Computer-Controlled Machining

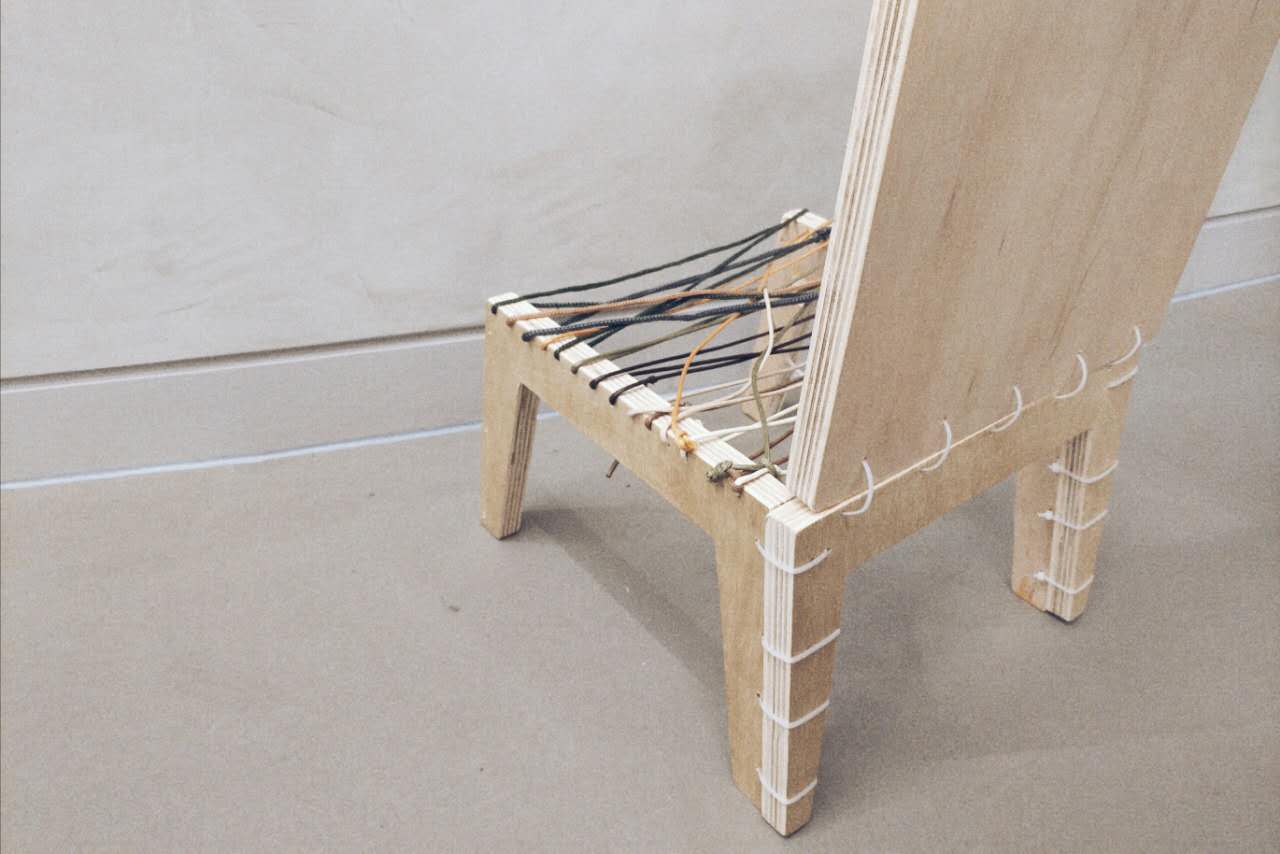

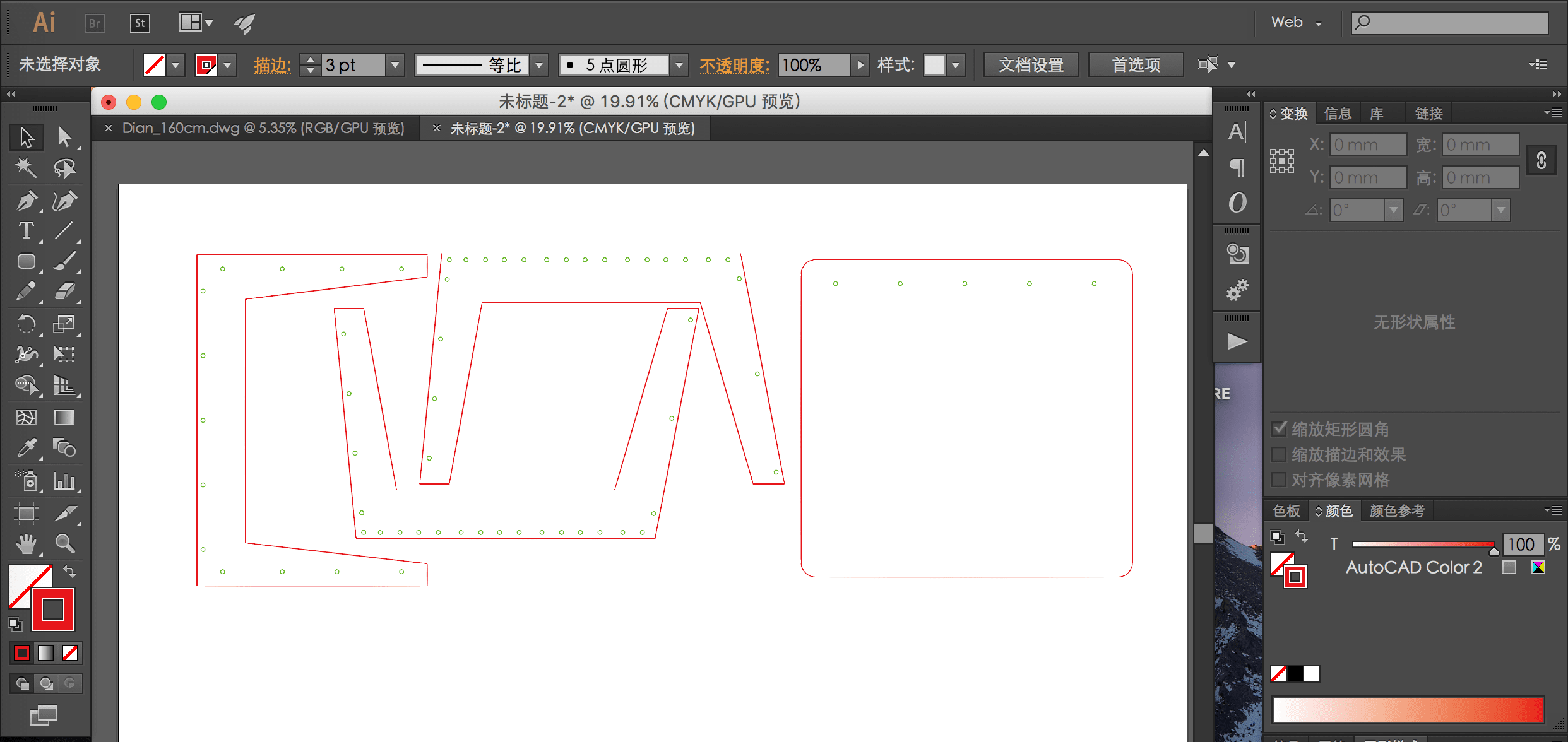

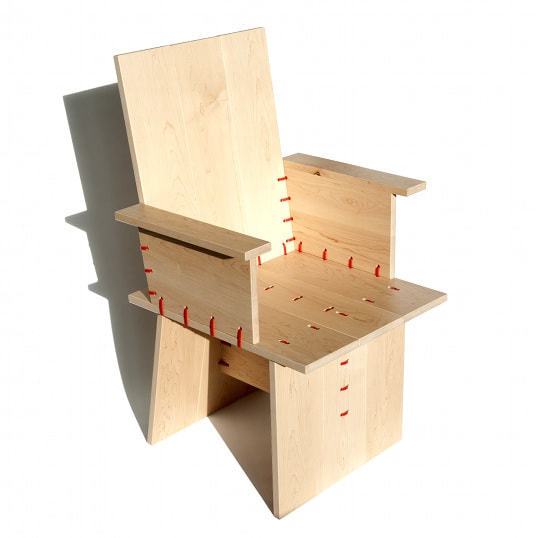

My Idea is a folding chair, which can be fold into a standing desk. The connecting structure was inspired by this website OpenDesk “zip tie chair”. Here to download the .Ai file: desk_dian.ai

