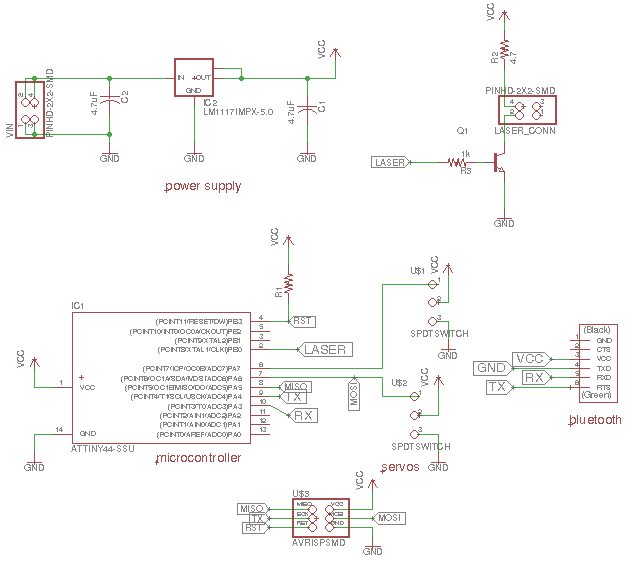

The components used

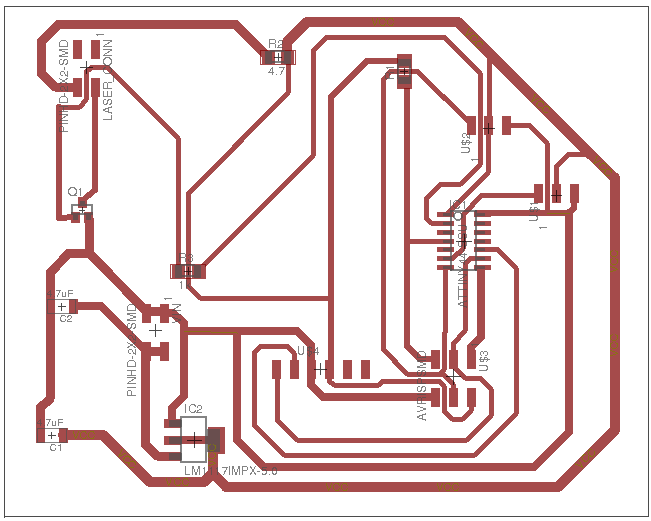

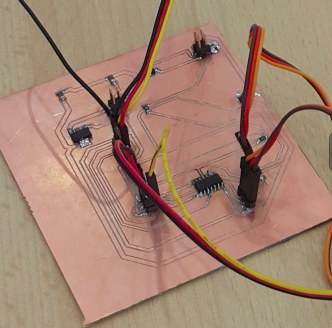

Electronic Design

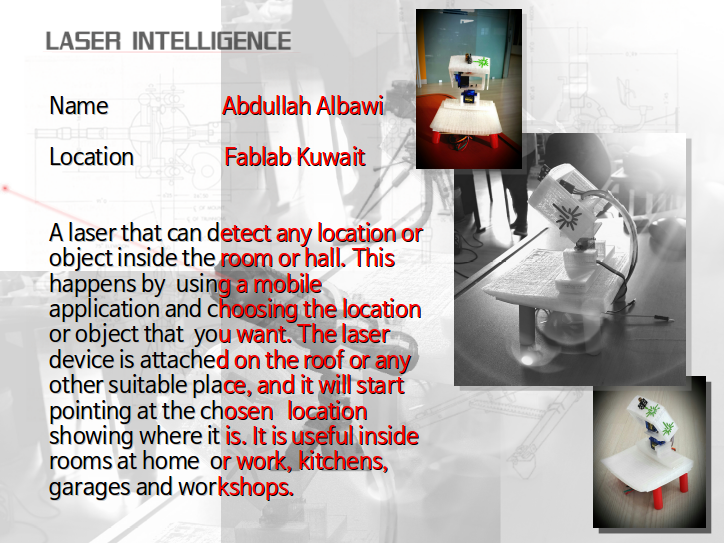

Input

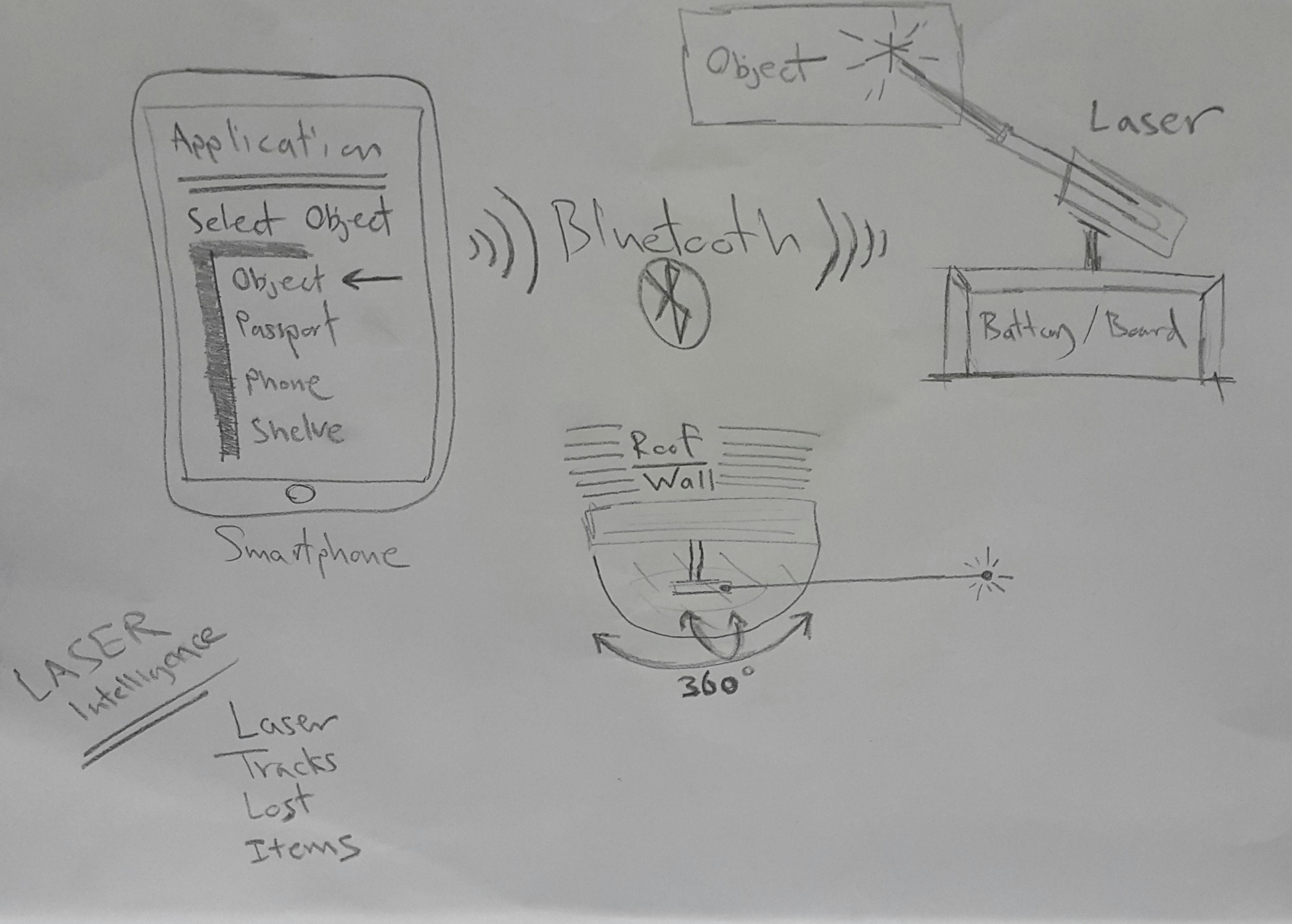

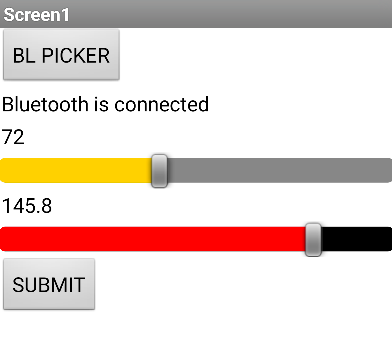

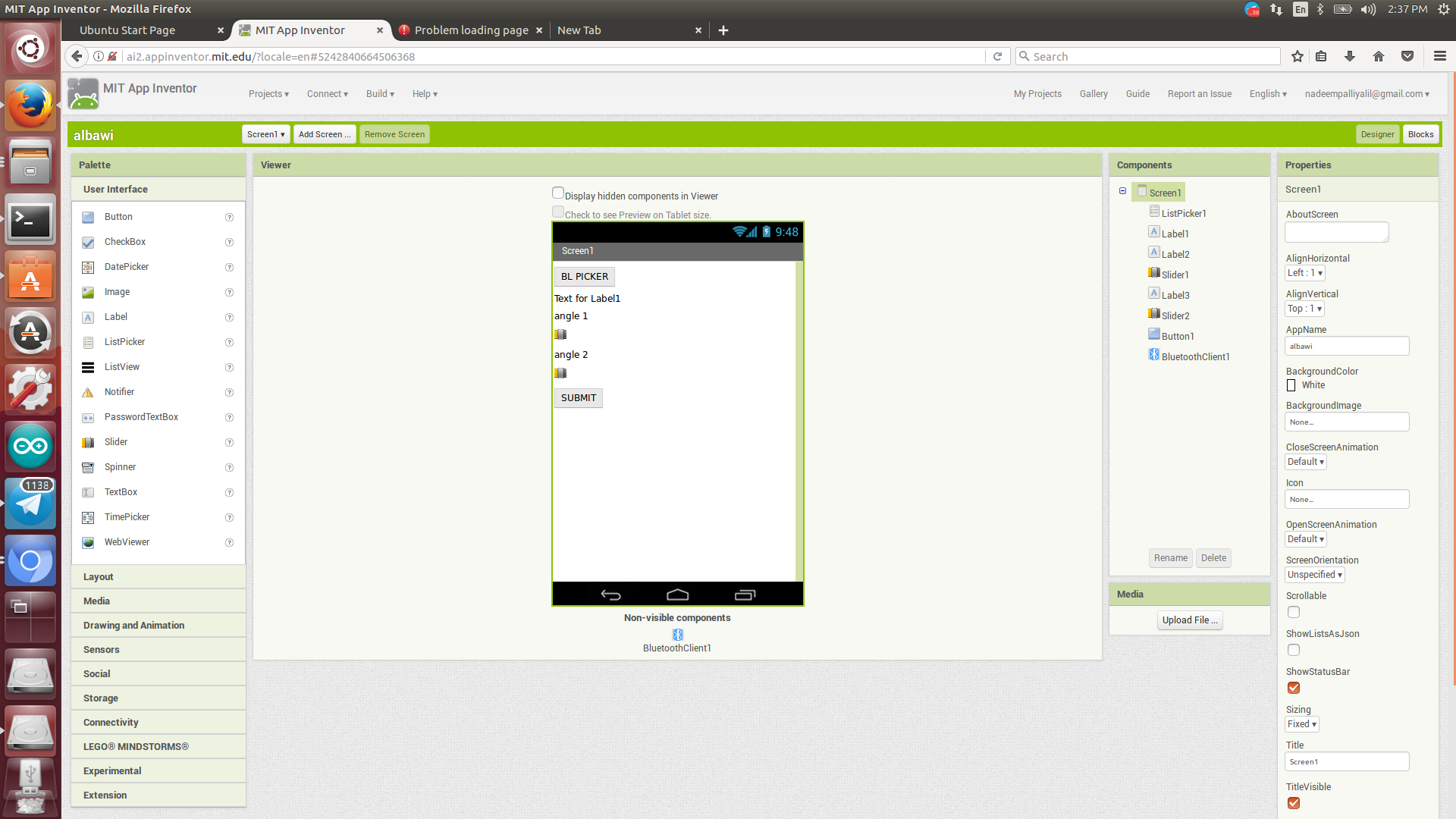

