#09. Mechanical Design

The Machine

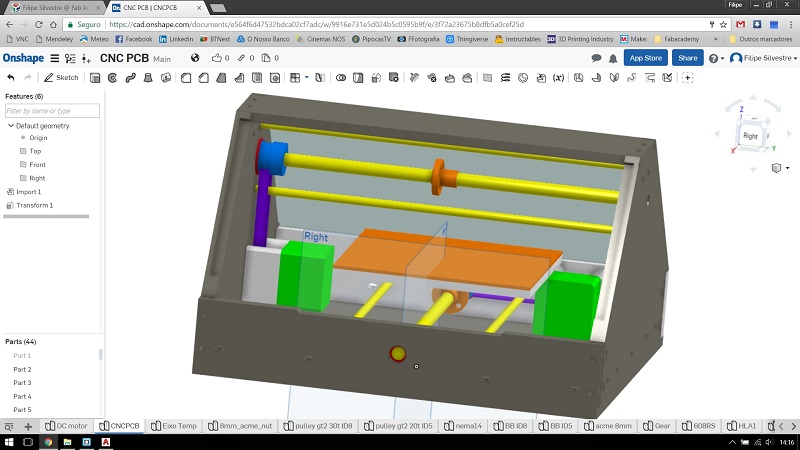

Here in the FCT FabLab, we (me, André, Filipa and João) decided that we needed to make a small CNC just for electronic production, something with a small footprint, for small electronics, ease to use and to carry around. We idealize a cubic form, 120x120mm pcb plate, only three positions on the z axis (safe, zero and machining).

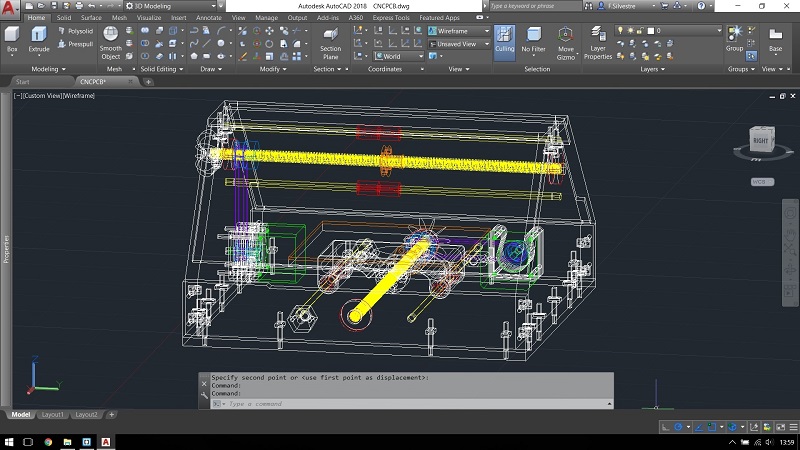

My contribution for this project was in terms of the design of it, started by using AutoCAD to do the basic shape of the machine. I had to have in consideration the fact that we already had some parts that we wanted to use and the design would depende on it.

Since for the cnc we didn't needed it to be fast i opted by using threaded rods on both X and Y axis, this way we could have a good control with a good speed and having great precision and strenght. Made a 8mm threaded rod, and in the end of it idealy would be the motor but the set we had wasn't like that so i designed a pulley for both axis and motor and connected both with a closed pulley. Used this for both axis, also, we didn't need that much strenght or speed as i said before so for space and weight safing we used 2 nema 14 motors.

To guide the axis we choose two M5 smooth calibrated rods with a couple of lm5uu ball bearings to secure the carriages. On the Y axis i've design a simple carriage to take a sacrifial wood where the pcb will be attached to, this way in any time we can just swap it for a new one easilly.

Then, after all parts are drawn i had to export them one by one in order to be able to import it on Onshape, here all my collegues could see and edit acording to our idea.

Below there's the video my collegue made after he assmebled it and put it moving around to test the axis.

Files to download: