Group discussion and knowledge sharing. Learning Eagle

On a next day itself we had a group discussion and knowledge sharing session where I learned Eagle. Our colleagues explained me about eagle and we all had hands on practice for first day

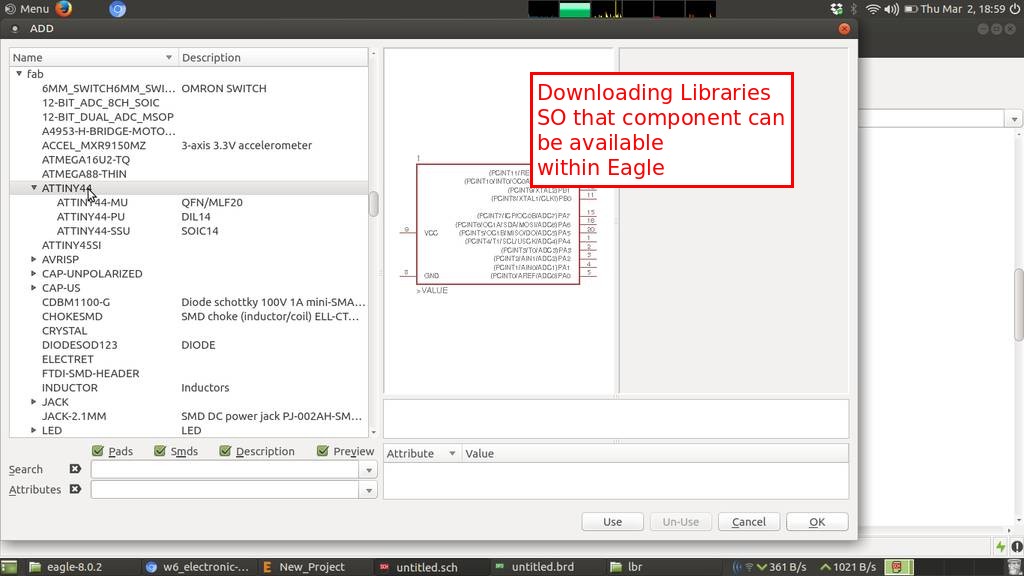

Downloading and importing fab library within Eagle

Library is a set of components which I can use within my schematic. Libraries can be imported and used or if required we can also create our own library

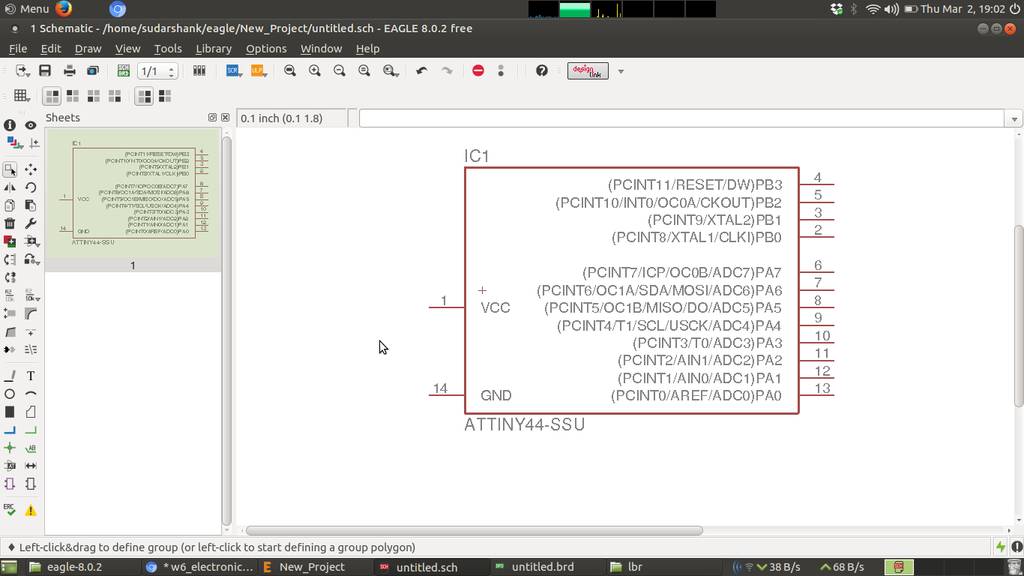

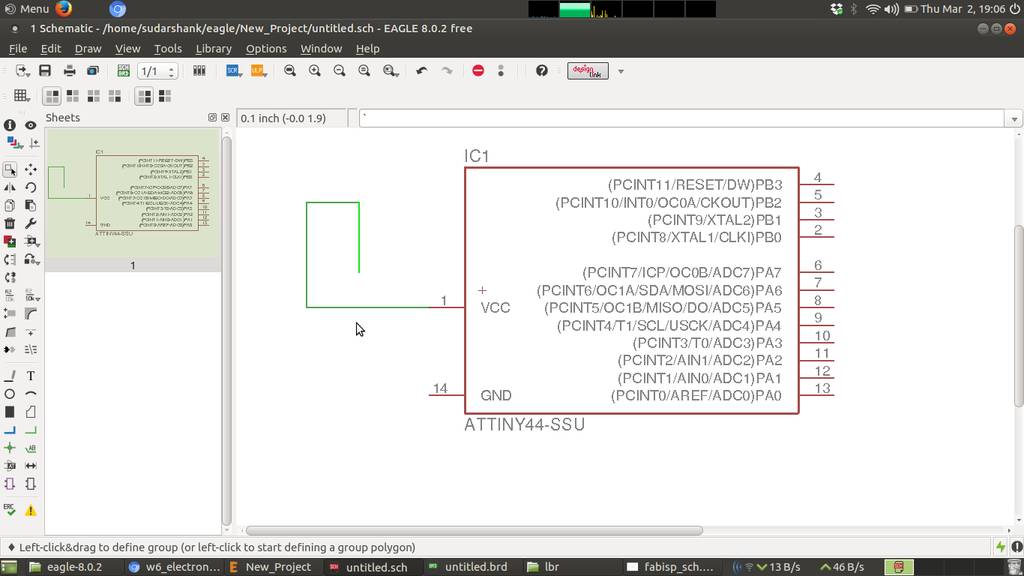

Imported the ATTINY 44

Connecting components to form schematic

That green line is called as a net. Which connects one component to another component. Its labelled as VCC. To label it do a right click and select Name. Provide a name and then again right click and select label. Place a label appropriately