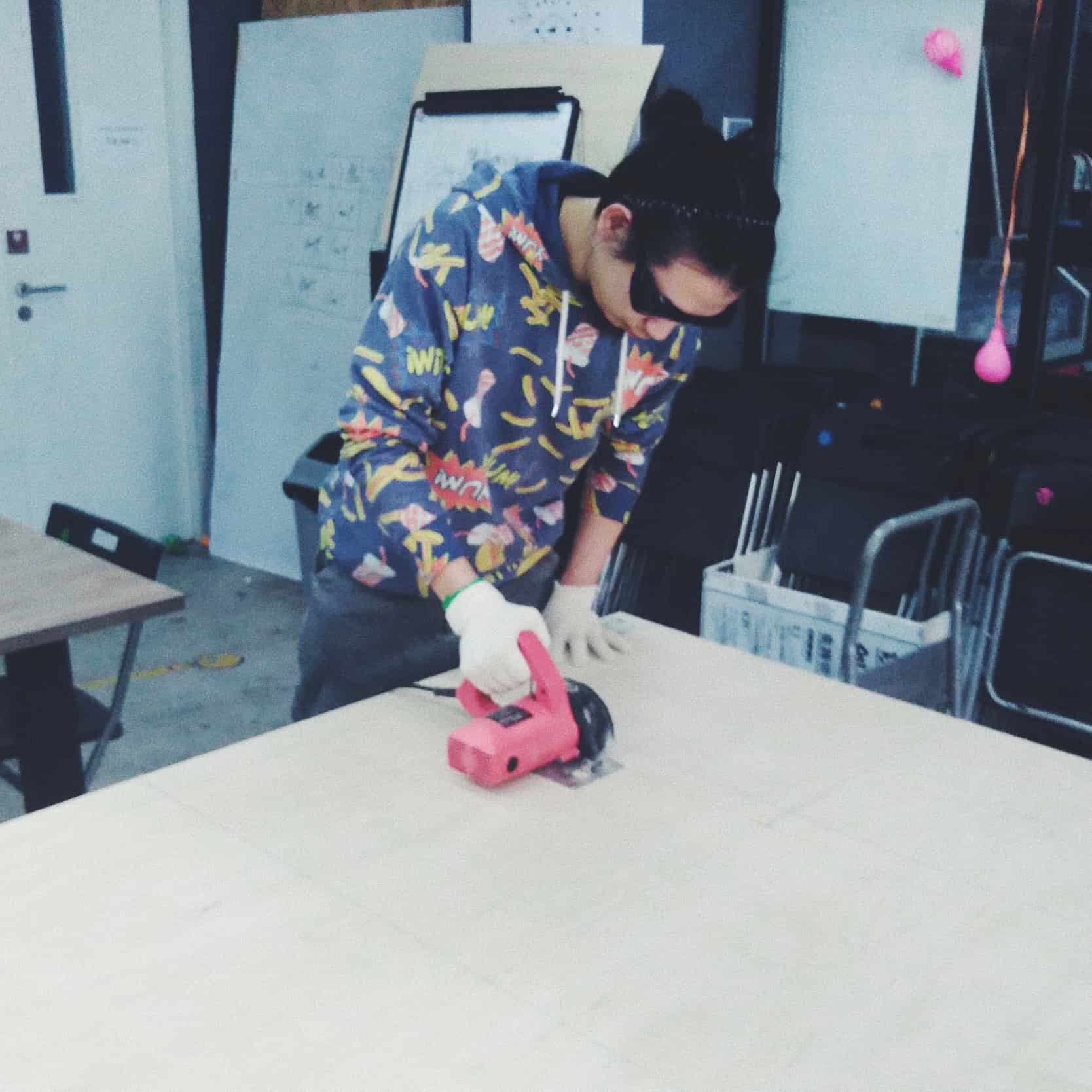

I used a 2440mm x 1200mm plywood, but it’s too big for our CNC machine working area, so I cut it into 750mm x 450mm.

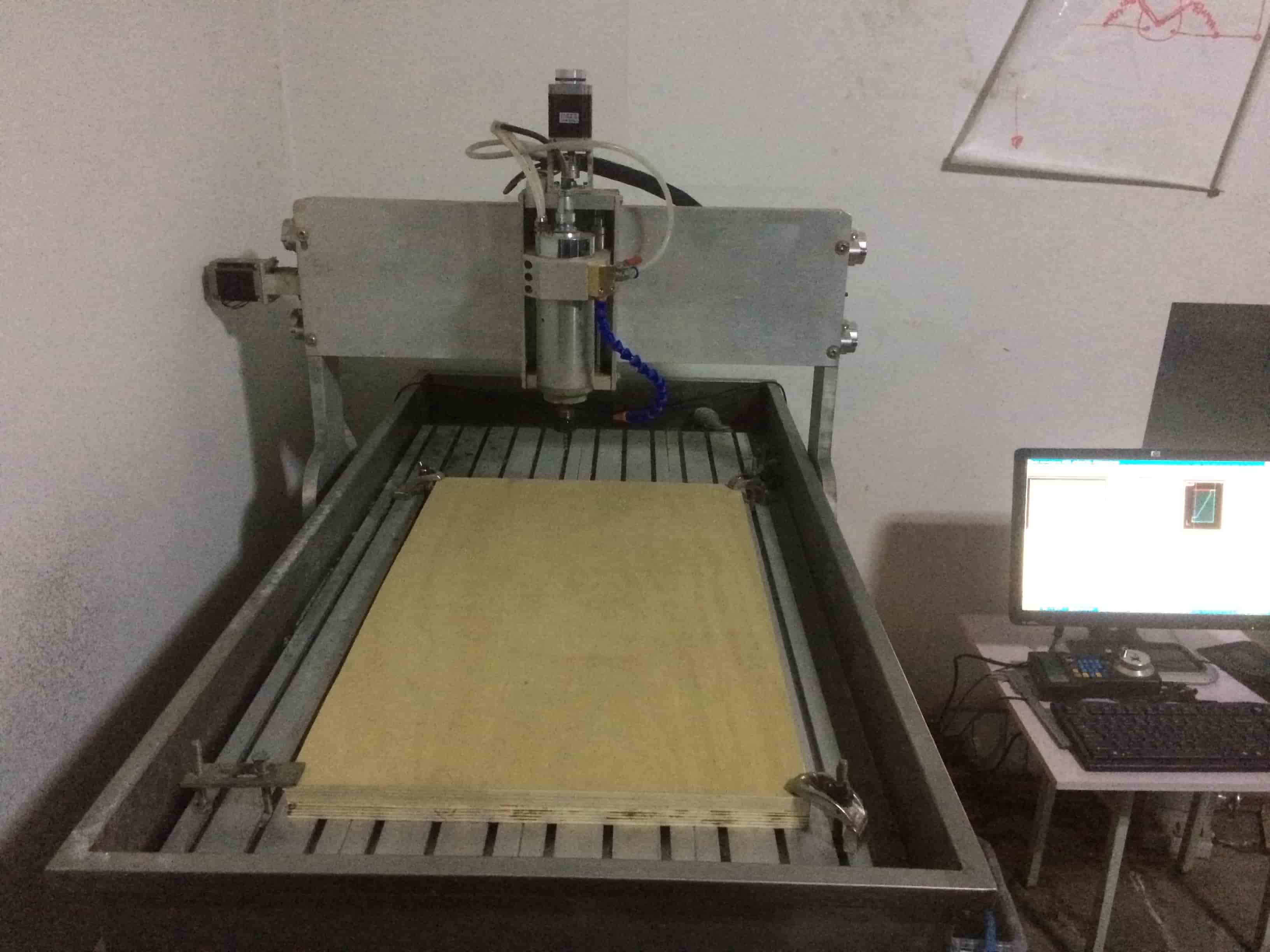

At First I try to fix this expensive one, near our Fablab with 750mm x 1200mm working area, but I can’t found appropriate adapter to connect it with my computer and It will take long time to deliver a new one. So, in the end, we use this small one with 450mm x 750mm working area. Science it have a sink with it, we can machining metals later some day.

