Computer-Controlled Machining

Design

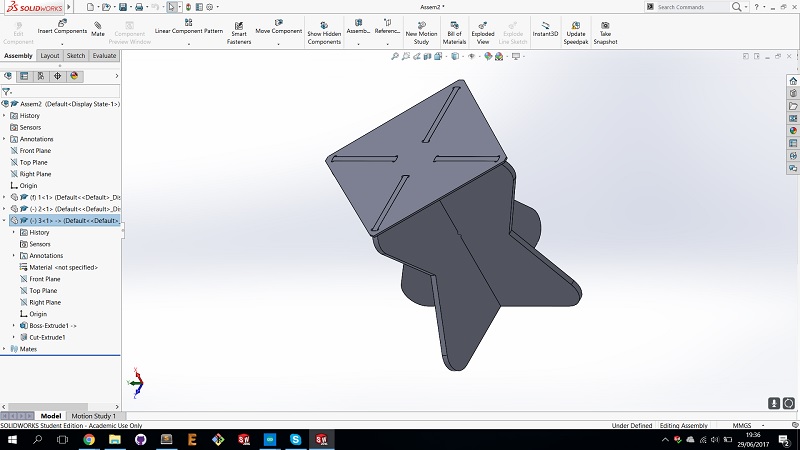

I design a table to make in cnc. I draw the table in solidworks.

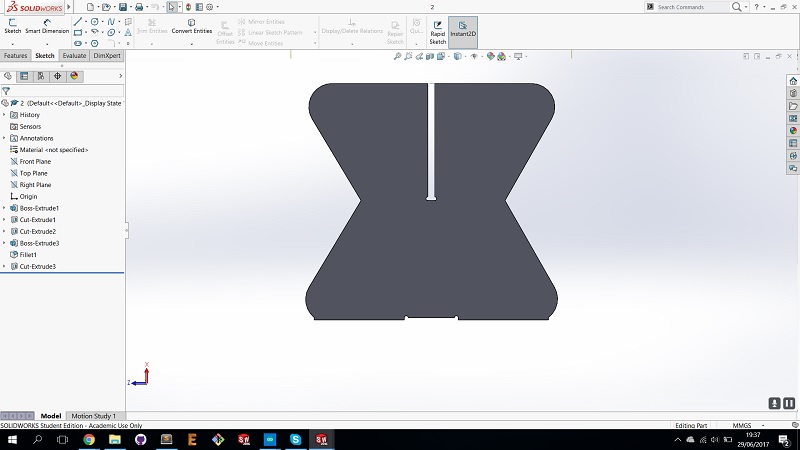

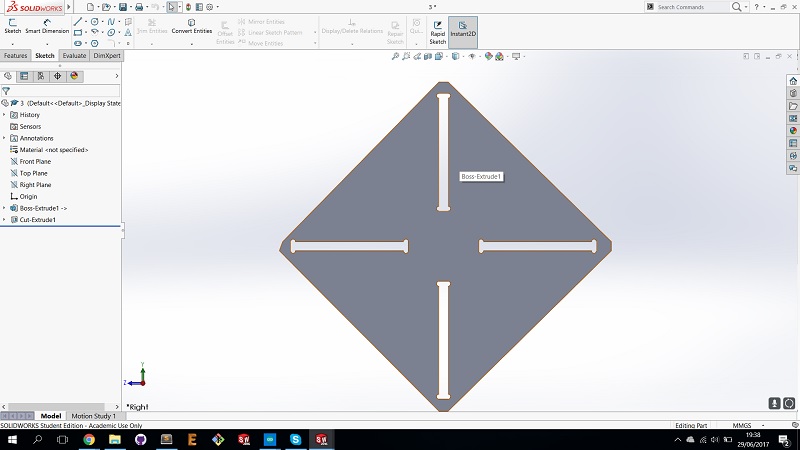

This table have 3 pieces, 2 legs that fit together in the middle and have the top of table.

This table have 3 pieces, 2 legs that fit together in the middle and have the top of table.