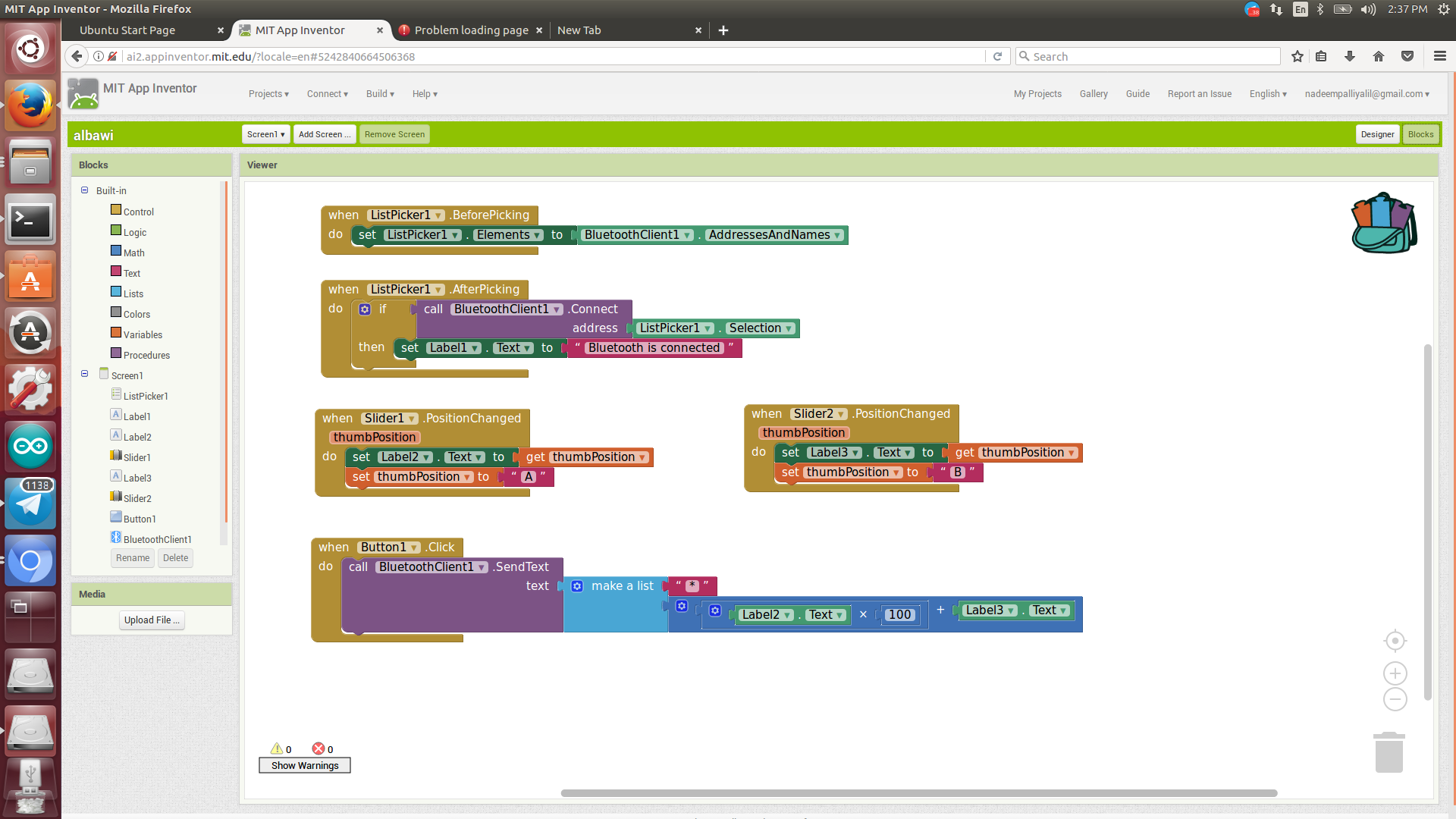

For the input, I have used a bluetooth device. This bluetooth device will be connected using a smartphone and an application to control the PCB to make the device function. The application contains two buttons and two sliders, bluetooth connection button, servo A slider, servo B slider and the Submit button.Output