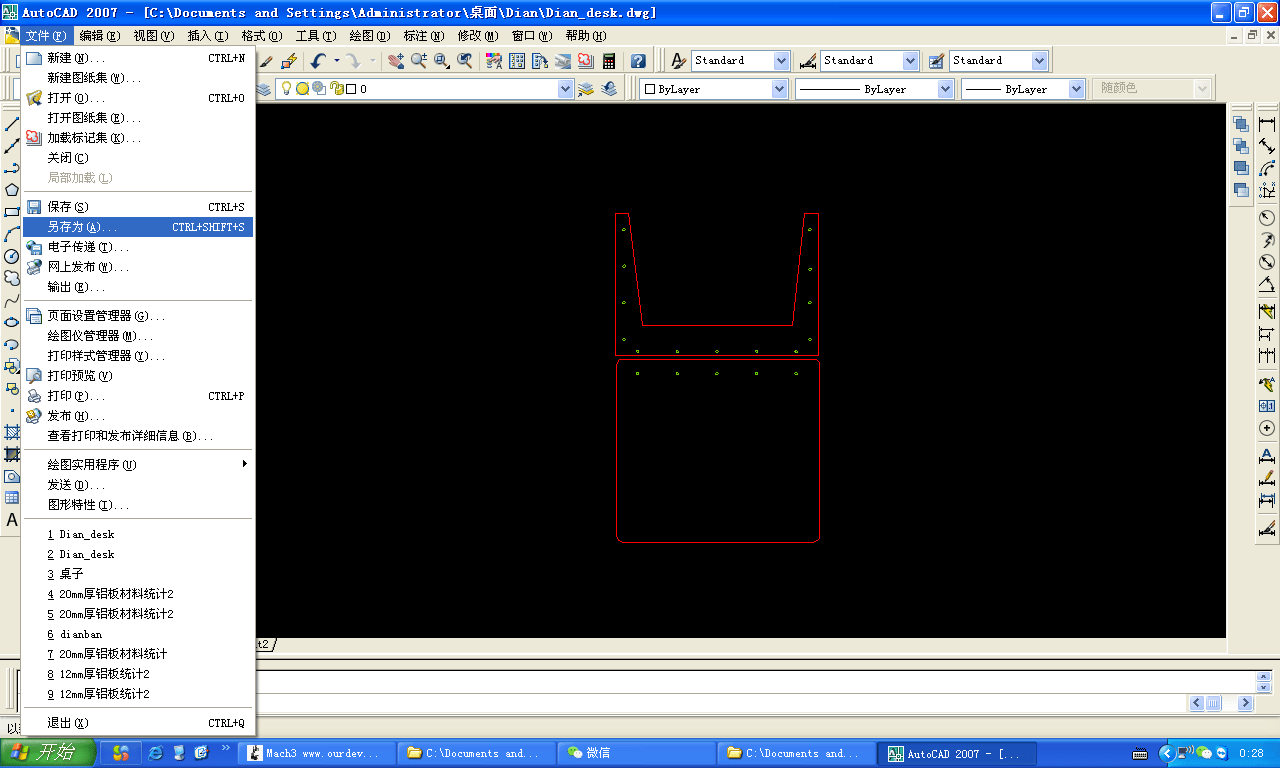

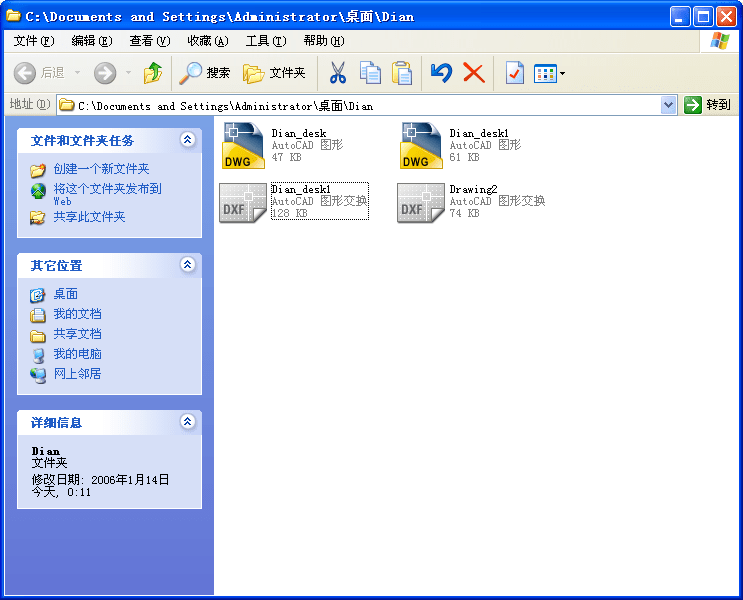

Export the .DXF file from Ai.

