Process

I make this gant to build my machine.

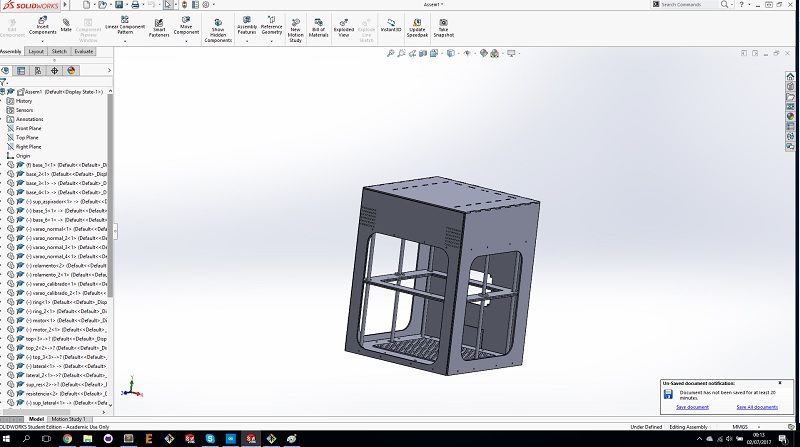

To make this machine first i design the machine all parts to build this machine and for this task i use the soldworks softare in this image you can check one assembled with all parts.

With this assembled i can know the quantaty of material i need.

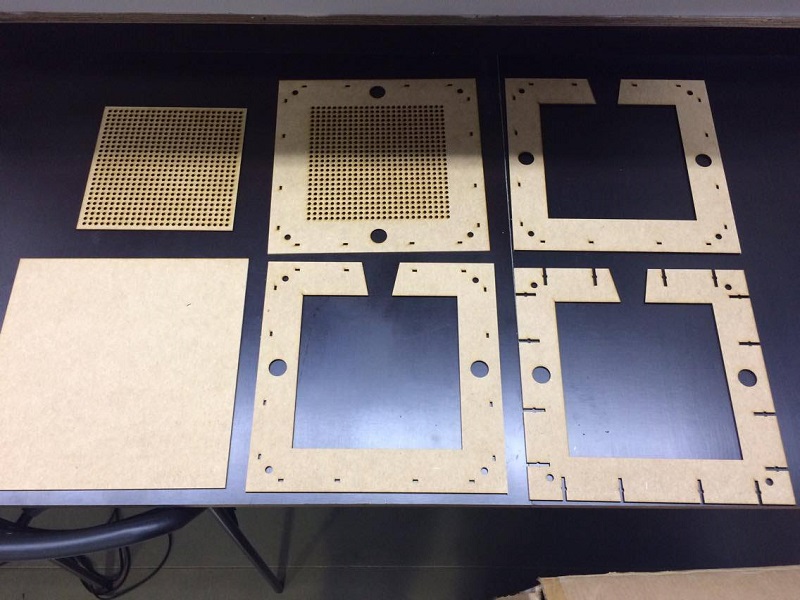

After e design the machine i cut the parts to make the vacuum table to cut this parts i use the laser cutter, and also i need to print the support to put the aspiratos.