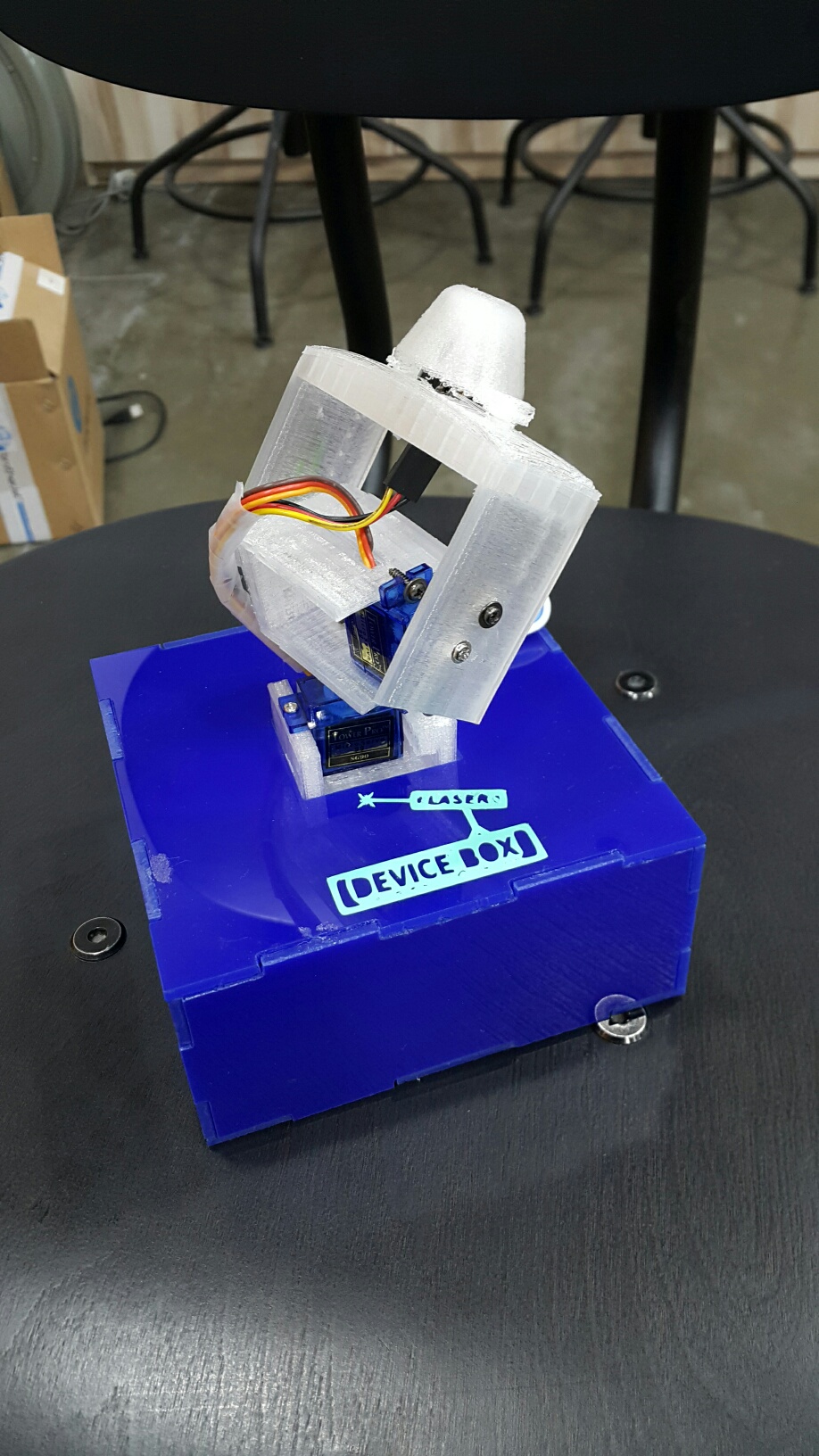

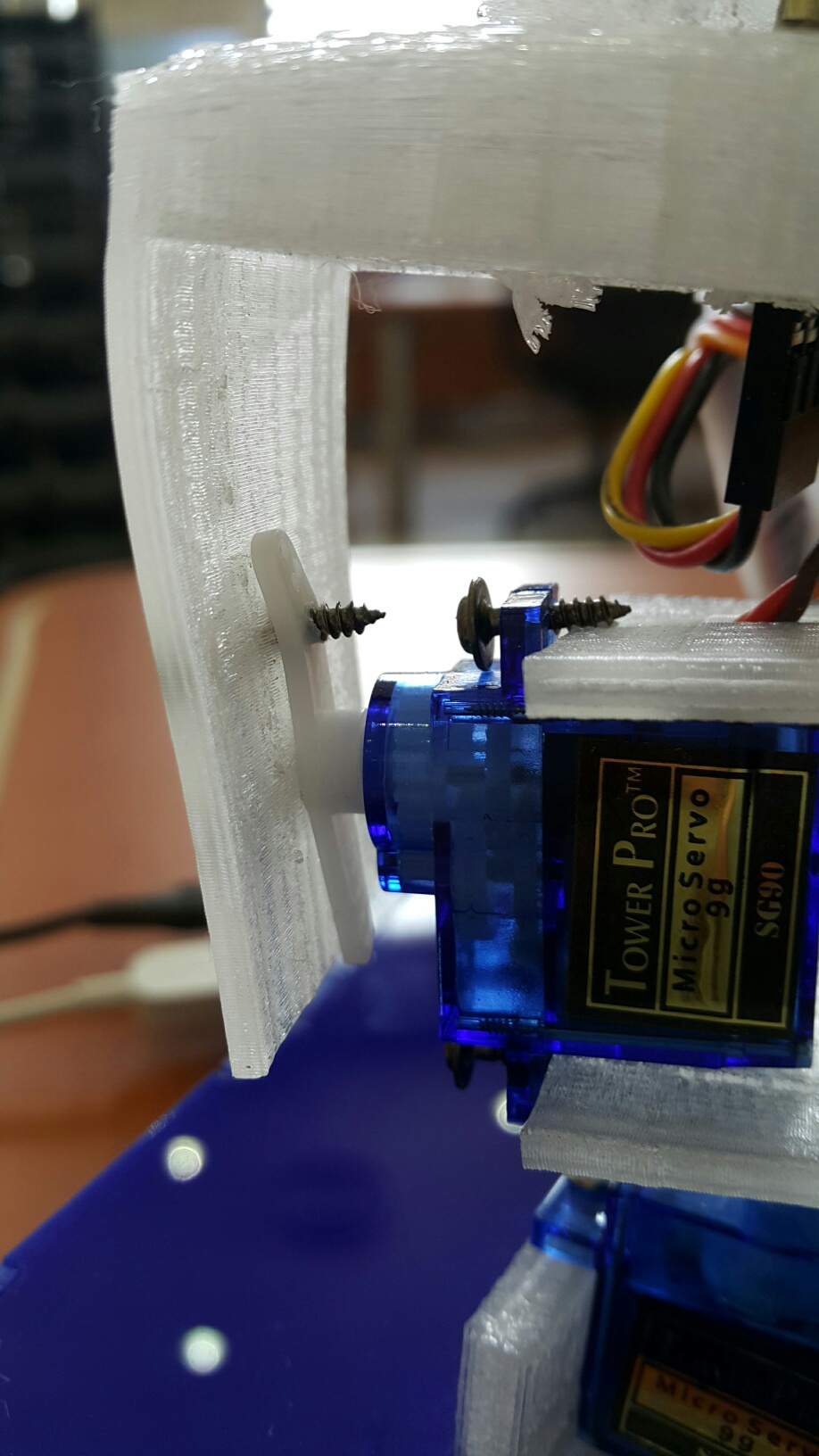

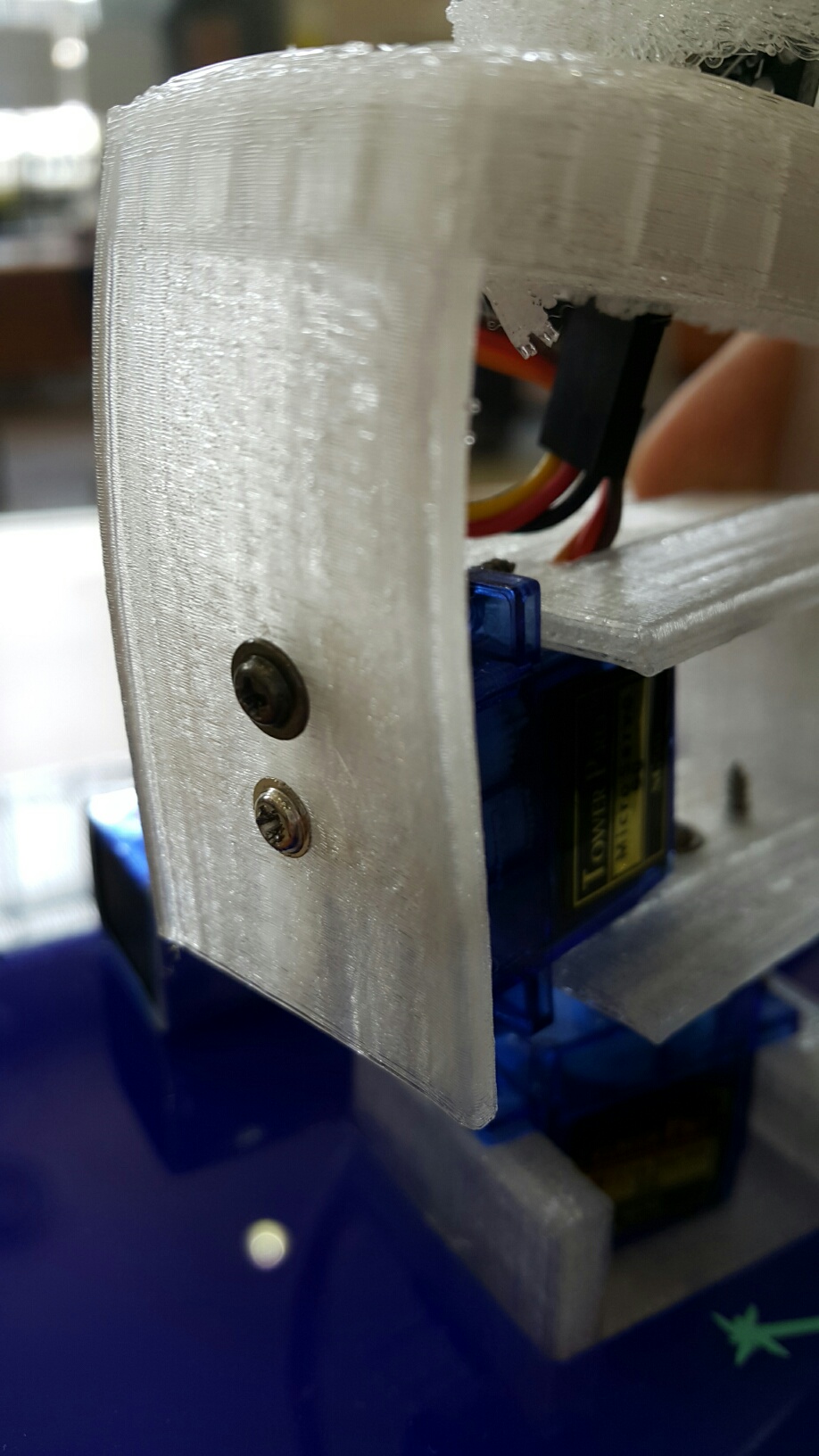

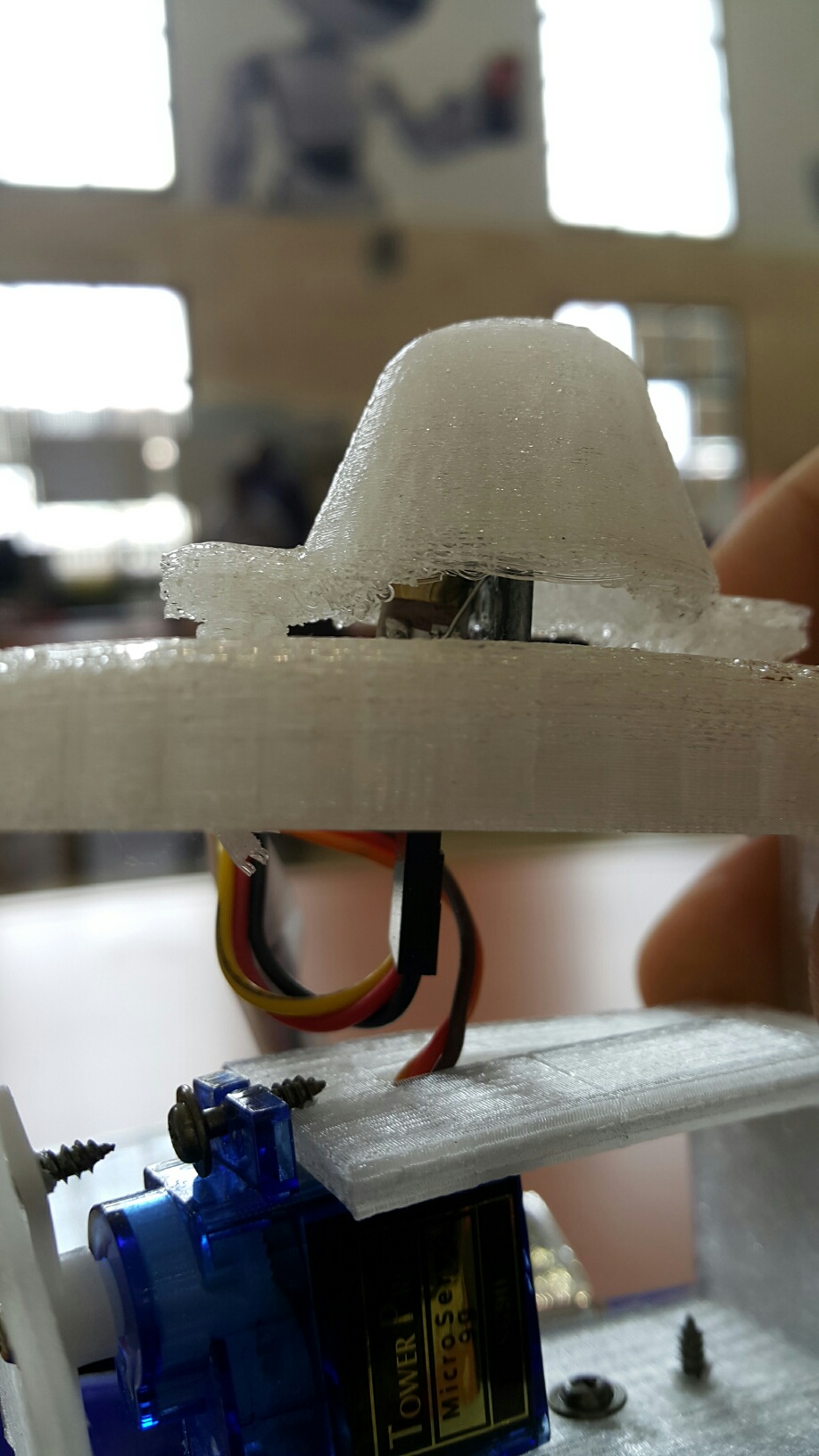

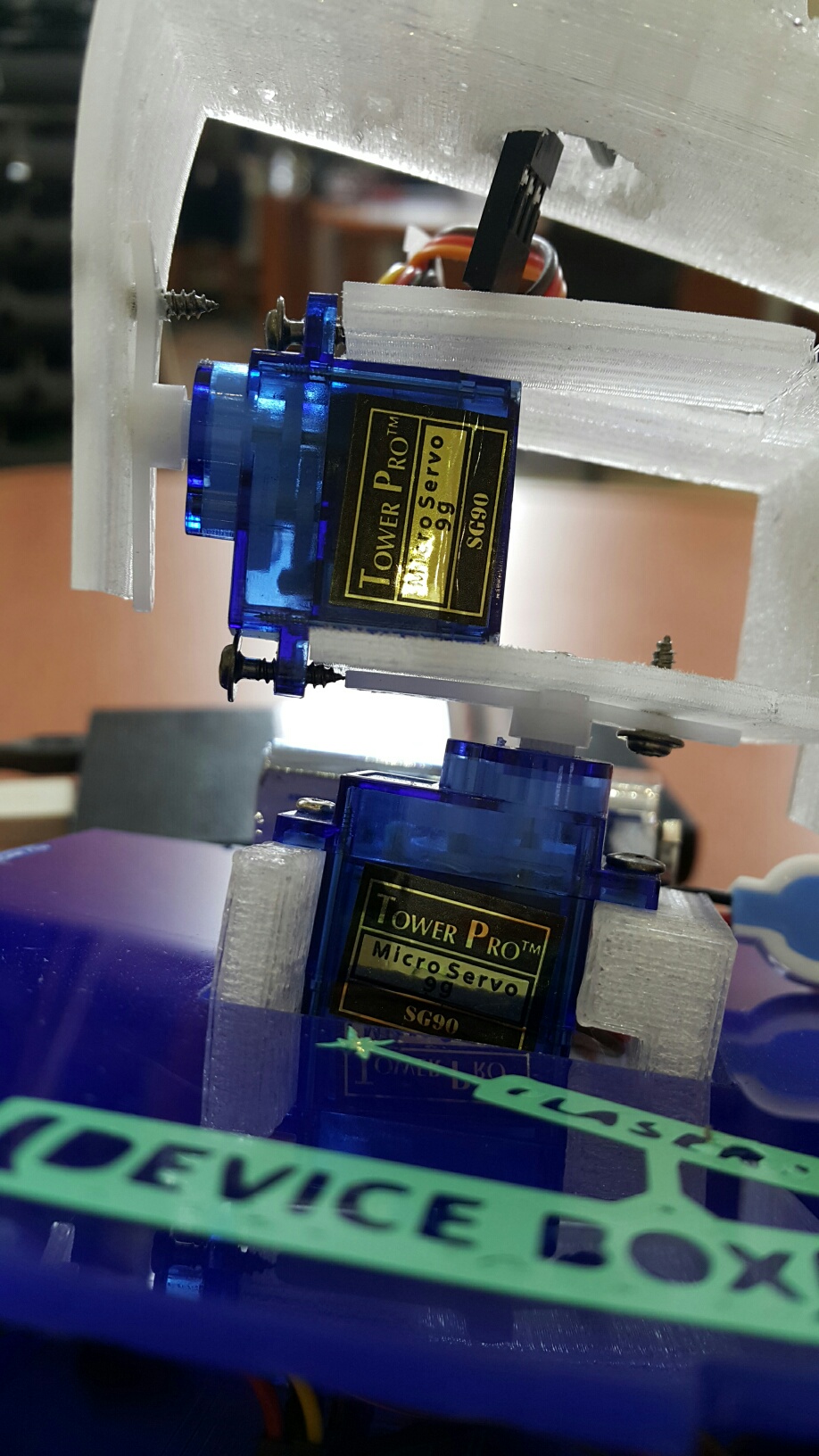

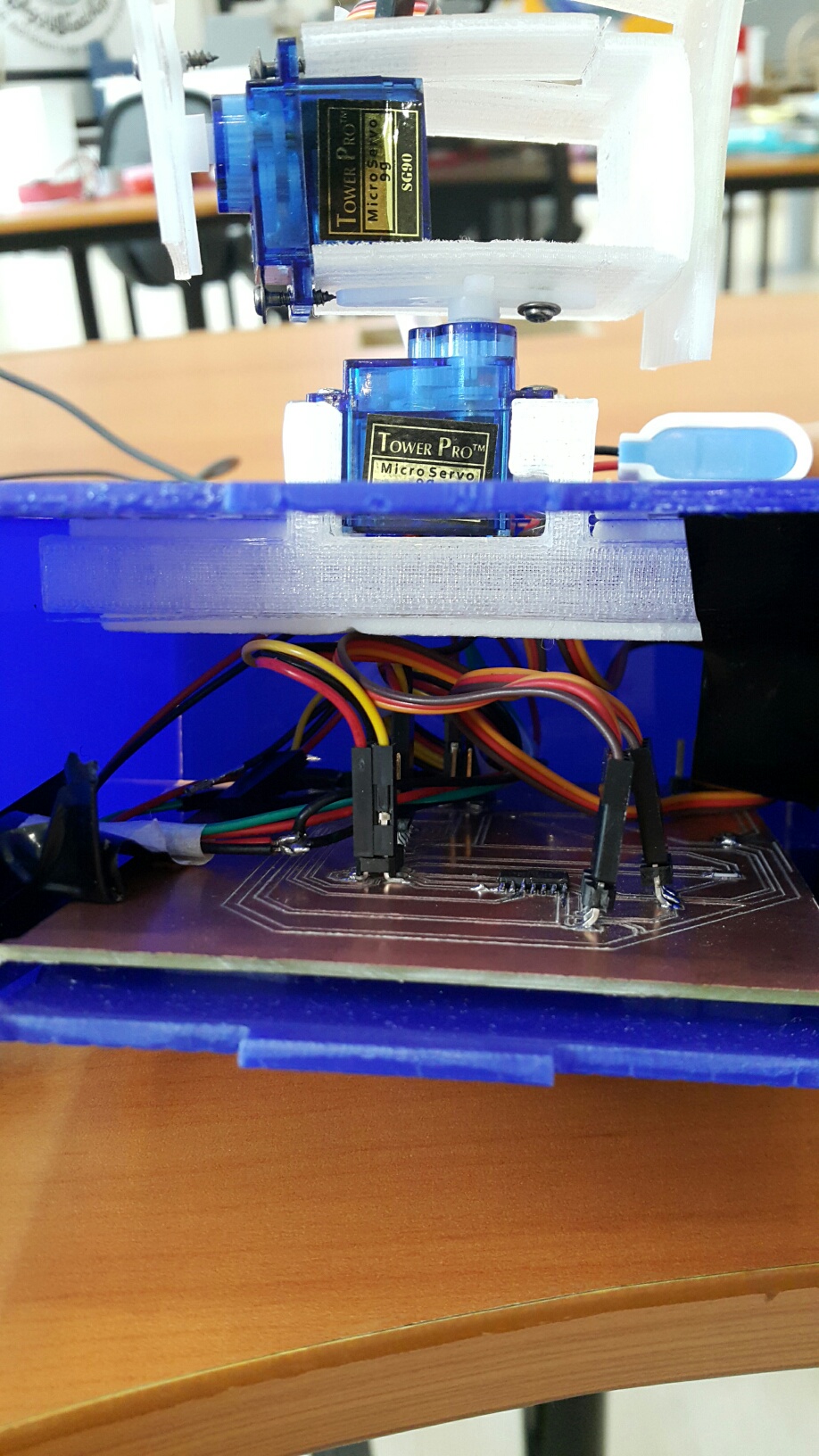

For the output, there are two devices which are the servos and the laser. For the servos, they are exist to make a 180*360 degree movement with is a half moon. To create that, the two servos are connected together with the 3D printed holder. They both move around to create a combination. The first servo will move 360 degrees, and the second servo will move 180 degrees according to the what we adjusted on the application.

