Well well, some things I have some knowledge of. Computer Aided Design is my forte. I have designed 3D work in Inventor, Rhino, and Solidworks, I have made a small line of tshirts utilizing the vinyl cutter, multiple engraving & fabrication projects with Laser Cutters, and some utilization of a shopbot.

Not the biggest fan of Corel, being an Adobe person myslef, I do the majority of any image preperation and augmenting within photoshop, and then finalize everything within Corel.

I made the design in AutoCAD, moved the design over to Graphtec Studio, and cut in heat reactive vinyl. Took the design after the negative was fully removed and heat pressed onto my now favorite tshirt.

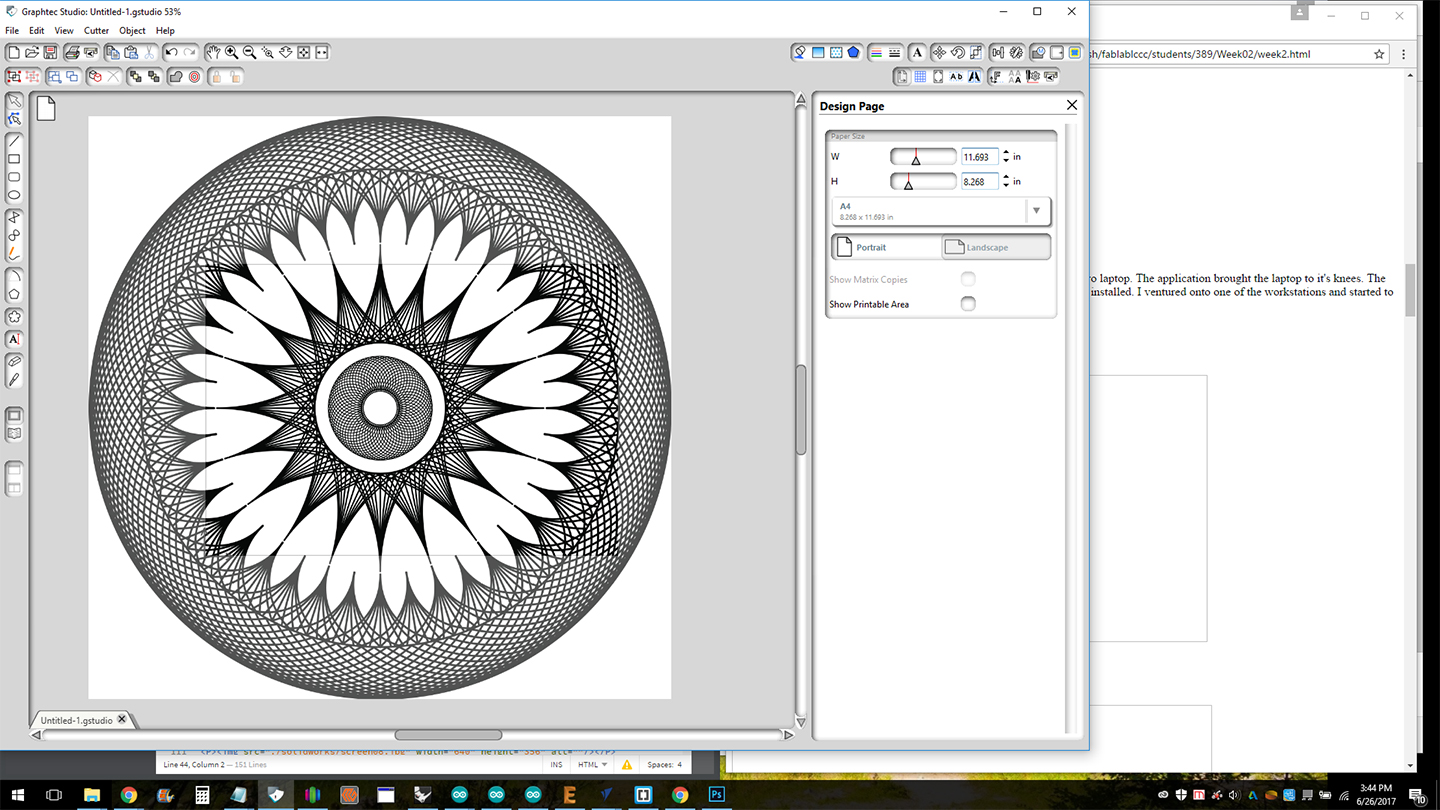

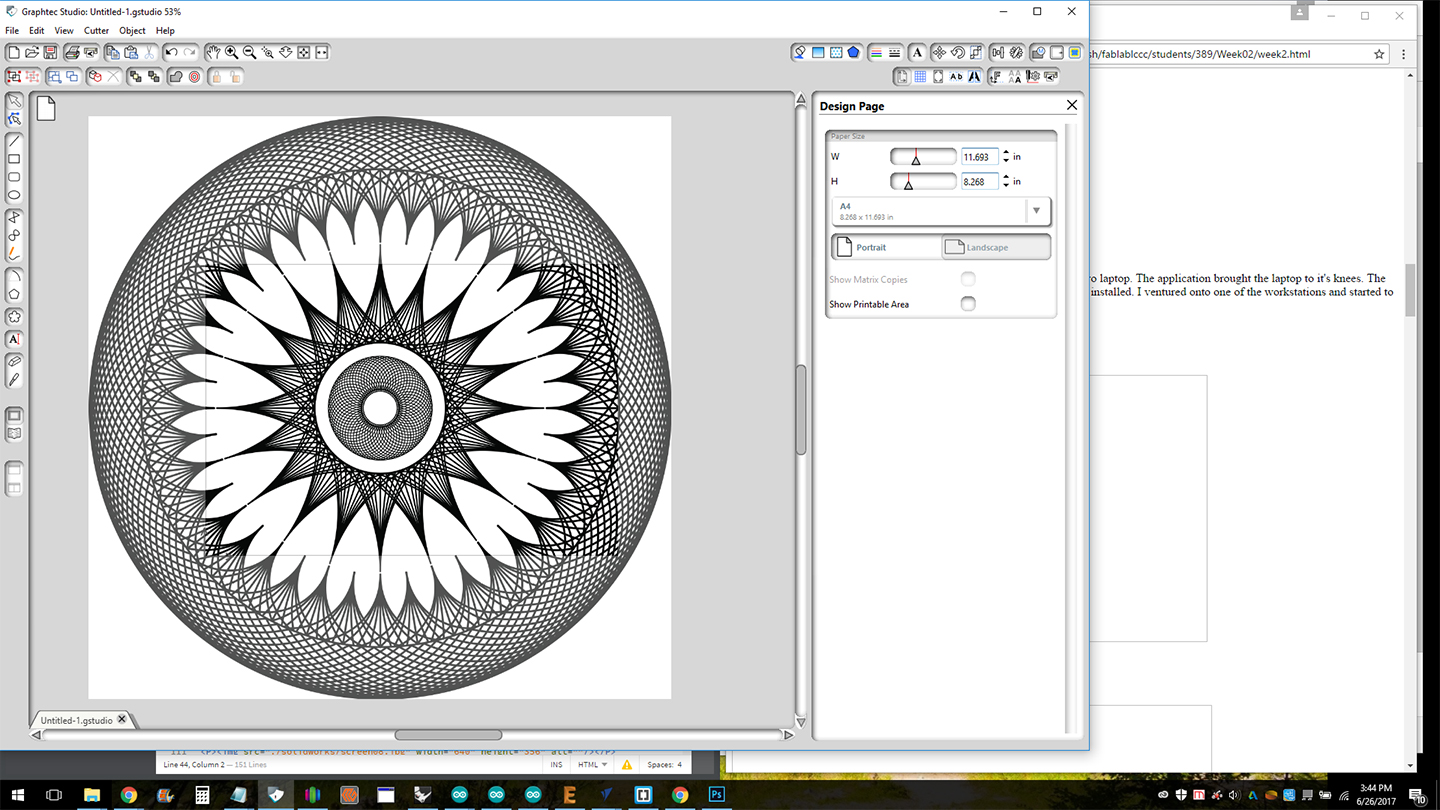

I began the design in AutoCAD, and moved it over to Graphtec. Once the design was processed I cut it on the vinyl cutter