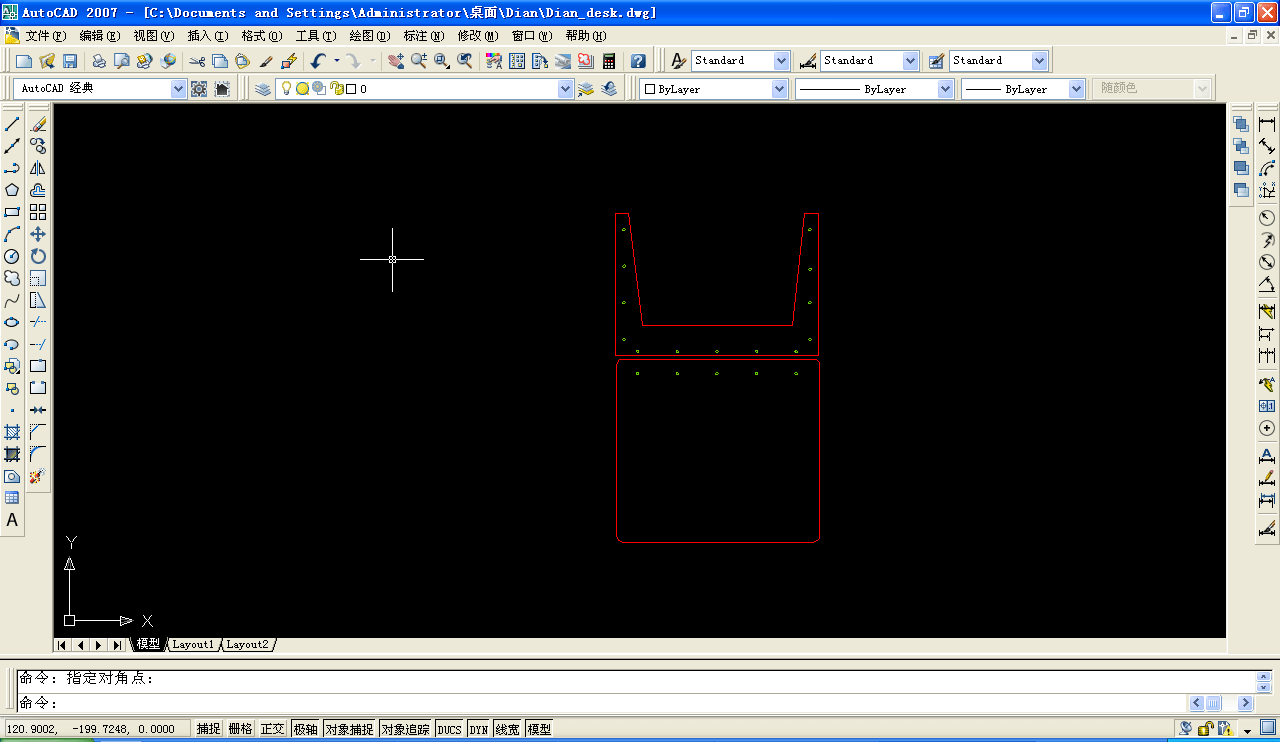

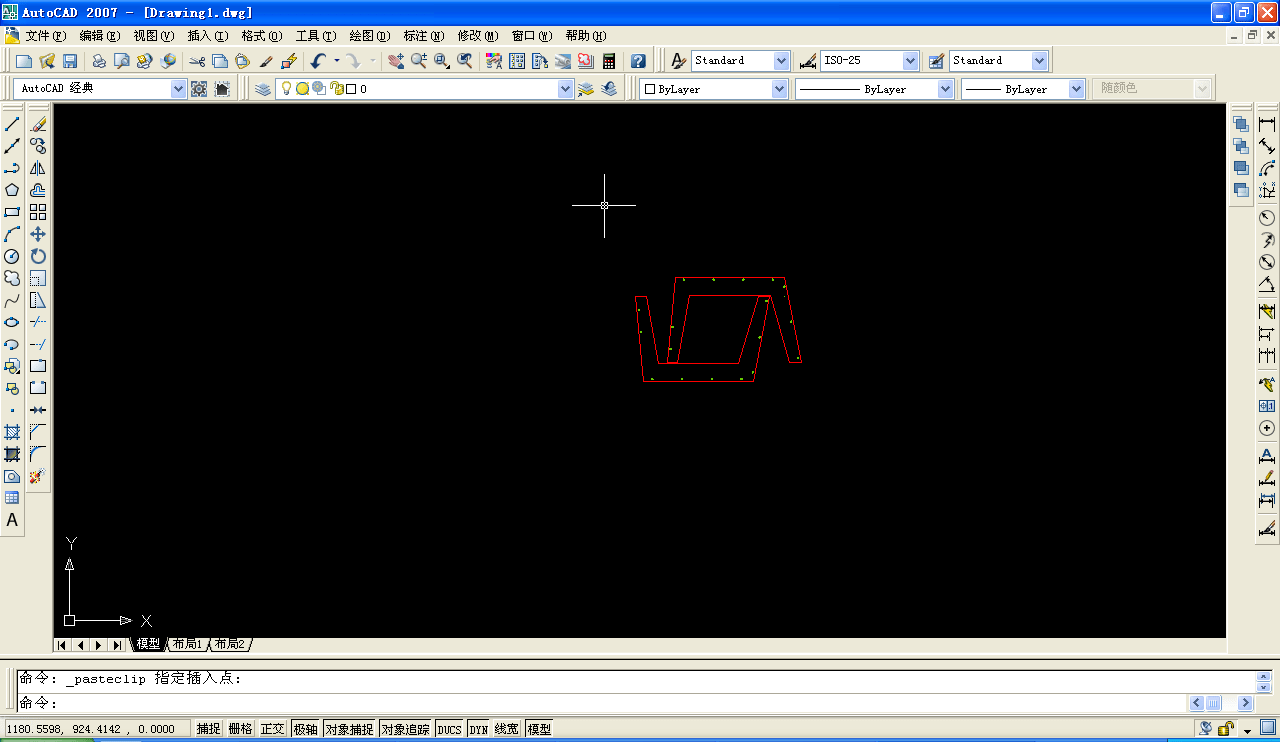

Open the DXF file in the CAD (better in a windows system) and reposition for cut than save it.

