• Ductile iron

• Aluminum

• Steel

• Copper

• Zinc

For more details

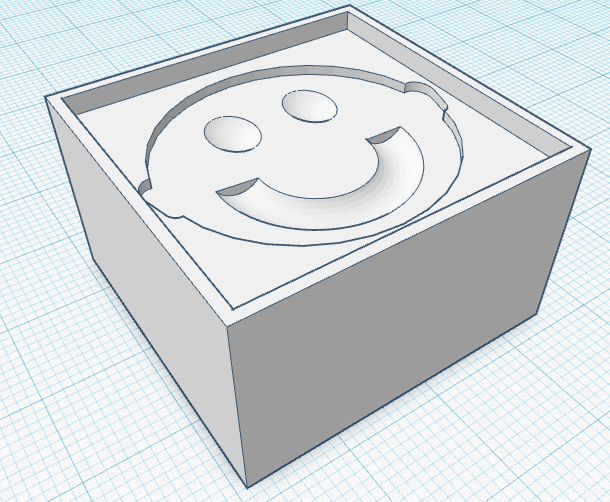

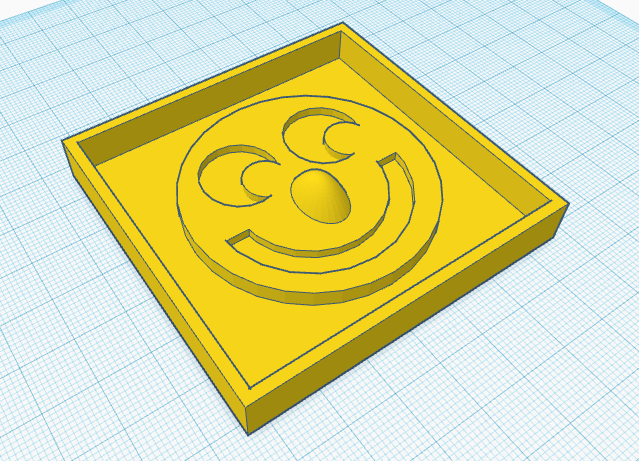

The Design (Tinkercad)

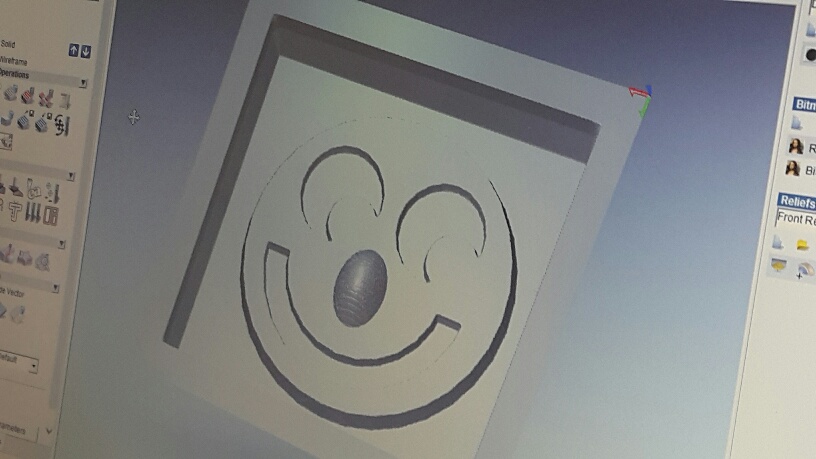

I will make a smiley face using tinker cad application by drawing a hole face on the box shape.

After merging the two shapes, the face will be shown on the box.

This final design has to have a certain measurement for the CNC to cut.

