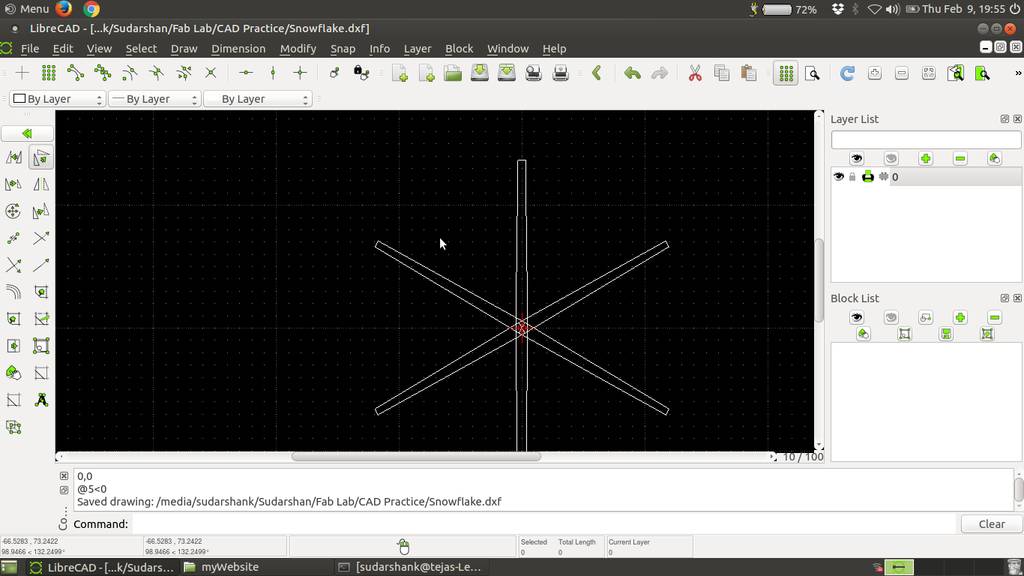

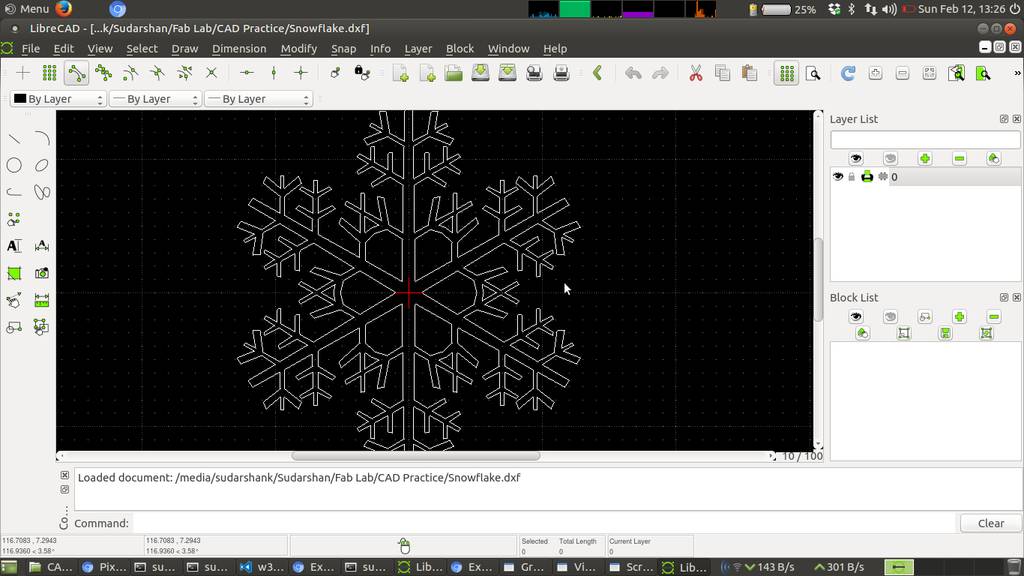

Working with LibreCAD

Making a snowflake on Librecad

Following commands used- Line : Two point line

- Scale : Which scales selected object with reference point which we define [Menu : Modify -> Scale]

- Move : Moves selected objects using reference point [Menu : Modify -> Move]

- Rotate : Rotates selected objects from reference point [Menu : Modify -> Rotate]

- Trim : It trims line intersected by another line [Menu : Modify -> Trim]

LibreCAD Move, Rotate, Copy

I found it very useful where LibreCAD provides options to output multiple copies. Its actually an array which you can generate using these options

- Delete Original : Remove original objects and Move / Rotates

- Keep Original : Keeps original objects and Copy / Rotates

- Multiple Copies : Creates Cartesian array in case of Copy and creates polar array in case of rotate

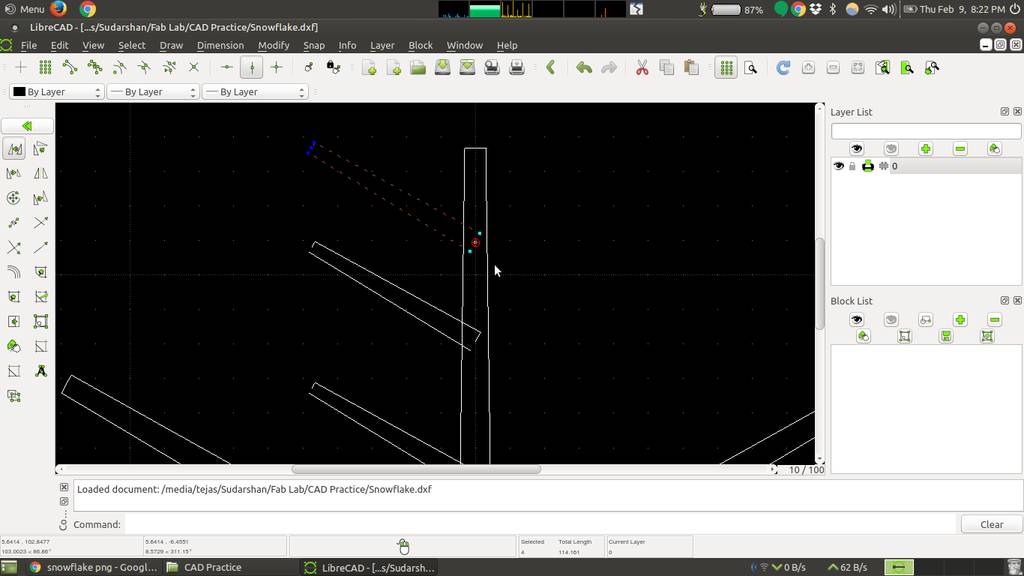

Created initial structure at 60 degree apart

Created line at a distance 20 mm from center

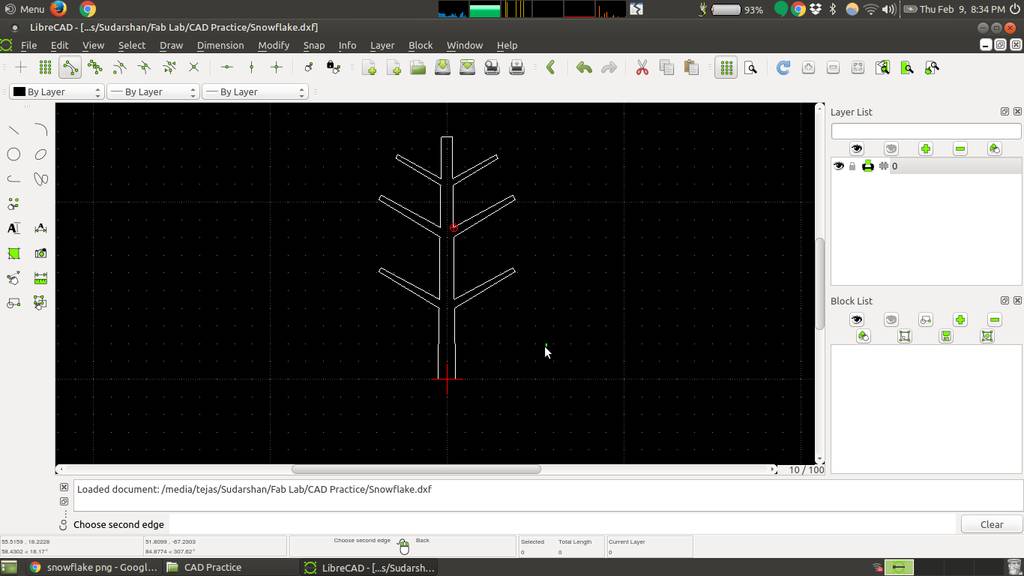

Created leaf geometry and rotated

Copied geometry using copy tool

Geometries are scaled and trimmed

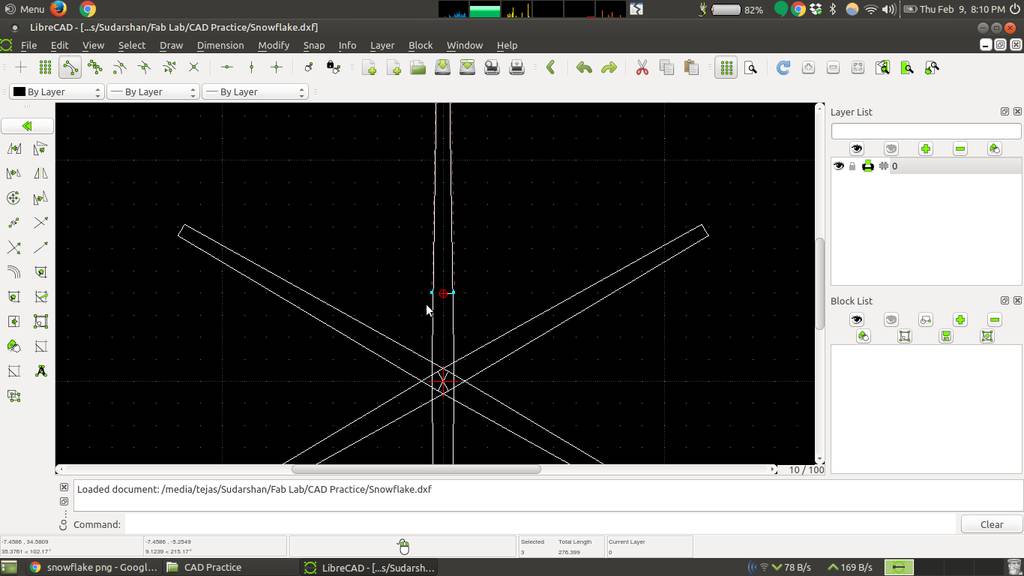

Rotate with multiple copies

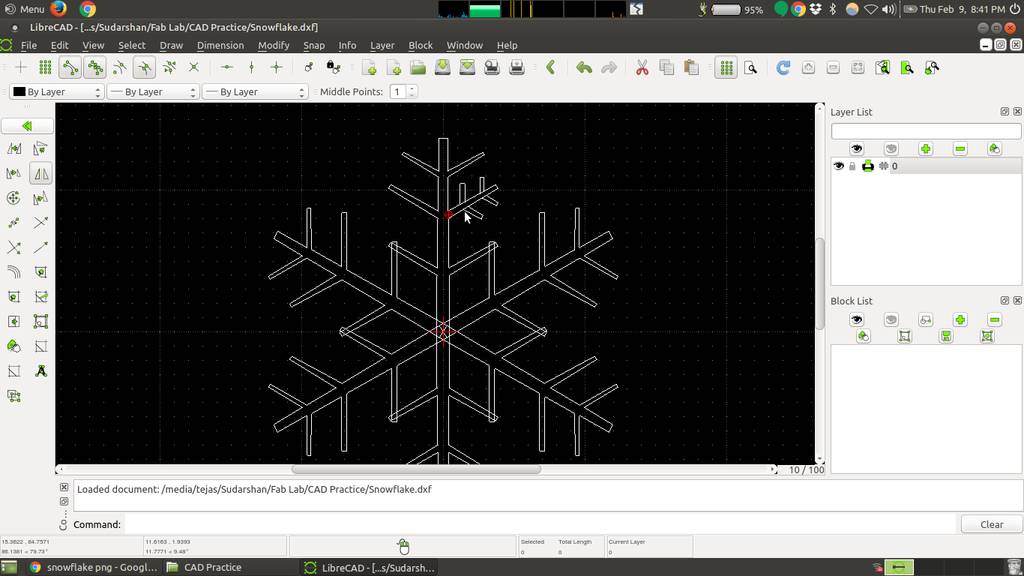

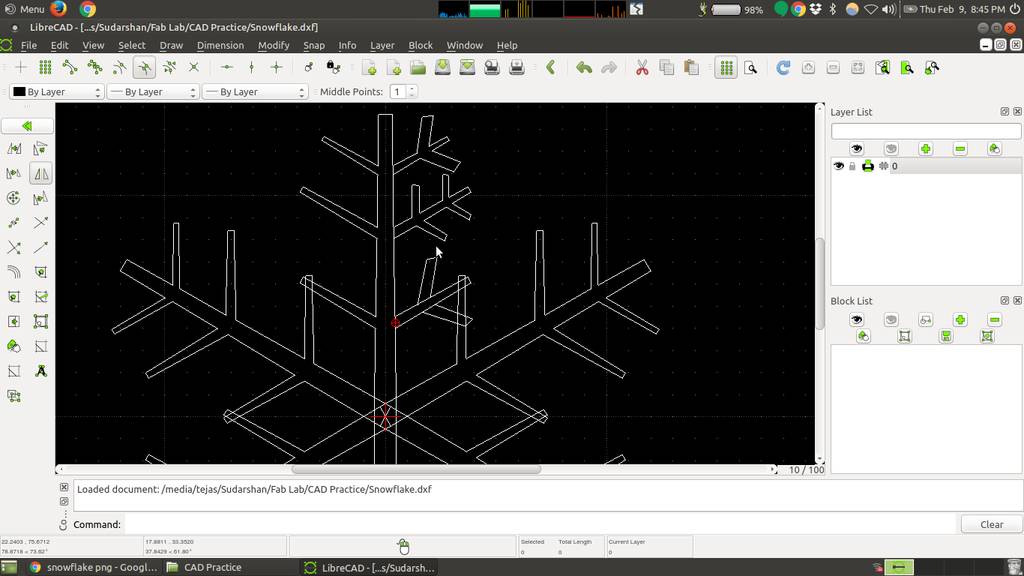

Using trim tool to trim intersections

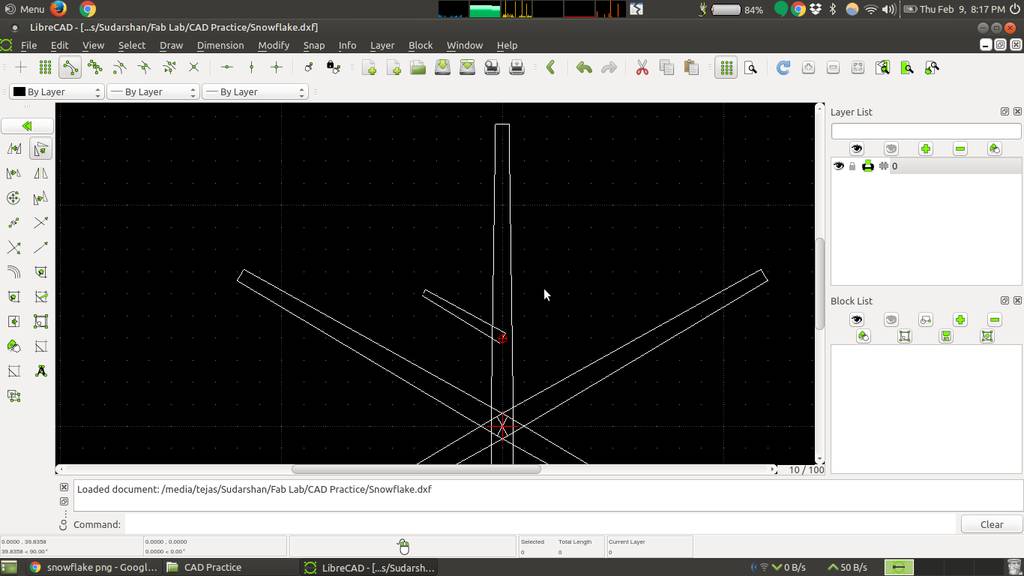

Final Snowflake using LibreCAD

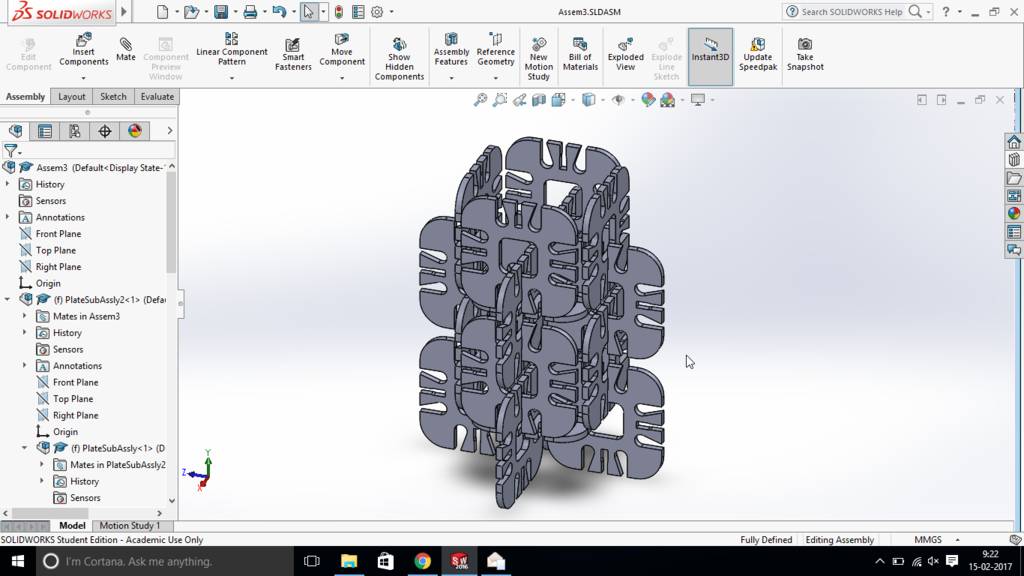

Exploring and working with Solidworks

Solidworks I found really easy and user friendly to work with. Obviously because of proprietary software and huge team of exprts involved in developement of Solidworks

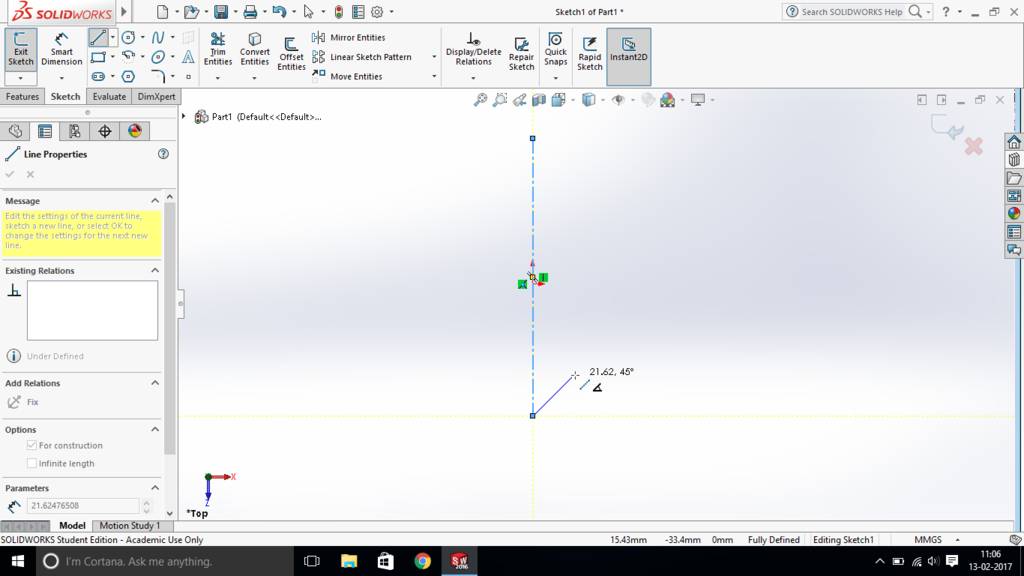

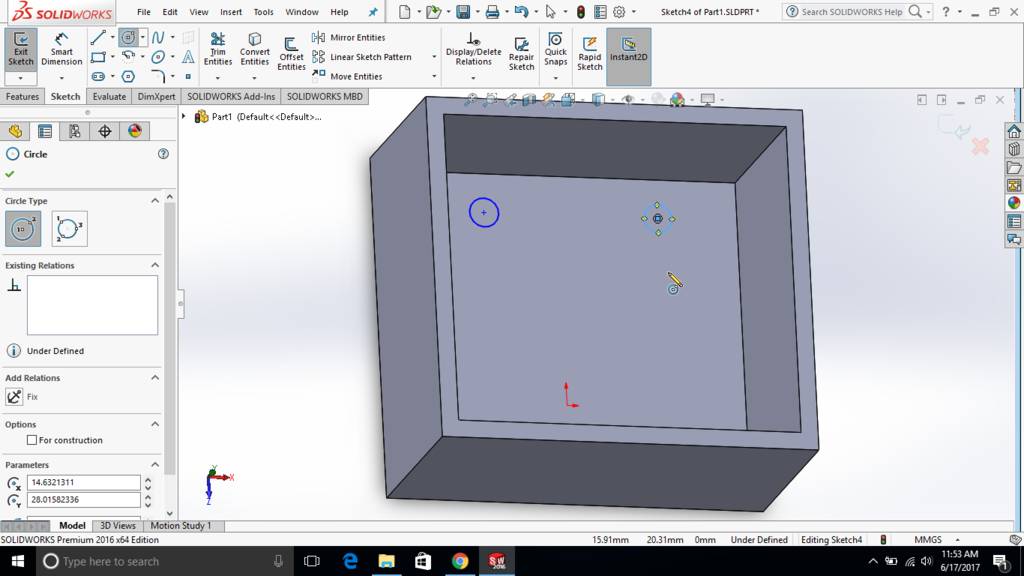

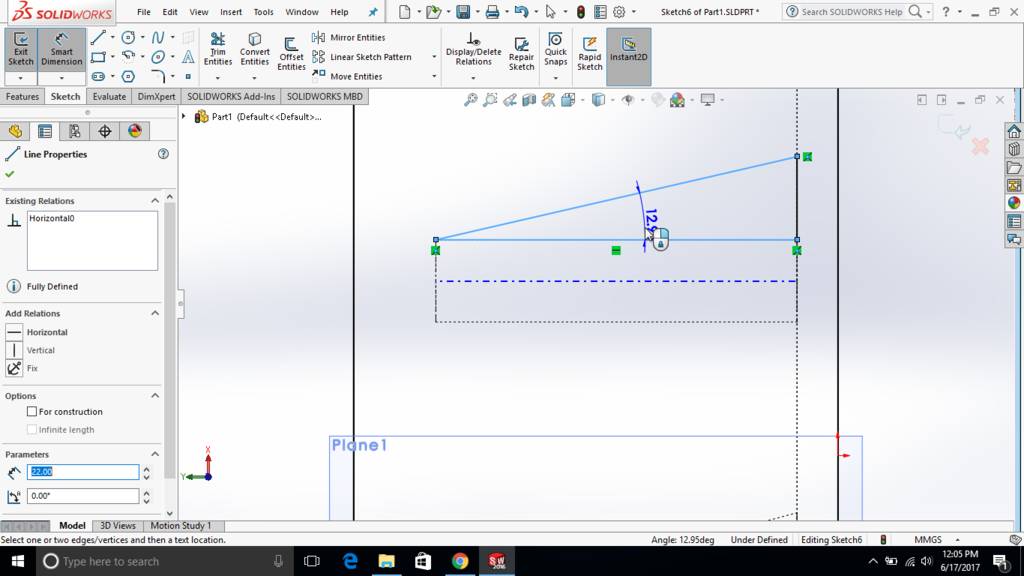

Working with Sketch in Solidworks

Drawing lines and apply constraints

Sketcher in solidworks I found that it can automatically puts constraints as I draw. Those green symbols in screenshot is a constraints applied for current entities

Fillets, Trims, Dimensioning in sketch mode

Converting 2d sketch into 3d solid using extrude command

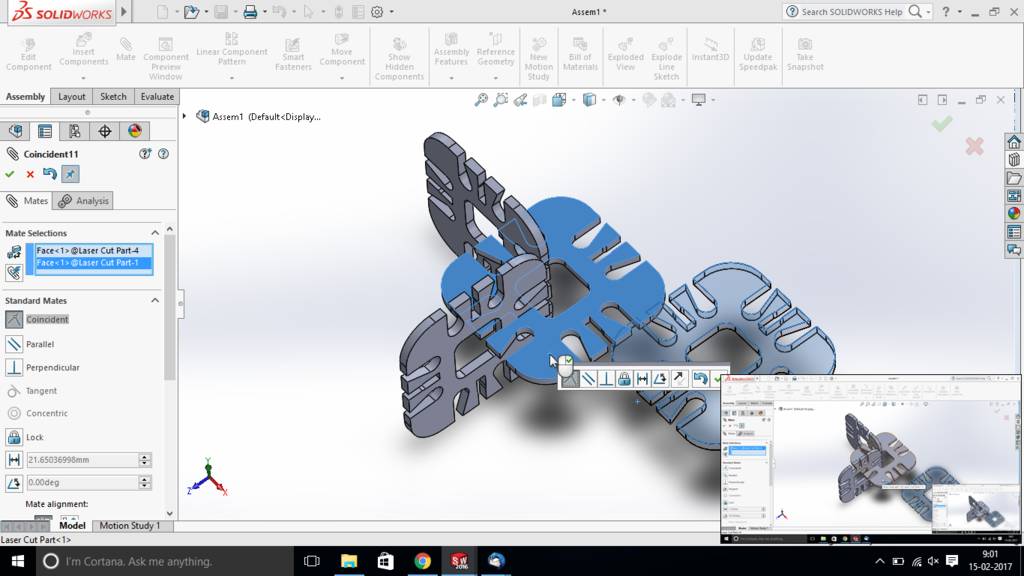

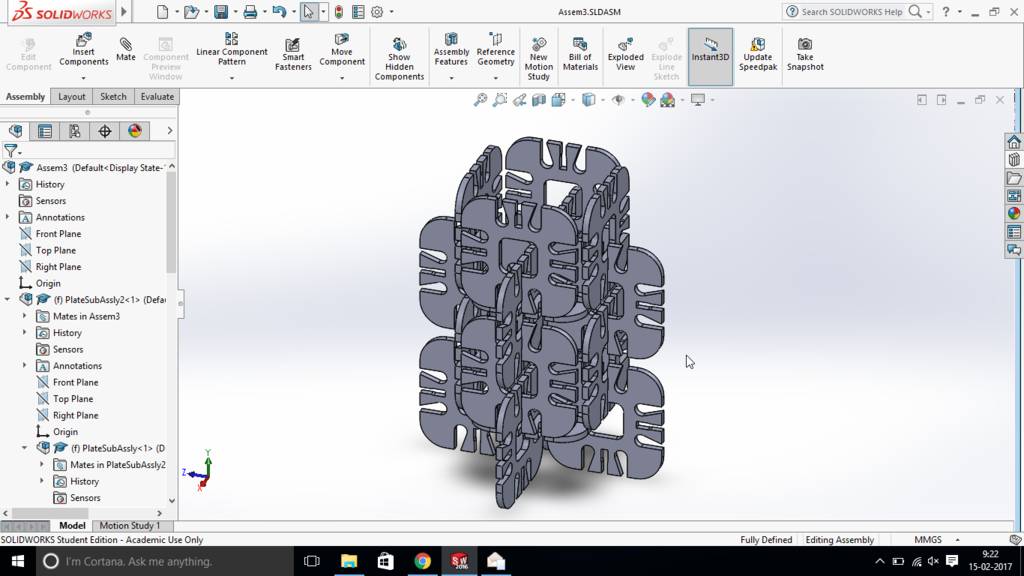

In assembly mode. I had imported existing component for multiple times

After activating "mate" command from tool bar. I have selected surfaces to align in two different components and it shows an option to Coincident, Parallel or Perpendicular

Based on entity selected solidworks provide options to add constraints to align those two components. In case of conflicts it shows conflicts too.