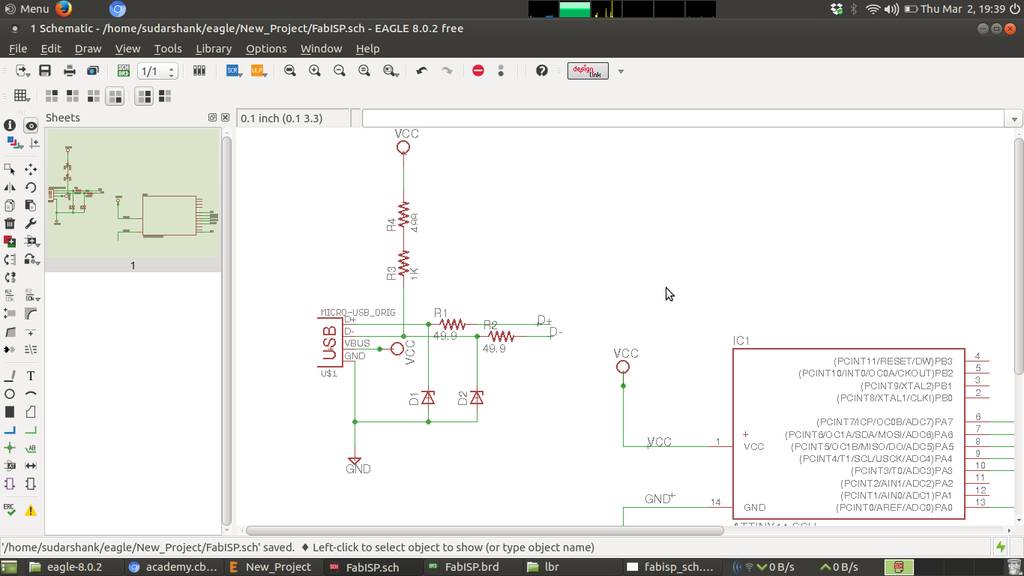

Connecting things using reference label

Net with same labels virtually connects with each other. For example in this case VCC of ATTINY44 will connect with VCC of USB. This is how we can connect using references. Using this technique we can make this design modular and move a part of it to another page to make it neat and clean