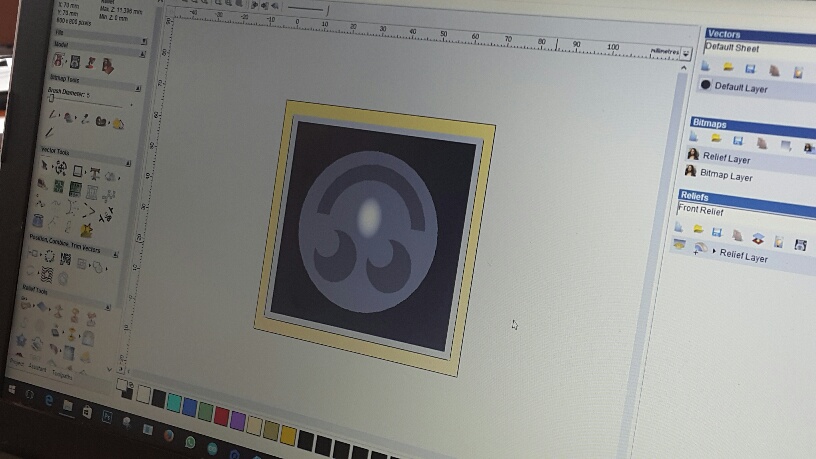

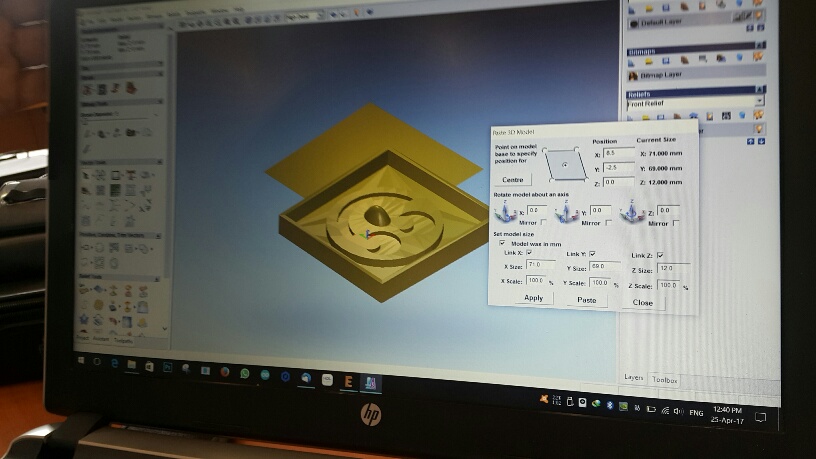

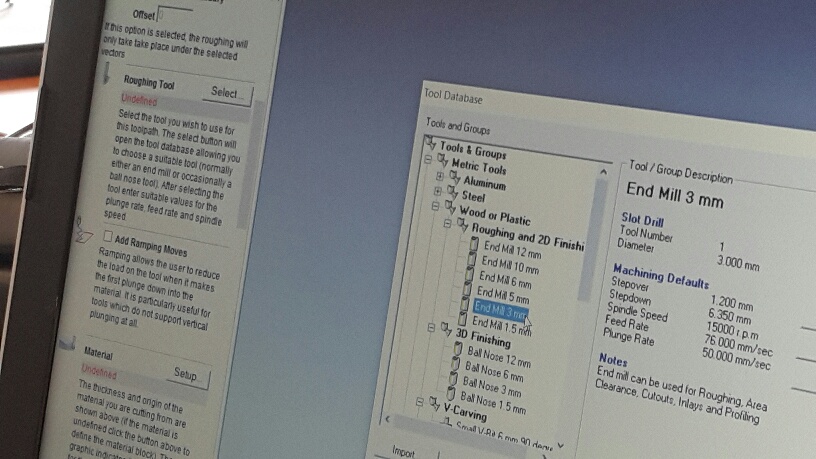

Art Cam I need to use the Art Cam to convert the shape to be cut on the CNC.

I need to adjust the X,Y and Z for the CNC trace.

The bit will be 3mm to cut the smiley face.

This is the final shape that will be cut with the CNC.