Finally entire thing is assembled

Files for download

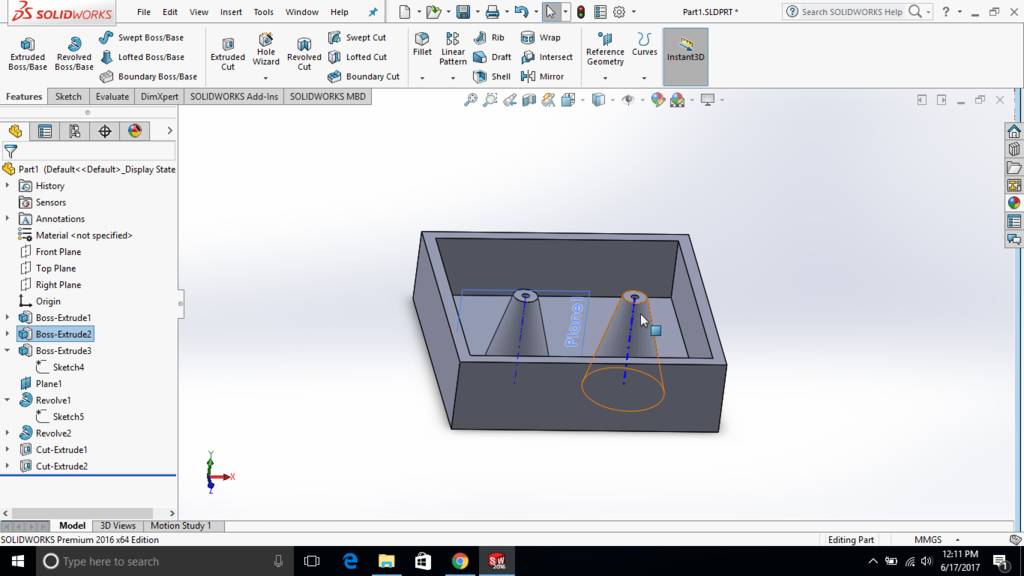

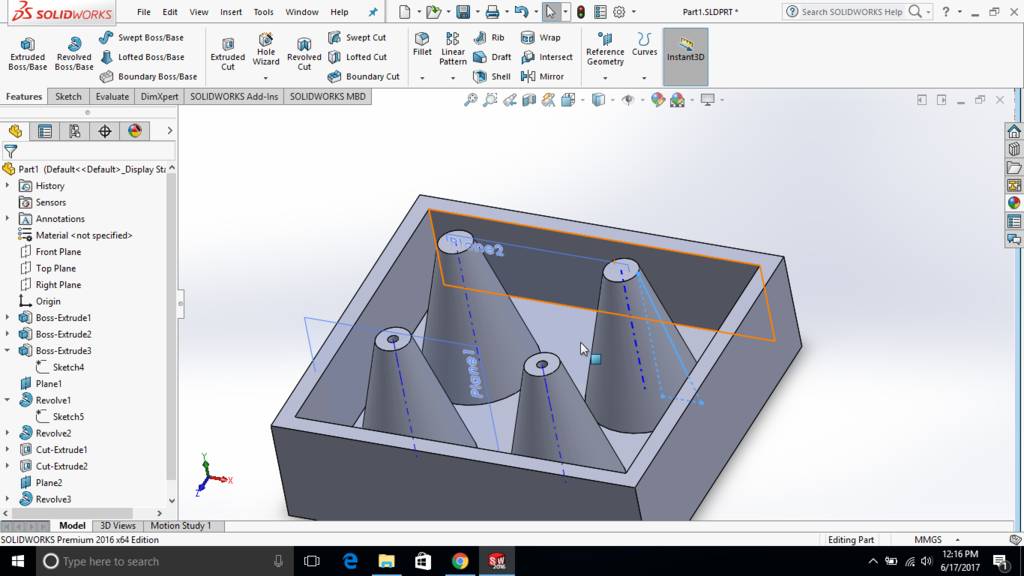

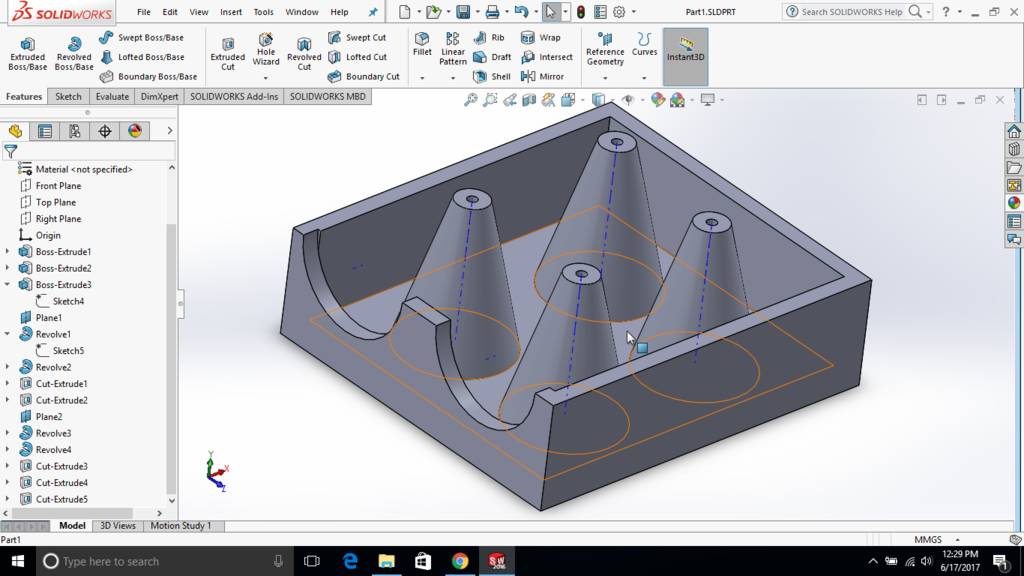

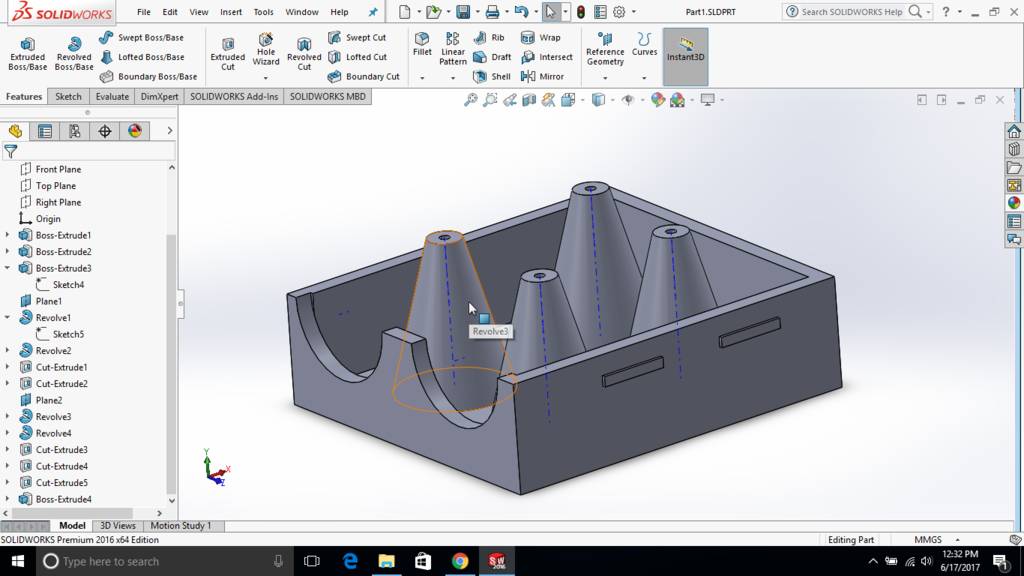

Creating Final project model using solidworks

Making outer box

Creating a reference plane and support

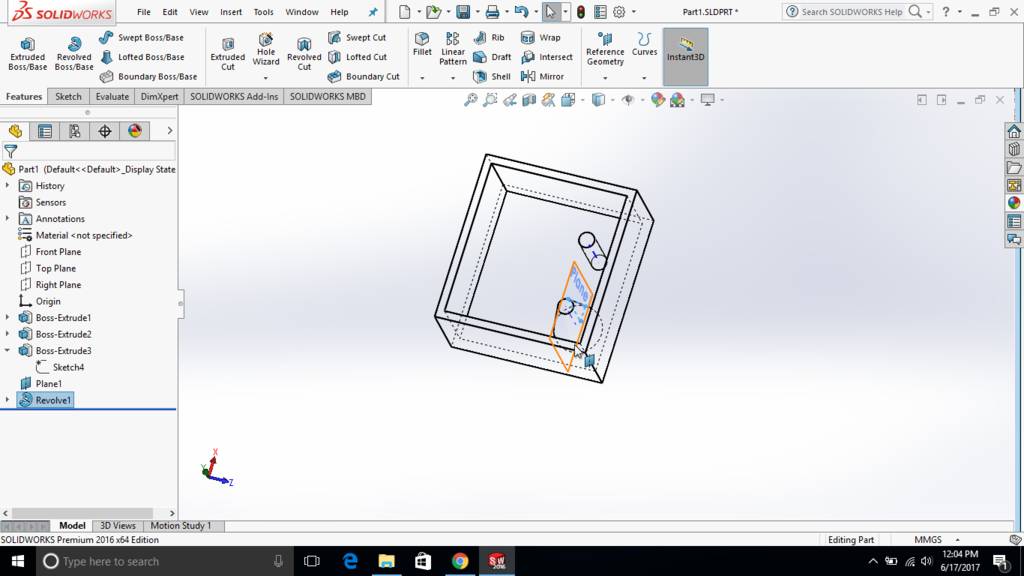

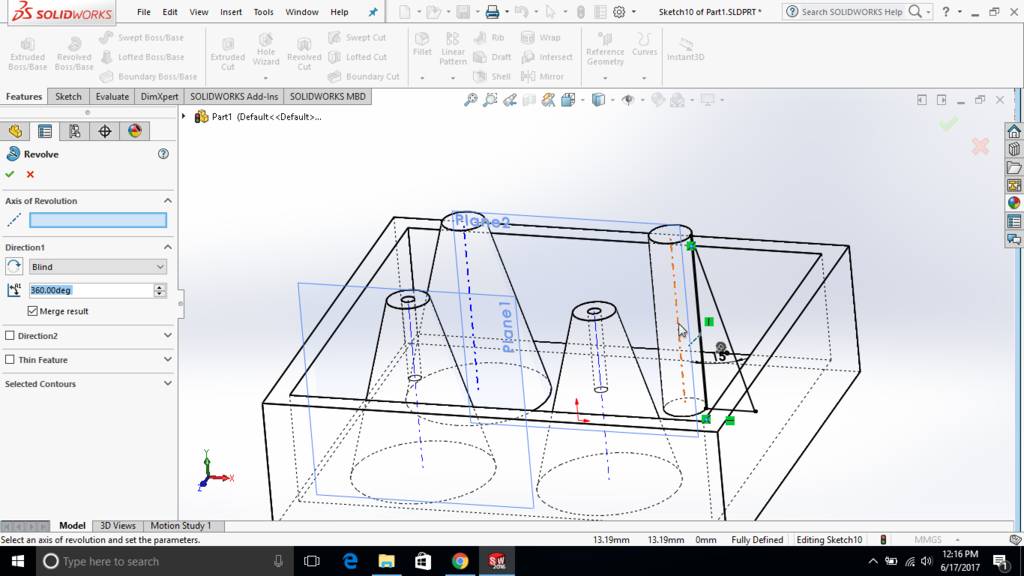

Revolve to form conical support

Sketch is created wit 15 deg angle for cone

Created another sketch on same reference plane

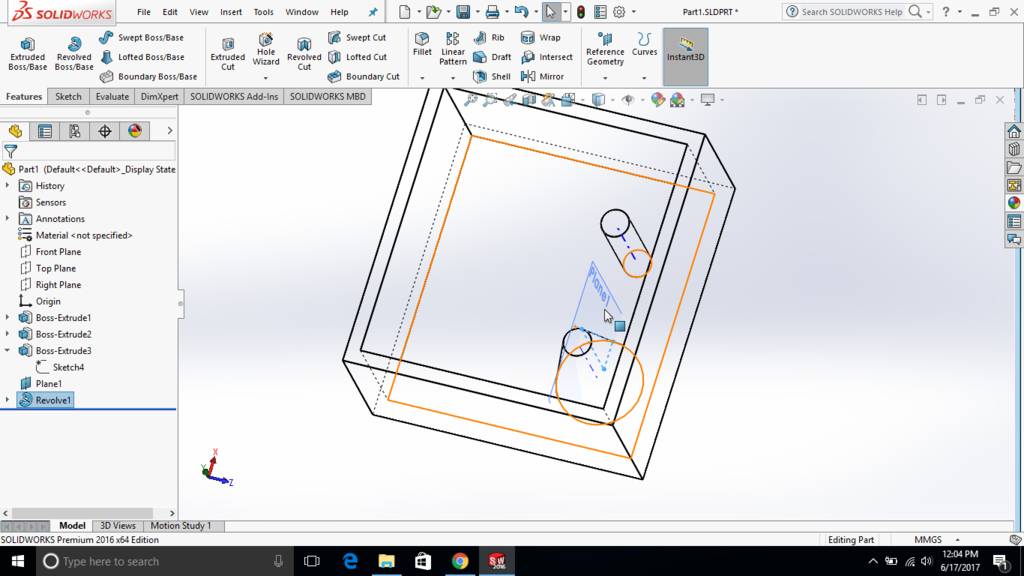

Second conical surface

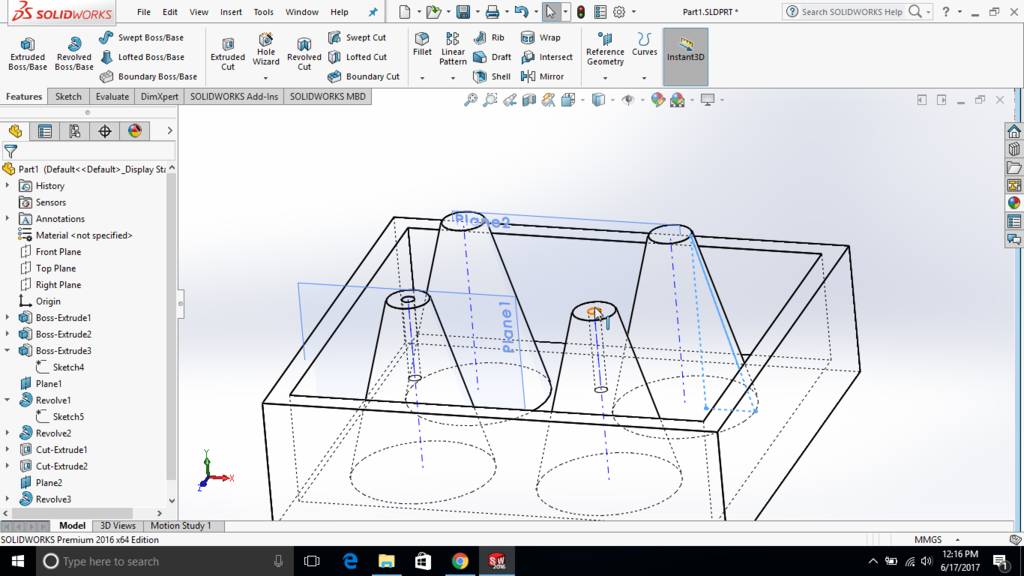

Created another two cylinders

Revolve tool to create cone

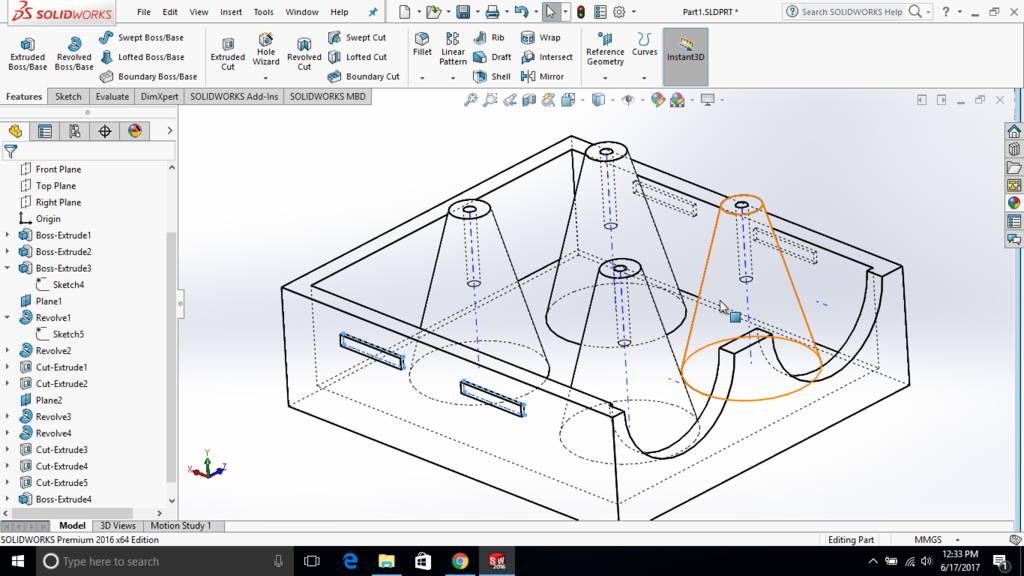

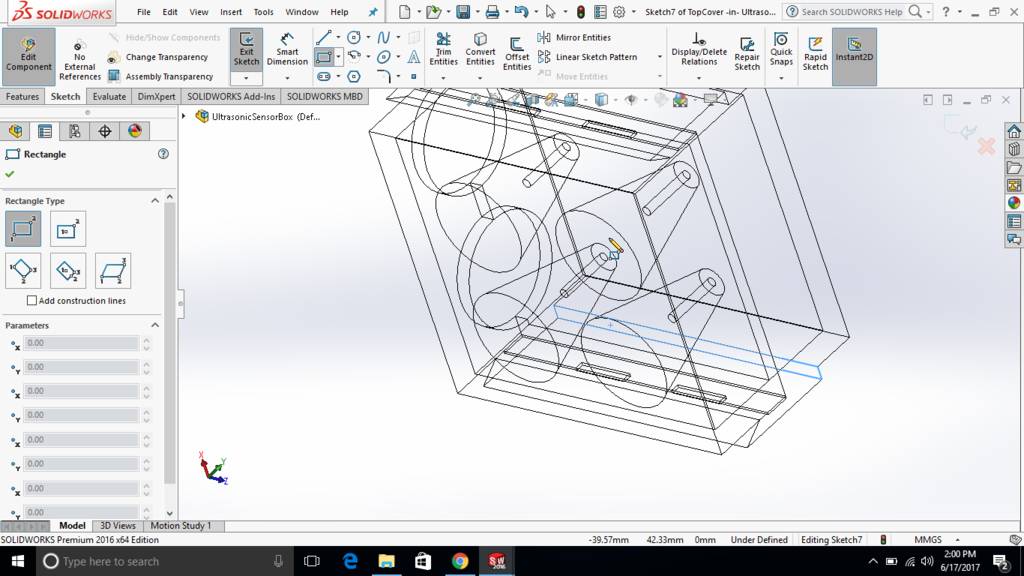

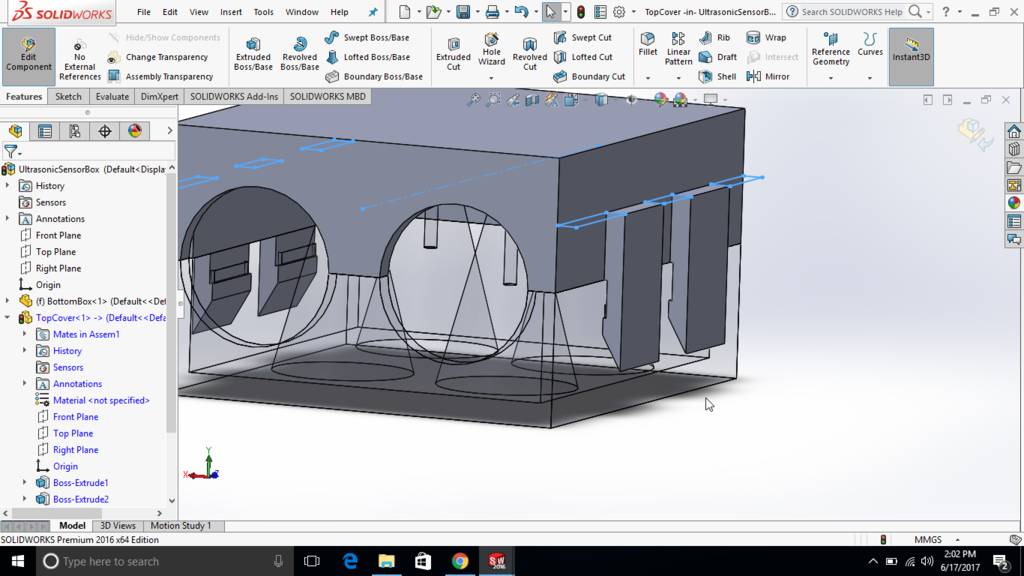

Used wireframe view to see interiers

Used solid mode to see how its actually going to look