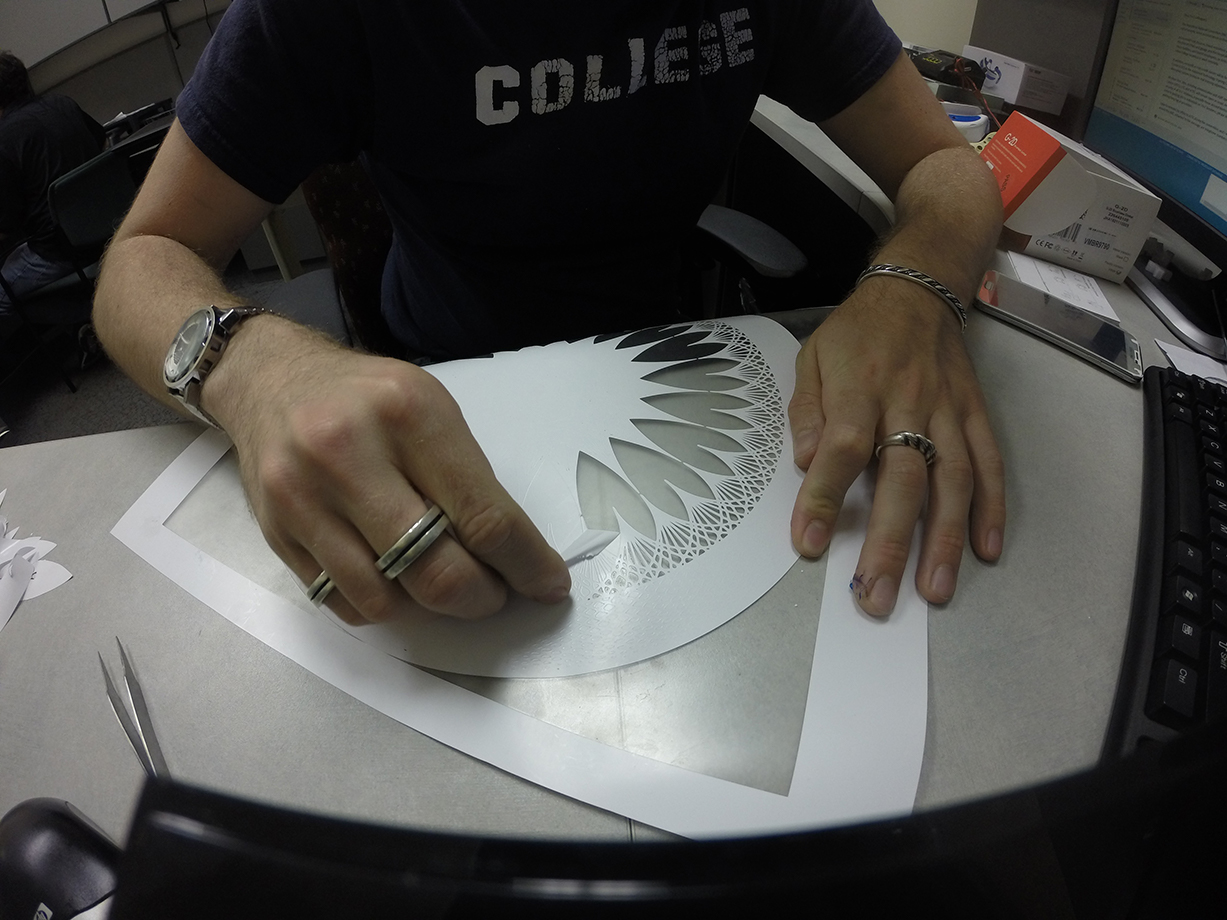

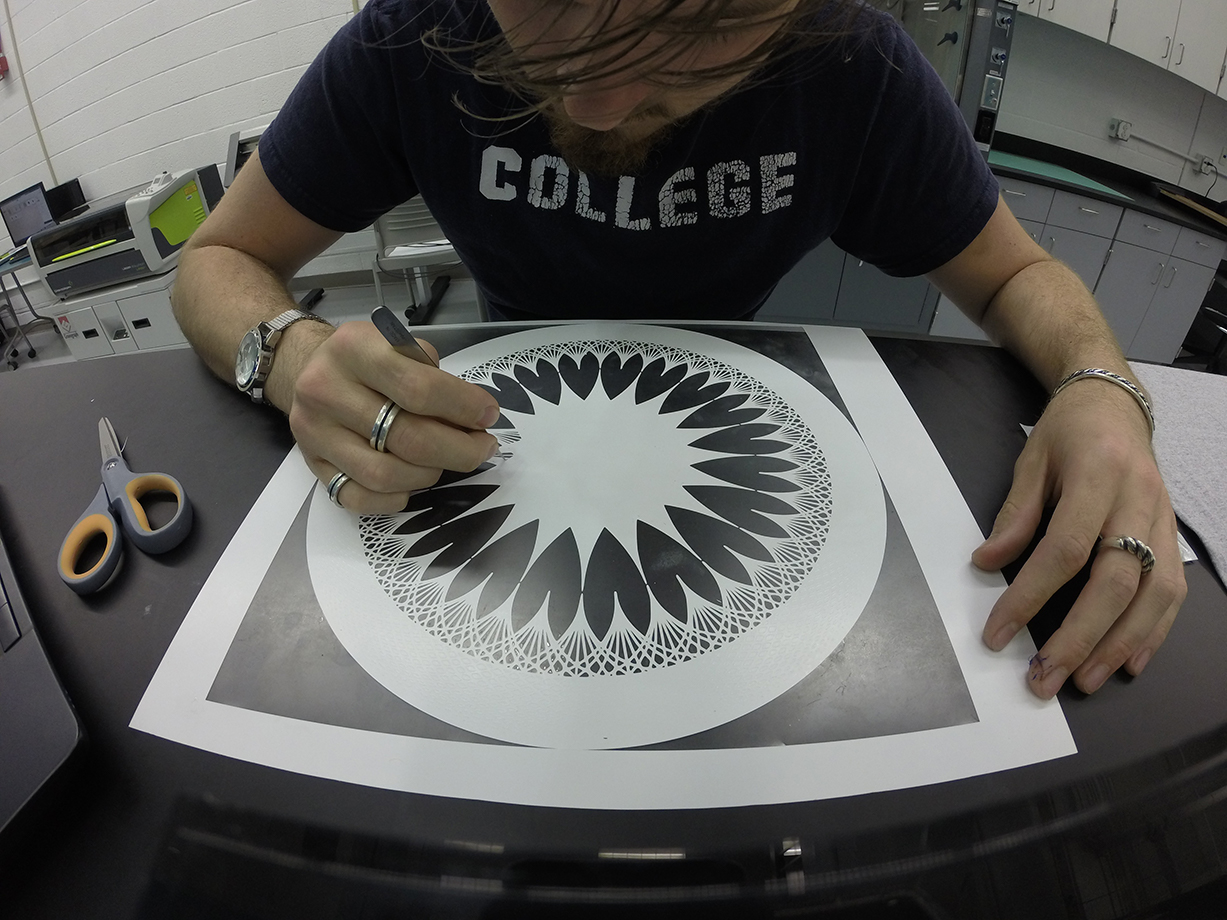

After I got the design cut into the vinyl, I began the very long process of peeling away the negative.