How to interface

As we said, The application contains two buttons and two sliders,

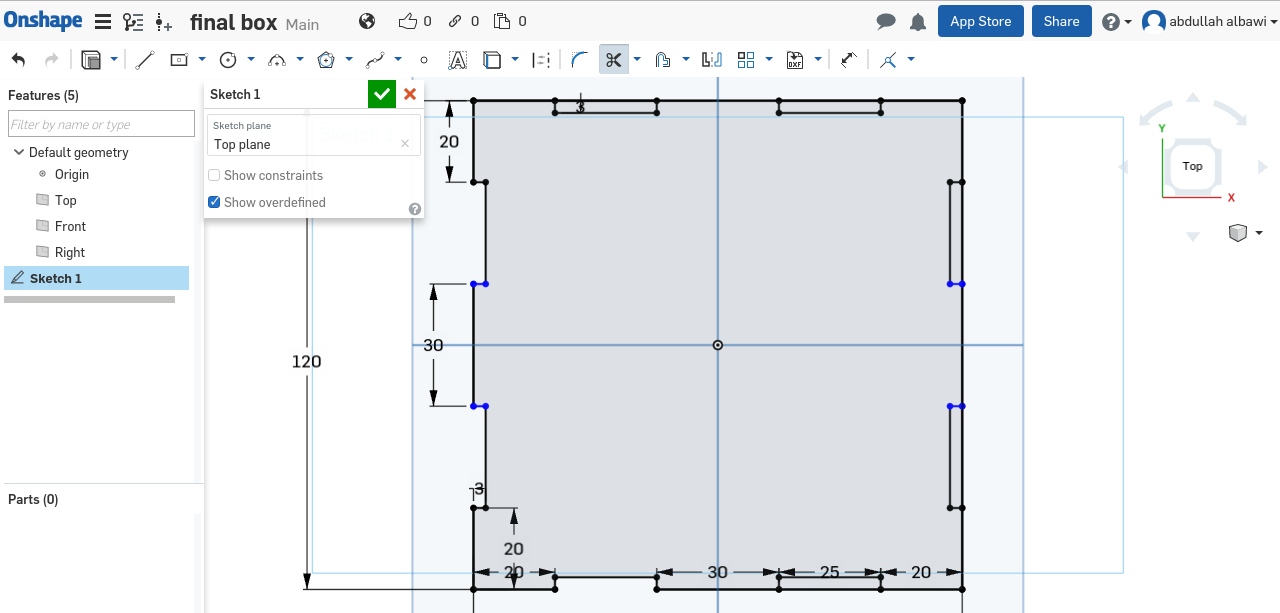

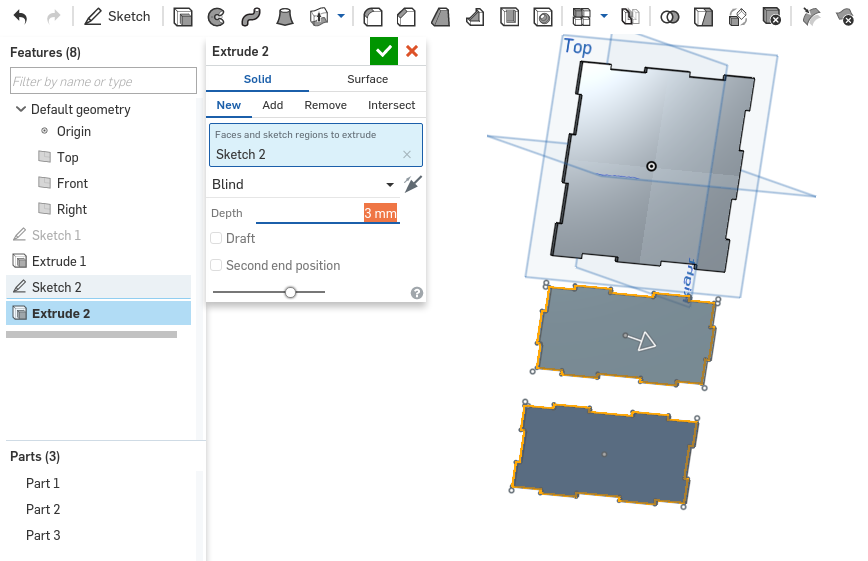

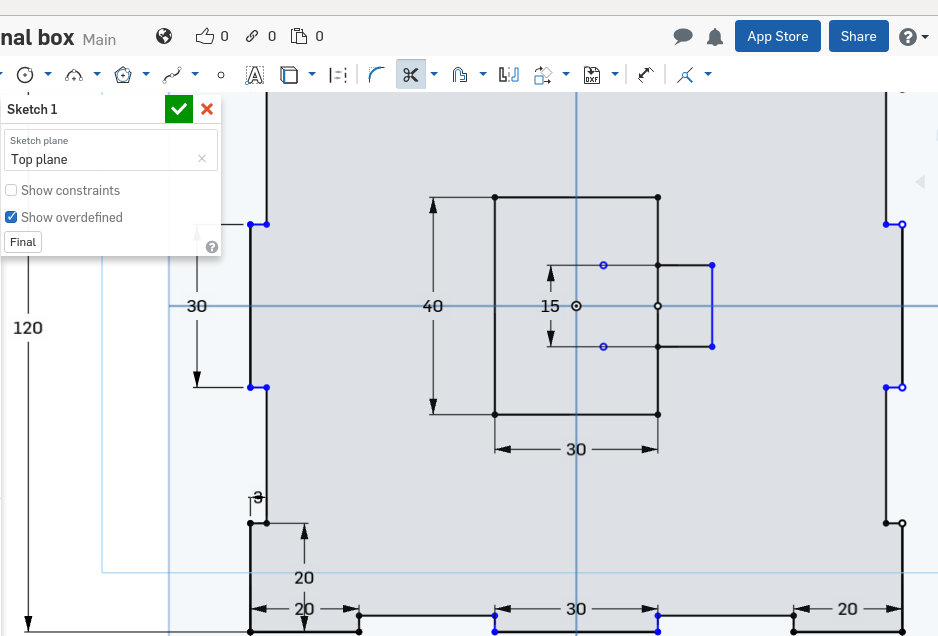

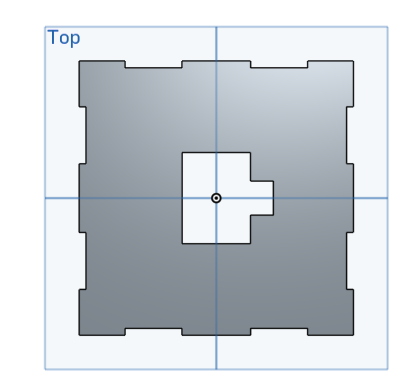

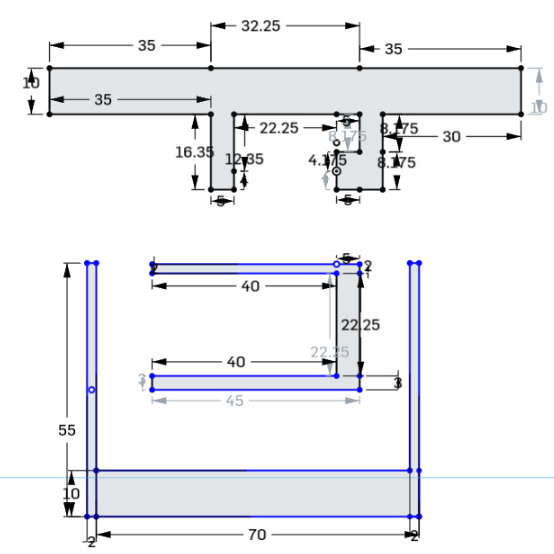

Box Design

The box has been made using the Onshape application. Sketching the box is easy. First, drawing a square using the box tool and then giving it lines on the edges according to the measurements wanted. After that we will but the lines and create the space and teeth shown in the below picture.

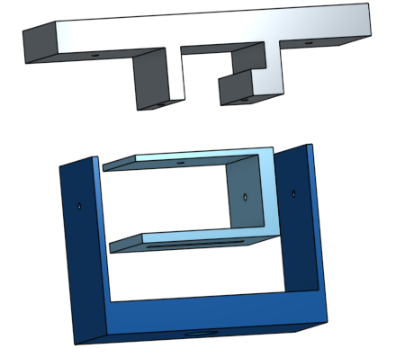

3D Printing

The importance of the 3D printing objects is to connect all the servos together using three parts.