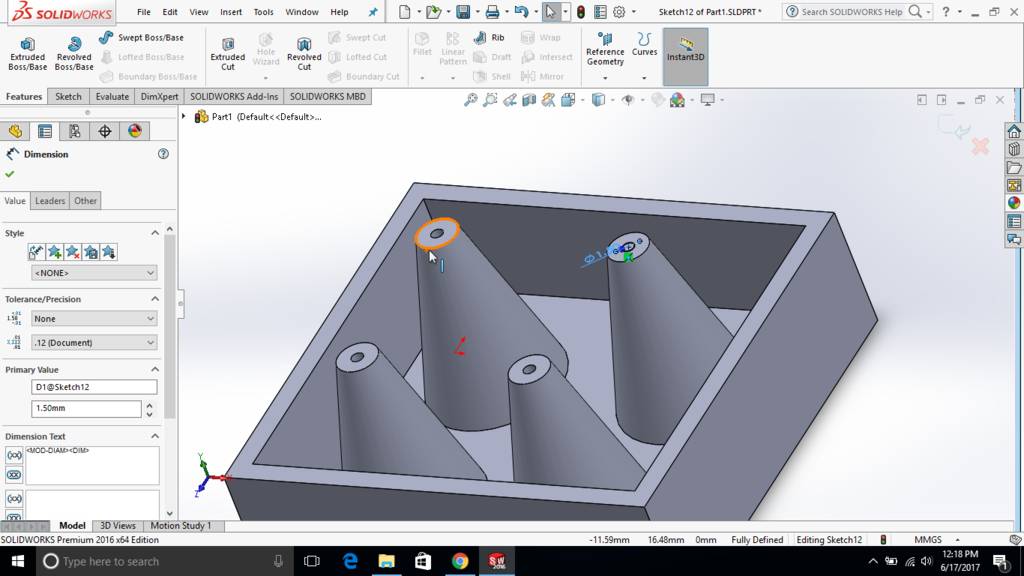

Drilled hole at the top of cone for clamping of board

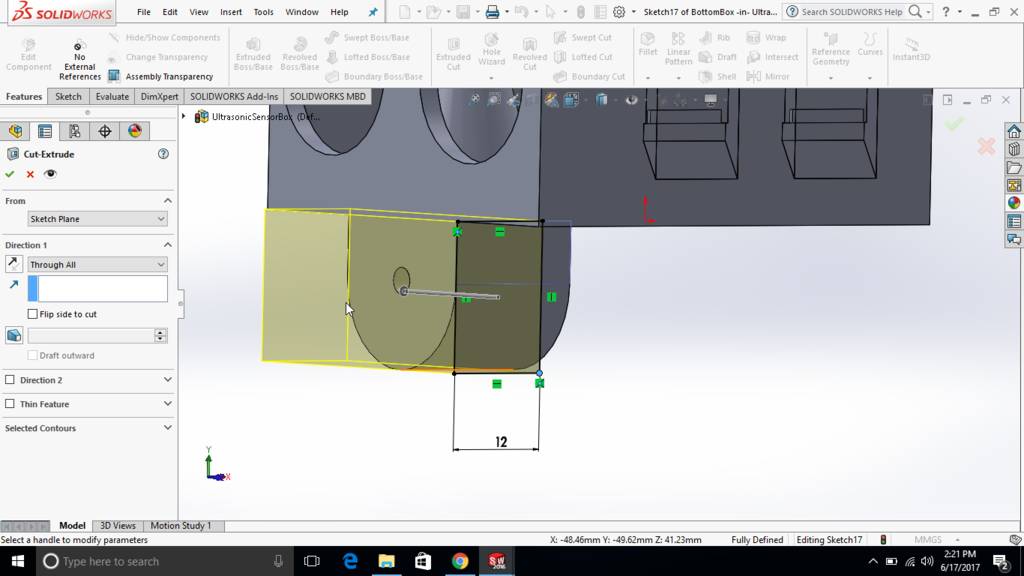

Extrude cut to form opening

Create two of such holes

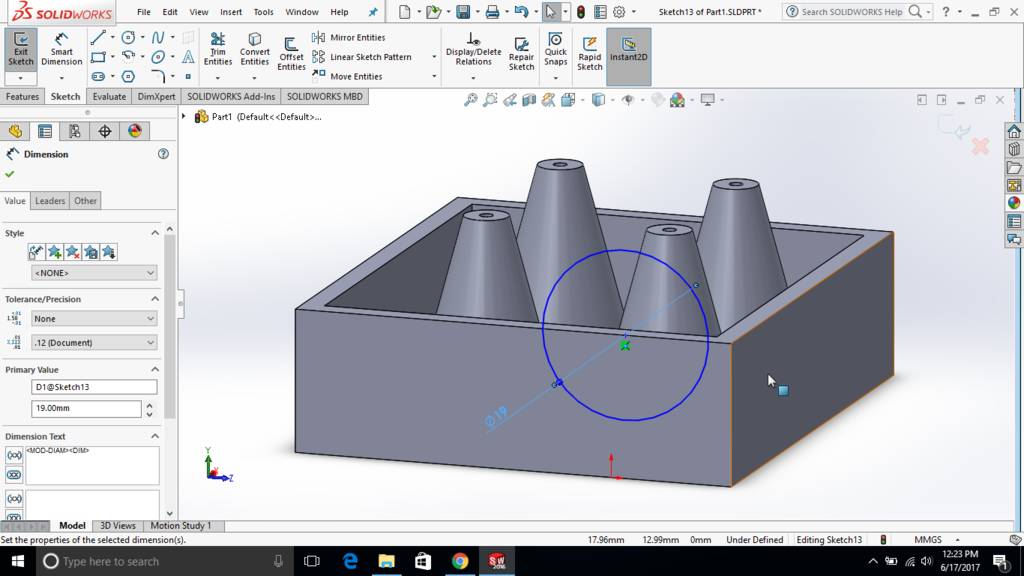

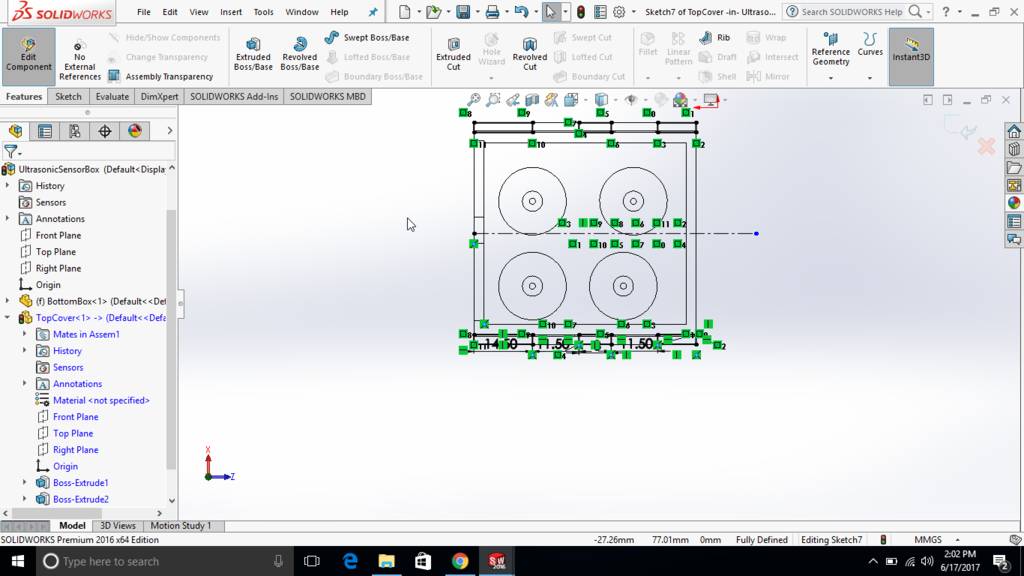

Created extruded notches at the side of a box for snap fitting purpose

This is how notches looks in wireframe mode

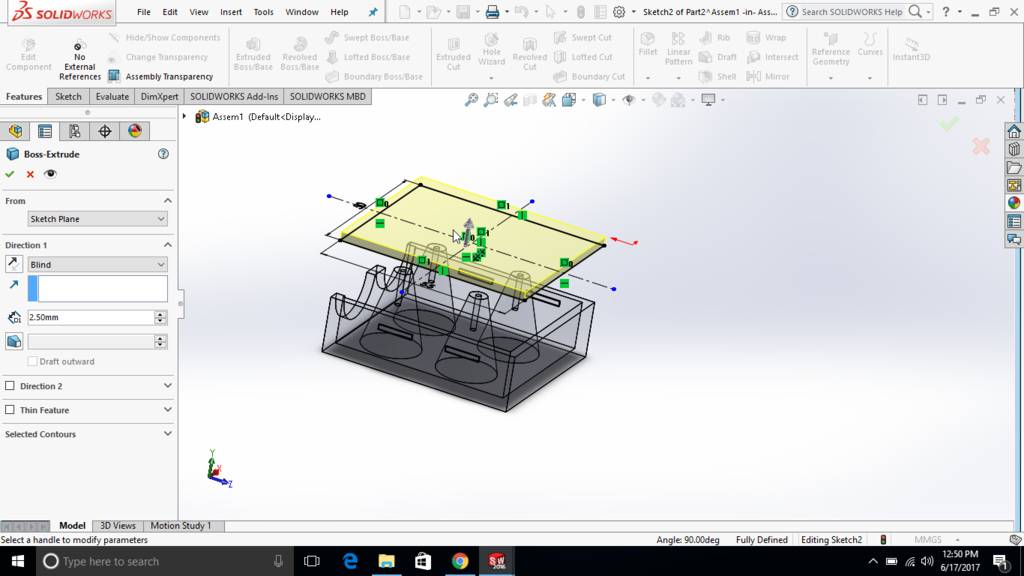

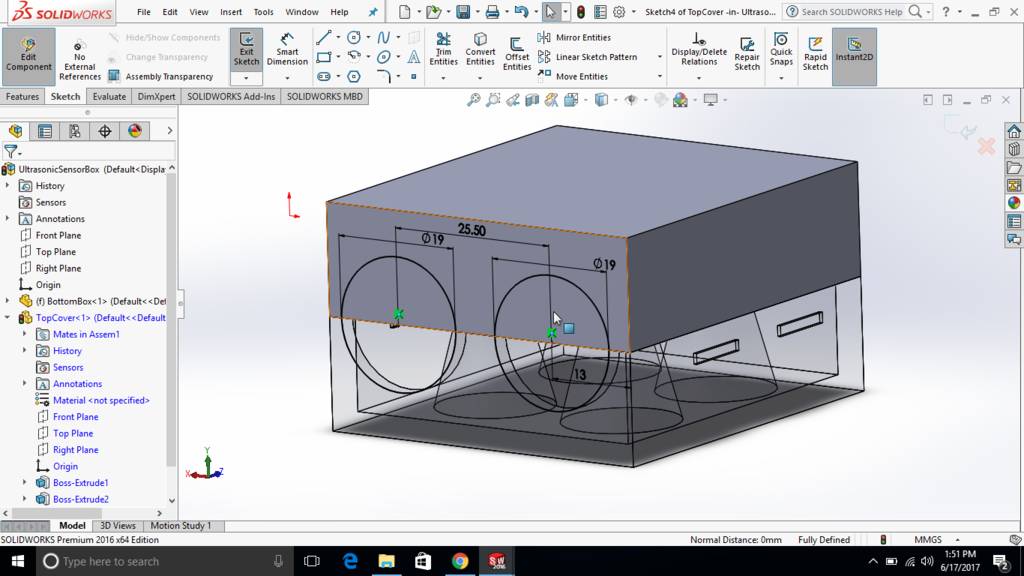

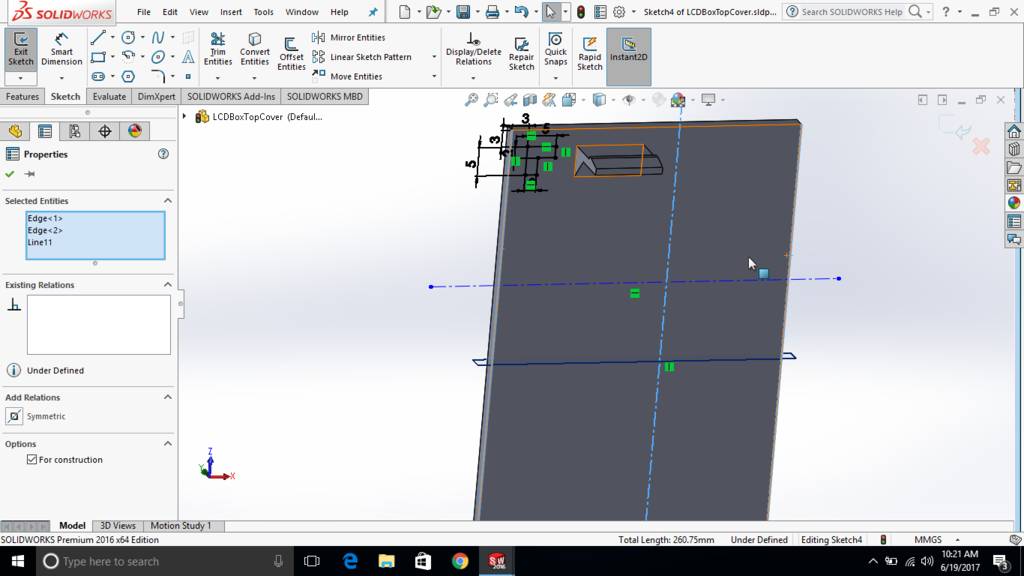

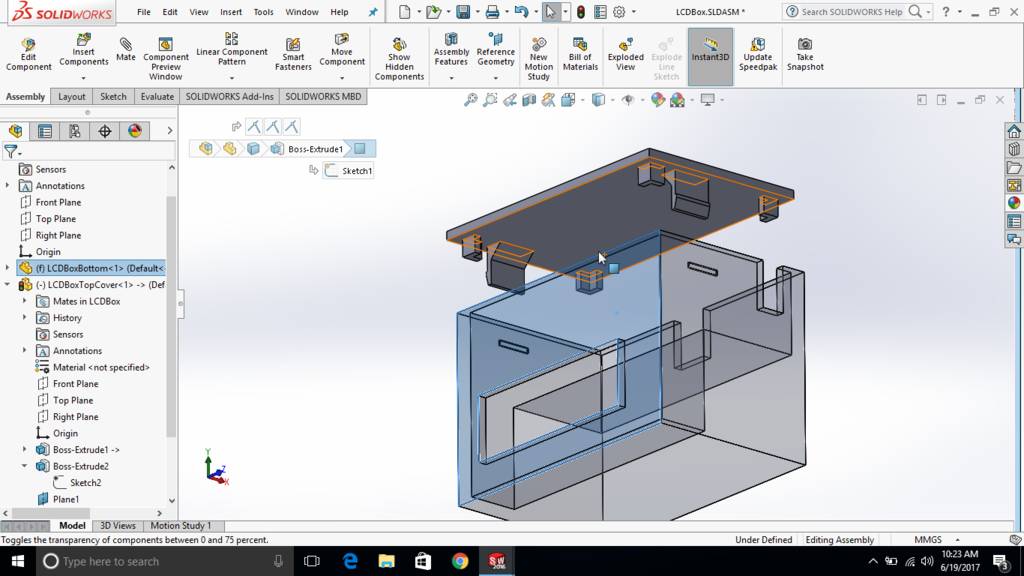

Creating top cap

Skethc extrude to form a plate

Another sketch extrude to form hollow box shape

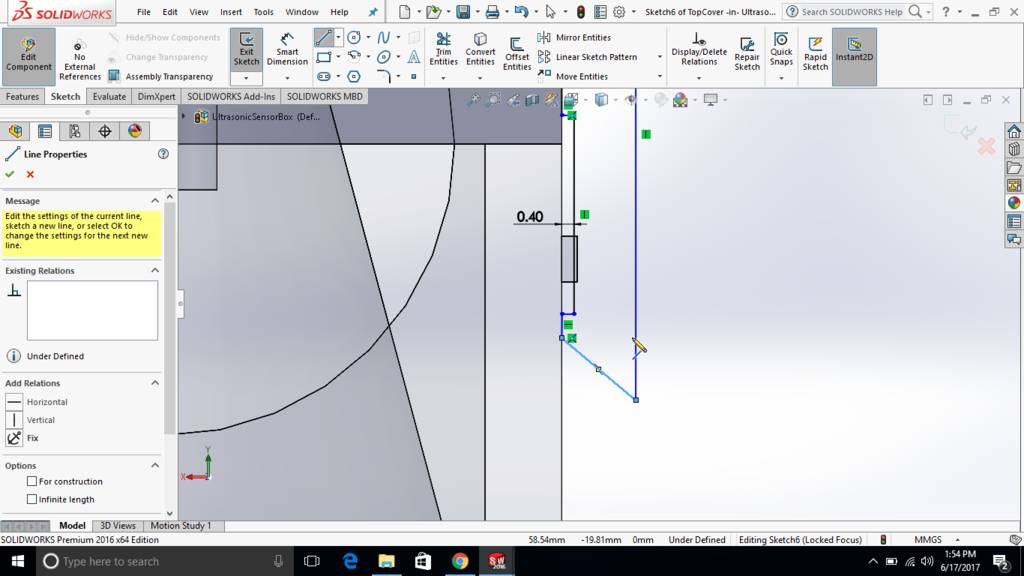

Snap fit jaws are created and extruded

Extruded jaws are aligned with extruded notch to snap fit

Extrude cut from top surface to trim snap jaws

This is how jaws are lookign after extruded cut

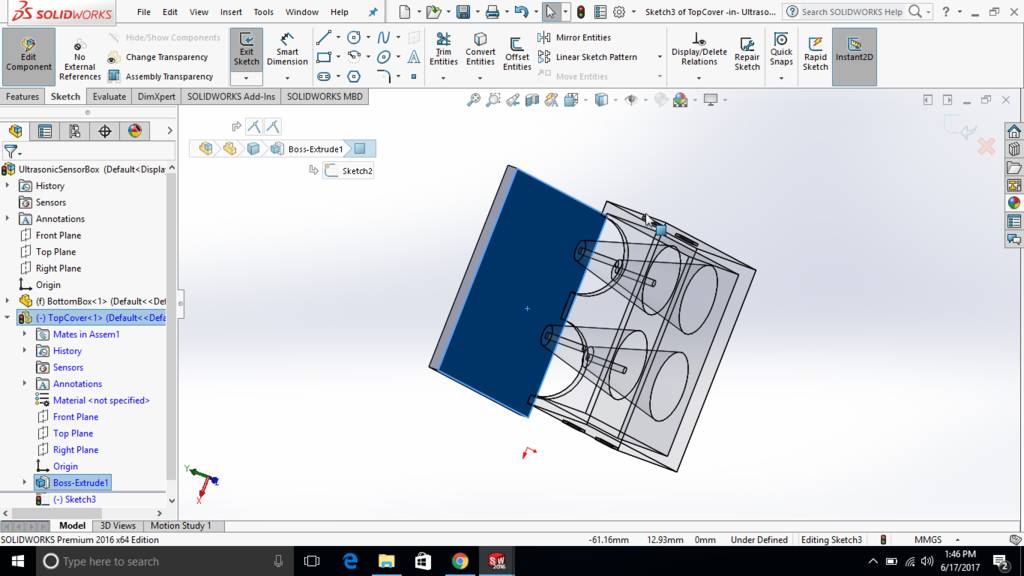