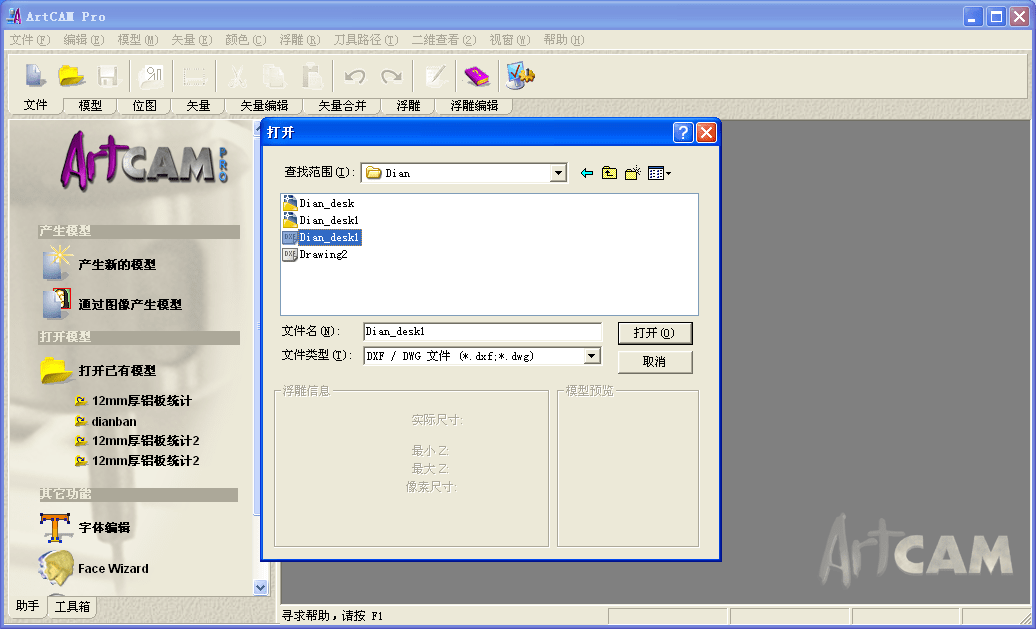

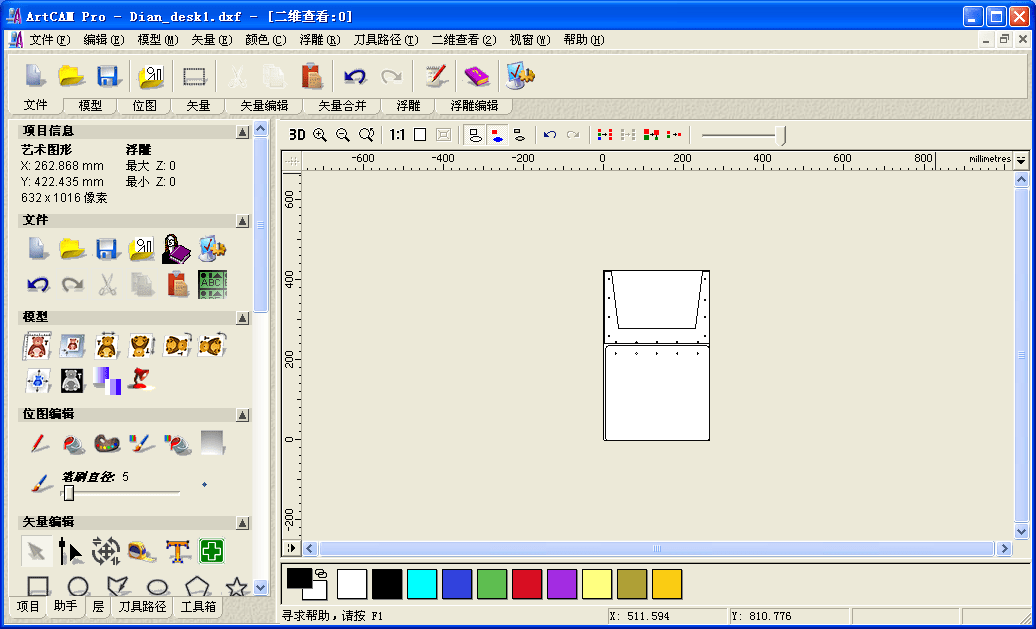

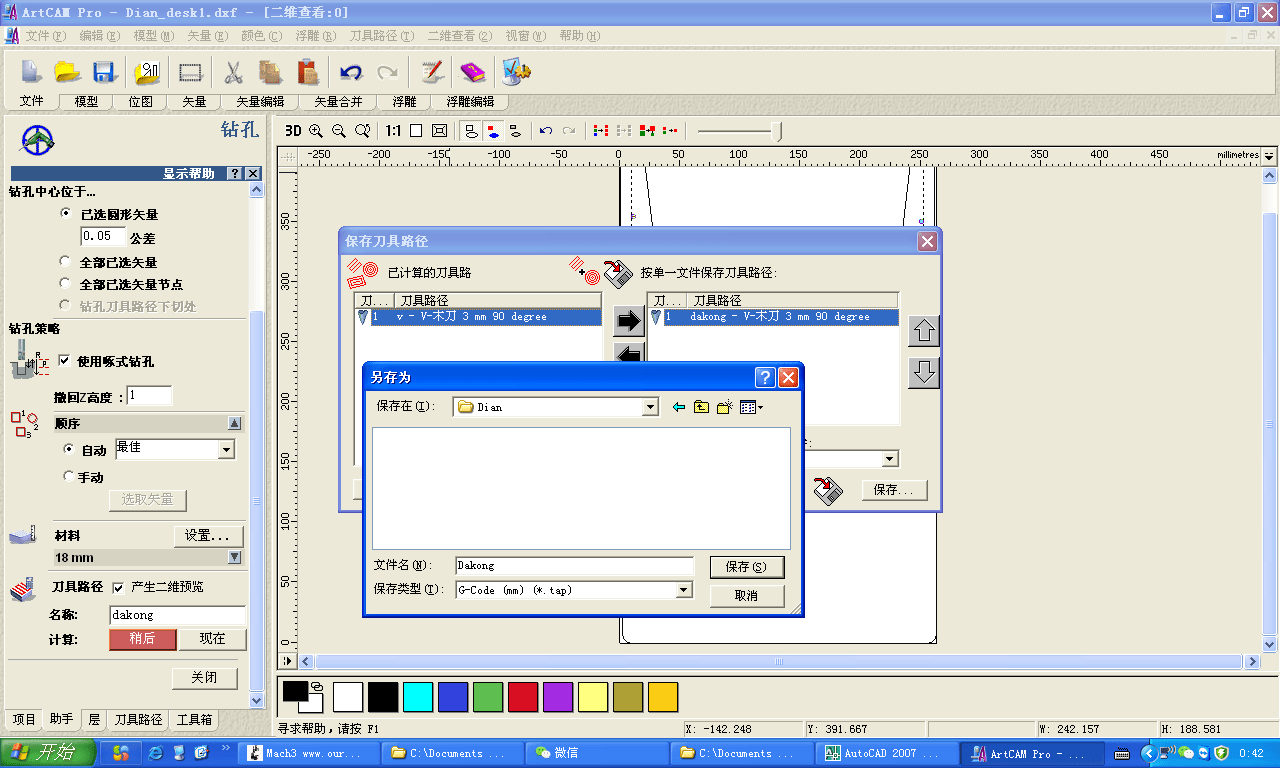

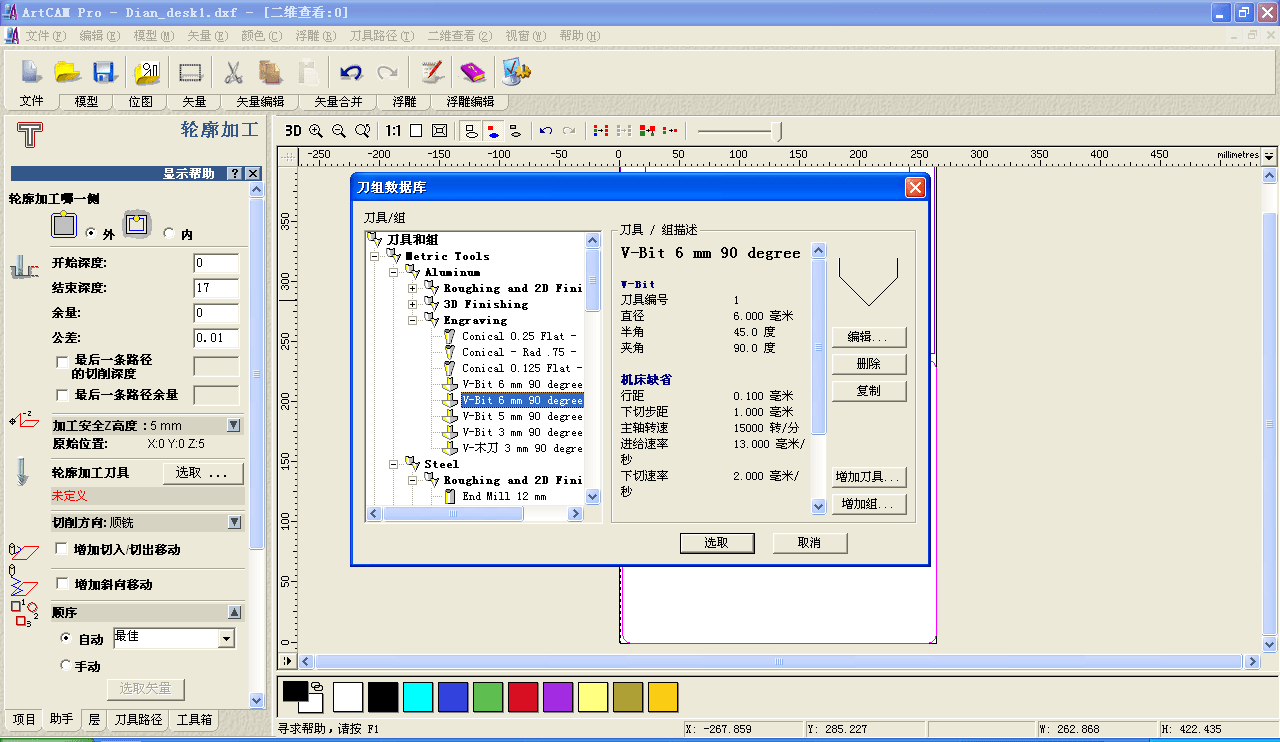

Open the ArtCAM, import the DXF file again and set (X0,Y0,Z0) position.

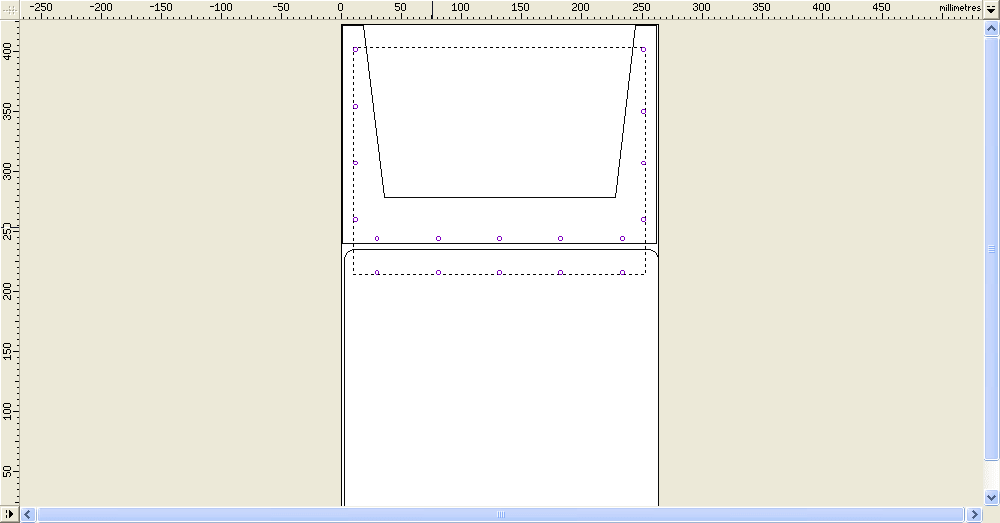

Select which part you want to mill first.