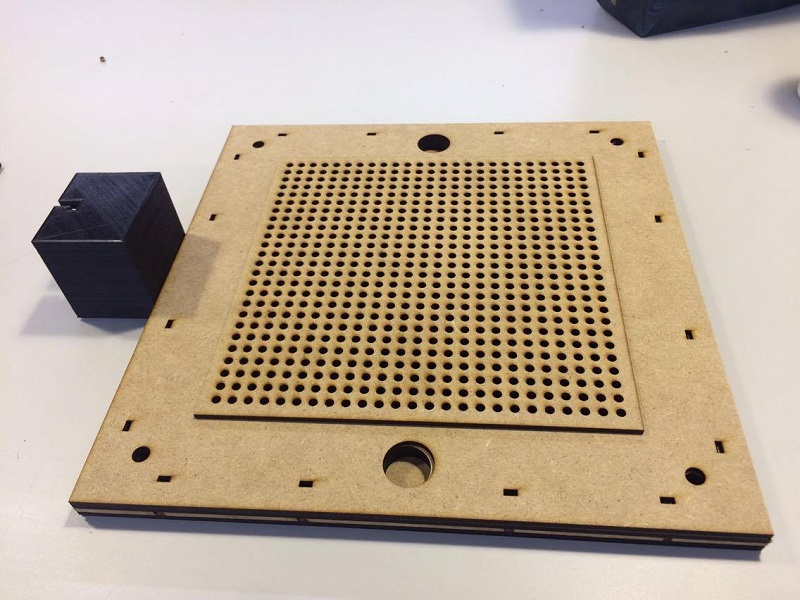

After e design the machine i cut the parts to make the vacuum table to cut this parts i use the laser cutter, and also i need to print the support to put the aspiratos.

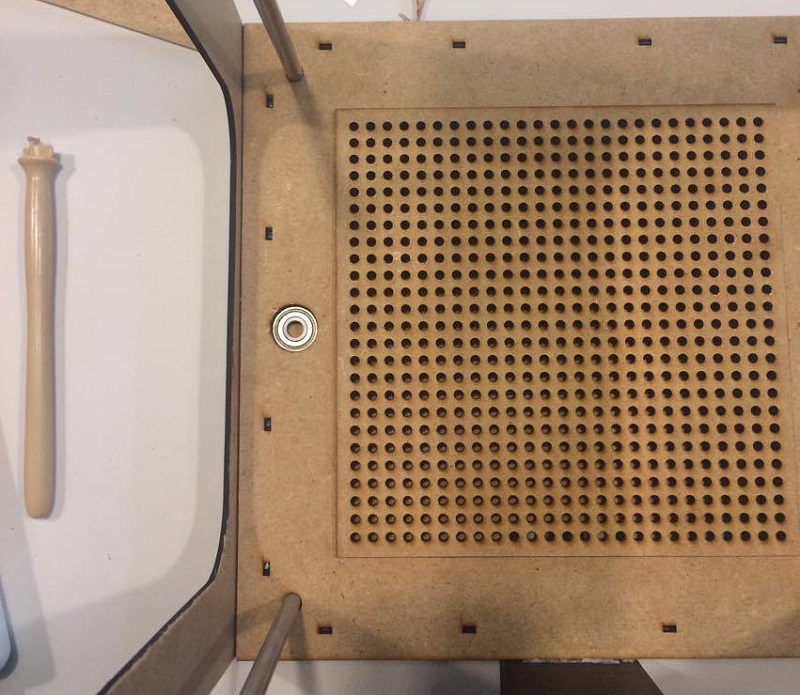

This is the parts which form the vacuum table after ir cutter.

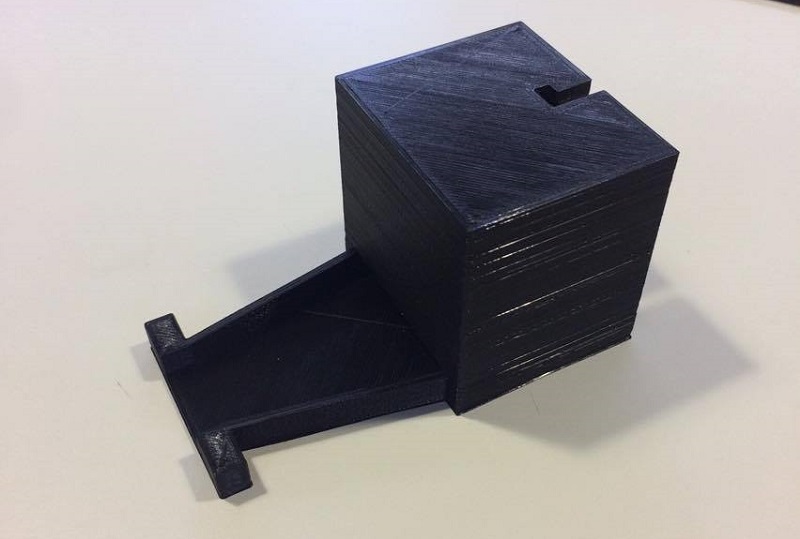

And this is the part i print in 3d to put the aspirator.