Clamping lug is created

Extrude cut is used to reduce its thickness

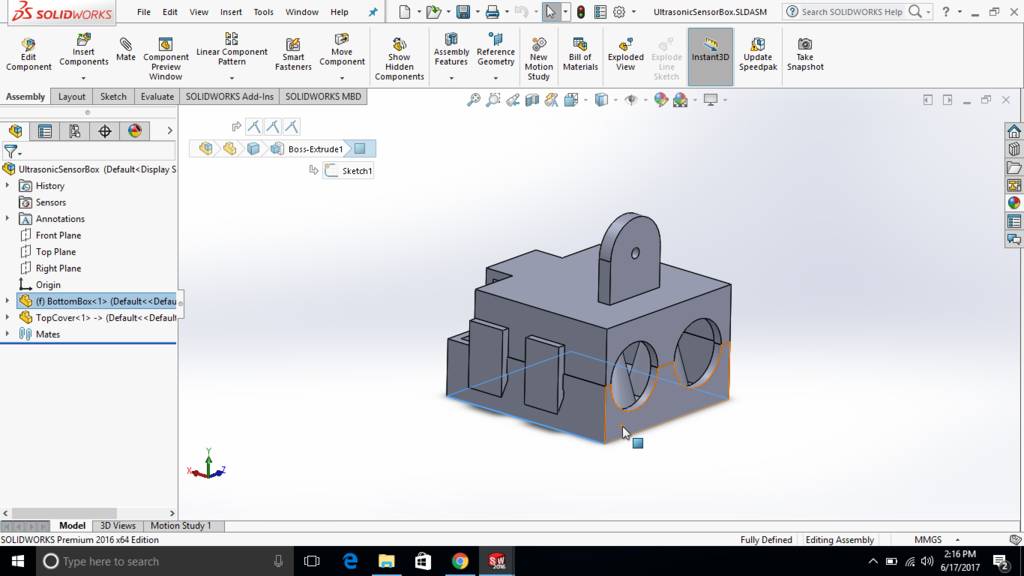

Final ultrasonic slave module case is ready

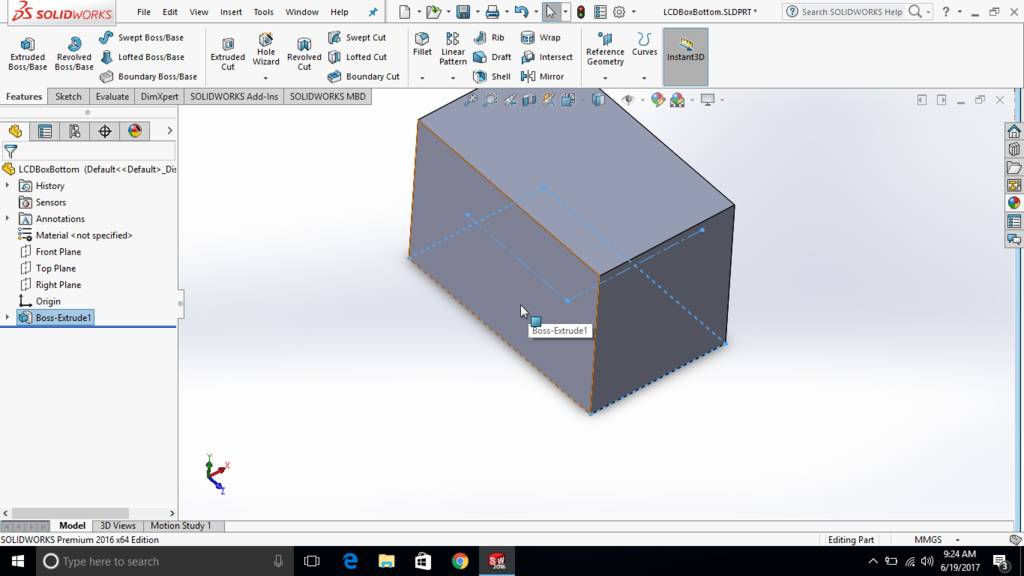

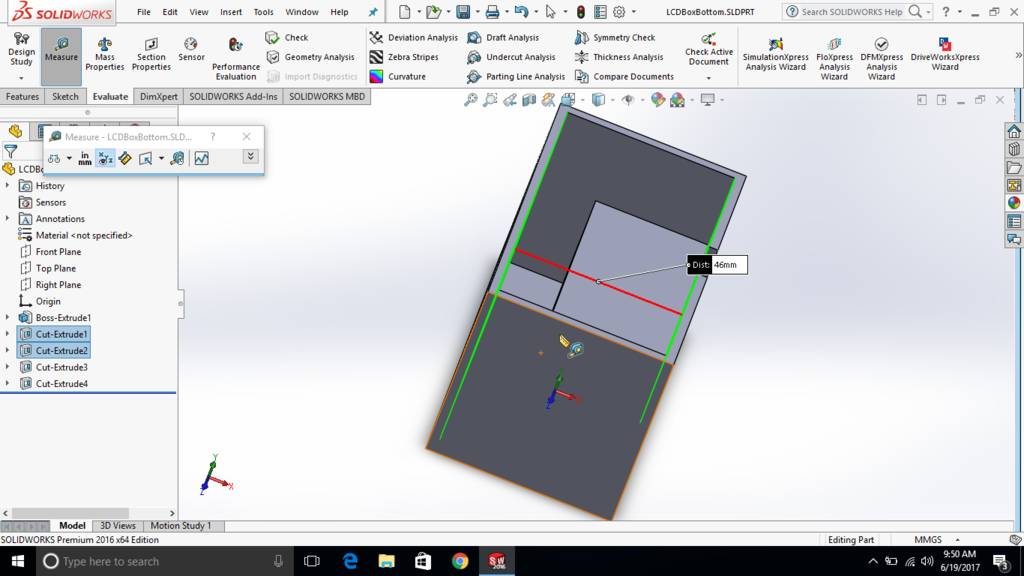

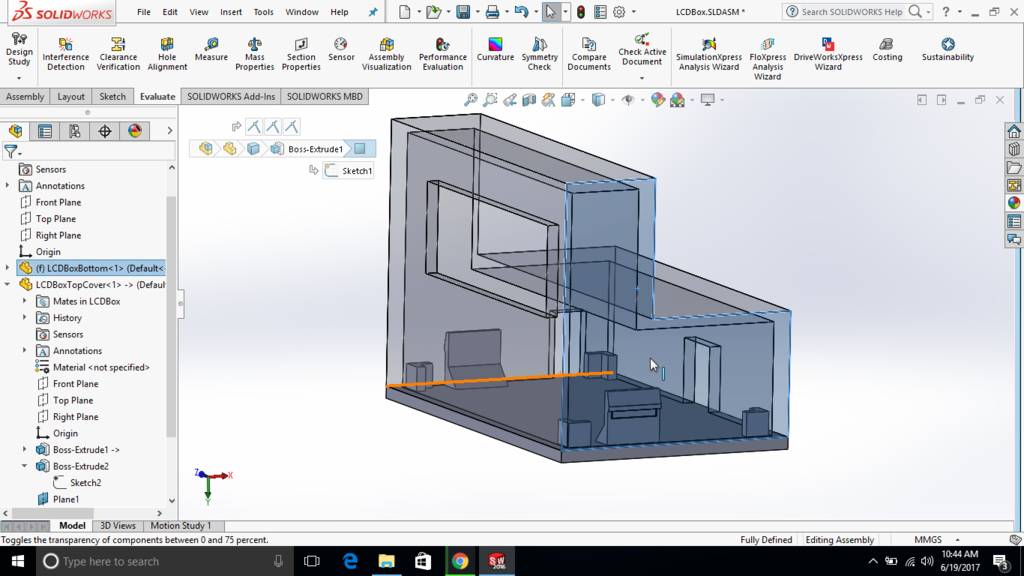

Started master board casing

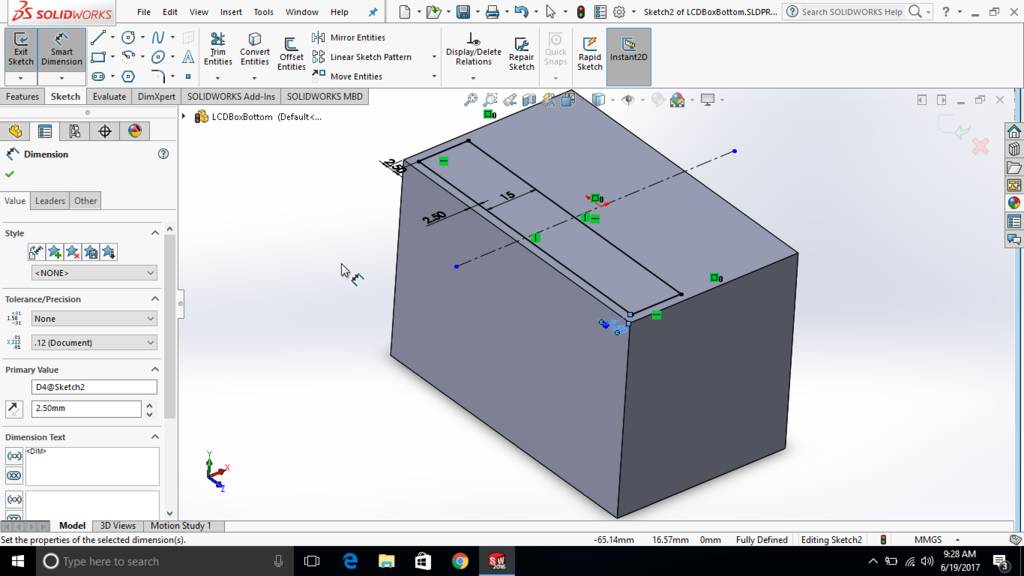

Used a sketch and then extruded

Hollow section is extruded

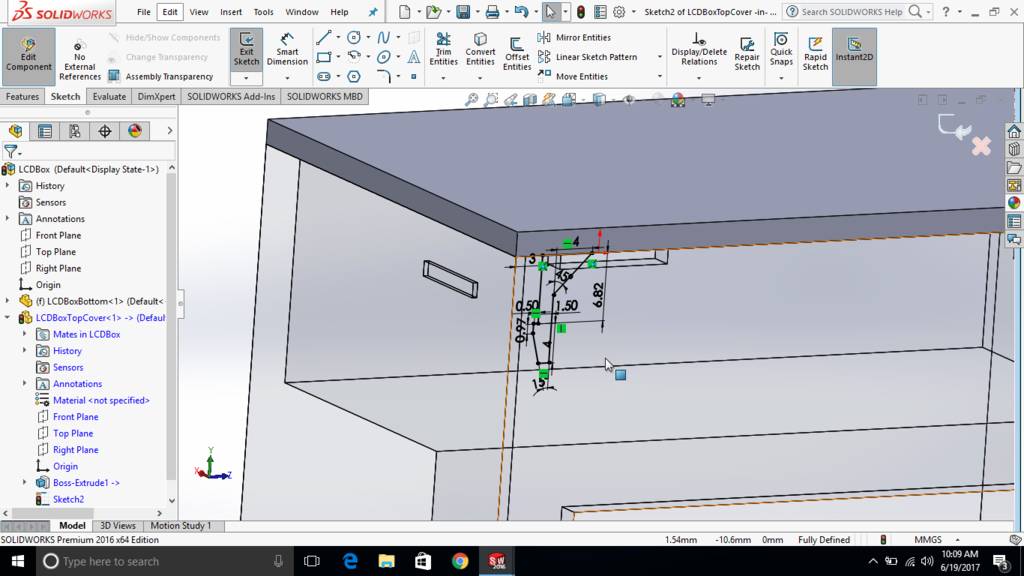

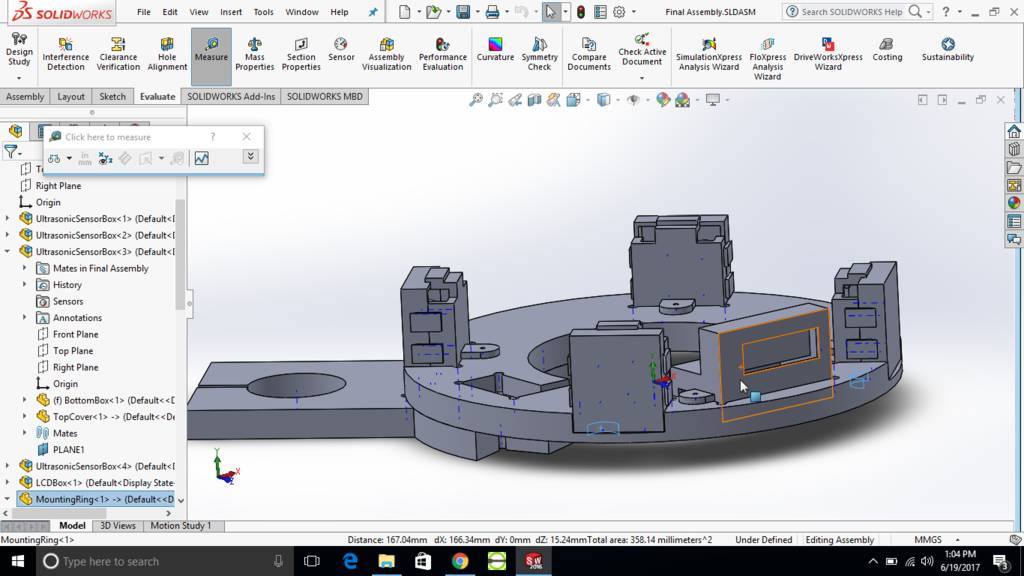

Sketch created at the sides to create opening for LCD

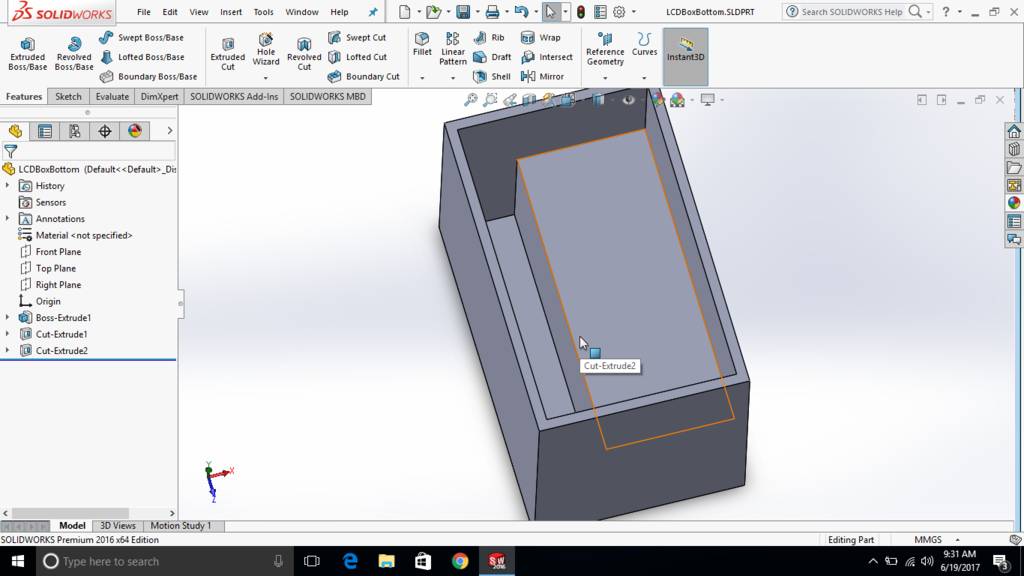

Sketch is then extrude cut to form an opening

This is how its looking in solid

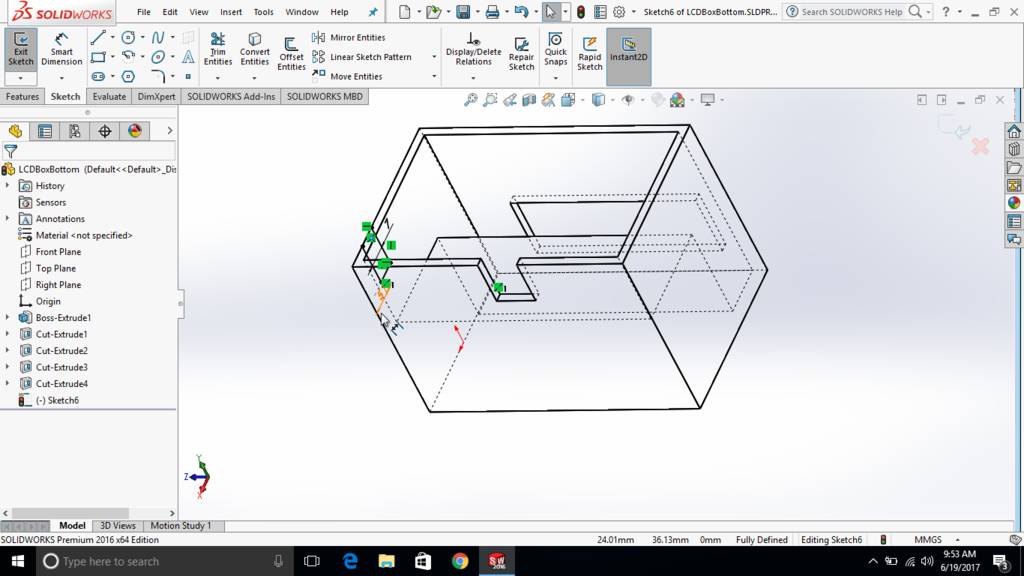

Sketch created at back wall

Use of distance tool

Second notch to insert another set of wires

Both the notches can be seen in screenshot

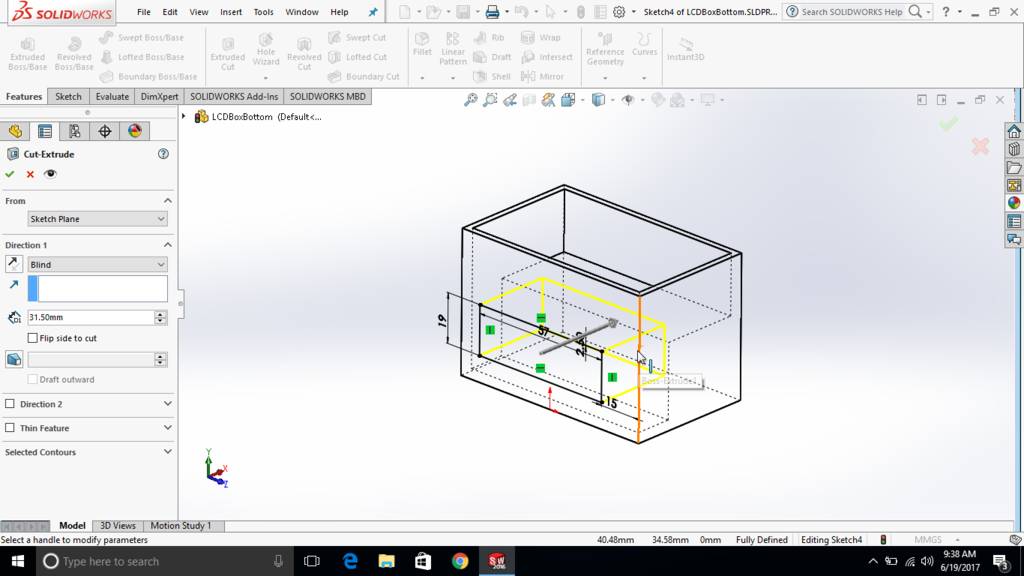