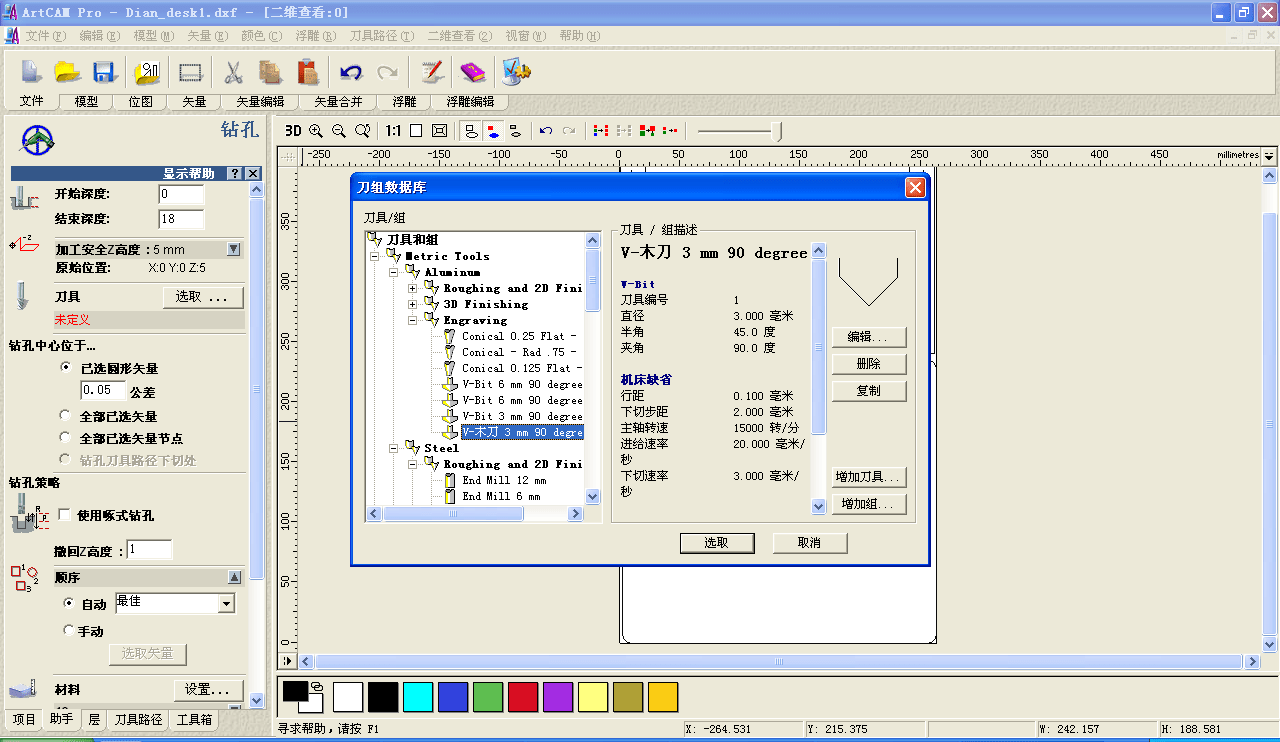

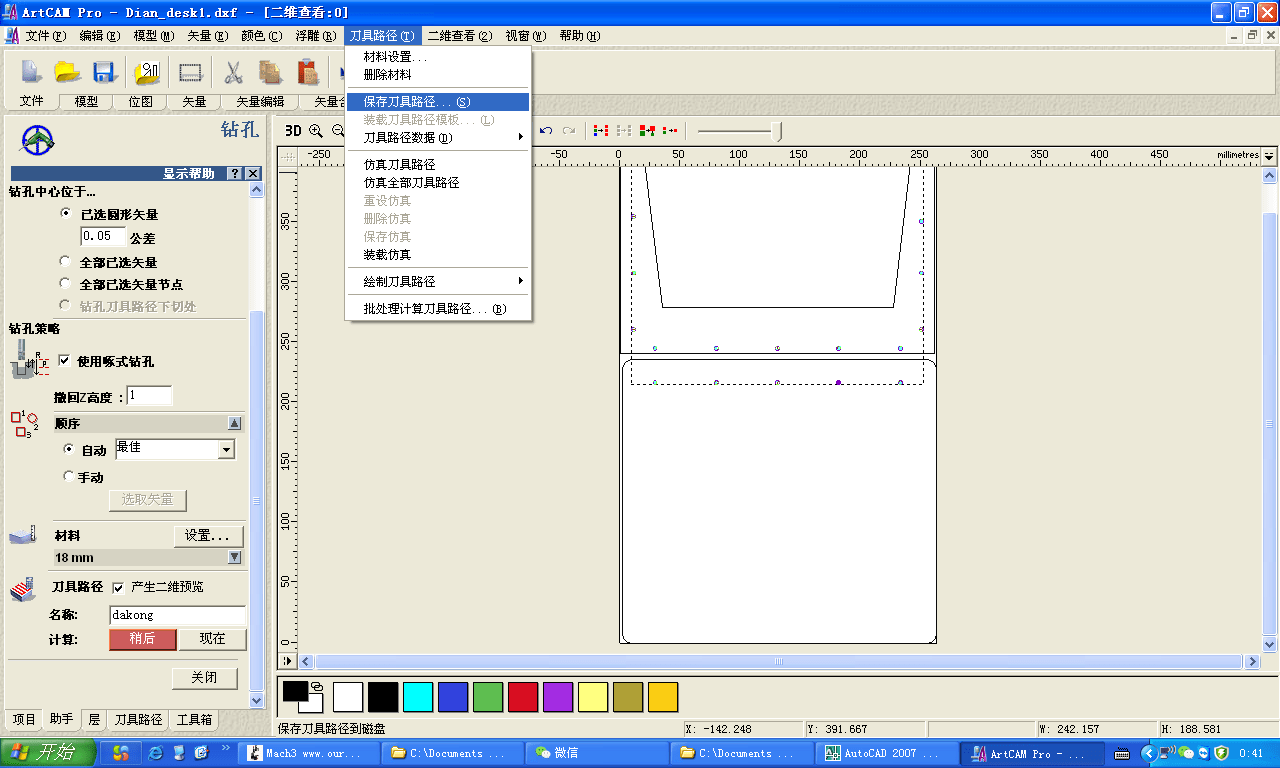

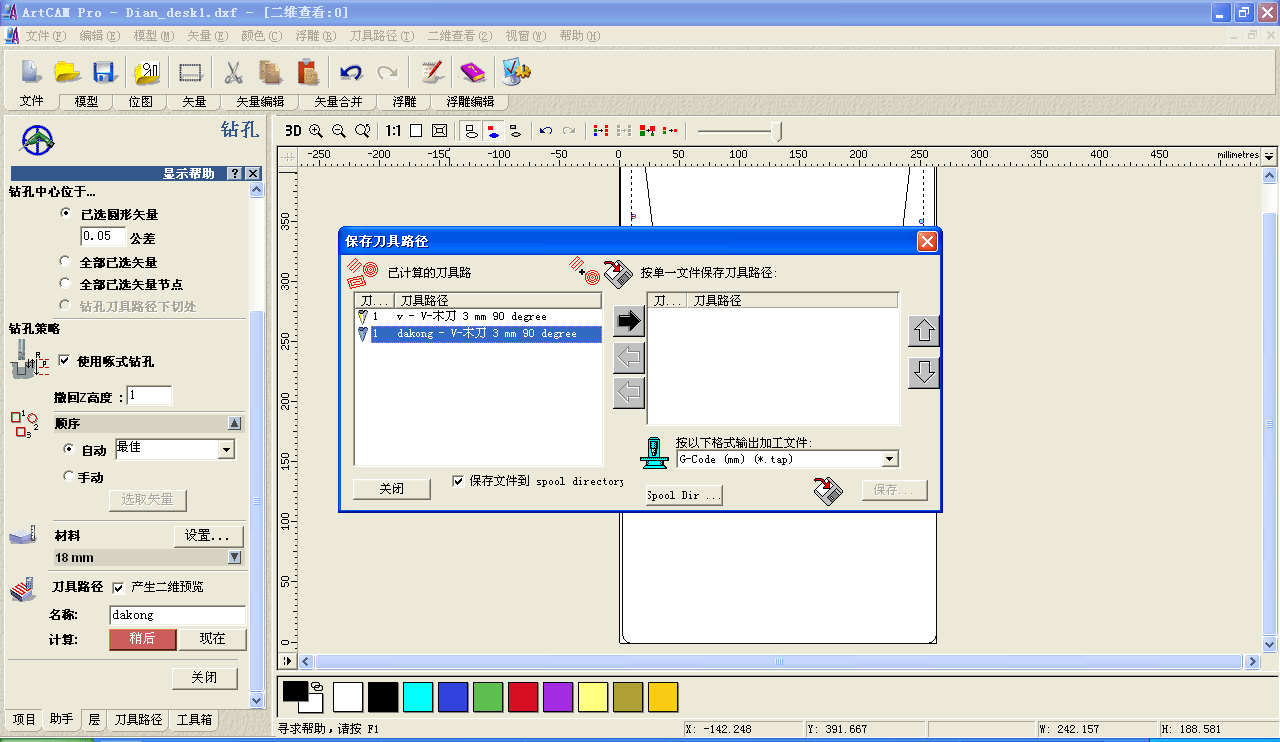

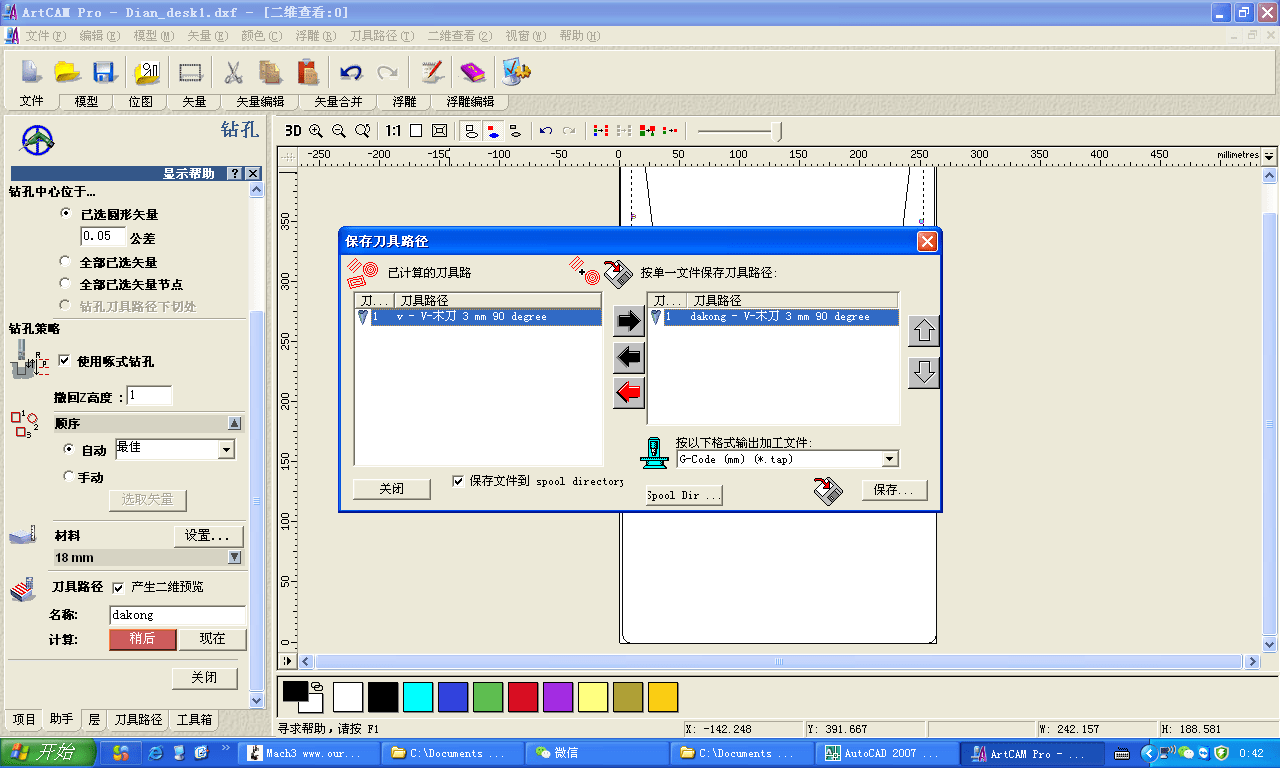