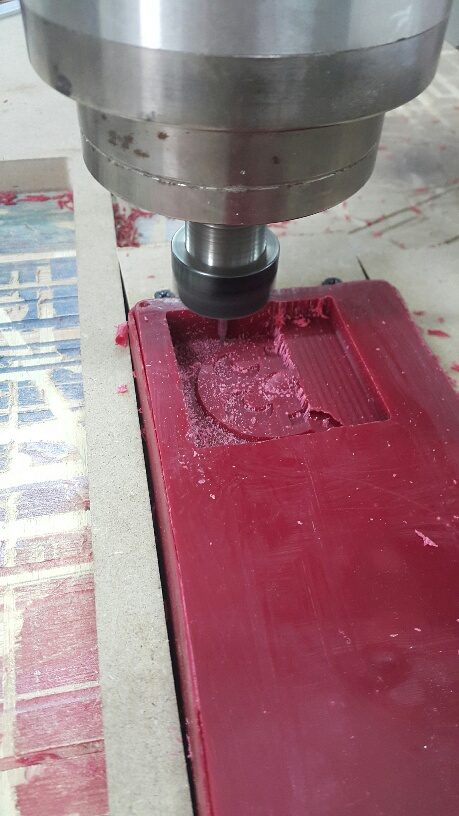

The creation using CNC The celicon needs to be stationary in order for the CNC to cut without vibration.

The CNC is cutting the celicon nicely and constant.

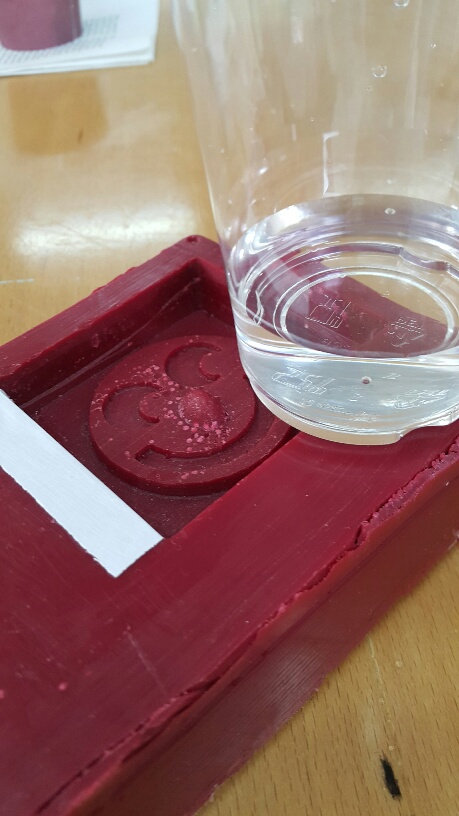

There was a hole with water inside the celicon because i did not melt the celicon well. But anyways, i have fixed the problem using a white tape.

