Molding and Casting

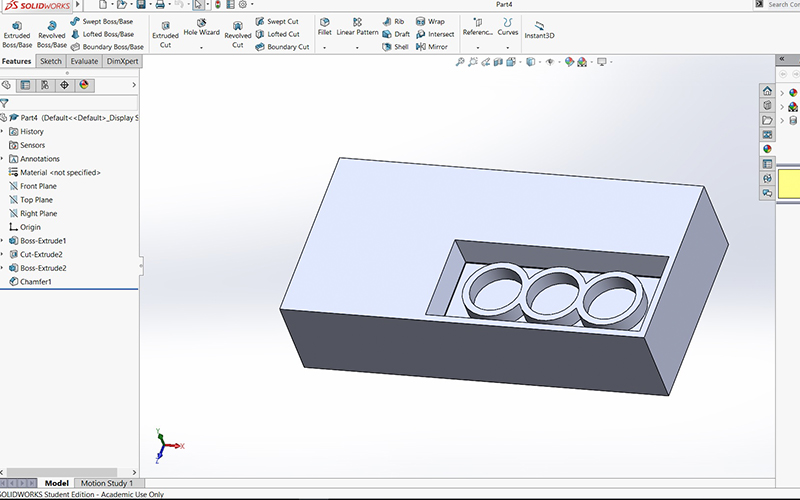

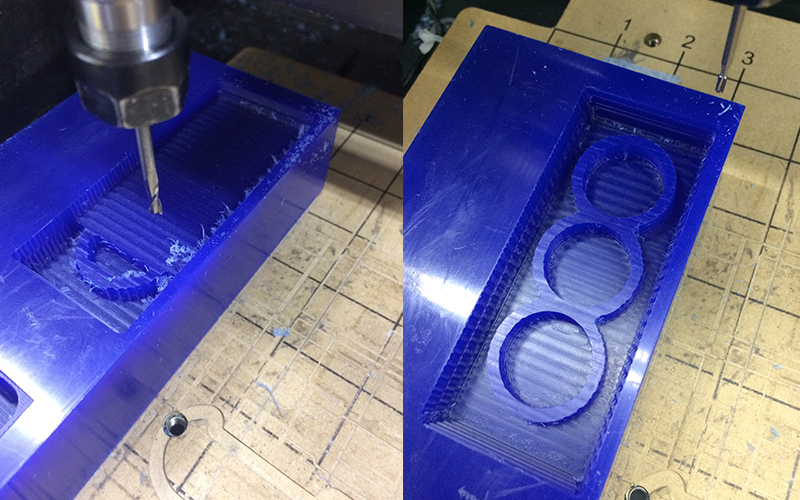

For this week i make a mold of fidget spinner. I draw the mold to machine in cnc. In the mold i draw the walls sloping walls to be easier to take out the silicone mold. First i draw the mold in the solidworks.