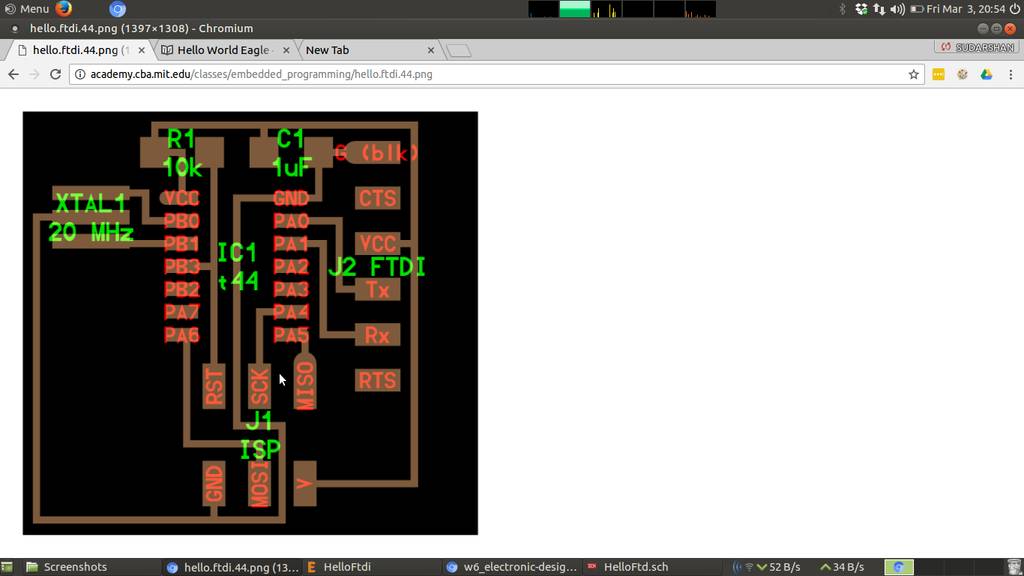

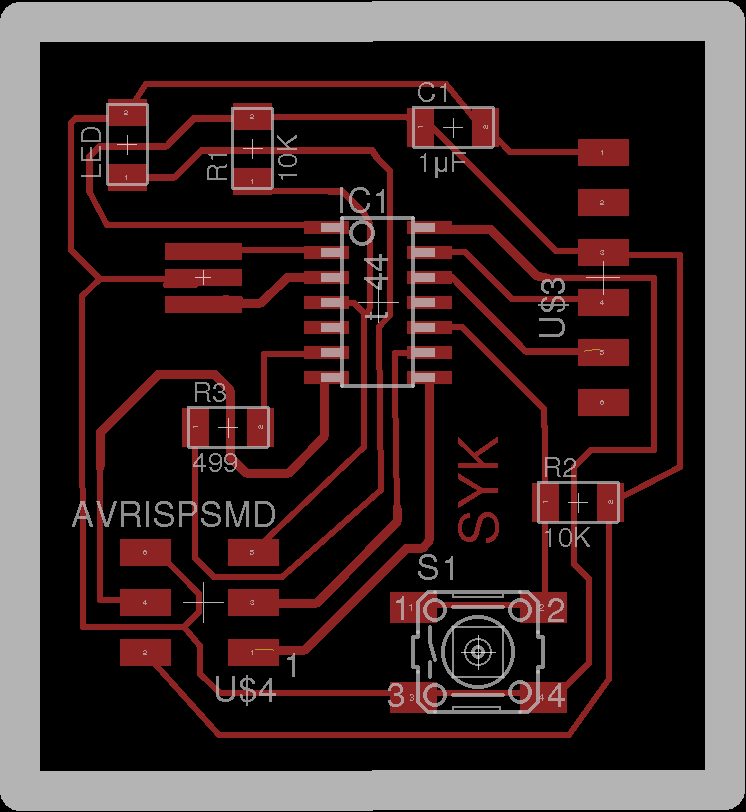

Hello ftdi board for reference

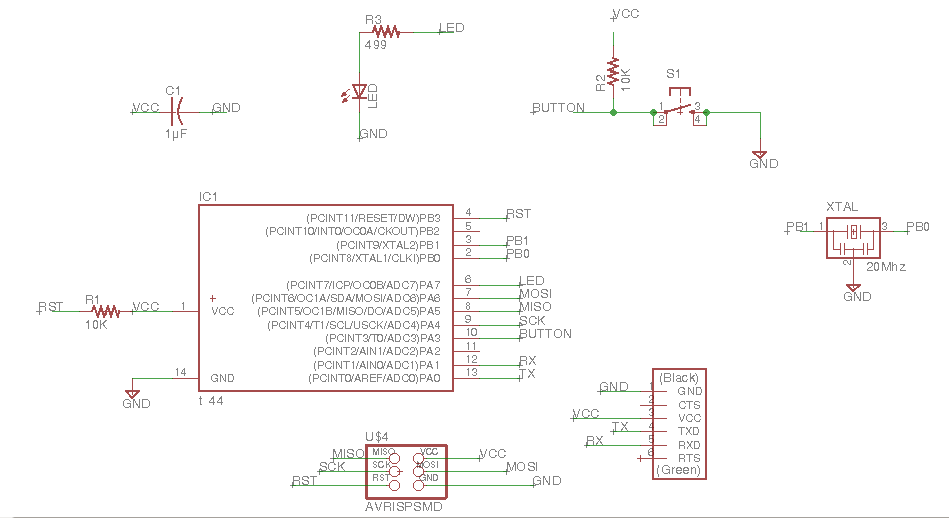

Schematic WIP

Imported components required for hello ftdi board

- ATTINY44

- 6 pin connector

- LED

- Capacitor

- Resonator

- Resistors