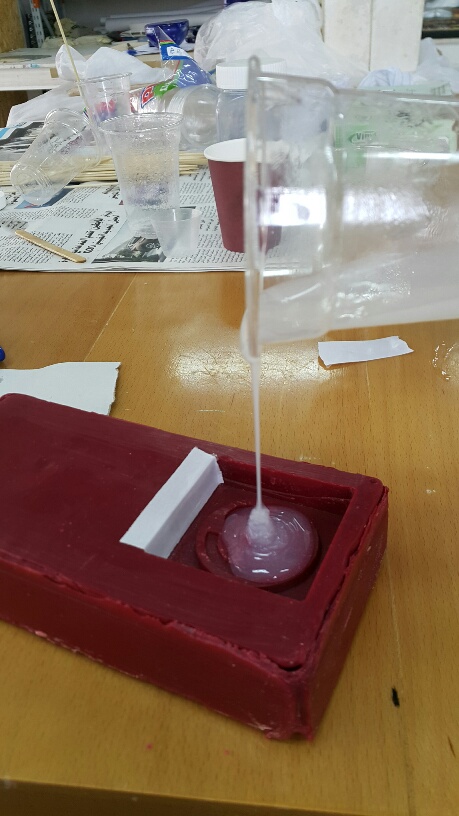

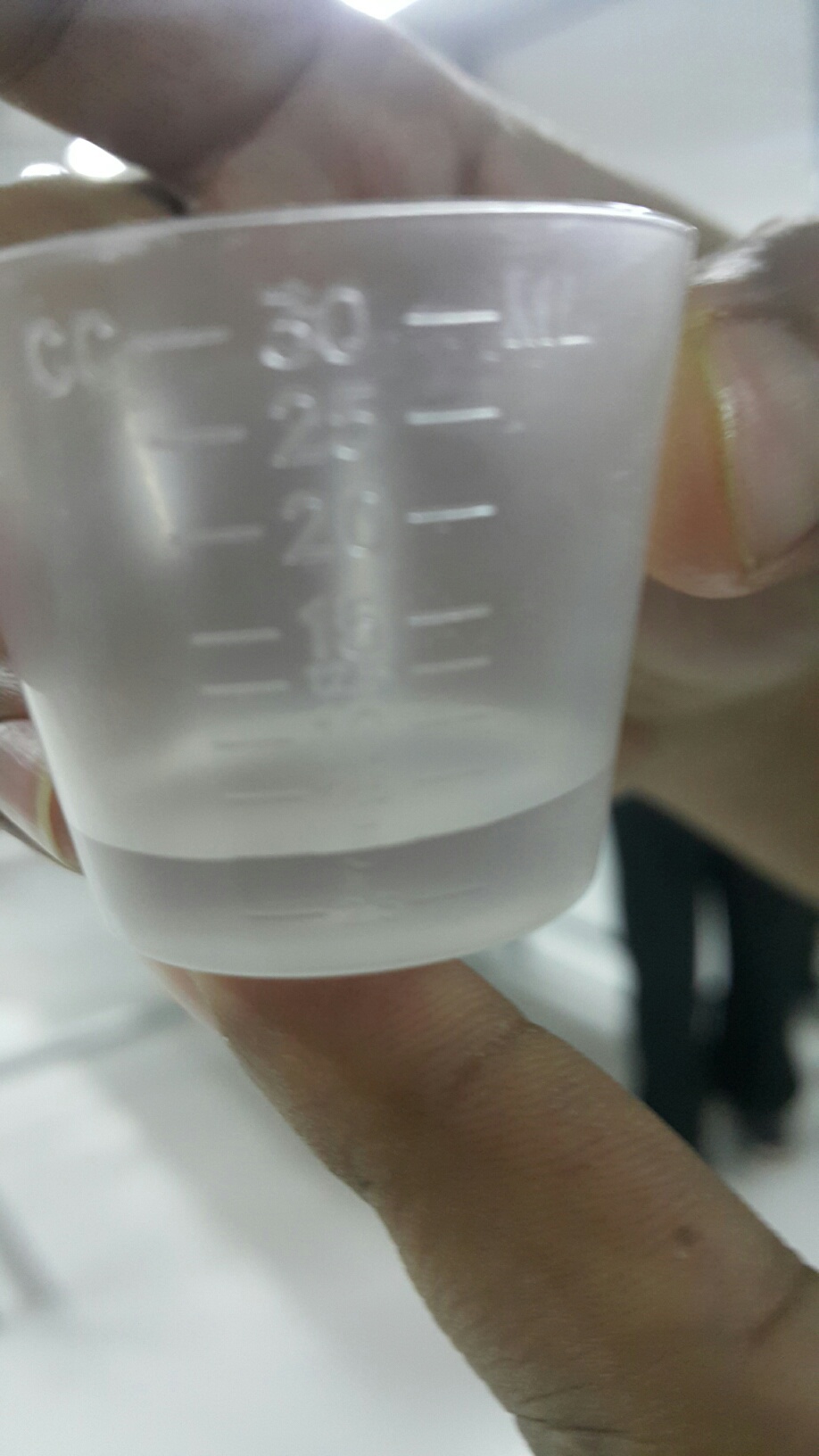

I poured water on the shape to see the quantity.

It is 30ml + 15ml = 45ml. I will increase 5ml to make it 50 better to fill up the whole place.

Now to pour the white celicon to create the smiley face.

We need to pour slowly to avoid the bubbles which is not good.

Now it is now time to wait for the celicon to dry out.