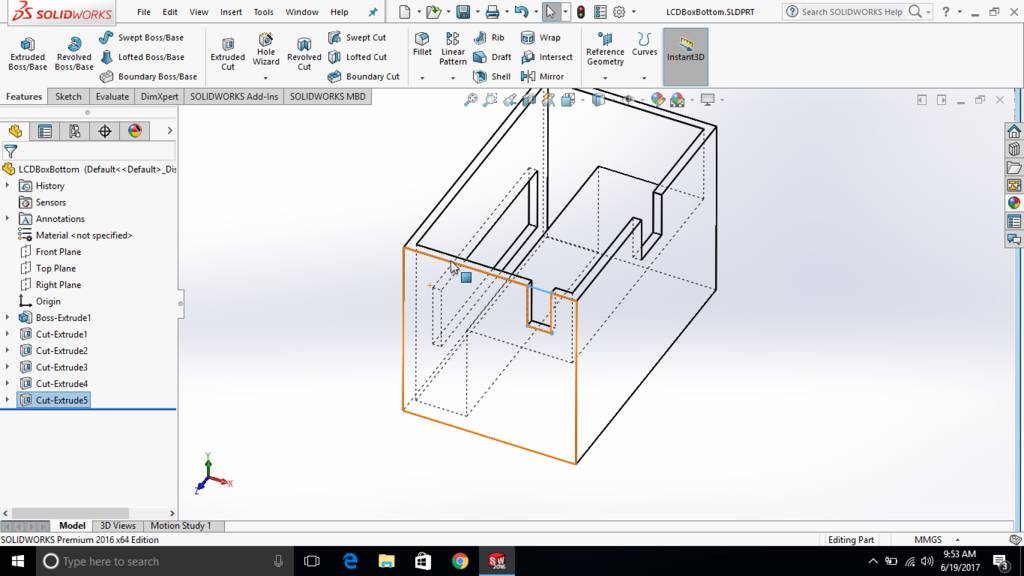

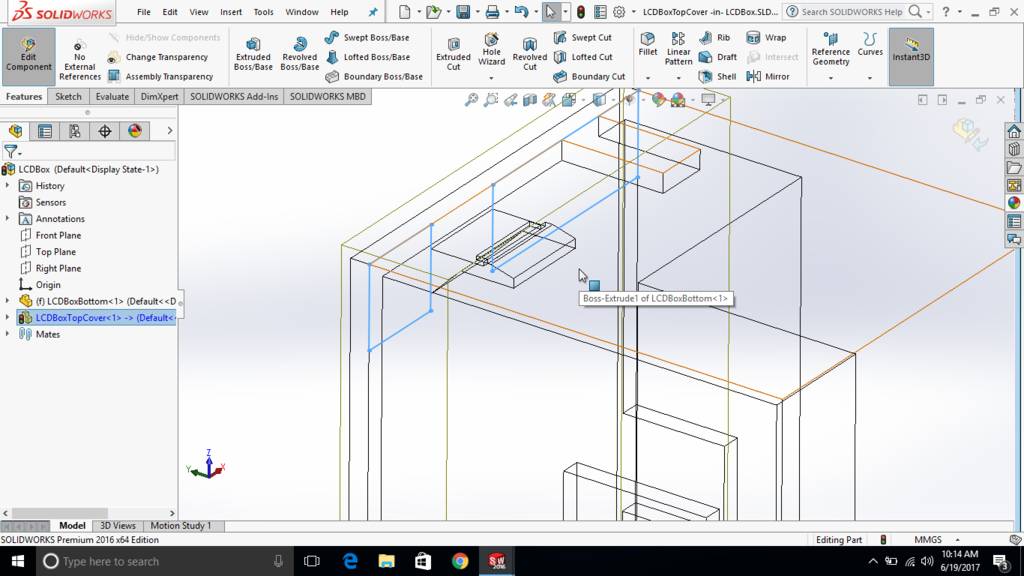

Created projected notches for making snap fitting

Created extruded jaws for snap fitting

Jaws are then trimmed using extrude cut feature

This is how it look like

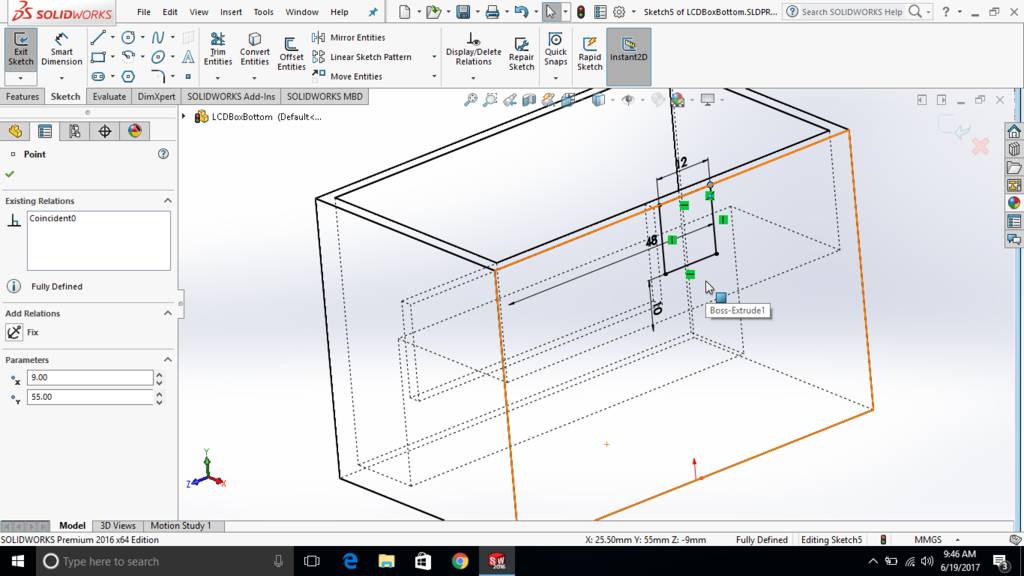

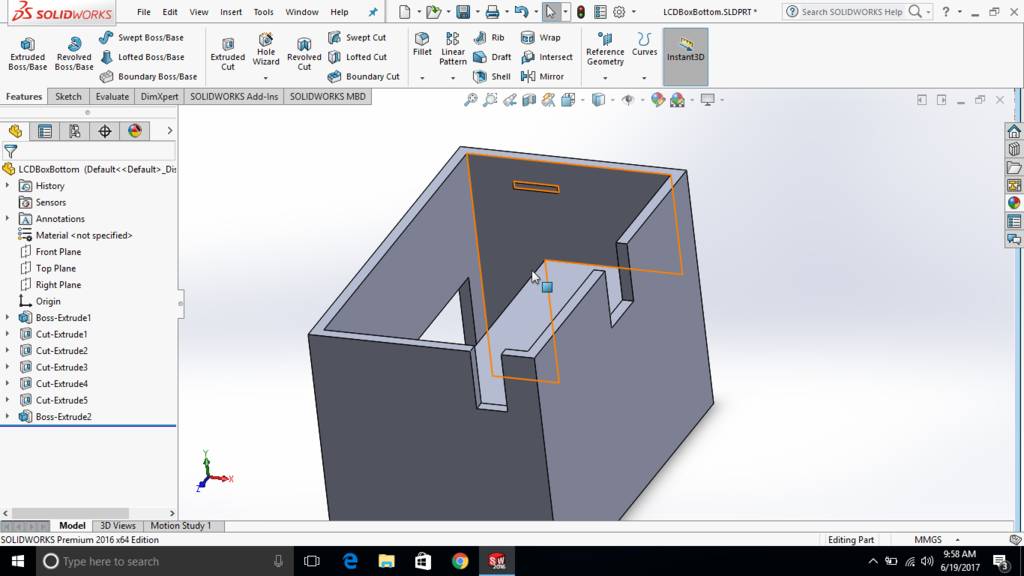

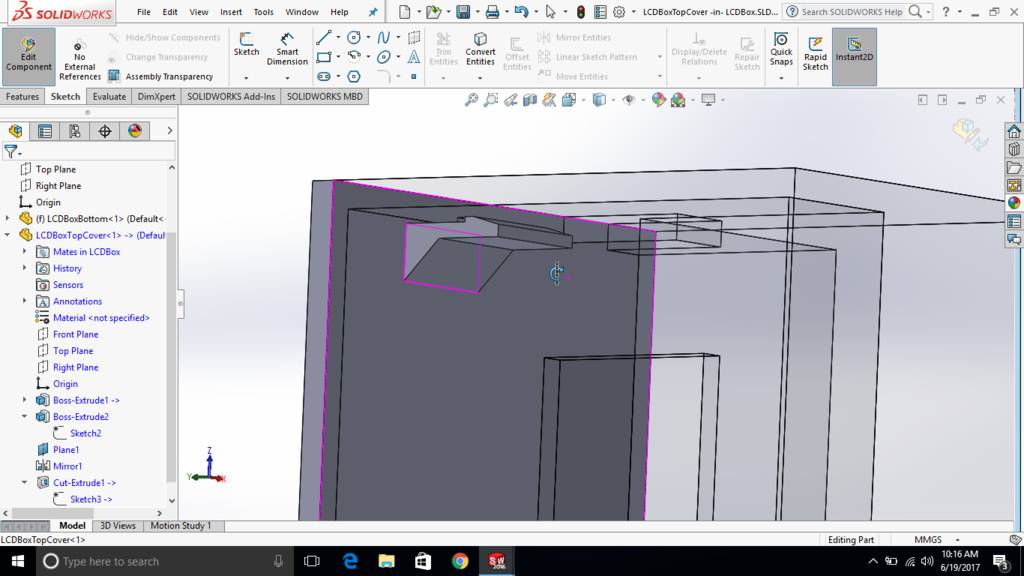

Created locators to prevent top plate from moving

This is how top plate is then mounted over master board box

Inverted upside down. This is a final position of a box

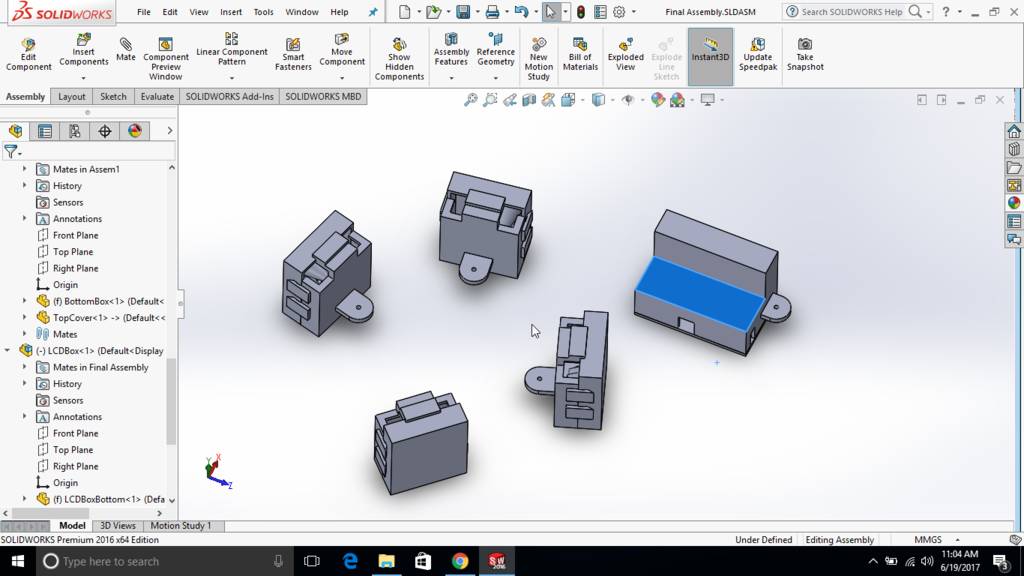

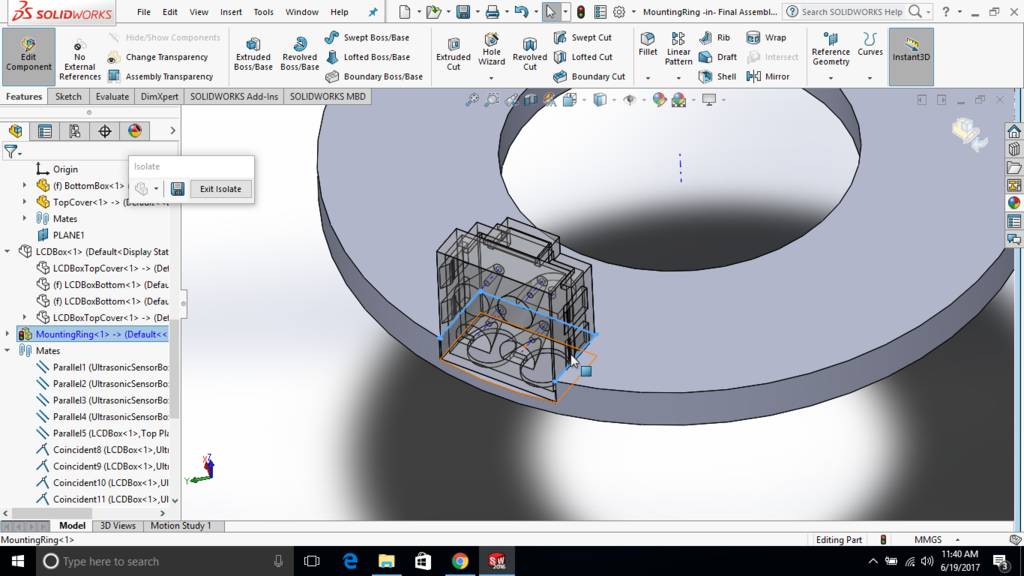

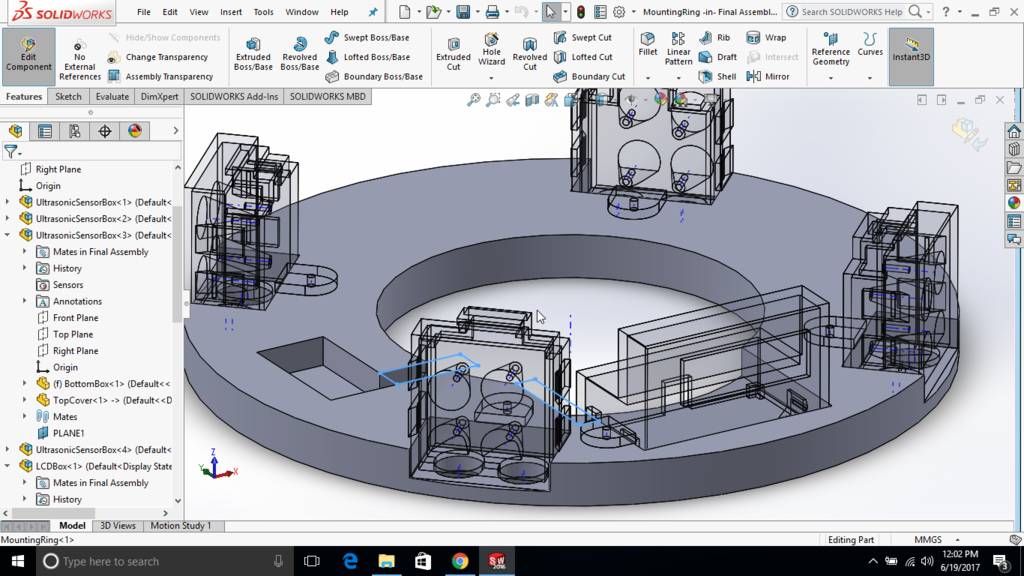

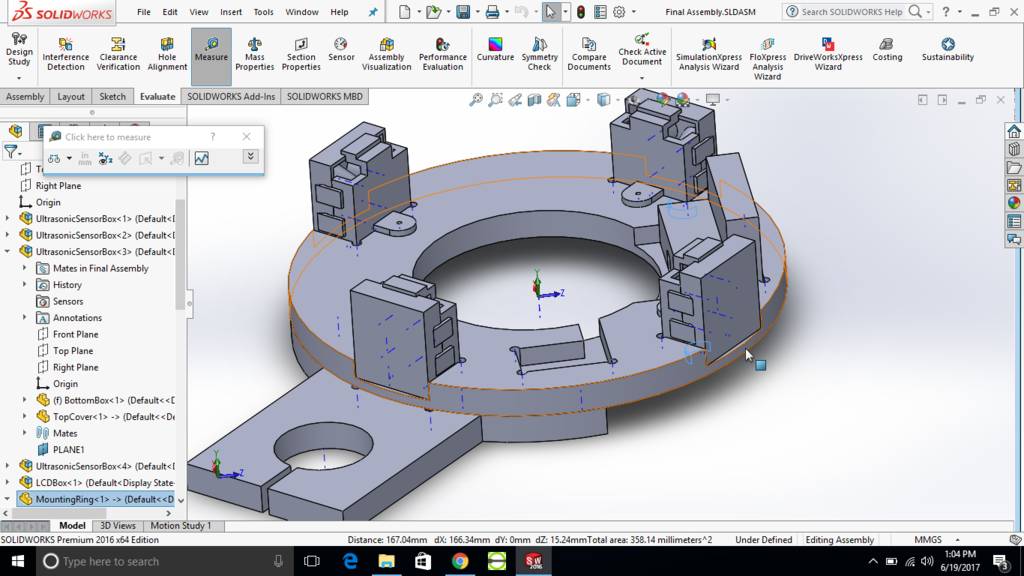

All components are taken in assembly mode

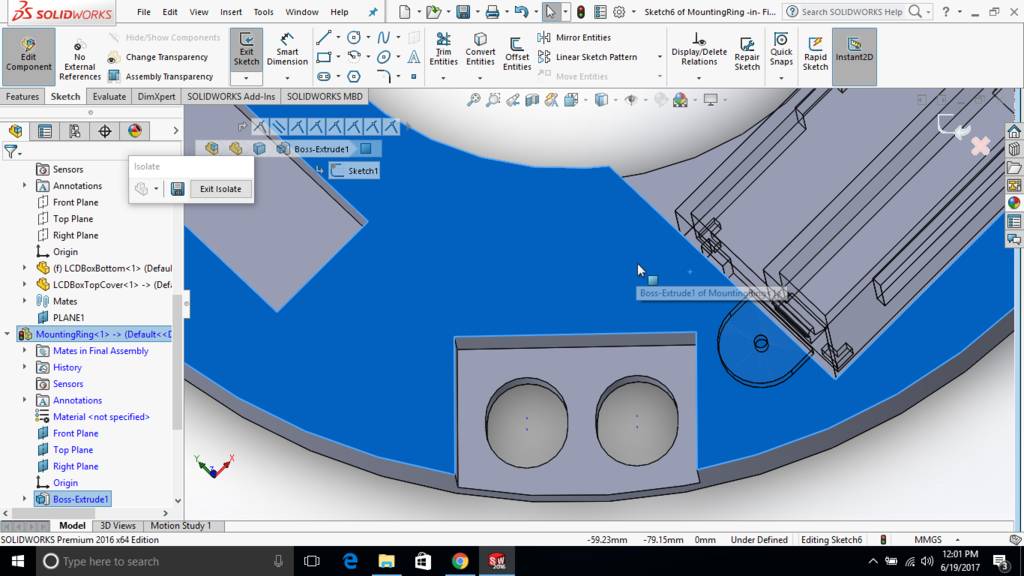

Mounting ring is then created in assembly mode

Cavity is created in mounting ring

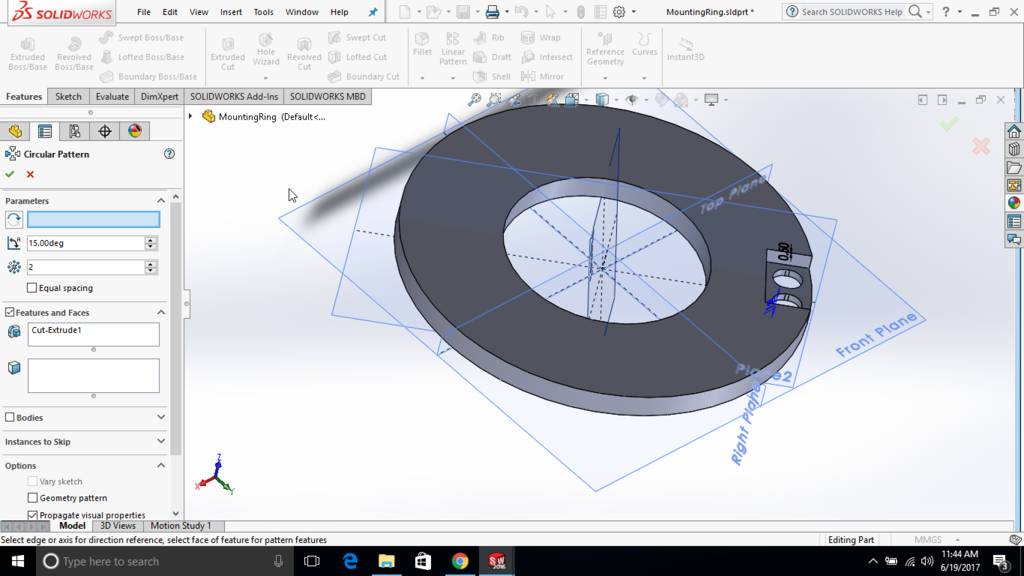