And this is the part i print in 3d to put the aspirator.

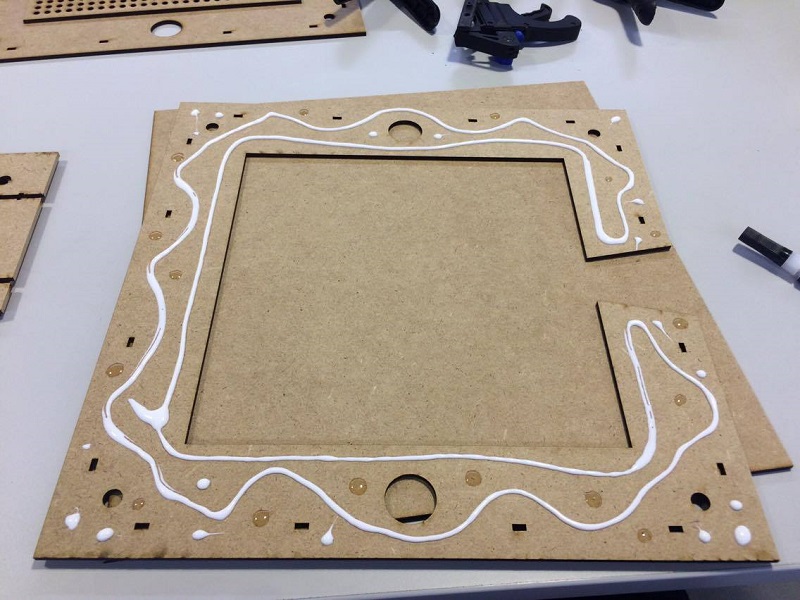

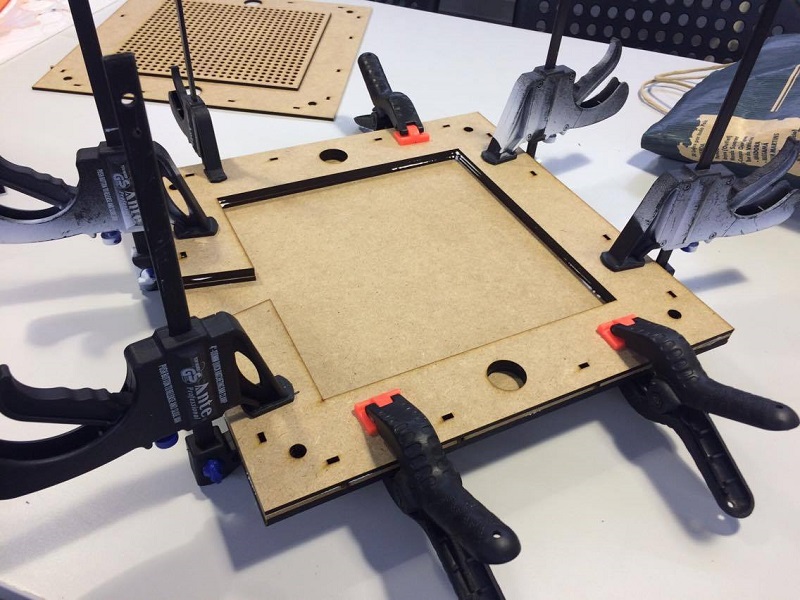

Ãfter i have the all parts of the table i glue the part to form the table.

