-Computer Controlled Machining-

Objective:

This week I had to design a large-scale object using the program On Shape and then cut it using the CNC Machine (Computer Numerical Control). The cutting process is done on a thick wooden plate, which requires precise drilling depths.

Design:

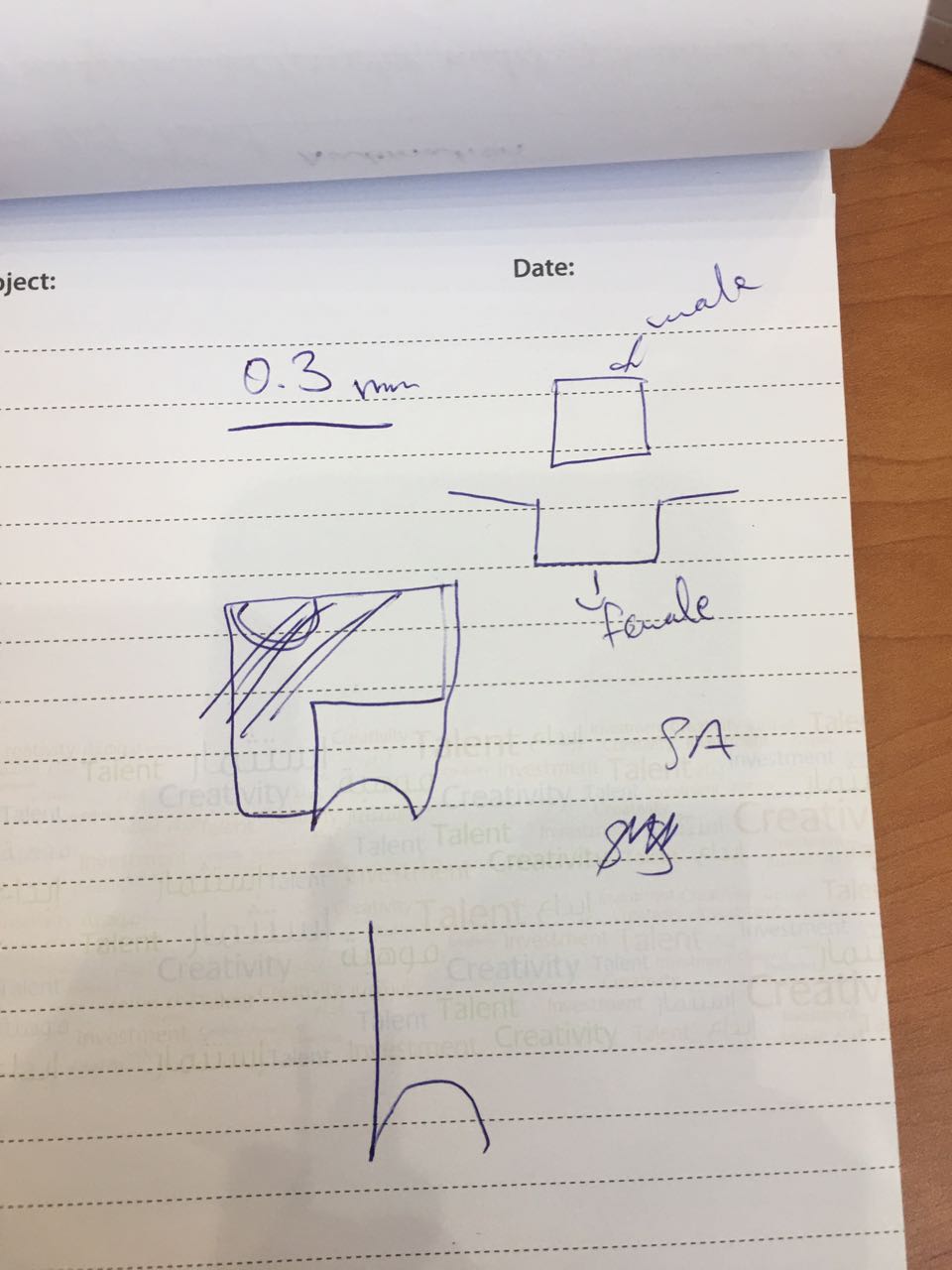

I decided to make a chair for kids and young teenagers. The design required lots of calculations in the design stages because the pieces are going to be cut separately and connected together manually through male and female edges.

I put in consideration the thickness of the wooden board that we are working with which was 18mm, and after a few trials and errors was able to complete the design. The main issue in calculating the lengths was putting ‘Tolerance’ space in consideration.

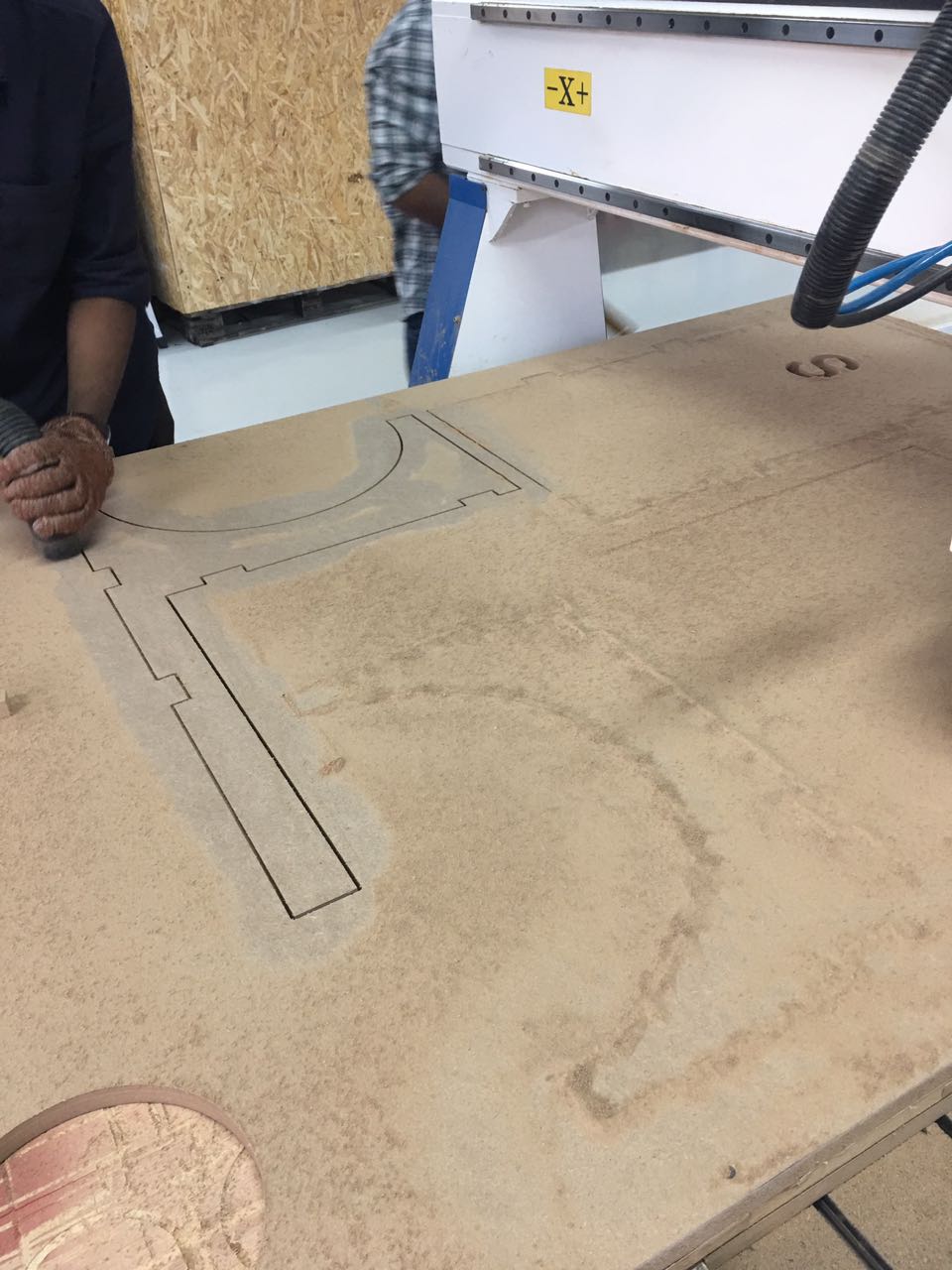

Cutting:

