3D Scanning and Printing additive production

Test the design rules for your printer what can it do and what not

Teamwork discover together

Part Aleks: Printing Beam Structures and Braille Dotshow small can we print

Im interested in beam structures and I thougtht it could be interesting to test some beam structures. I found out that fast printing is better than high quality printing, as the material starts sticking to the nozzle and getting out of shape. You can see below a high quality printing of an 3cm tetrahedron. The beams are 1mm in aperture.

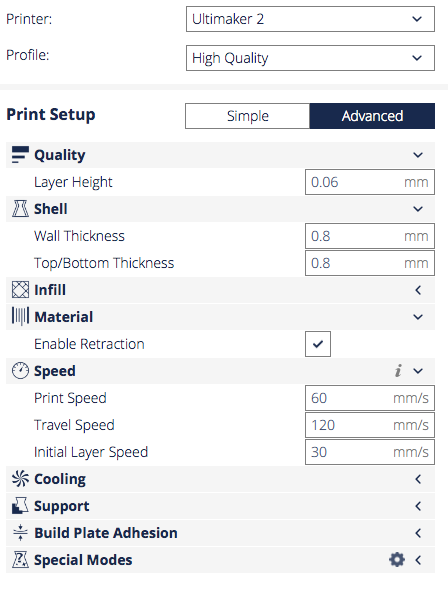

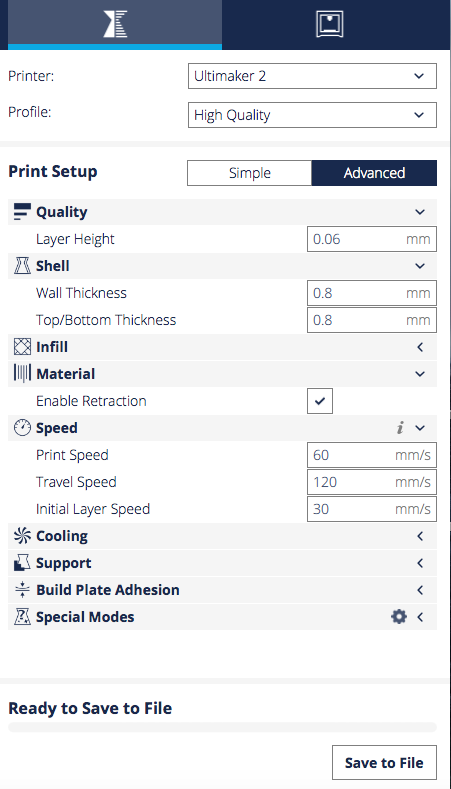

The setting was just high quality:

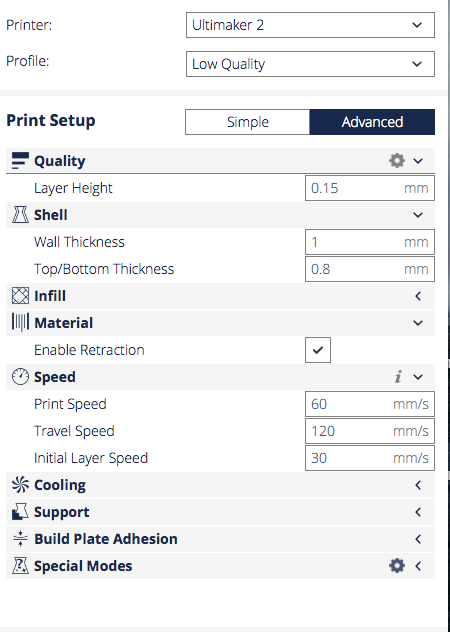

I skipped the normal print because I was curious about the low printing quality, same size 3cm and 4cm:

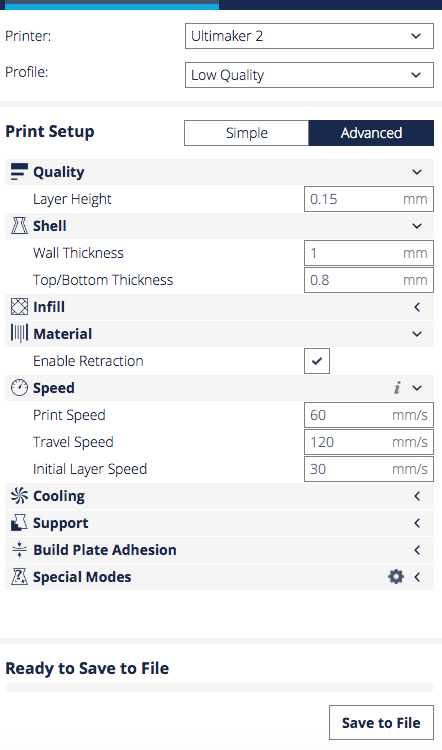

The settings:

It was really astonishing for me. On the one hand it is logic on the other hand it shows how loose it is. Afterwards, I wanted to know how it will be if I increase the tetrahedron to 5cm low quality print:

One can see that the bigger beams are getting cleaner, they are 2mm in aperture in comparison to the smallest ones with 1mm diameter.

An other question I wanted to solve how it will work with Braille script. Braille is a script for blind or nearly blind people. And these very small dots are really challenging.

First I have tried the defaults for low, normal and high printing quality. I have used .jpg files and converted them in Cura to 3d objects. The dots are about 1mm in diameter.

High Quality Print

Medium Quality Print

Low Qality Print

They do not differ from each other as much as I expected but at least the low printing modus couldn´t set the dots properly and the high quality print started to melt them again.

Part Marcel: Test the Ultimaker to go Make some test parts

Marcel's Part

Here I have invested a lot of time, but can not deliver any decisive results:

I have downloaded 2 different test files from thingiverse.

The first object of my choice was this.

The following attributes were observed for the round test object:

Z-Height Check, Warp Check, Hole in wall, Raft Test, more Overhang Steps 50° - 70°.

The second object of my choice was this.

Here I had to check some diameters and heights.

The Ultimaker 2 Go printed in differnt stages of quality. Fast, Normal, High and Ulti. If you look closely one recognizes, of course, very fine differences. Nevertheless, I do not feel it as very decisive. Only the printed brim can be seen the diminished quality at the printing:

All quality-stages togheter

Fast VS. Ulti Print

Fast VS. Ulti Print

In my weekly group assignment, I want to test how our 3D printer handles moving parts. When printing parts, that has multiple moving parts, it is necessary to know how huge the tolerances are. When the parts have to less space between each other it can happen that they melt together. When the tolerances are to huge, the construction may become too lose.

I designed a test model to check this parameter of our printer.