Starting to remove larger areas

Finishing outer ring

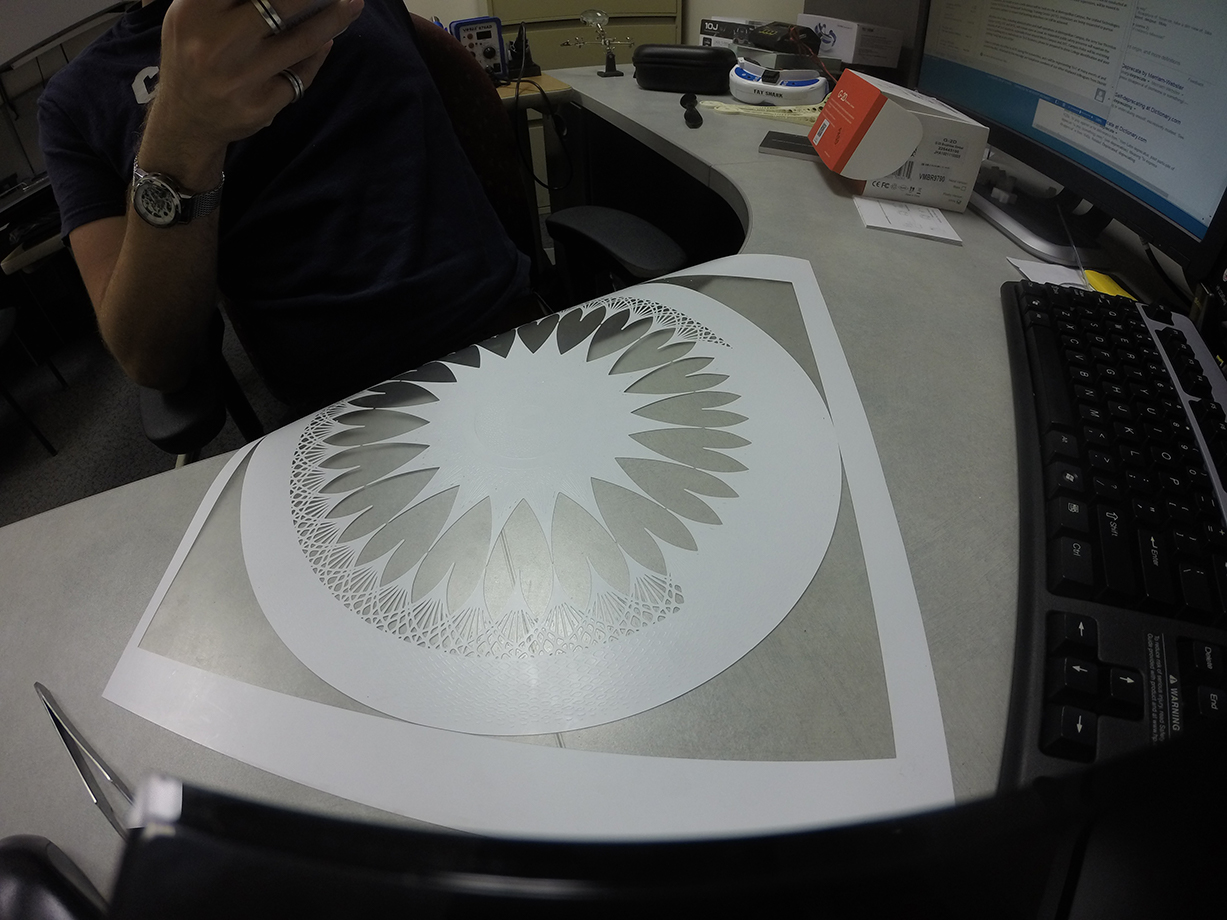

Working on the inner spokes

Finished inner spokes; woking on outermost ring

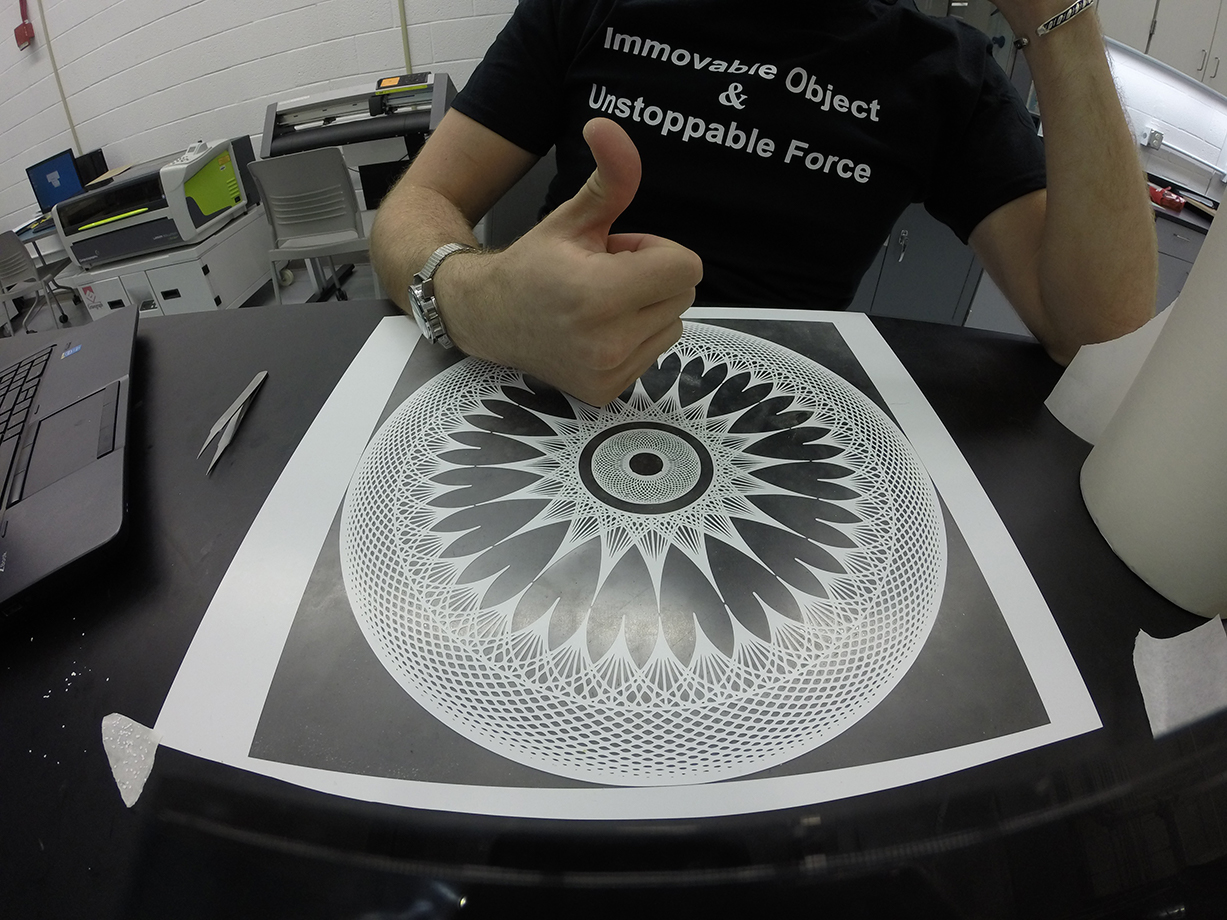

Working on the innermost circle

Finally finished. It took ~18hrs to peel

Some other examples of work I've done in the past

Solidworks, Rhinoceros, Inventor, etc. are all based on similar procedures and methods for making and designing in 3D space. All three do work slightly differently and are used for different applications. In my experience, Rhino is best used for organic, artistic, and complex forms, while solidworks is best for simple, but acurate forms, machined parts, and engineering applications. Inventor is overshadowed by both of these other more powerful and popular applications.

Initial designs for a prosthetic design made in Rhino v5 + T splines plug-in