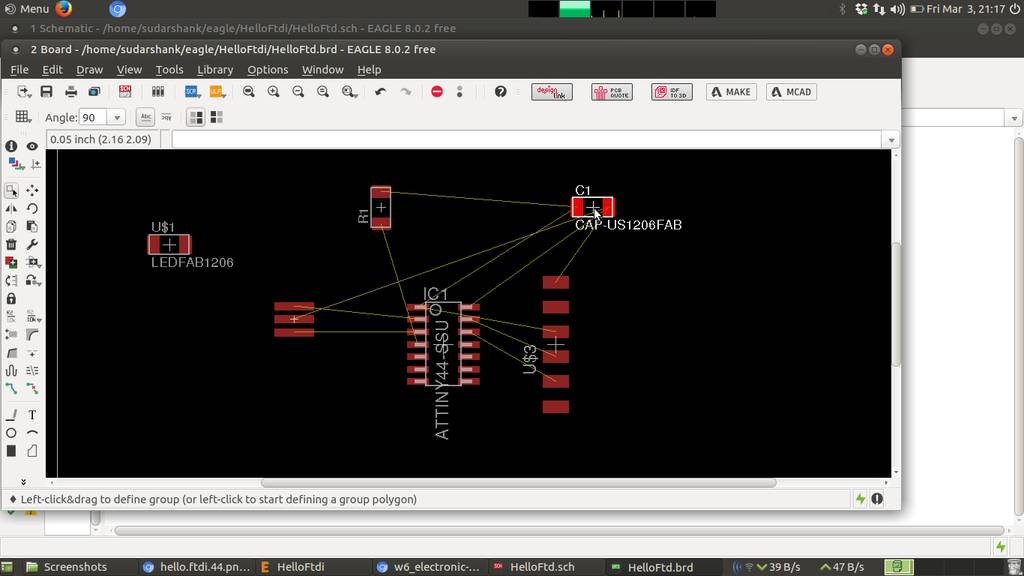

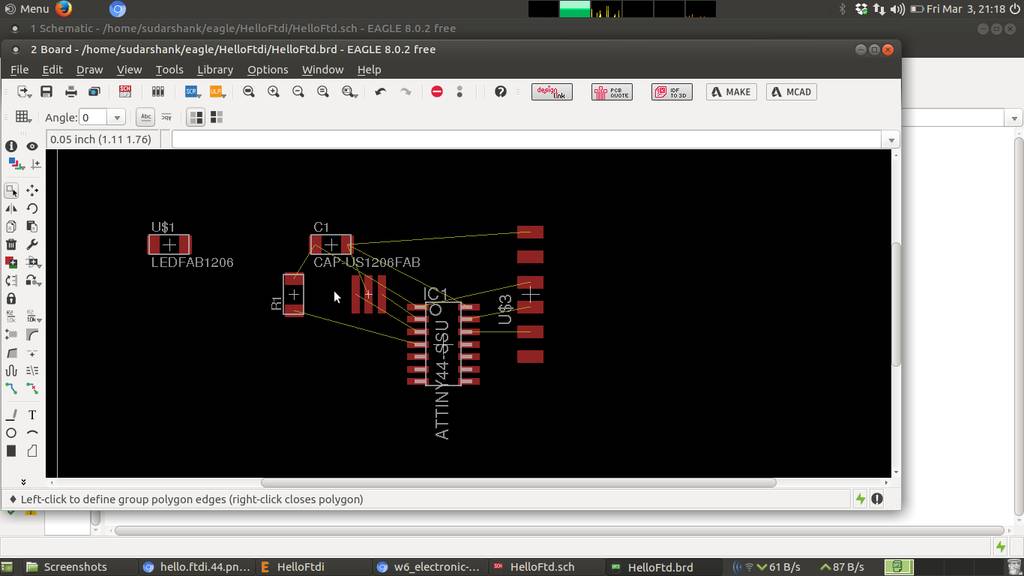

Repositioning compoenents within board layout

Repositioning again

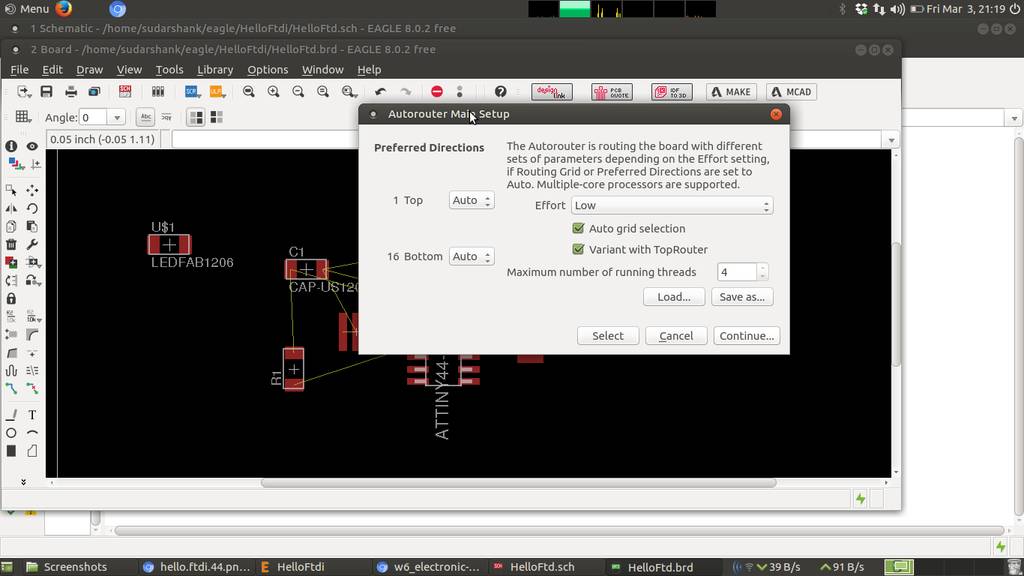

Generating traces using autorouting

Auto routing creates traces algorithmically and try to connect all of the traces to complete this circuit