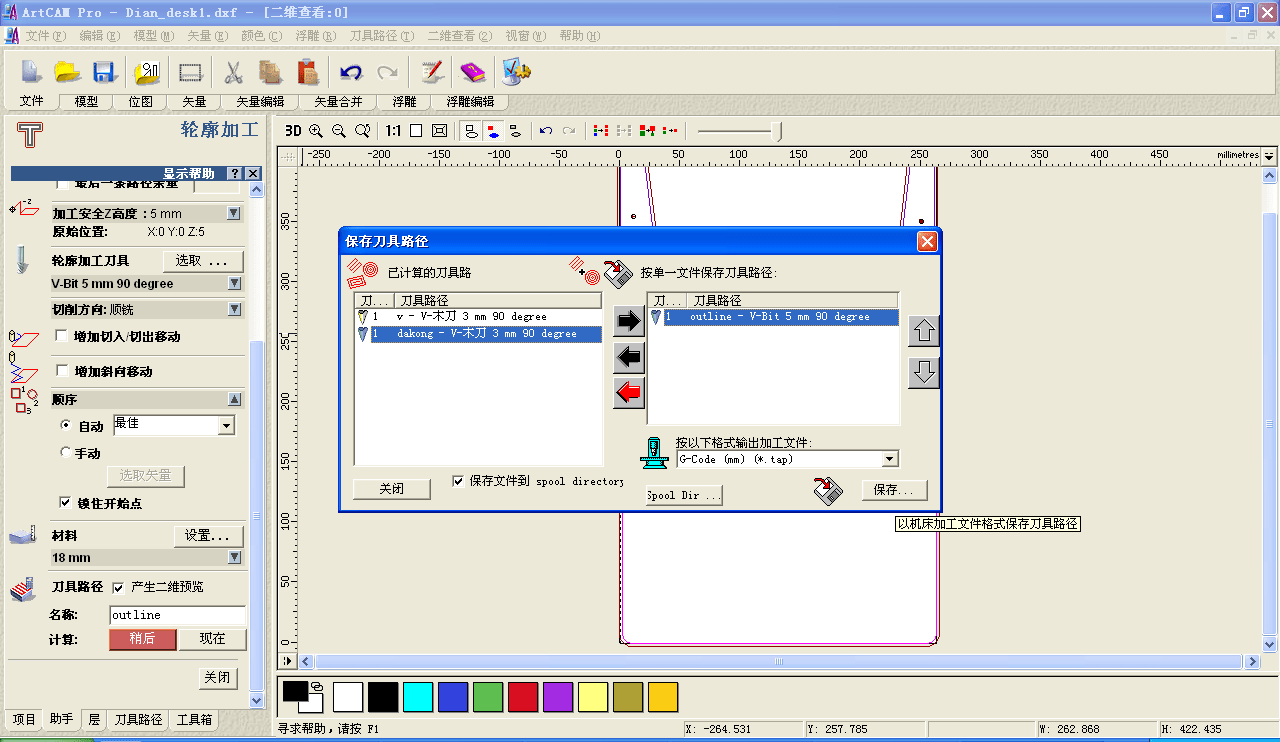

Select Outside cut, Thickness 18mm, 6mm-end-mill than export mill path files generate G-code.

