Composites

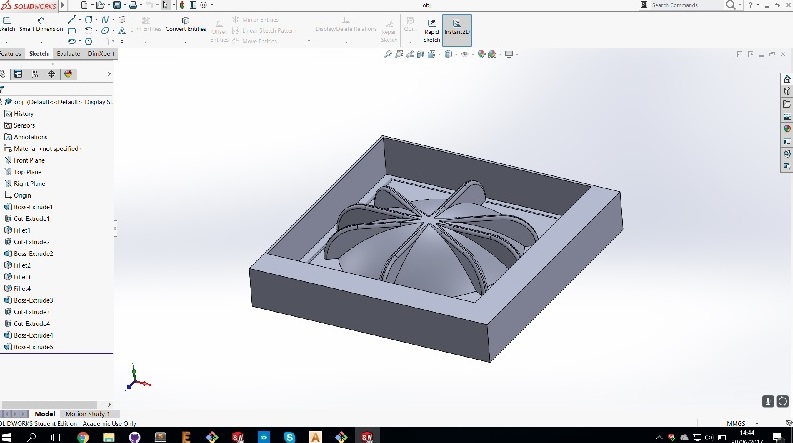

Design

First i design a part in solidworks to make the composite, my part have round sides to test the composite.

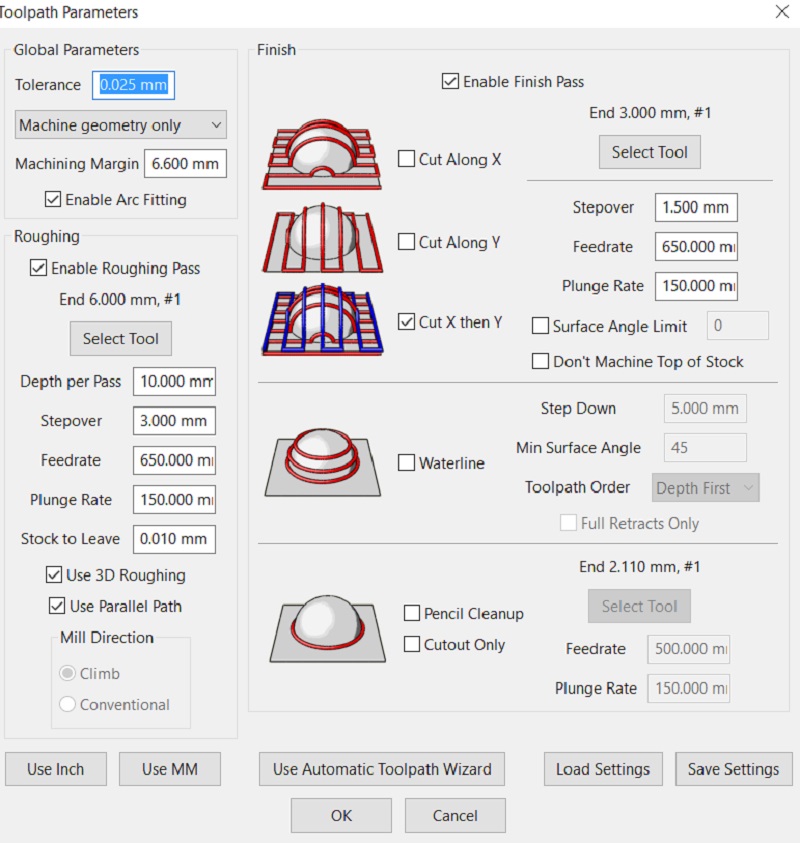

Machining

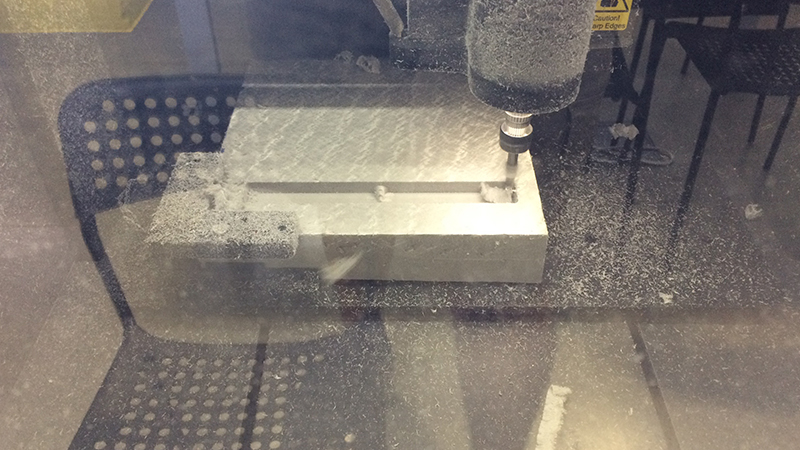

After i design e go the carvey cnc to machining the roofmate foam 40mm. I machining in 2 parts on with a tool 6 mm and to finish i use the tool 3 mm. I use the MeshCam to make the cam file to the carvey. The total time to machinnig the ocject round 2 hours.