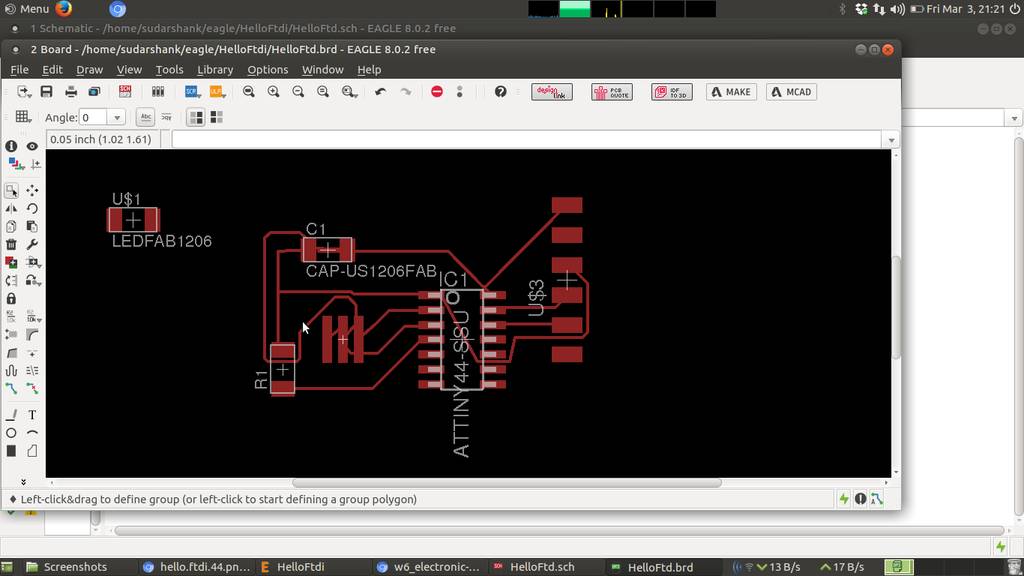

Traces generated using auto routing

Finally LED and switch is connected

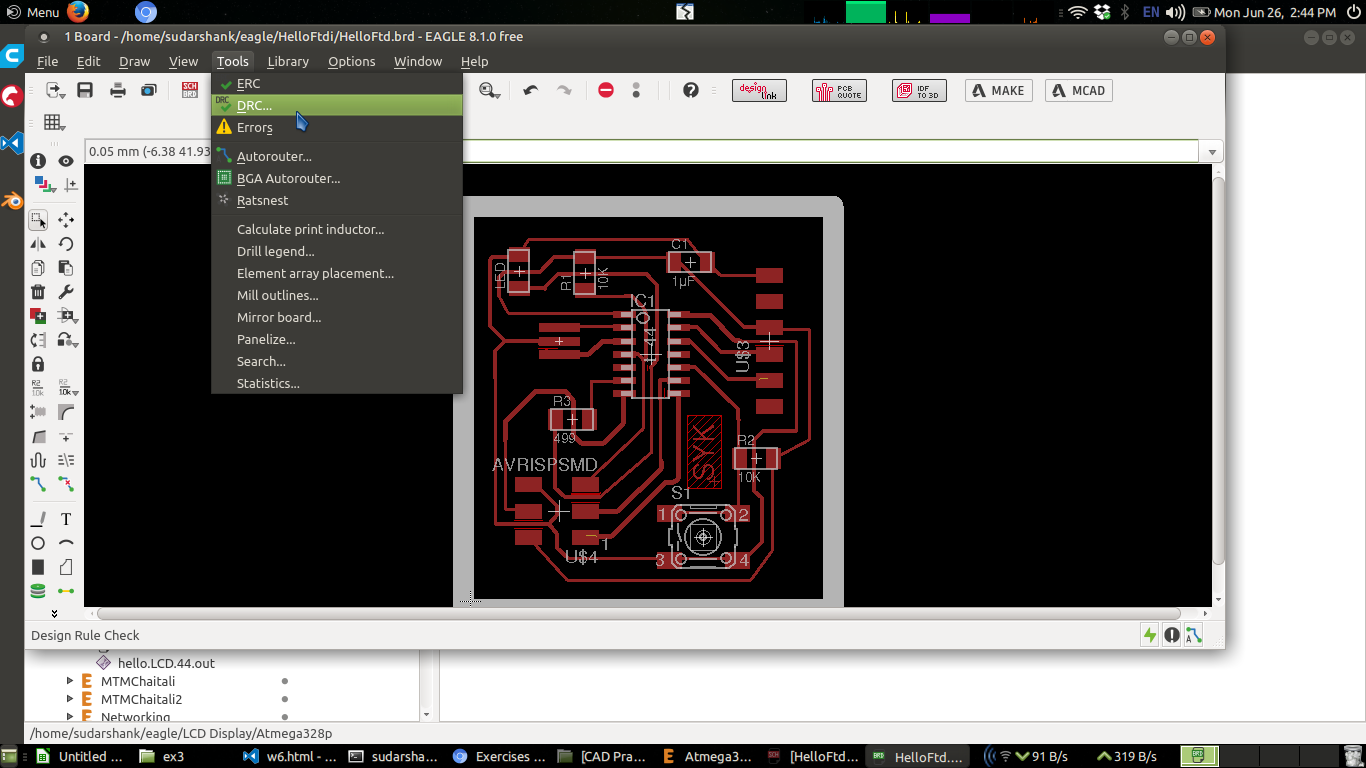

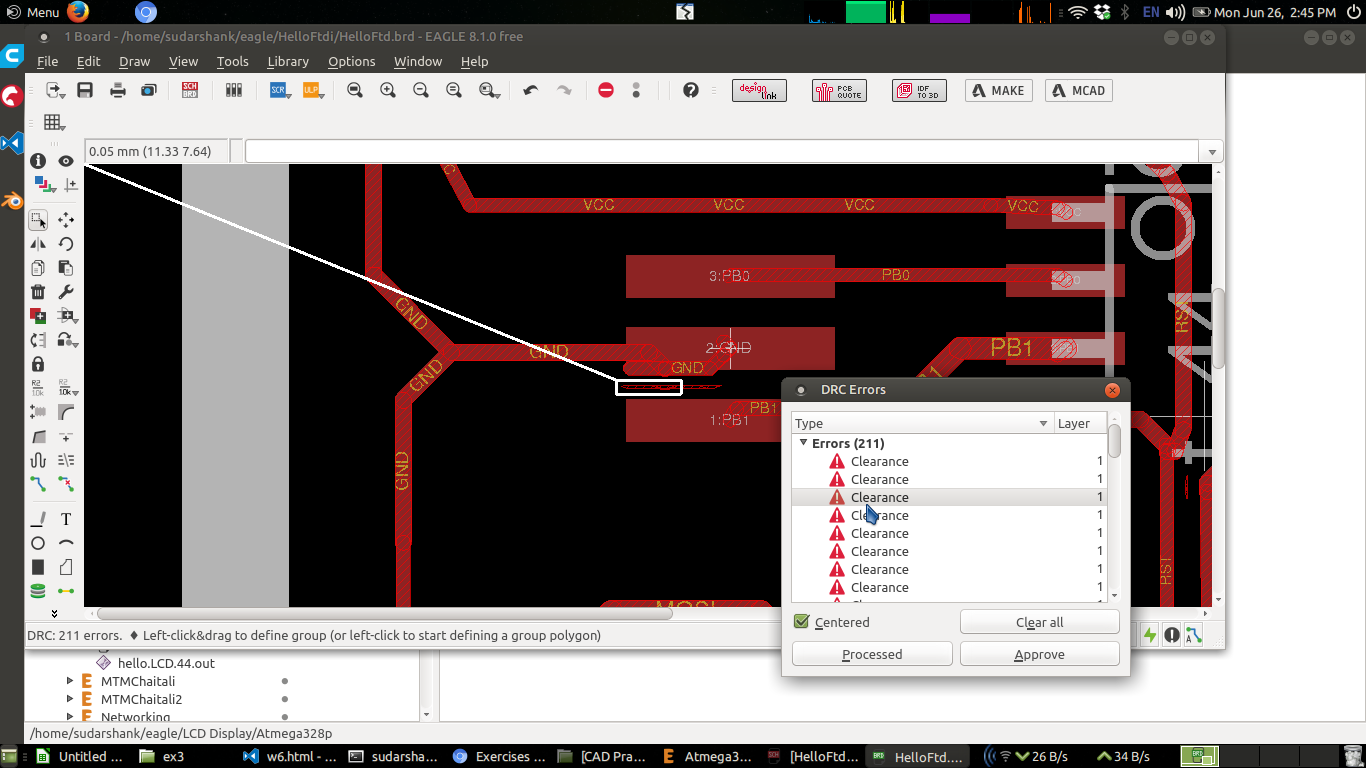

Design Rules Check for Eagle CAD

For example if milling bit is of size 0.5mm then traces should be defined with atleast 0.5mm clerance. Otherwise you may end up with very thin traces or else sometimes traces will vanish