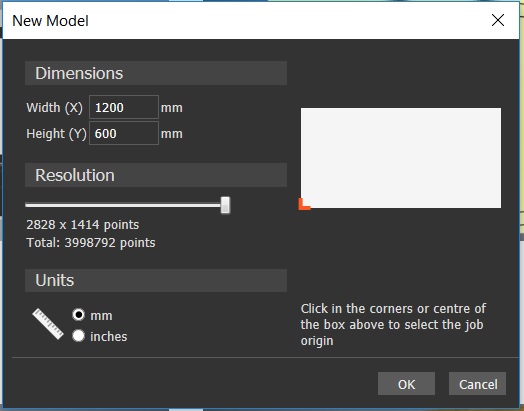

Make CNC File

To make the g-code i export from solidworks one dxf file. To make the cam i use the artcam from autodesk. In artcam i create a new model in this area you can put the size of your material the resolution and can put de zero anywhere you want.

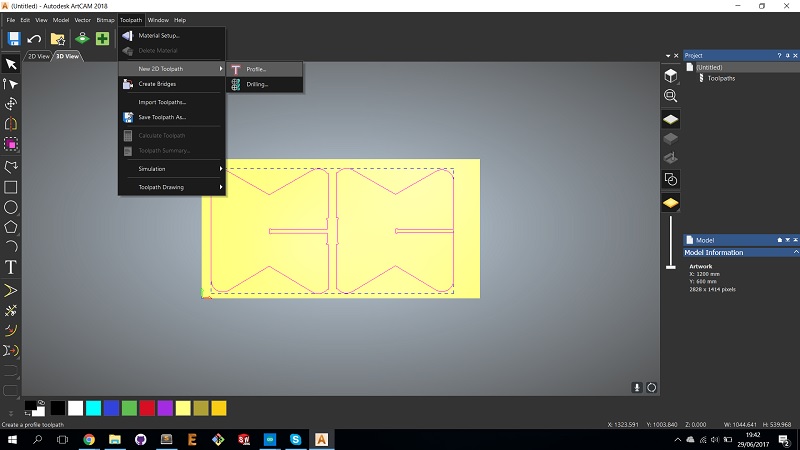

After you import the files you what to put in the material area. You go to the toolpath and create a new 2D toolpath profile.

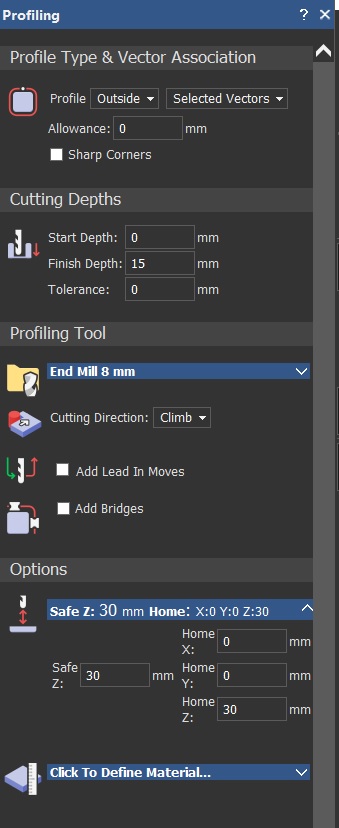

In the profile o have many options, i my case a select te type of cut in my case outside, in cutting depths i put the finish depth 15mm, profiling tool i select the 8mm tool and i chose the stepover 4mm and stepdown 4mm Feed rate 42 mm/sec Pluge Rate 13 mm/sec spindel speed 15000 r.p.m. I use this parameters becase i prefer to cut in more spindel speed becase in wood if use low speed the tool start to burn. You can define the height of material im my case for the legs i use 15mm wood and for the top i use 5mm wood. And the final i click in calculate now.

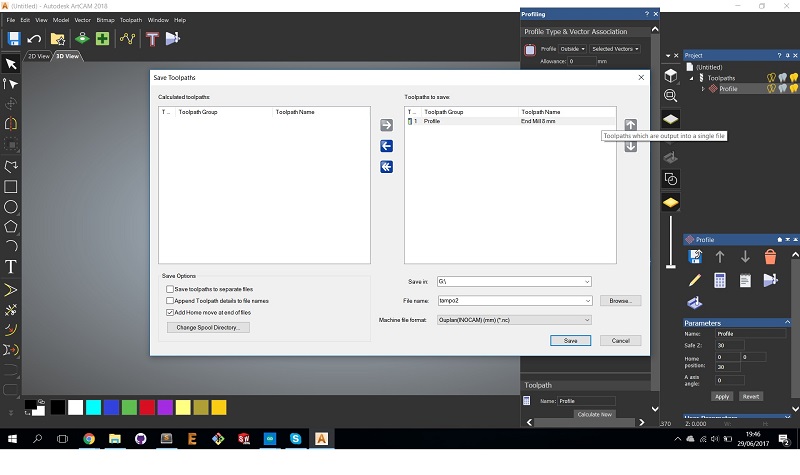

After you put all setting you want you go to the profile and save to machine you want in my case i use a outplan.