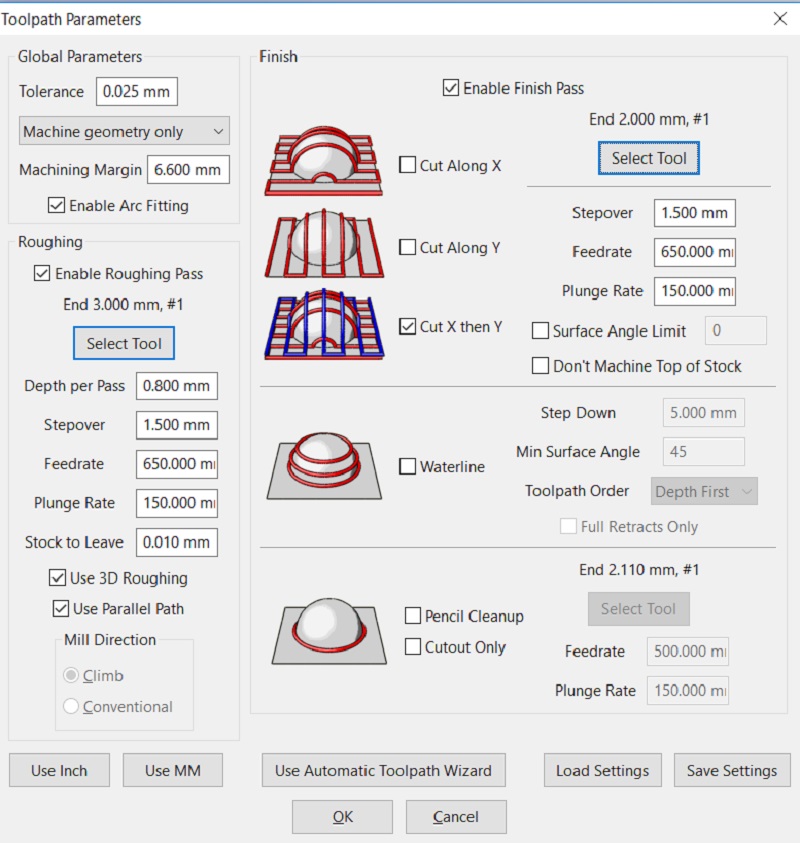

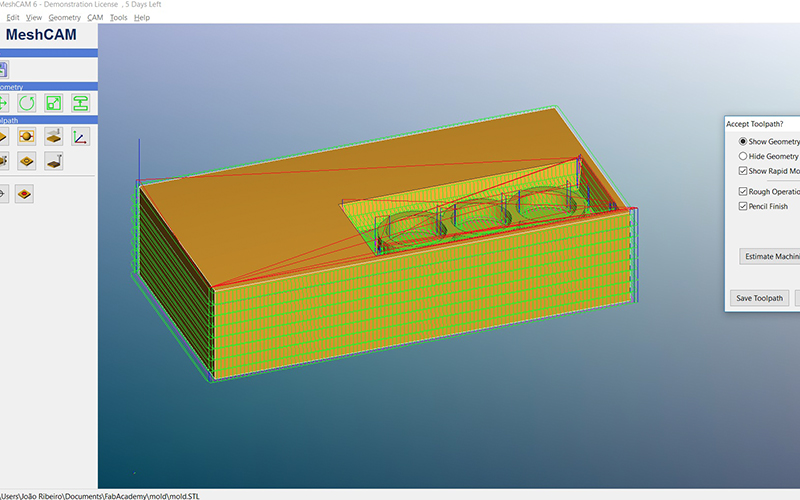

To make the g-code i use the MESHCAM. To machine the mold i make in two steps first roughing and the finish step. In roughing i use 3mm tool and to make the finish step i use 2mm tool. And this is the values i use.

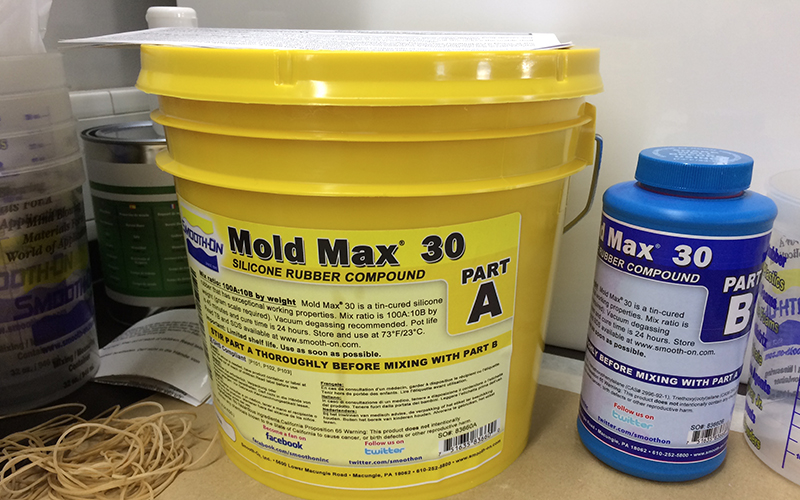

I use the Mold Max 30 silicone to make the mold. To make the silicone use 100A:10B. To know the silicone i needed to used i fill the mold with water. The Pot life of this silicone is 45 minutes and the cure time is 24hours.

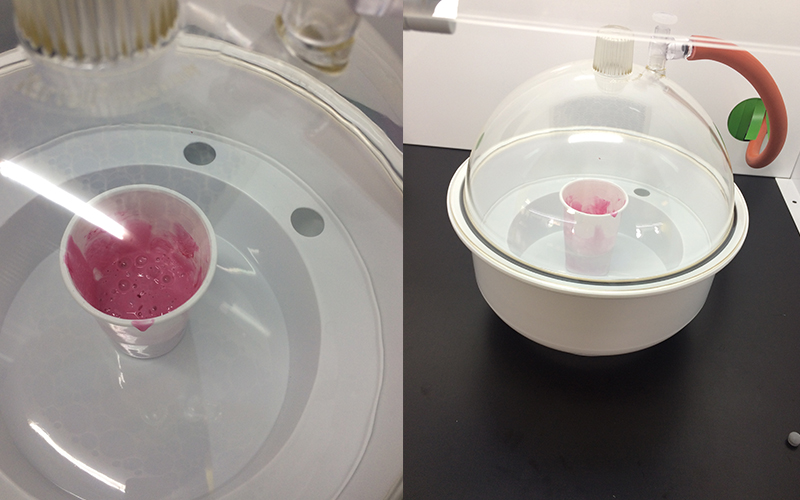

After mixing the A/B i use the vaccum chamber to remove the air from the silicone.