Ãfter i have the all parts of the table i glue the part to form the table.

After i have the vacuum table all assembled with the support for aspirator i test to heat the material with a ceramic lamp with 75W but the results are faild the material i use for this test is PETG with 1mm but the material dont heat uniformly.

After i have the vacuum table all assembled with the support for aspirator i test to heat the material with a ceramic lamp with 75W but the results are faild the material i use for this test is PETG with 1mm but the material dont heat uniformly.

I go to buy one resistor grill with 18000W to make the test and the material heat uniformly and is ok to test in vacuum tabel.

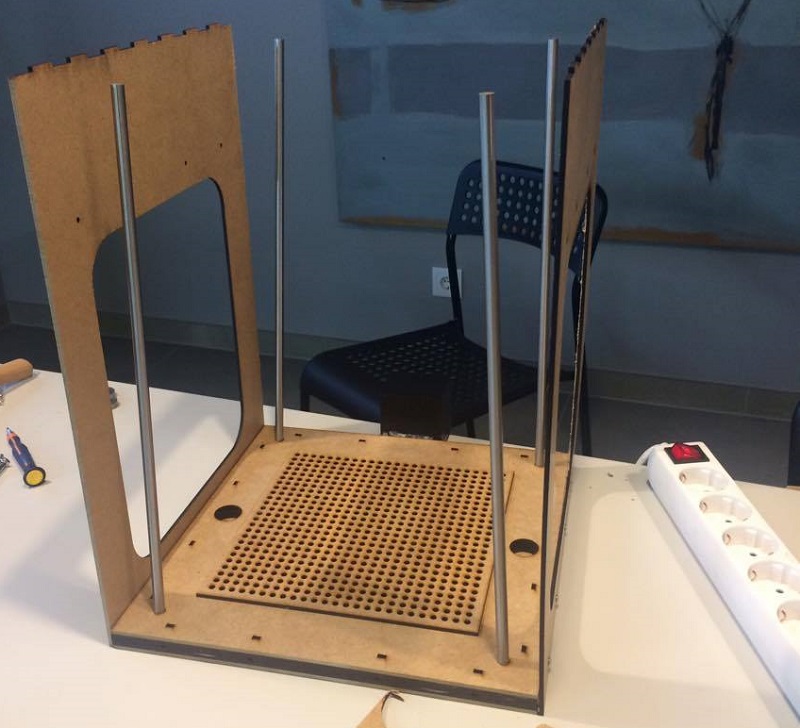

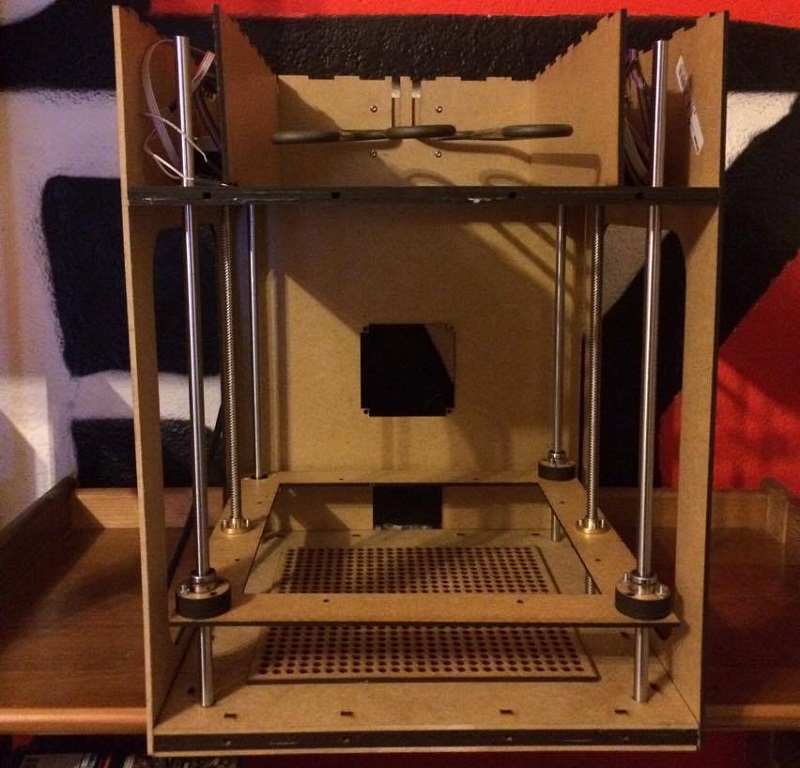

With the table vacuum tested and the resistor test is time to cut the remaining parts to build the machine.

In this video you can check i join the parts to form the machine and thes the material and resistor and test de movement manualy.

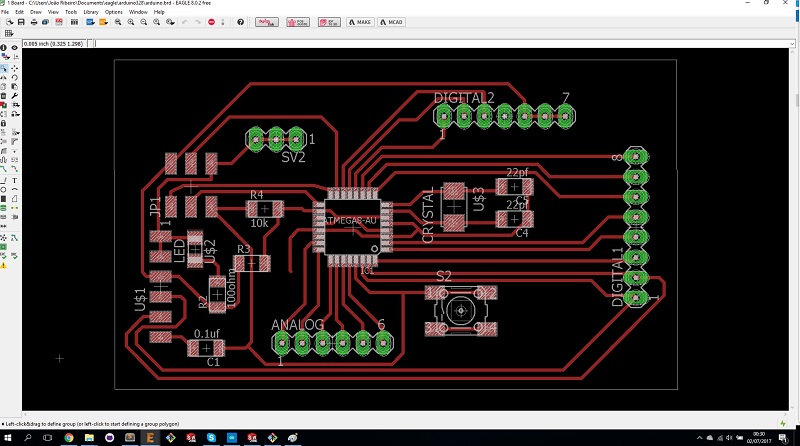

After i make the test and build the machine is time to design the electronic i need the electronic i need is a microcontroller and two breakout for the driver.

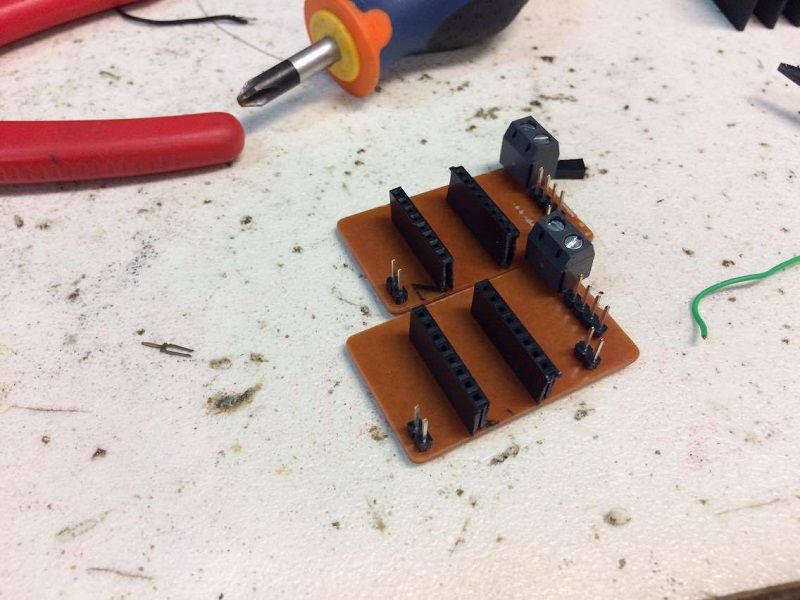

I design this board with Atmega328 and i have digital and analog pins and vcc and gnd pins.