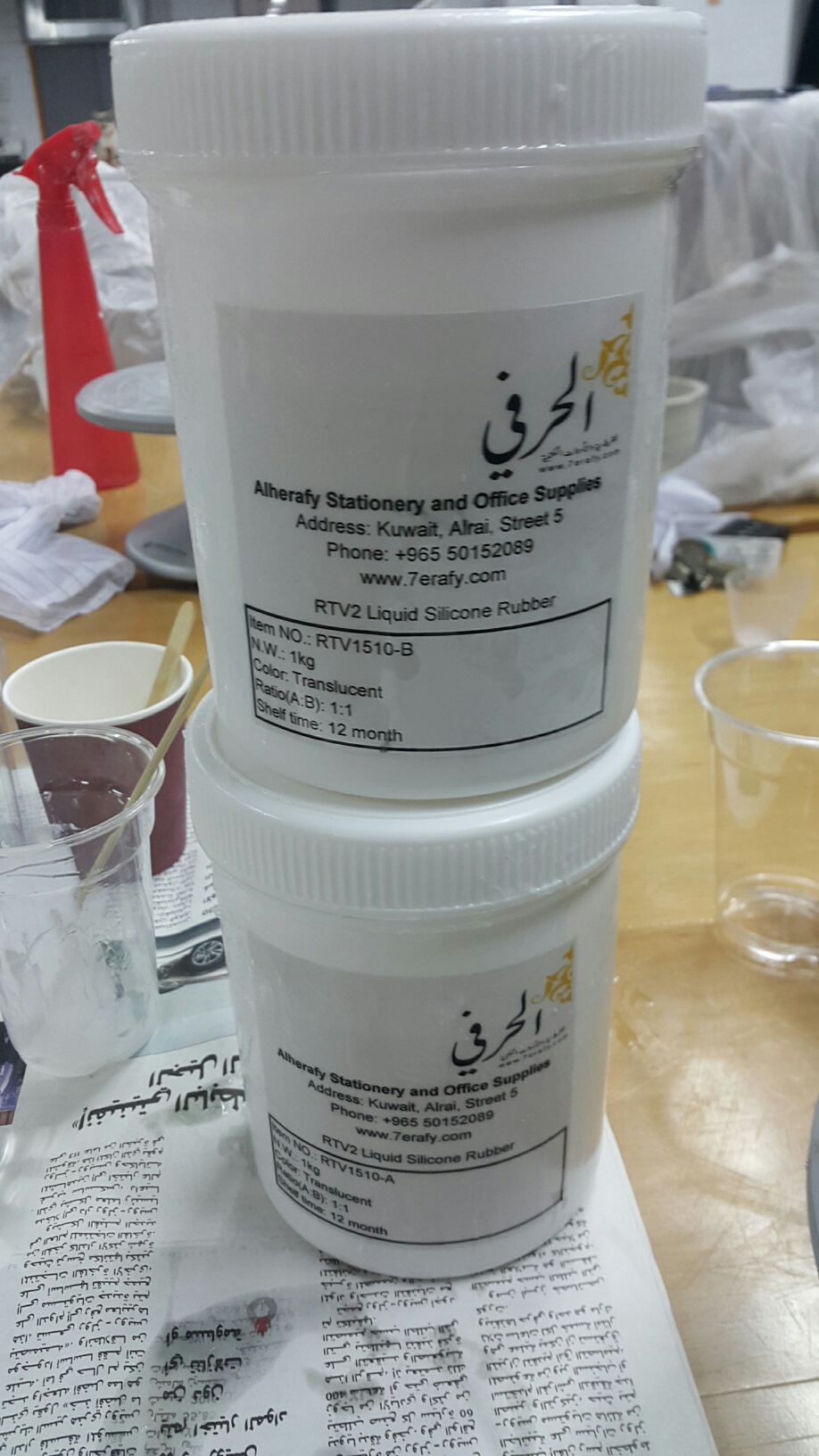

This material is Celcon which will dry and make the wanted shape.