Machining

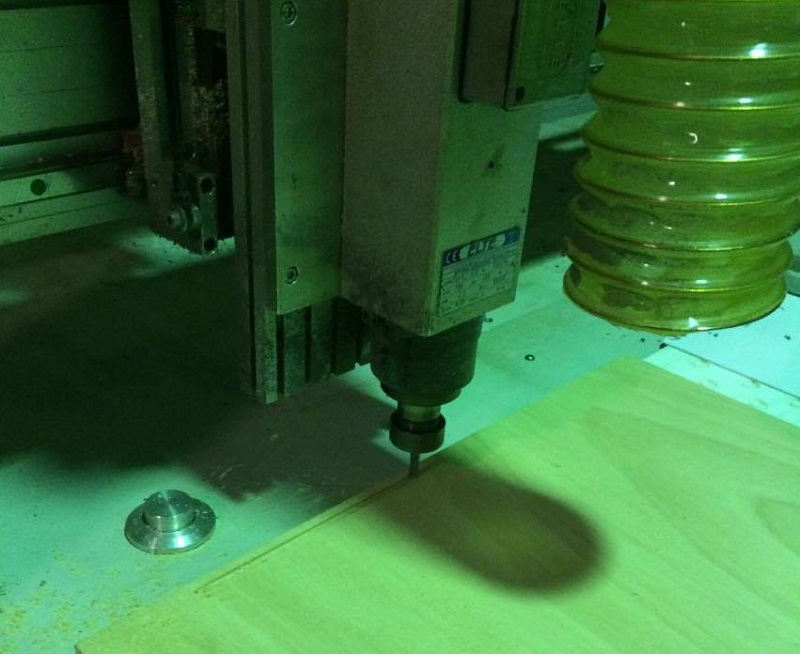

To machining the cnc i use the inoControl. To cut the 15mm and the 5mm wood use this 8mm tool.

I the material in the place to cut and to help to fix to the table i use the vaccum and this gramps.

Before i start the cut the material the cnc go to this button to now the size of the tool.

After is already done i can click start in the inoControl.

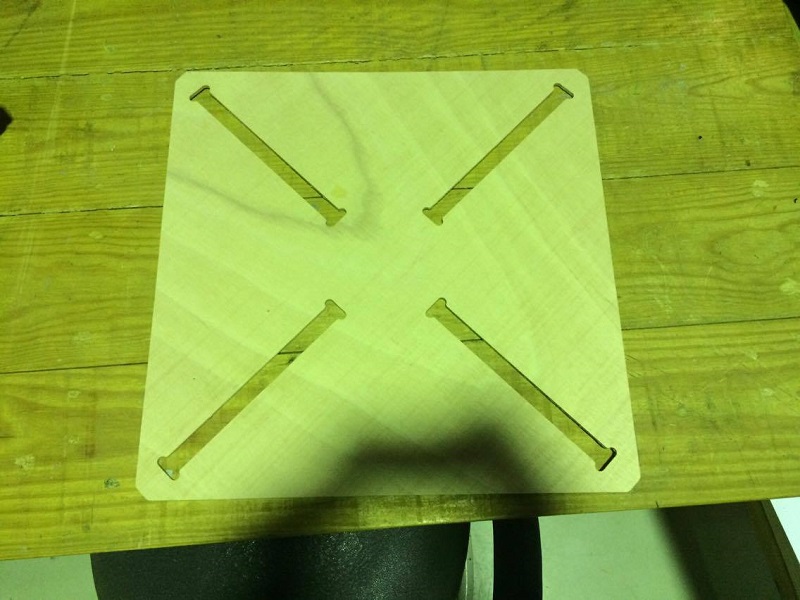

This is the top off the table.

And is this the 2 legs of the table.

And the final result.