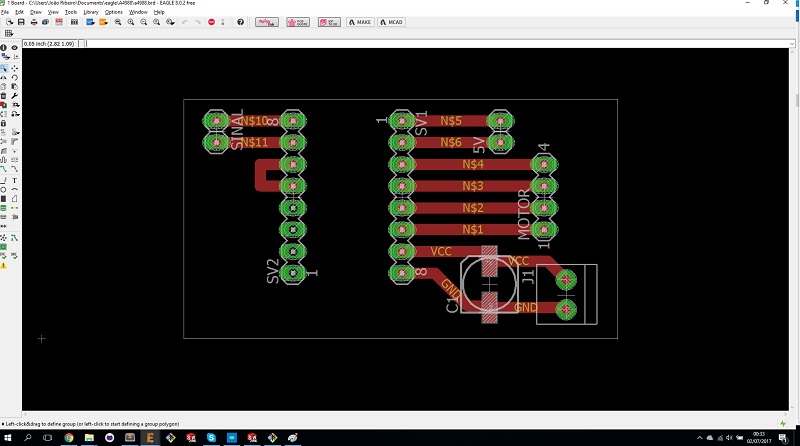

And I design this breackout for driver i use the DVR 8800. This brrackout have terminal to connect the 12V power supply and the pins to connect the arduino the steppe pin the direction pin anda the pins for the motor steppers.

And I design this breackout for driver i use the DVR 8800. This brrackout have terminal to connect the 12V power supply and the pins to connect the arduino the steppe pin the direction pin anda the pins for the motor steppers.

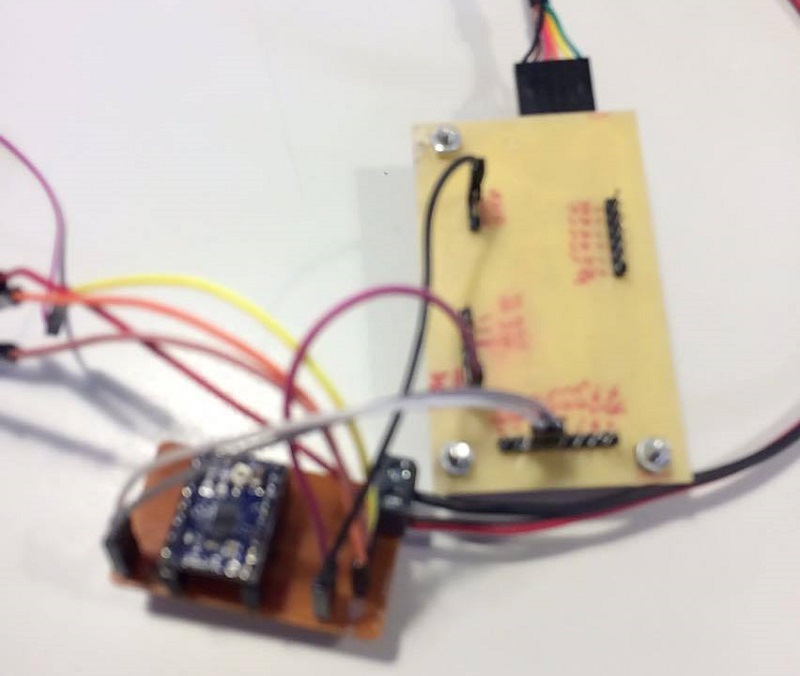

After i have machining the boards and soldering the boards i the test the electronic with control the motor stepper i use.

After i have machining the boards and soldering the boards i the test the electronic with control the motor stepper i use.

In this video you can check the test i make to control the motor stepper.