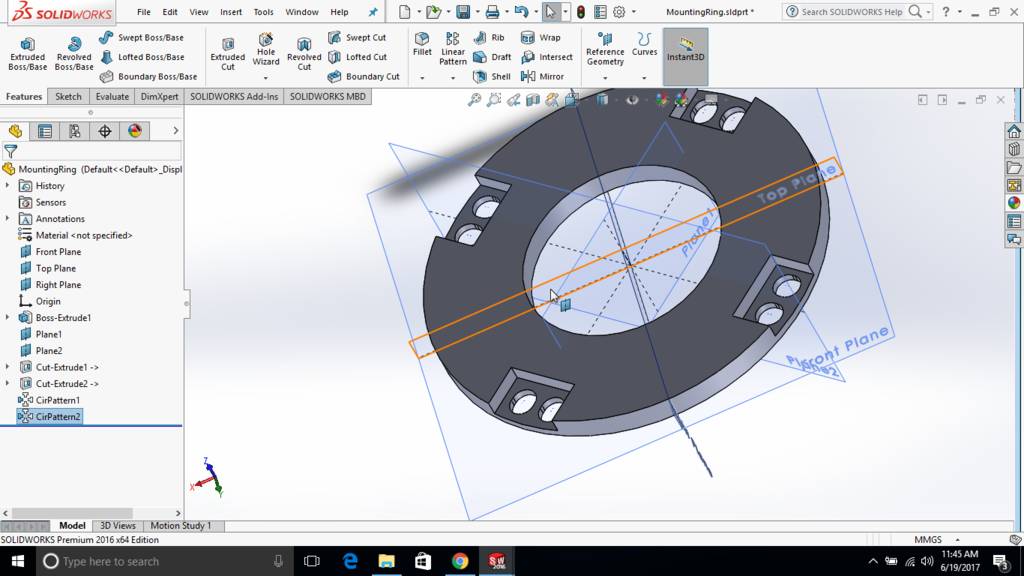

Mounting ring is then edited separately

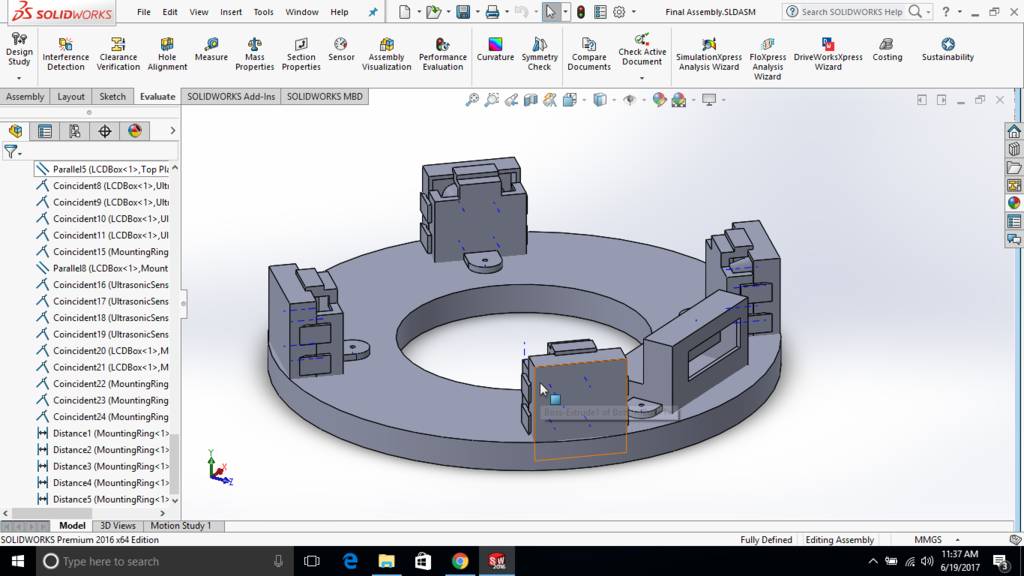

Pockets are then mirrored and total 4 pockets are created

Master board is also placed at location

This is how it looks in wireframe mode

This is how it looks at final

LCD opening is at the front

Files for download

| 3D Design Files made using Solidworks | DesignsSolidworks.zip |

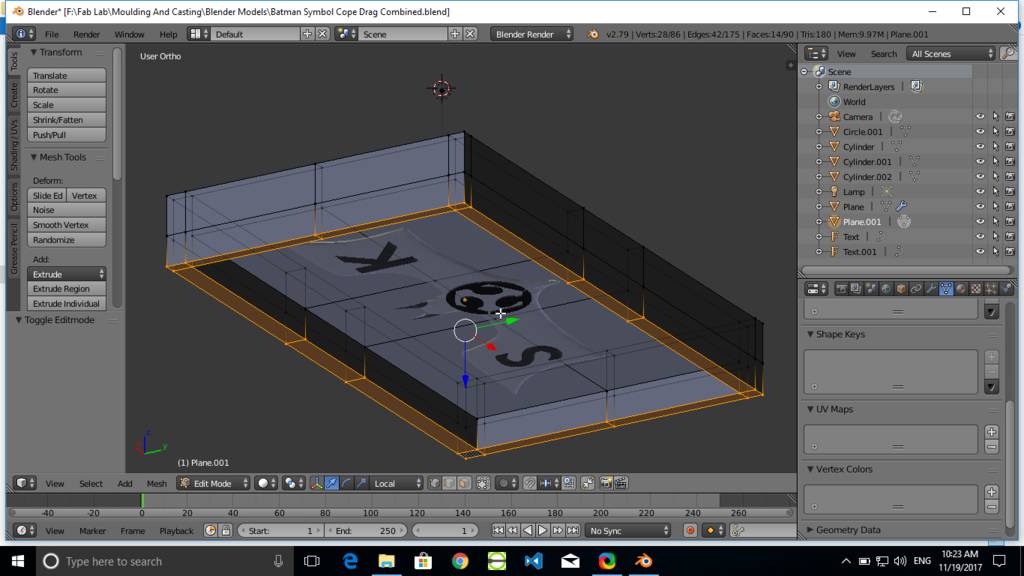

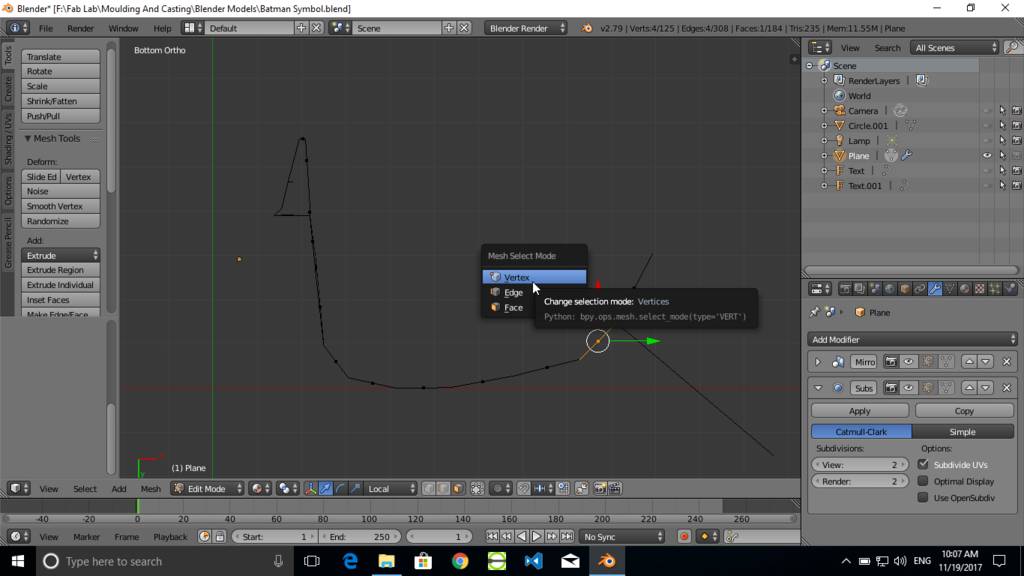

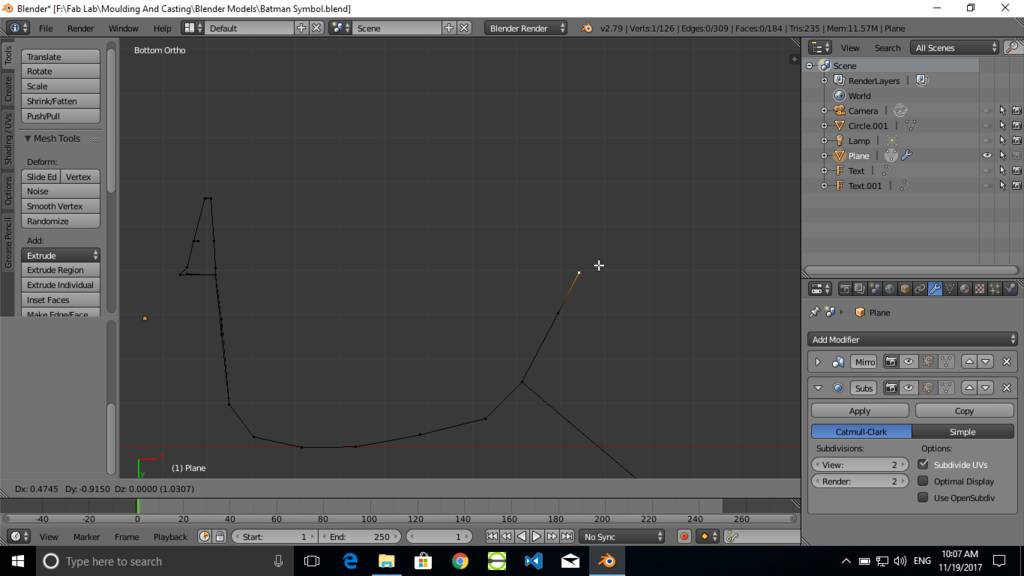

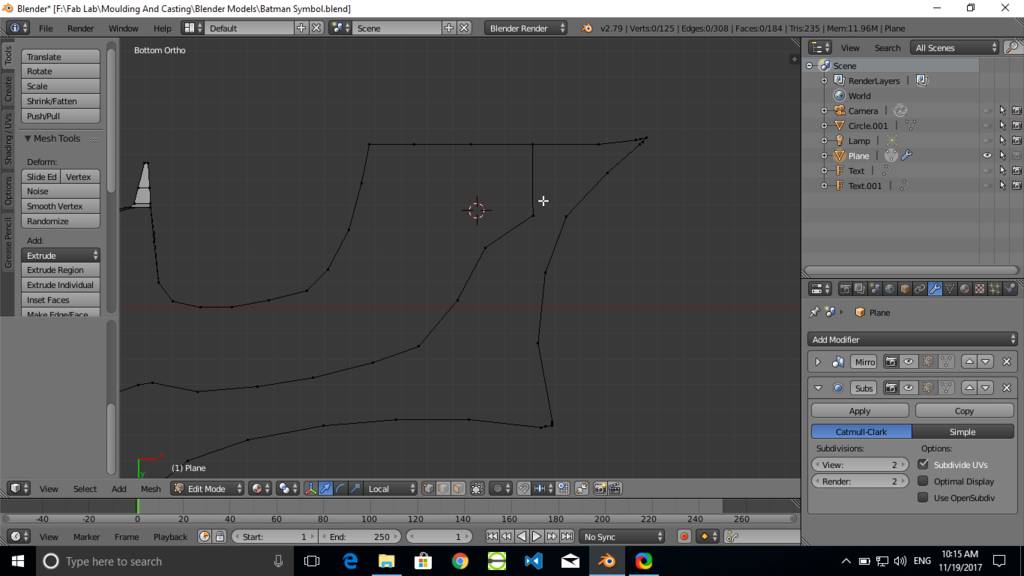

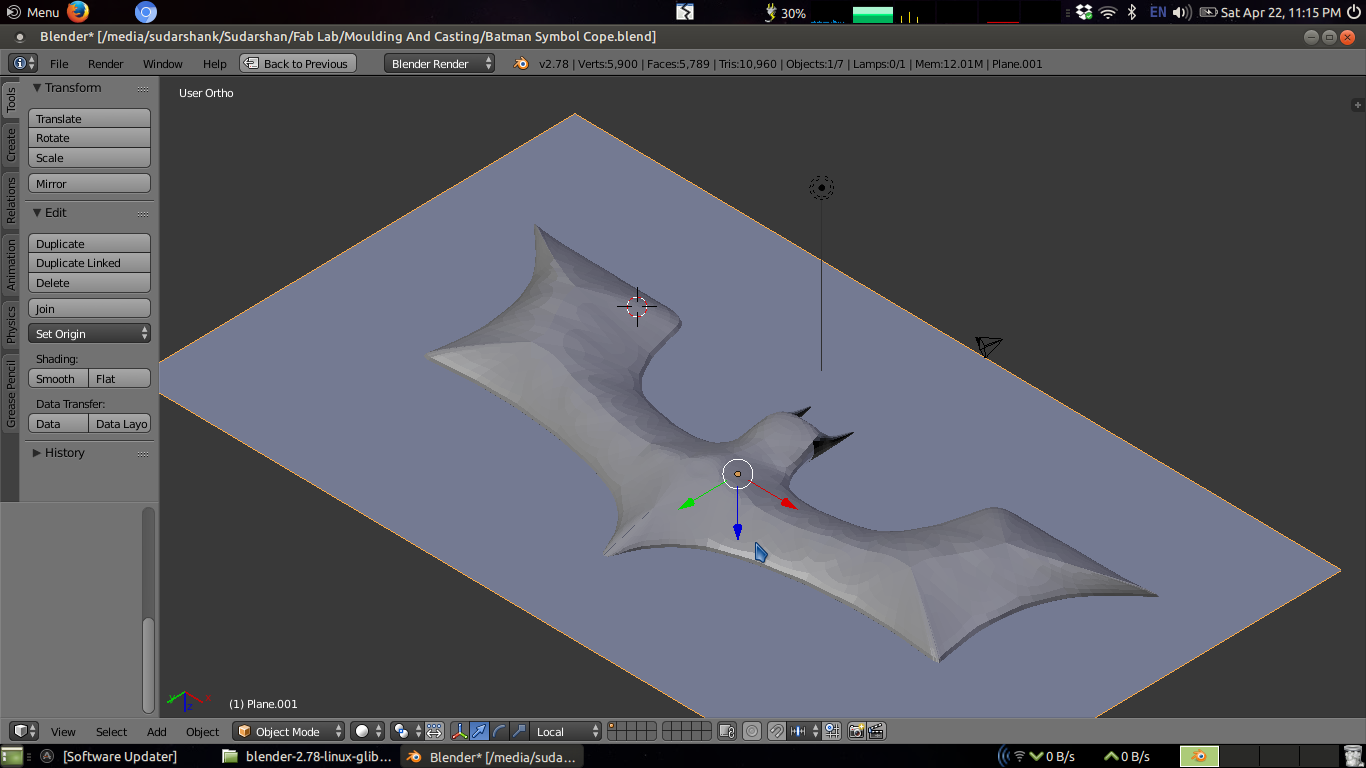

Exploring Blender to make model for moulding and casting assignment

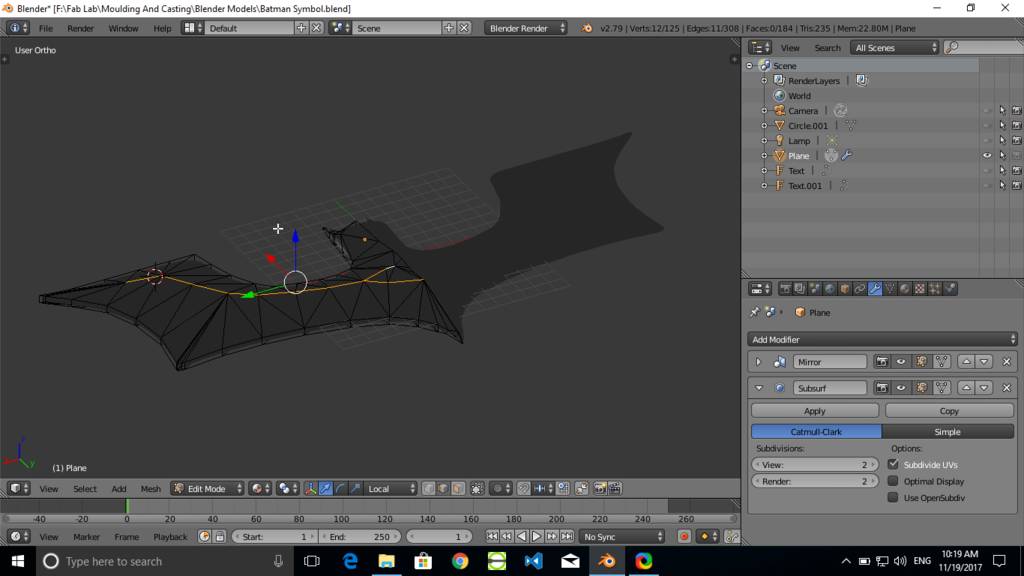

Use Numpad 7 Key for top view

Press numpad 5 to be in ortho mode.

Insert line and press Tab to enter in edit mode.

Press ctrl tab and select vertex select mode.

Select vertex and press E to extrude.