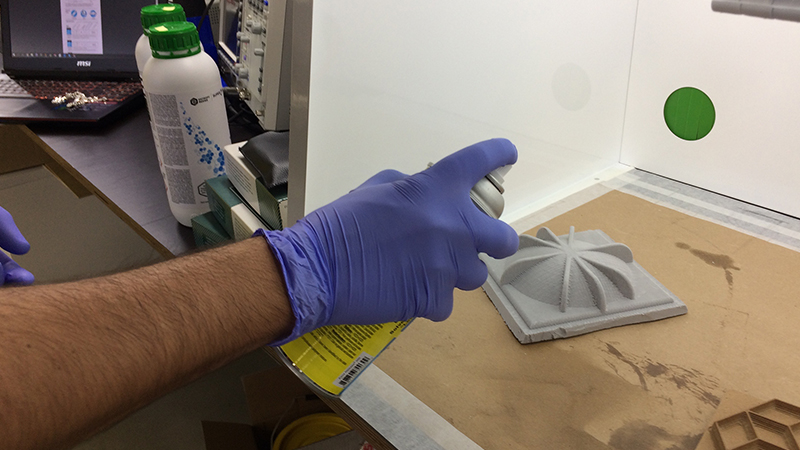

In this image is a finish parte with a 3mm tool.

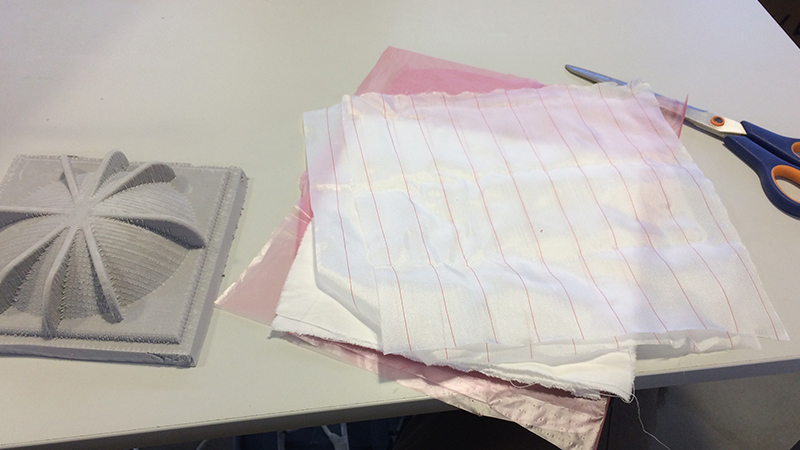

Composite

After i make the object i prepare the materials.

I use 2 release film, 2 peeal ply and 3 cotton cloth.

I prepare the object with a ease release to make more easy to release mold.

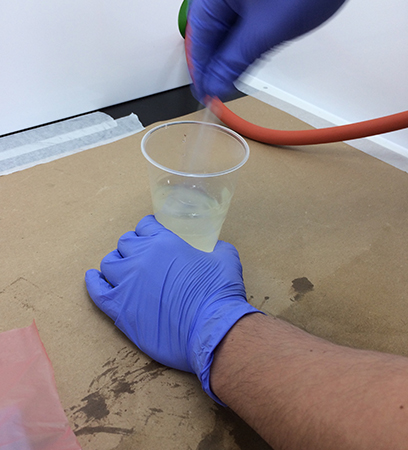

I use this two to make resin to apply in my composite. The dose is A: 47g to B:100g. The guide use to make the foarm is in this link

I misture the misture until well blended.

The order to apply the composite in the object is 1 release film / 1 peeal ply / 3 cotton cloth / 1 peeal ply / 1 release film.

And apply the resin in each layer od cotton cloth.

After the composite is in material use the vacuum bag. To make the vaccum i use the compressor.

And is this a final result of my composite.