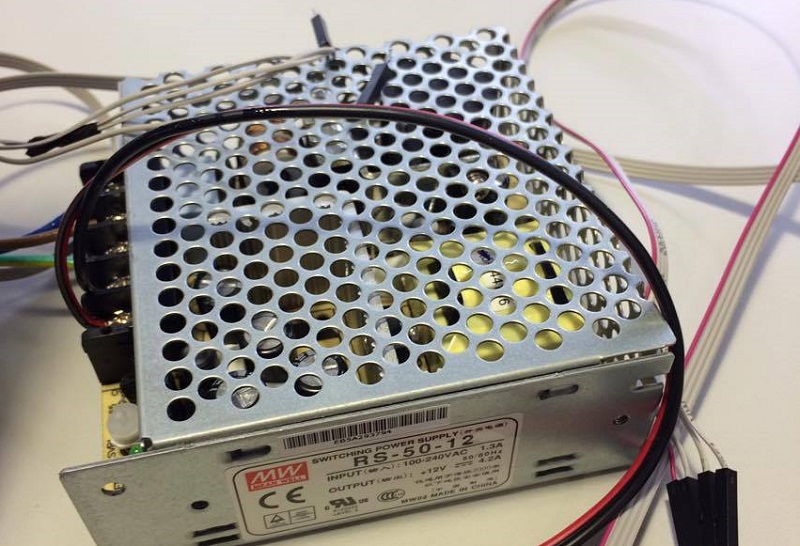

Thi is the power supply i use output: +12V 4.2A.

I put two buttons to control the steppers if you click in one the material go top to heat if you click in the outher button the material go to down to the vacuum.

I put two buttons to control the steppers if you click in one the material go top to heat if you click in the outher button the material go to down to the vacuum.

All electronic work and tested is time to build the machine.

I put two motor steppers to make the movement with Threaded rod and 4 Smooth rods to make the smooth movement of machine.

I put this bearings skate to put the Threaded rods.

I put this bearings skate to put the Threaded rods.

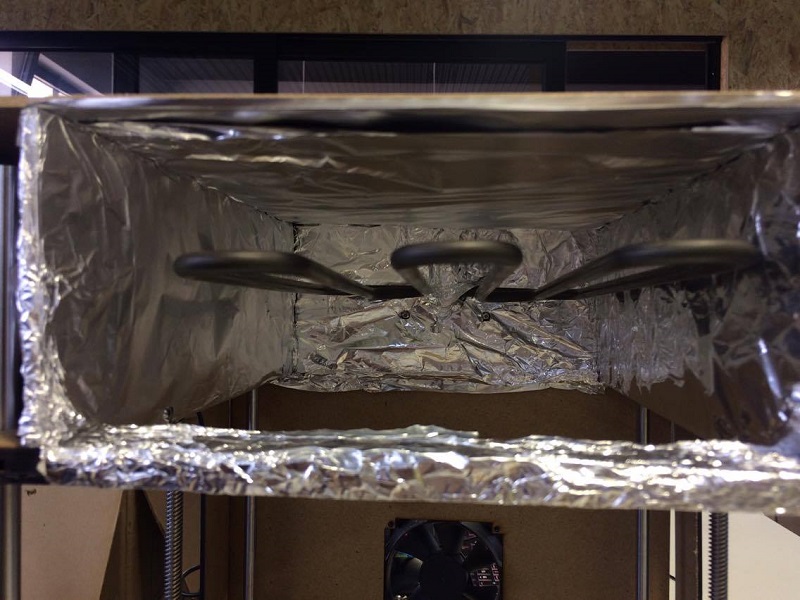

To isolate the wood to the heat resistor i use the aluminium paper.

To isolate the wood to the heat resistor i use the aluminium paper.

This is the position i put the electronic.

This is the position i put the electronic.

This is final aspect of my machine.

This is final aspect of my machine.

Problems an Resolution

In final in my plan i design all parts i nedd to build the machine.

I my plan i stipulated goals to make the objectives but i have problms in some objectives so i took some many time to make the objects.

In concept i design a closet box but i decide to make open box becase is so much easy to work with the machine.

And in i plan to use ceramic lamp to heat the material and dont work fine so i decided to use a heater of normal grill.