Design rules can be set in eagle cad under menu Tools > DRC

Tools > DRC

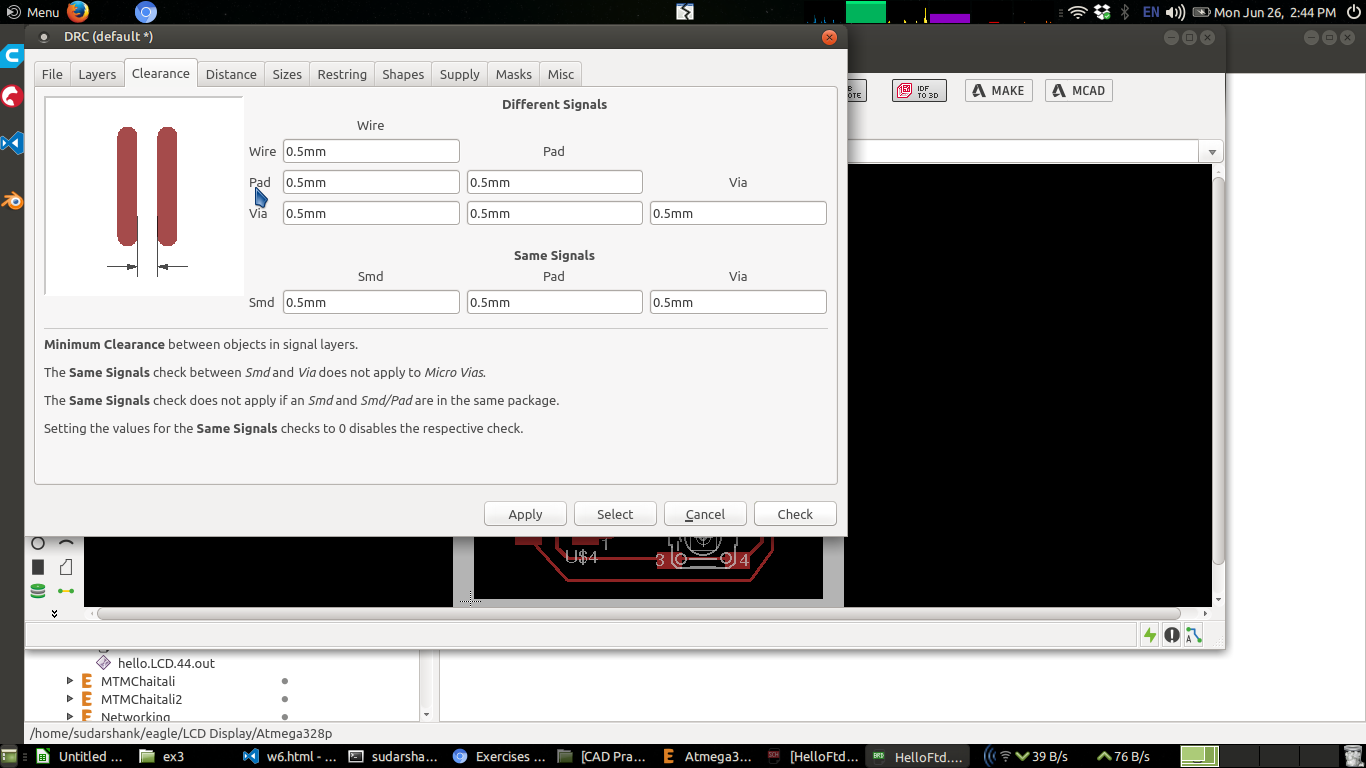

Clearance 0.5mm set

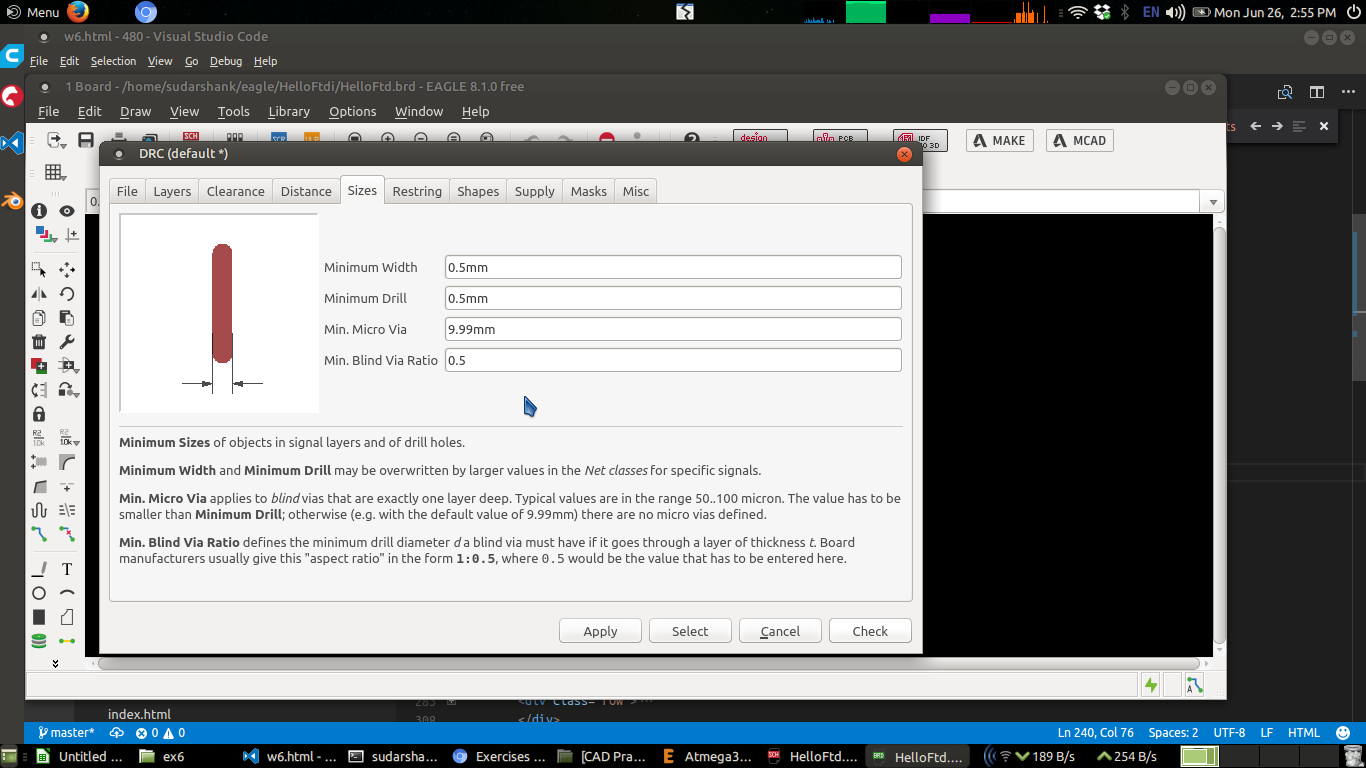

Trace width set minimum 0.5 mm for milling

Click on Check

Auto routing will also take care of these design rules you have set and will always follow design rules. You may not get 100% autorouting success when you set design rules.

