week 11

Machine Design

ASSIGNMENTS:

- Automate the machine.

- Documentation of the group project & individual contribution towards project.

home

about me

automated dsrl rig

( link to fablab cept )

weekly work

final project

personal contribution

contact

My contribution for this project was to figuring out the mechanism in a way, it becomes most efficient with the minimal number of parts without much complexity.

In the next week, I was documenting the whole process majorly. From taking videos, editing them, taking appropriate photos and the web documentation for the project in the FabLab CEPT site.

In the words of great photographer Platon : "If it's necessary, it's in there. If it's not necessary, it's not there.So strip it down, simplify it. Just go... for the core."

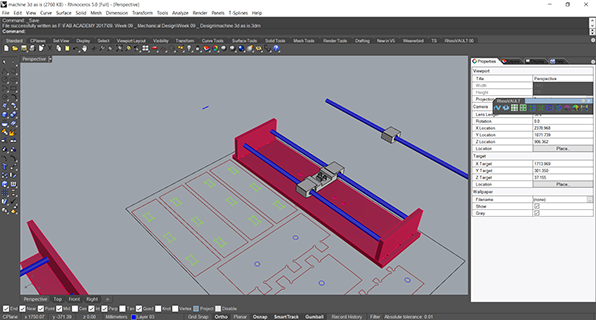

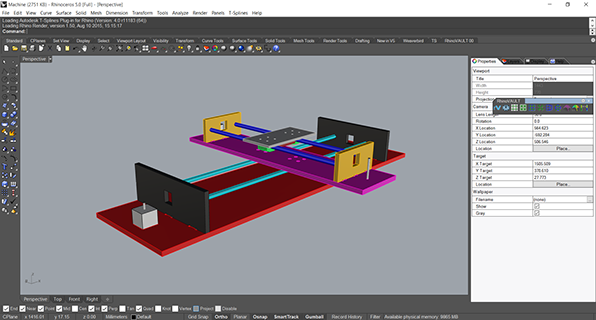

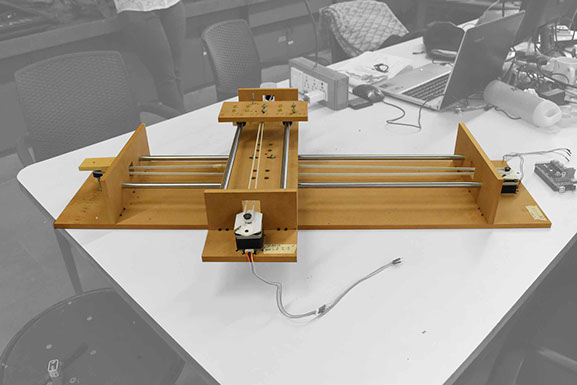

The model and drawings were generated in Rhinoceros 5.12. Below are the parts of the model as made in the software since the inception of the project. There has been 3 iteration of the project. The first one as totally manual and the next 2 was made using CNC cut and 3D printed parts.

The second iteration of the machine design through CAD.

The third and final iteration of the machine design.

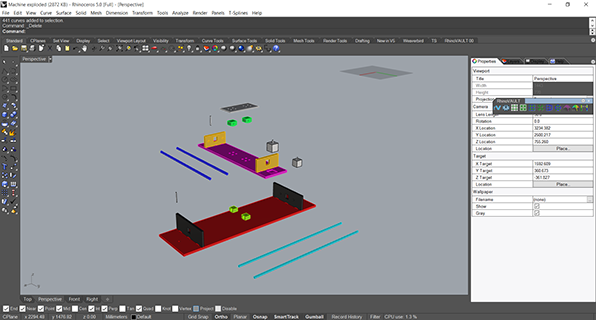

Exploded view of the machine showing all the parts.

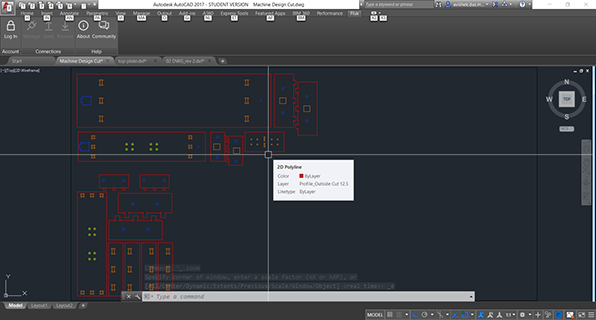

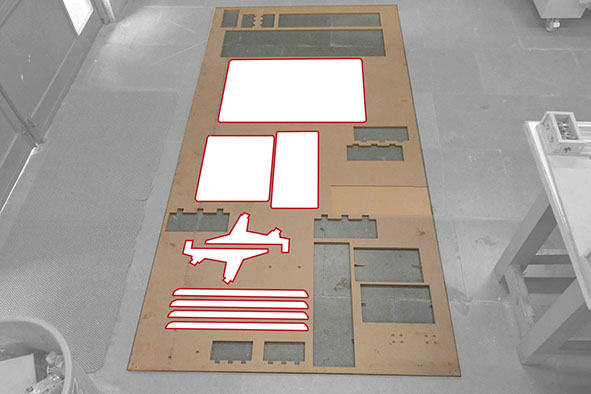

The next part was to extract and manage drawings from the 3D for CNC Machining. I had extracted the drawings from the Rhino file and exported to AutoCAD 2017.

The piece of MDF I used in the CNC week, due to bad nesting had lot of spaces free. So used that MDF to build all the prototypes from that. For that each part had to be processed separately and milled using custom origin each time in between the empty spaces.

CNC cut parts being prepared.

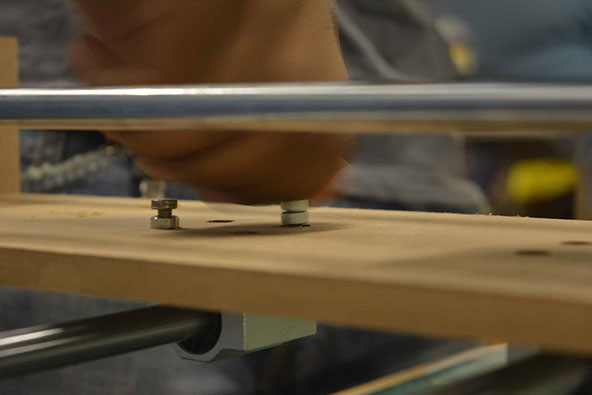

Assembly in progress

final

working prototype

The working file with the intermediate prototype version can be found here.

Room for Development:

After finishing the project we have assessed some improvements that can be done in future:

- Adding 1/2 Extra axis on the top for more degree of freedom of the camera.

- Making some subtractive pattern on the MDF Body so that we can reduce the weight of the whole assembly.

- Introducing more 3D printed part to reduce weight.

- Using rubberised GT2 belt than wire reinforced GT2 Belt. It will smoothen the action.

go to WEEK 12 >>

Avishek Das | 2017 | FabLab CEPT