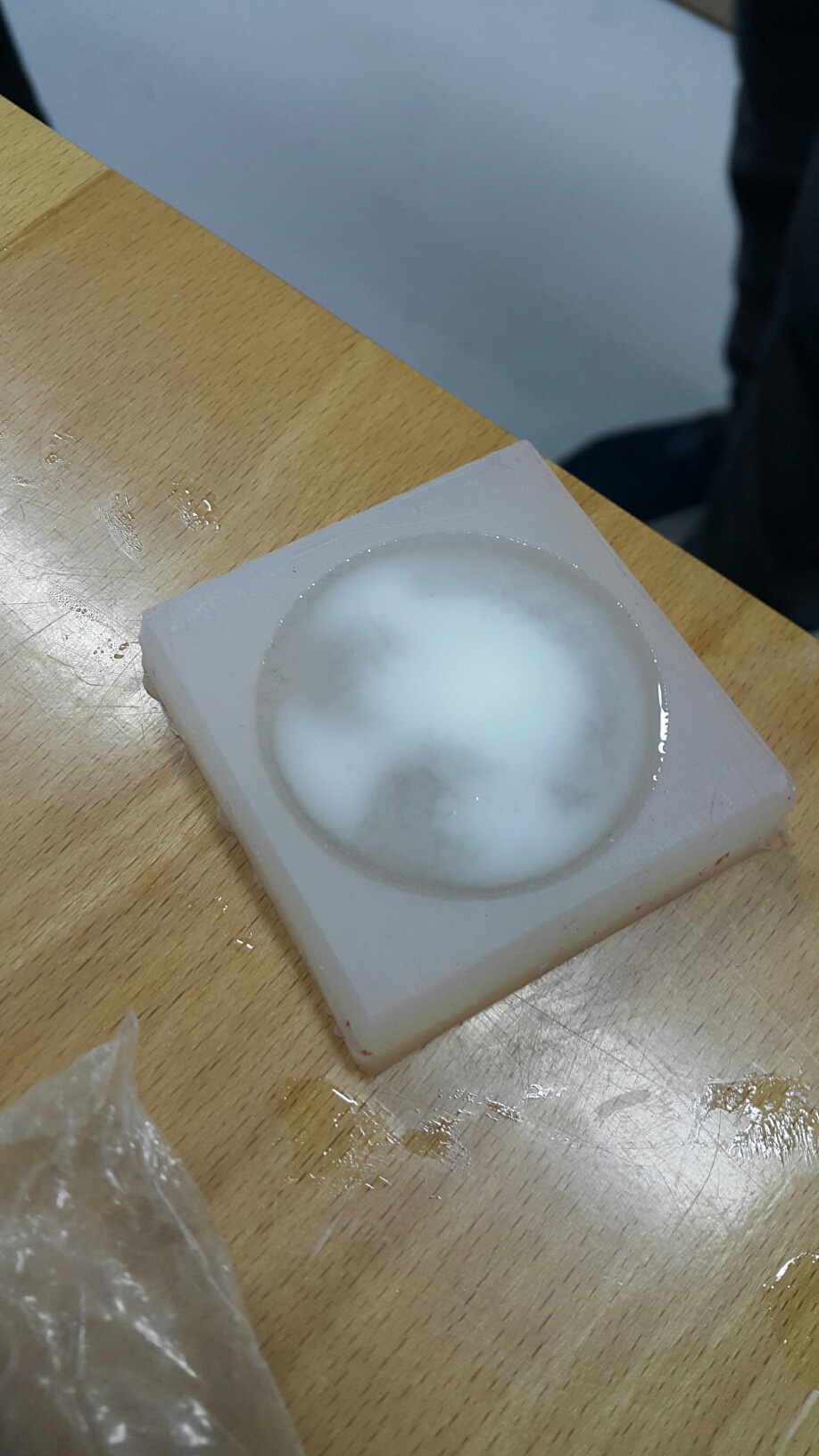

The Celcon dried out and gave us this shape which is the smiley.

Now, we will use the casting material and pour it inside the smiley face.

It will take 15 minutes only to dry out.

This is the result of the molding and casting. It was a fun experience and easy. We can make soaps, cake and cookies using this method. Problem Fixing There was a hole with water inside the celicon because i did not melt the celicon well. Since then, I have fixed the problem using a white tape. Download Files Casting and Molding tutorial This is a very simple guide on how to use the CNC hardware and a software to cast and mold explained by Brian Oltrogge:-

Smile Face

1.3mm

3mm