To put the silicone in the master i poured evenly all over the same place so that air bubbles do not build up.

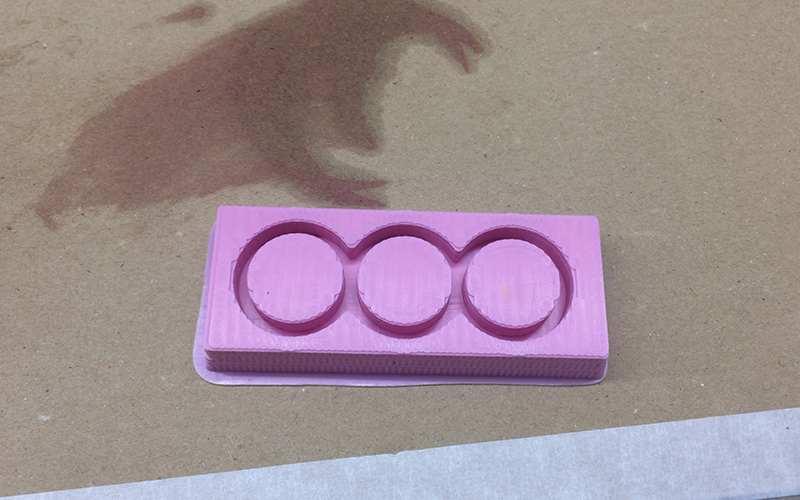

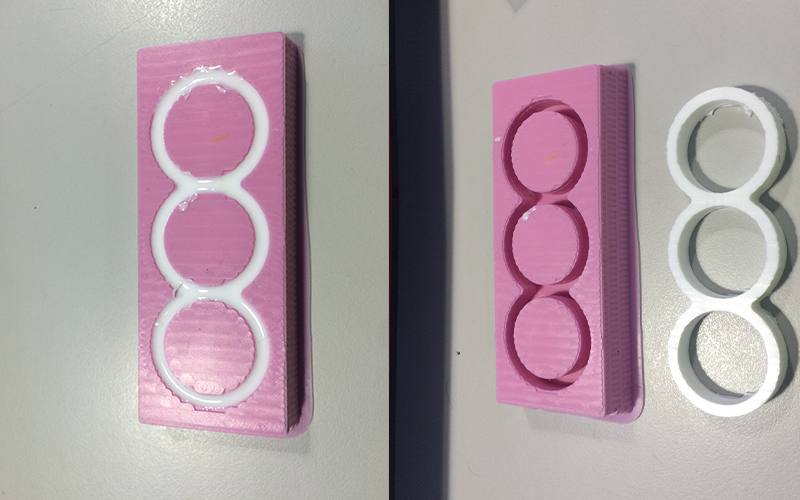

In the next day i removed the silicone from the master and this is the final result mold.

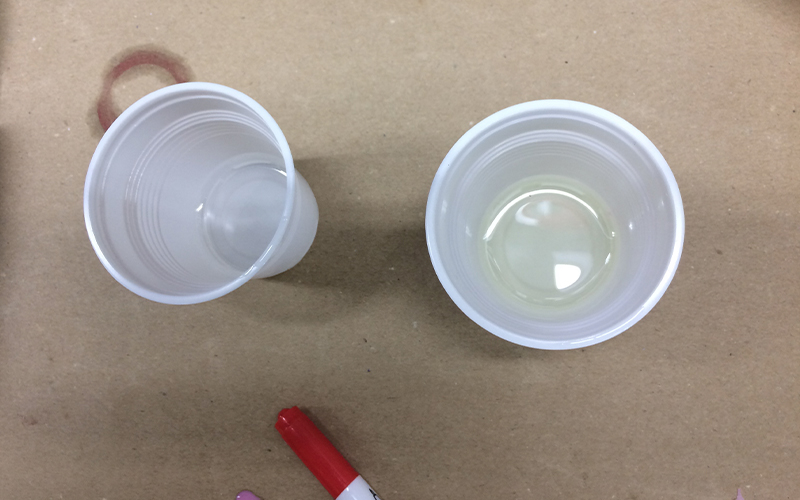

To make the piece i use smooth-cast 300. The mix ratio is 1A:1B by volume or 100A:90B by weight.

The pot life of this material is 3min and the cure time 10min.

This is the final Result of my fidget spinner.