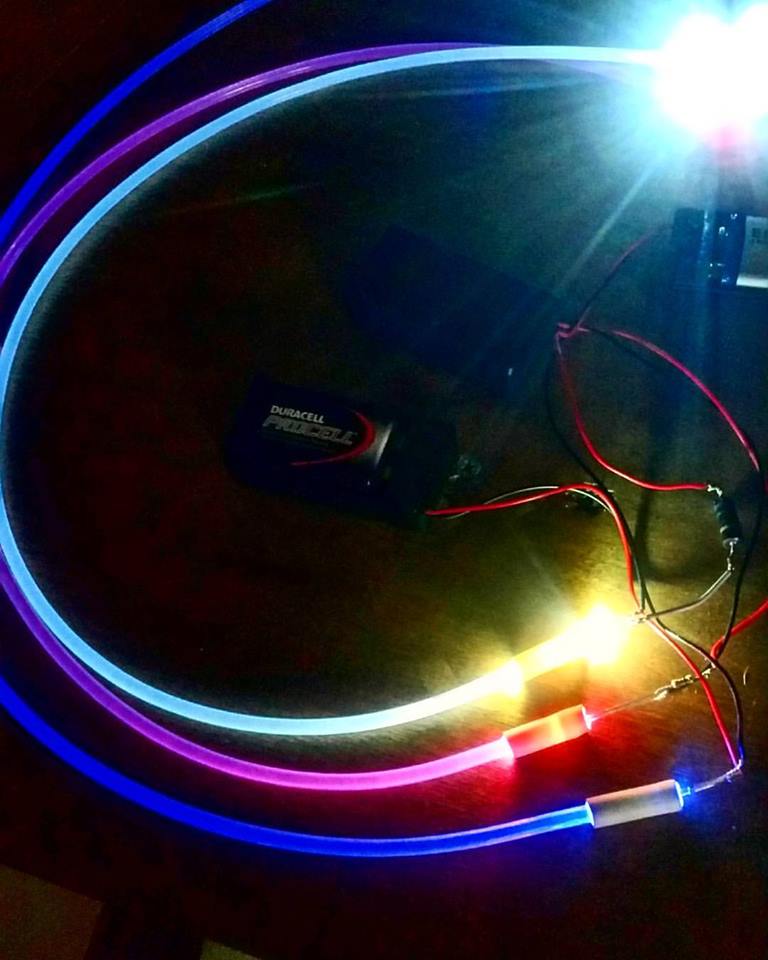

Wired up the LEDs and tested out which colors work best inside of the fiber optic cables

Picked out the LED colors, threaded the Cables through the pathways in the leg, gave the leg a few coats of paint, pluggen in a couple batteries, and BAM! It's finished.