DRC check showing areas violating DRC

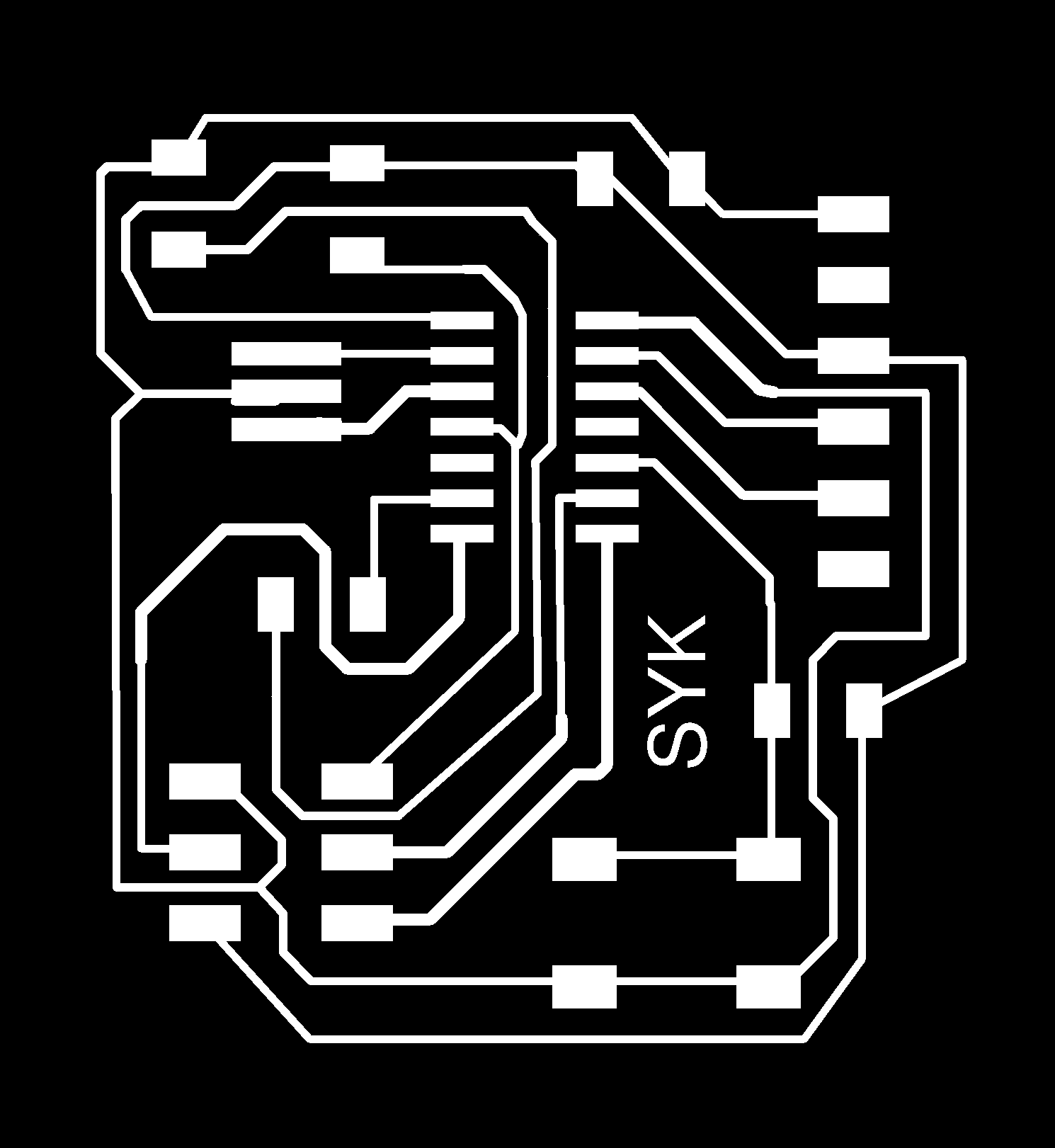

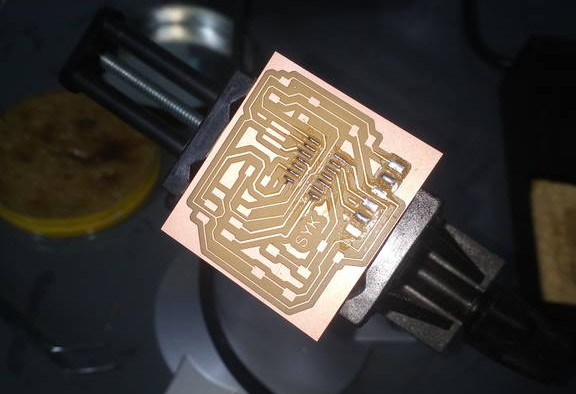

Final Board Traces

Board Cutout