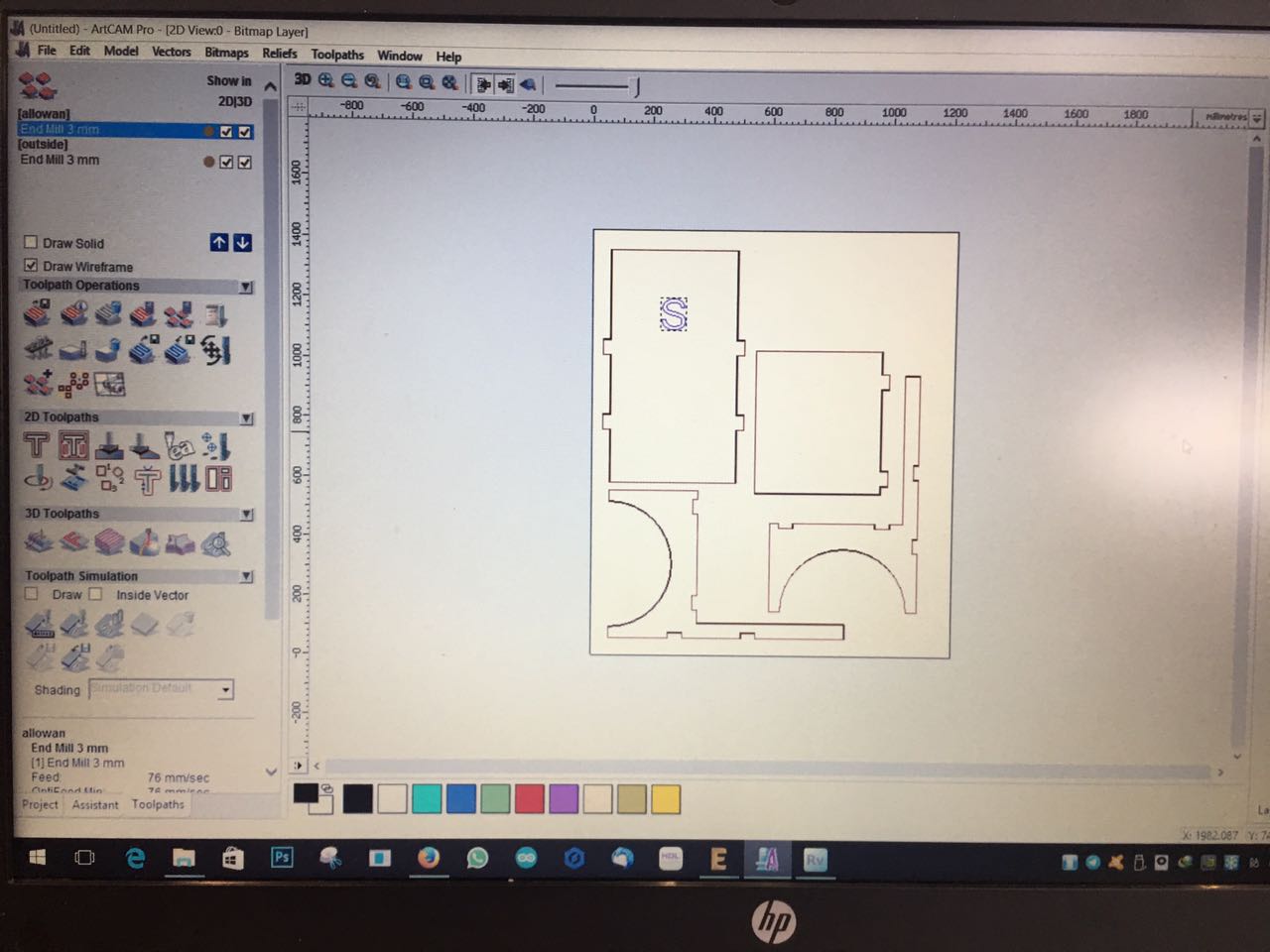

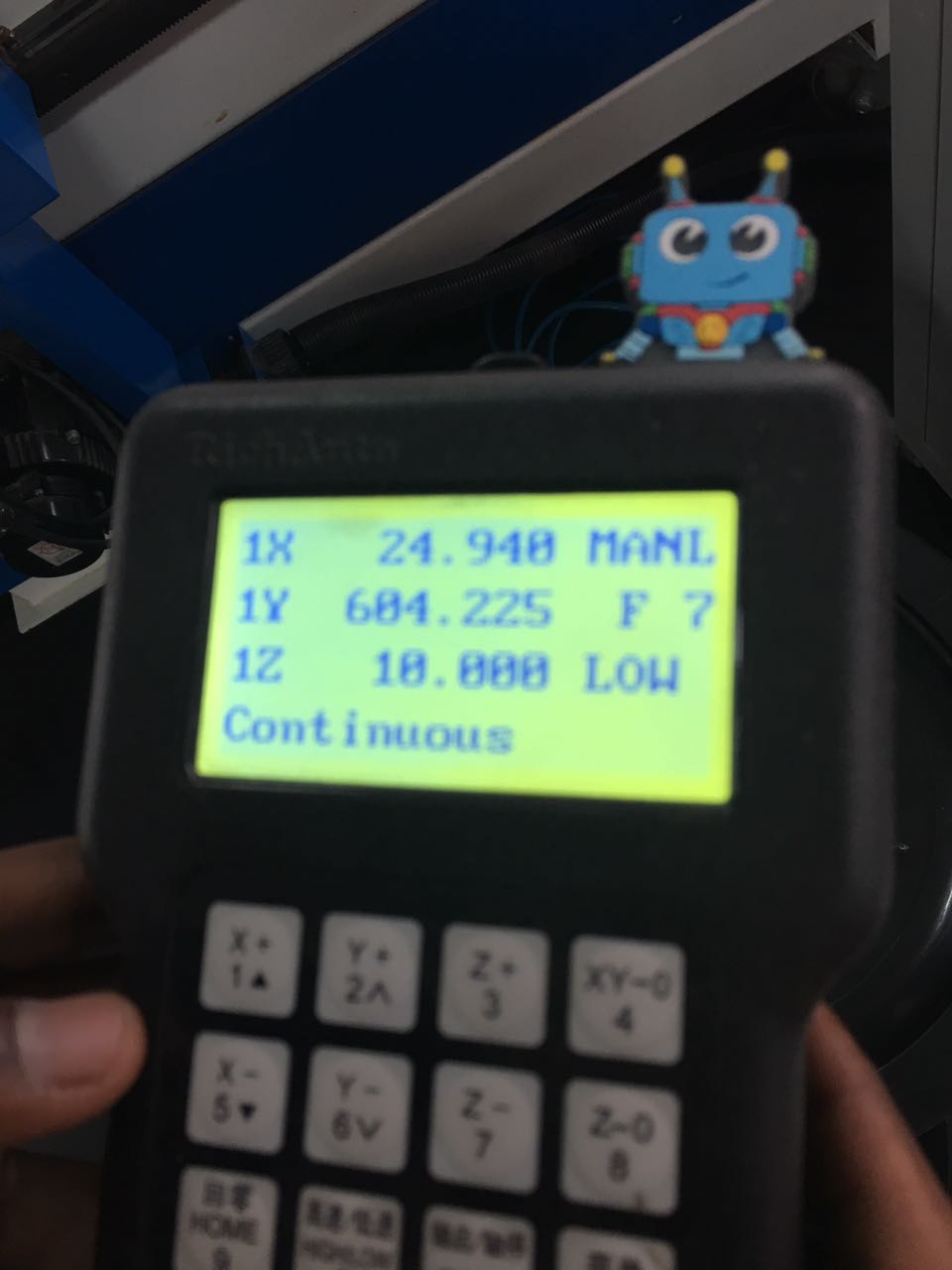

Following the design, next was the cutting process.I exported the files each one separately as DXF format and opened with ARTCAM software with a different laptop in the lab because this software (ARTCAM) is only compatible with windows and our laptops use LINUX system.

Following changing the format of the files I started the cutting process.

The Final Product:

Difficulties:

- Calculating the length spaces where I will connect the pieces.

- The drilling pin in the CNC Machine broke due to over use

- When I was sanding some of the pieces after cutting, a couple of the edges broke off just a little.