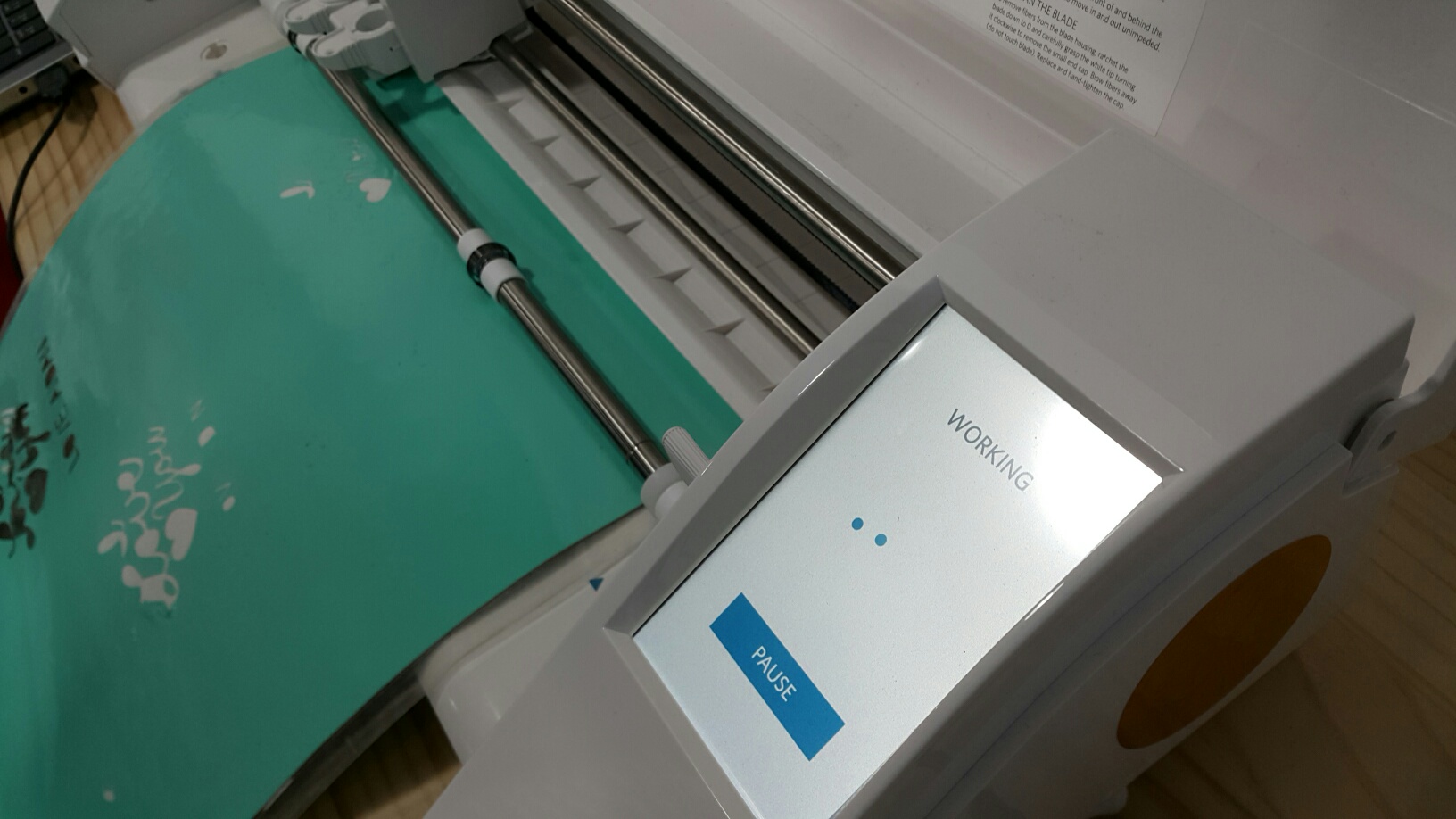

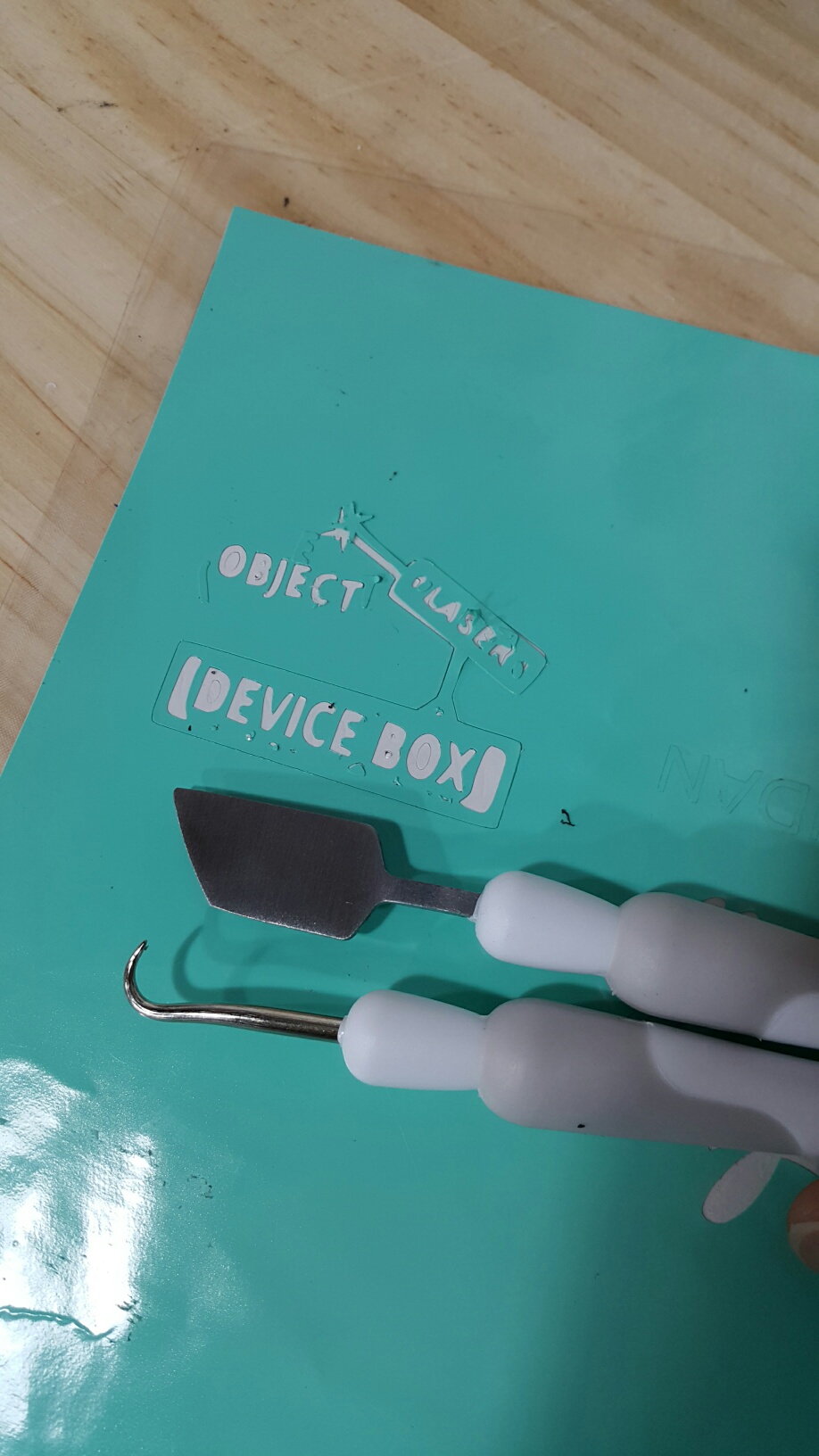

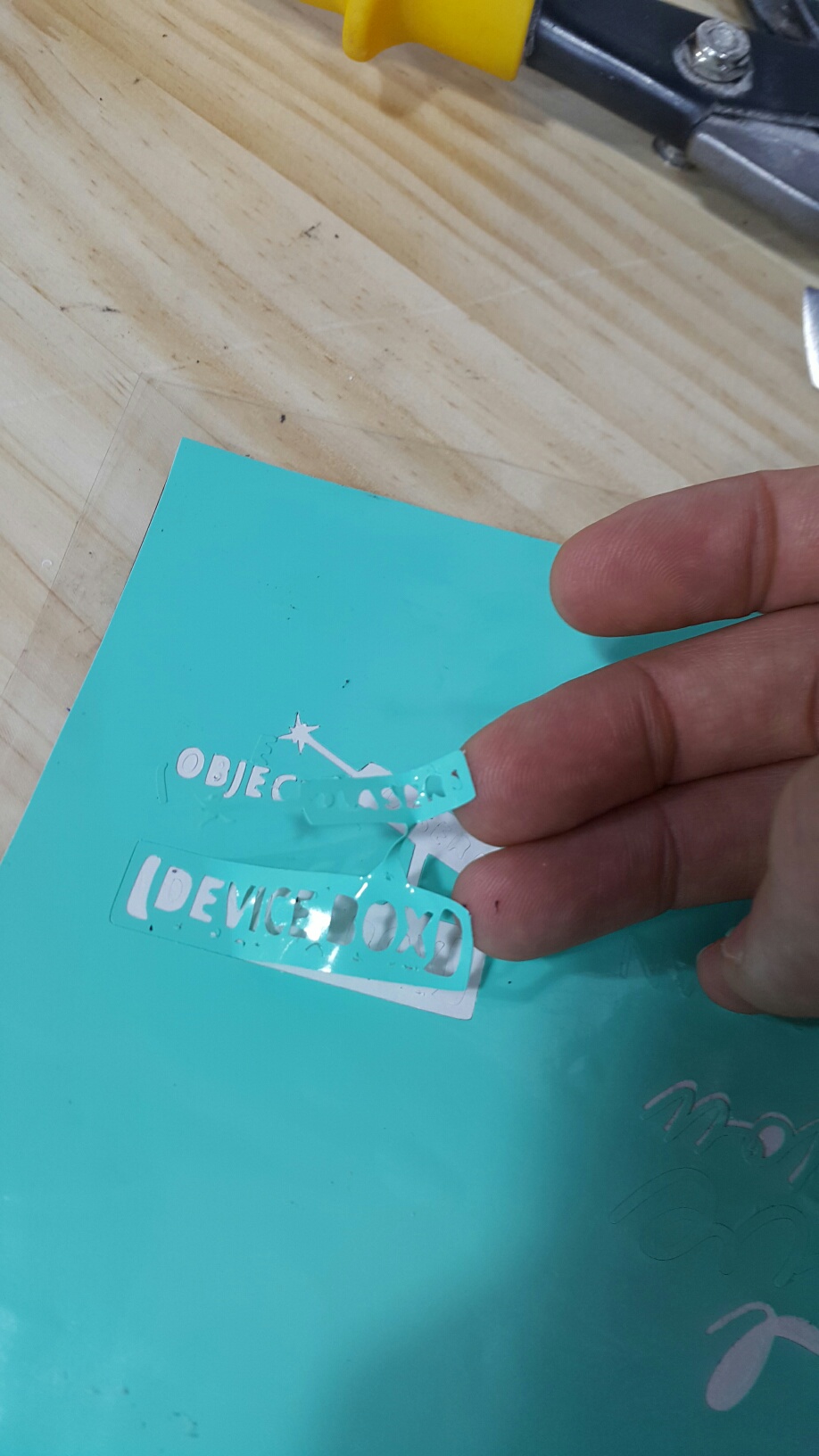

Vinyl Design

My project is new to the market and needs a lot of improvement using many points of views. Me, alone, cannot create a huge improvement for my project. So it is important to cooperate with the others to share information and make a continuous development of the project with trade mark exploitation.