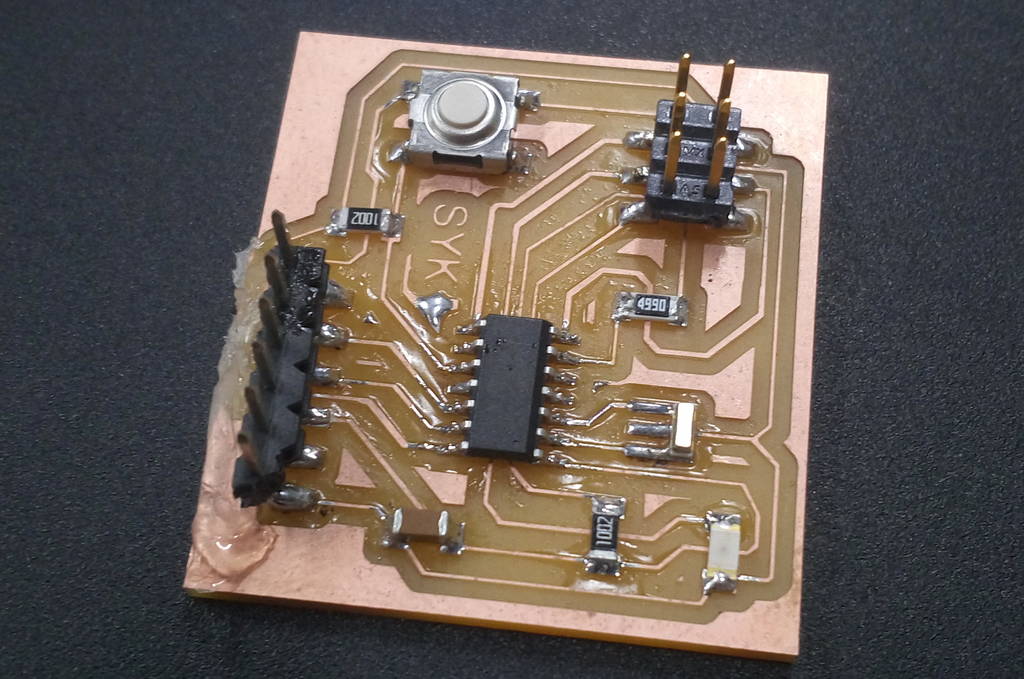

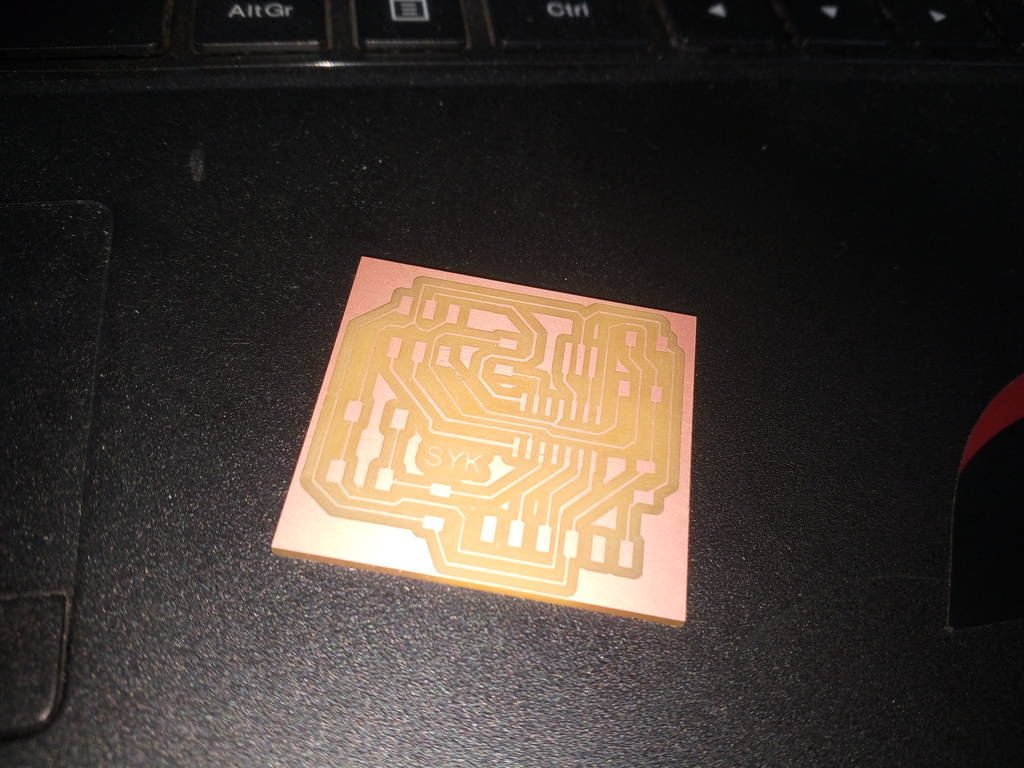

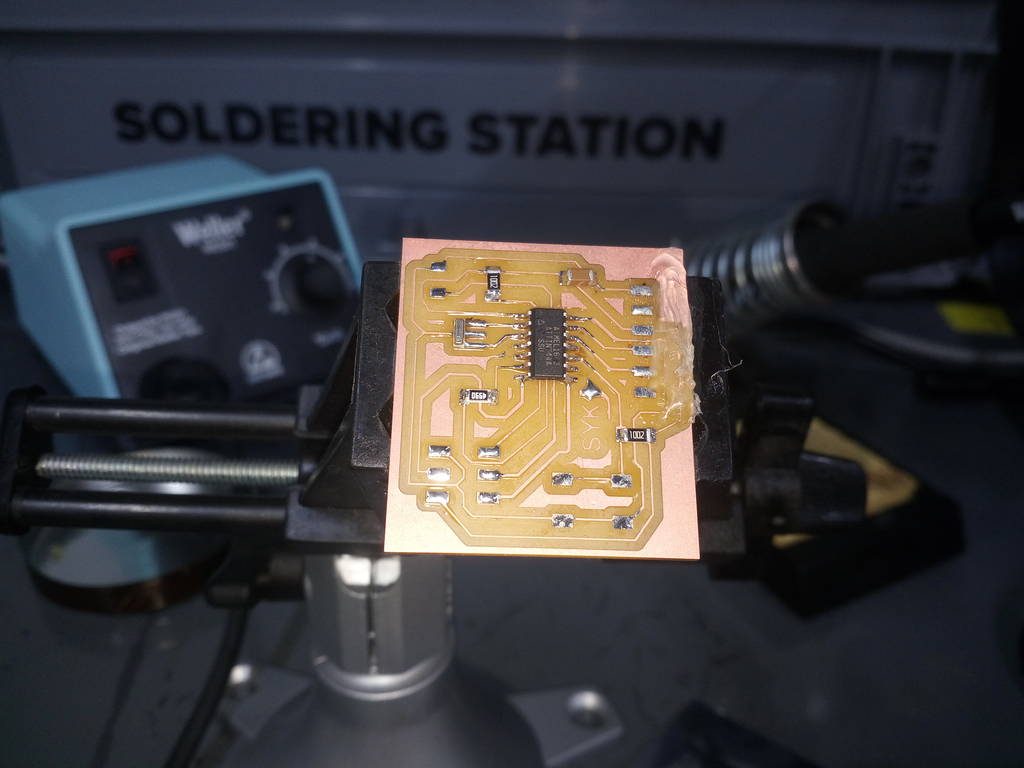

Final fabricated board