Make a shape as required. as shown in screenshot

Extrude vertex to form a required Shape

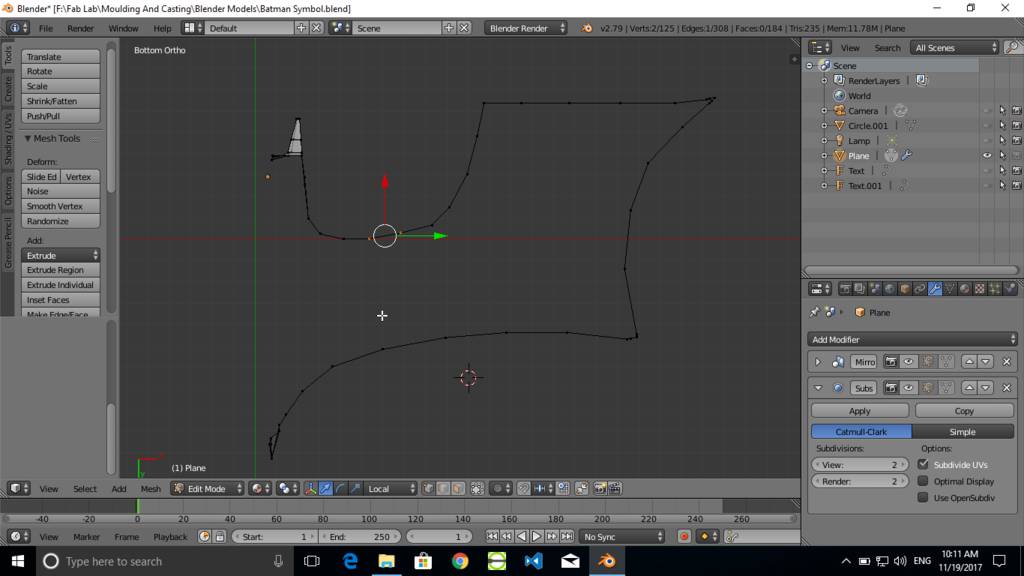

Draw complete outline as required

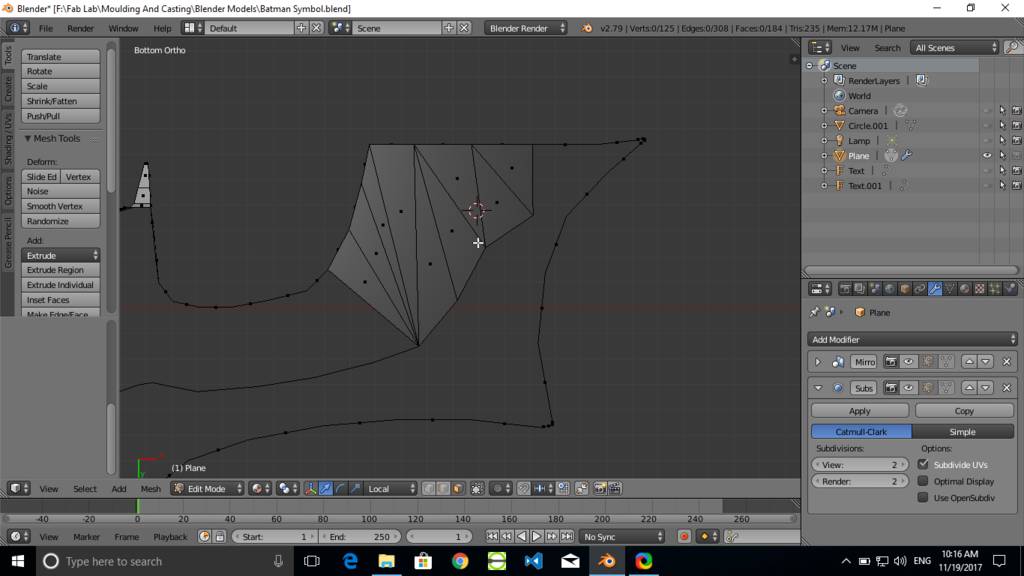

Add another line geometry

Join two points

Created line joining two vertrice points

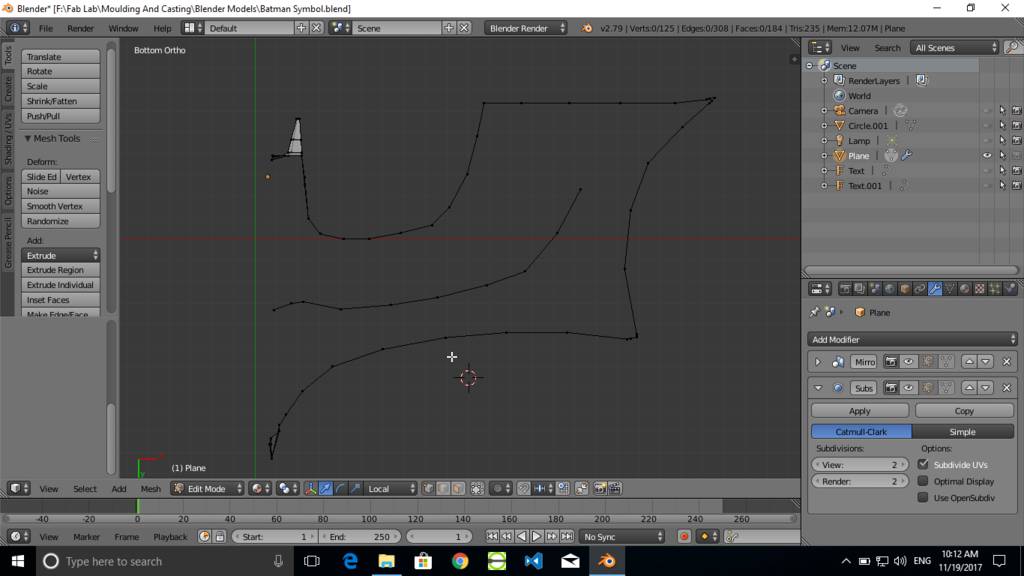

Create faces

Create remainaing faces to form a geometry

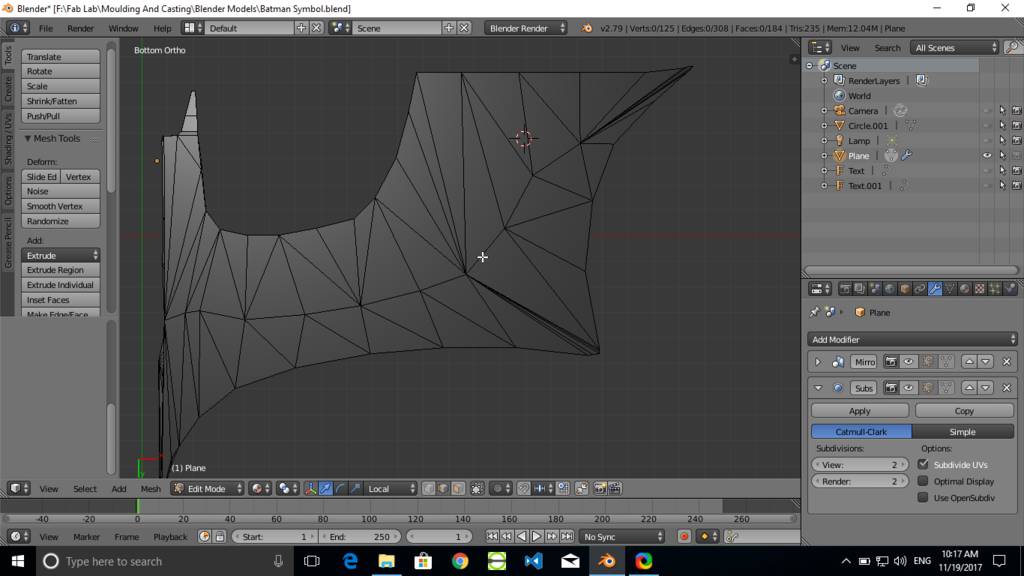

Create thickess to model

Manually move edges up to form required thickness and geometry

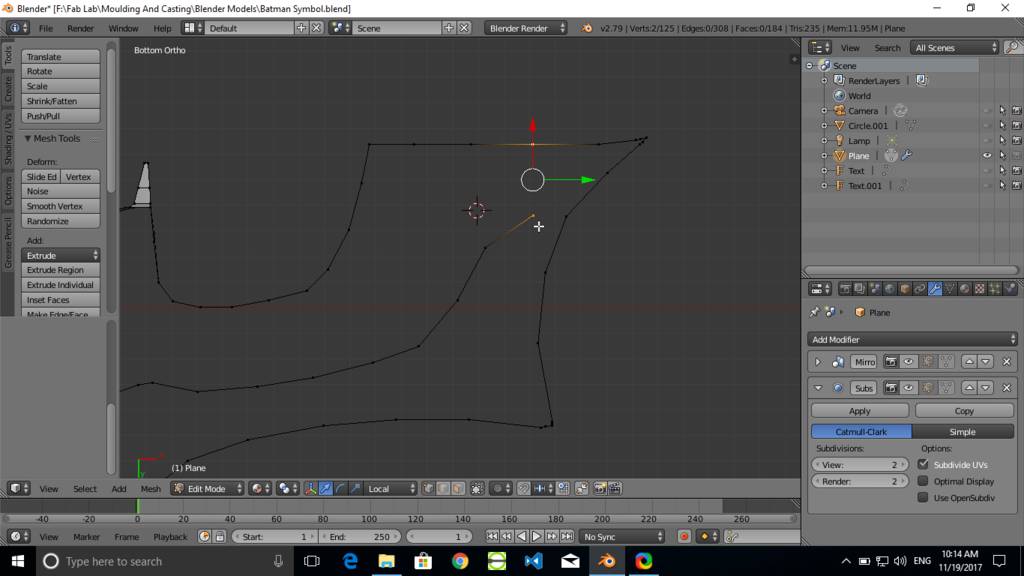

Use modifiers

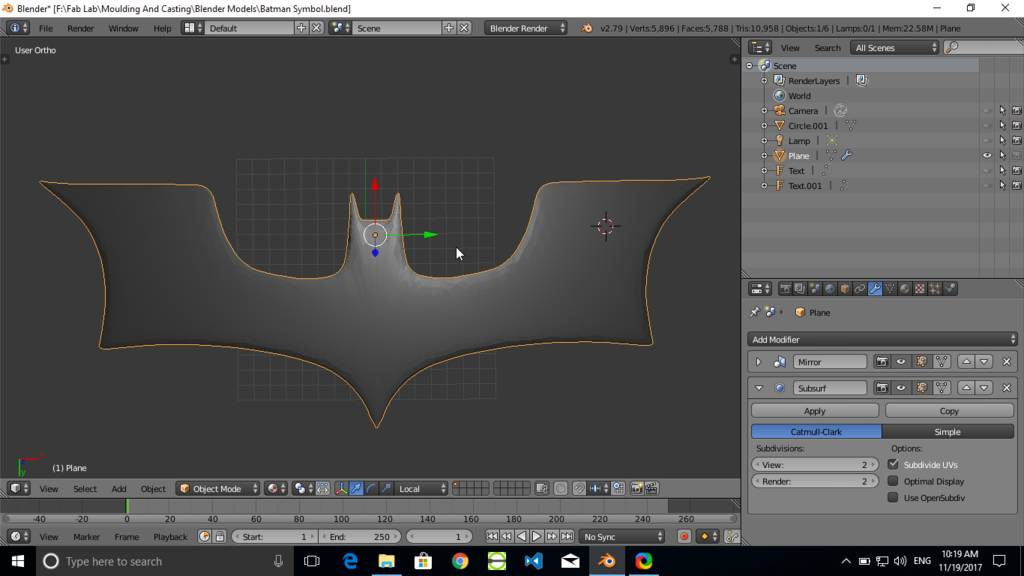

- Add mirror modifier to create mirrored geometry

- Add subsurf modifier to create smooth surface of geometry

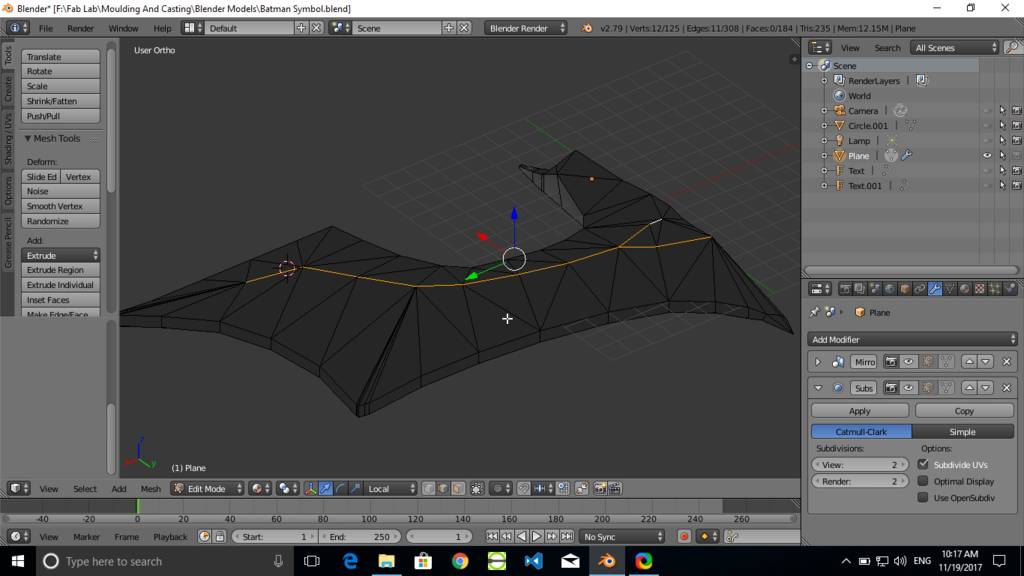

Basic completed model for batman symbol

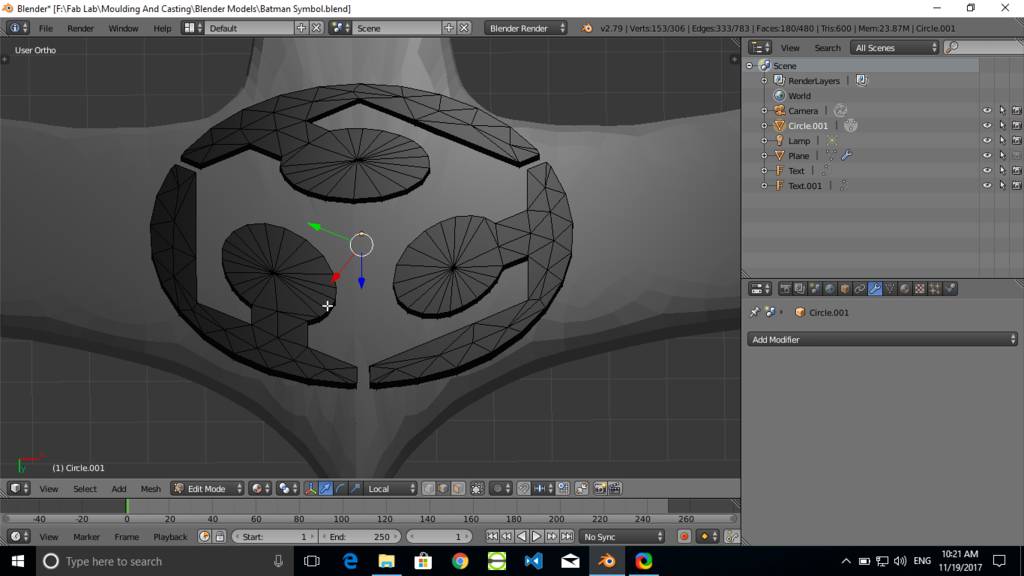

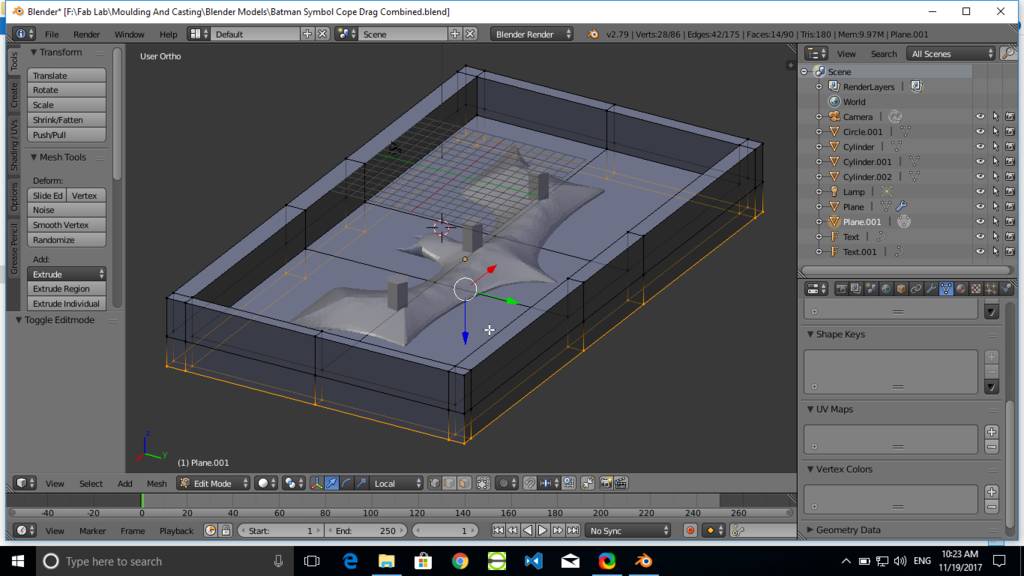

Created fabacademy sumbol

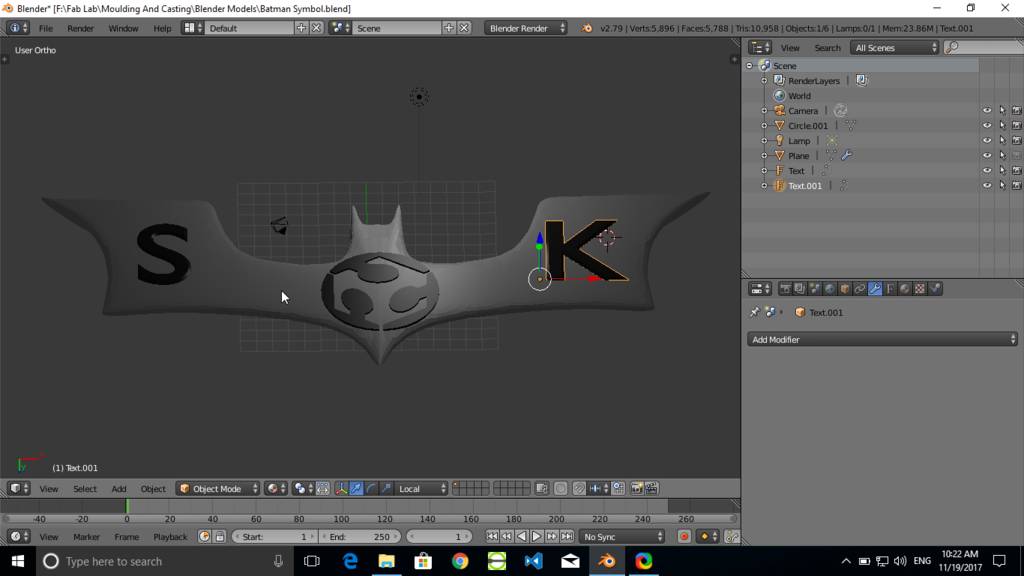

Creating letters

Crerated parting plane

Form a rectangular mould cavity

At the bottom it looks like this