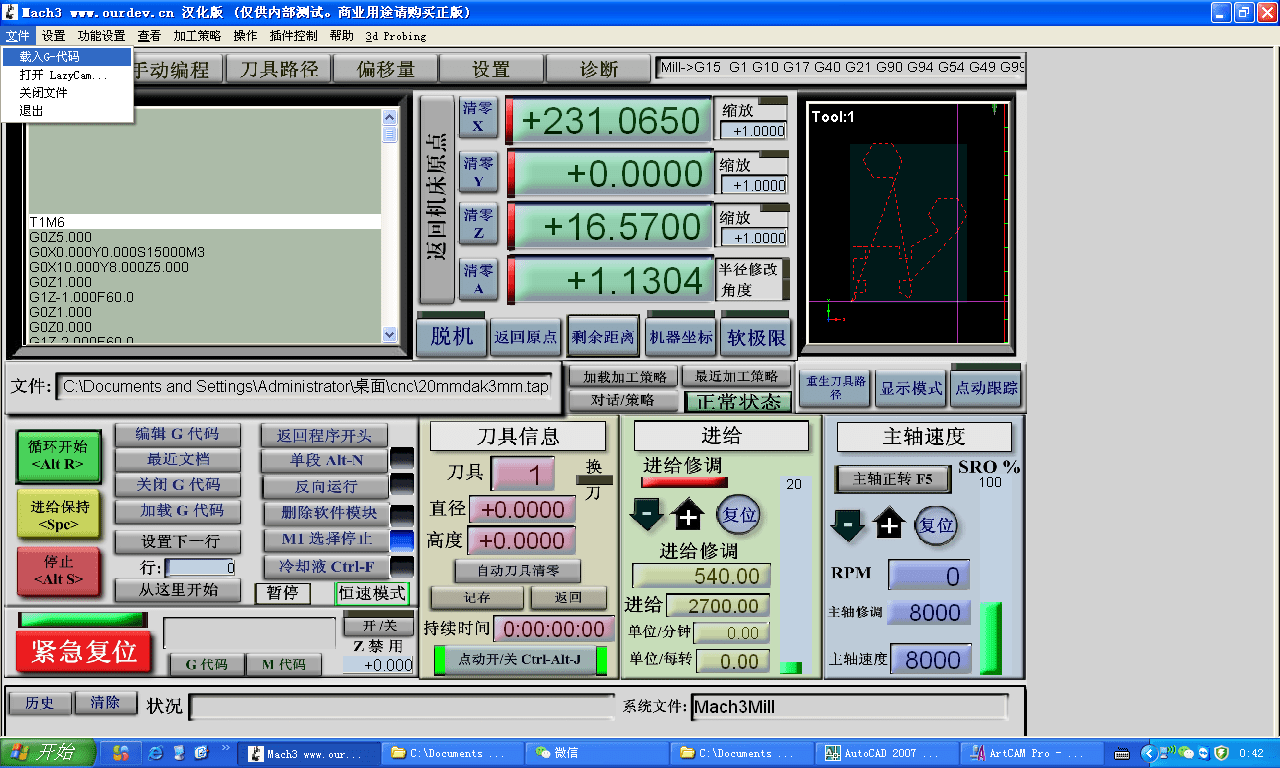

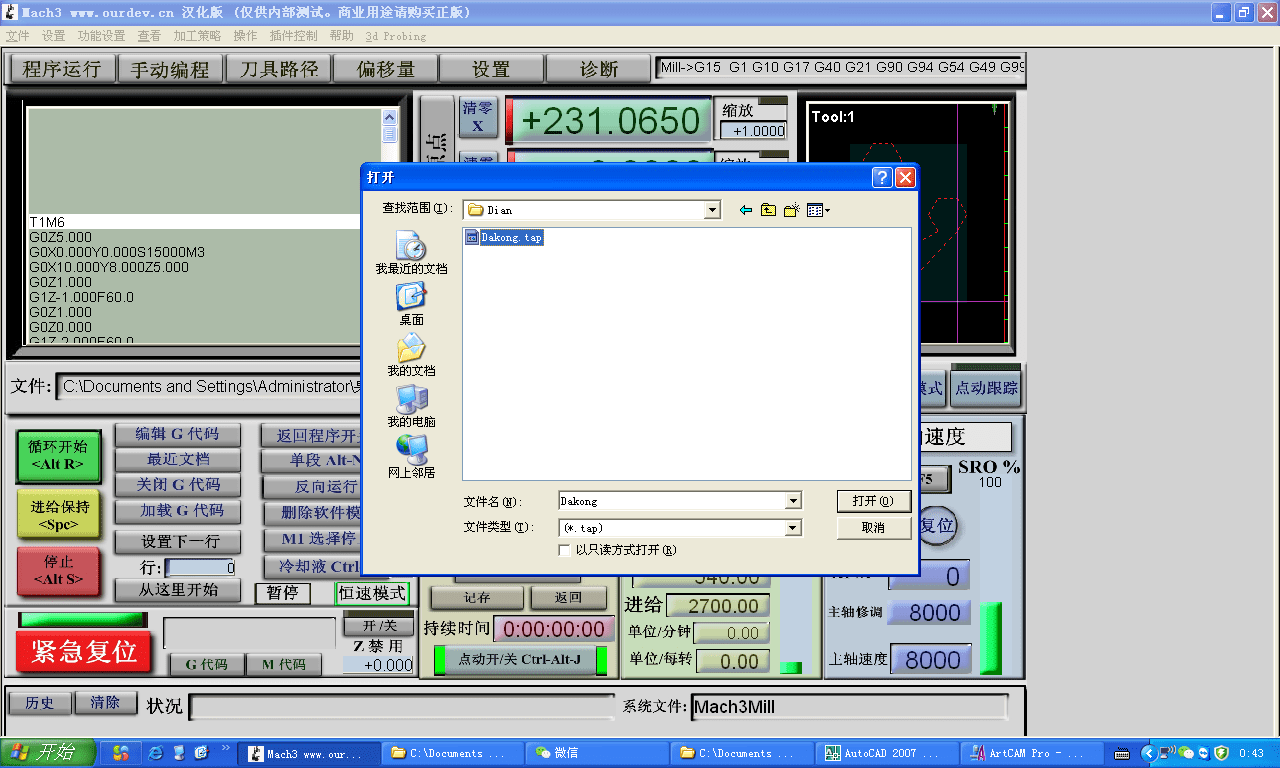

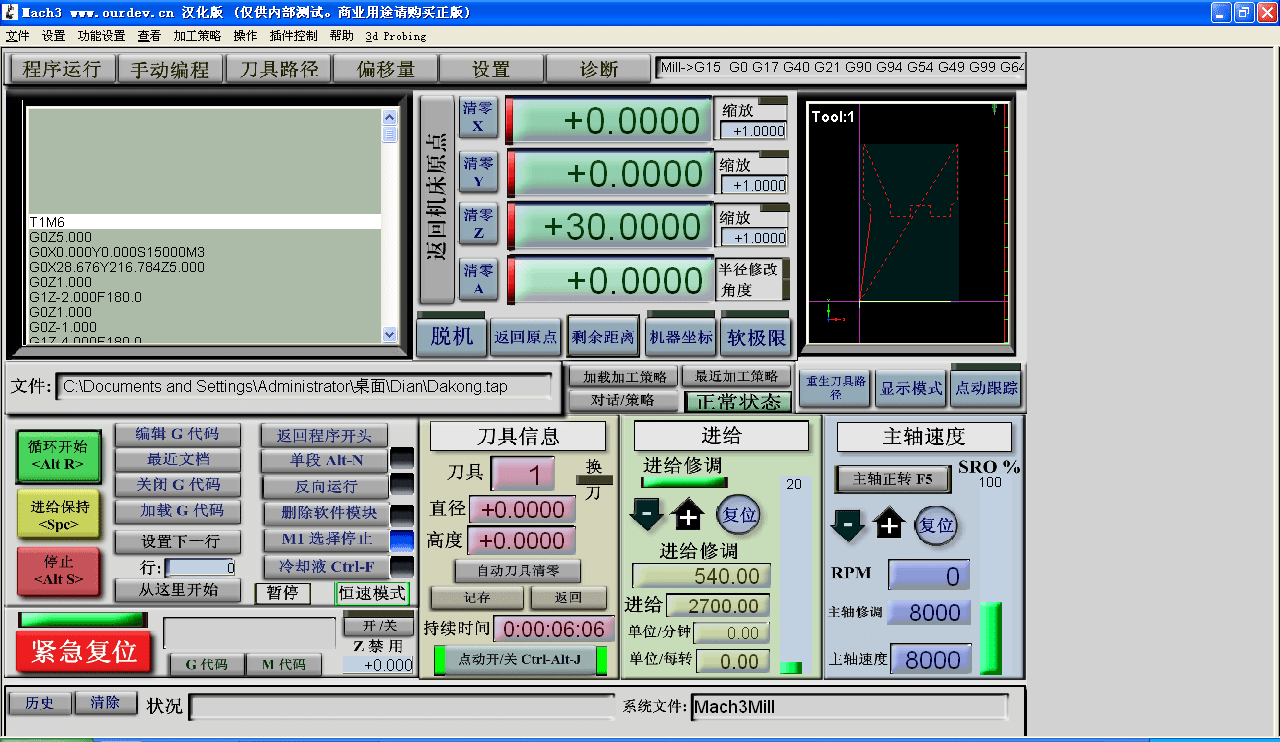

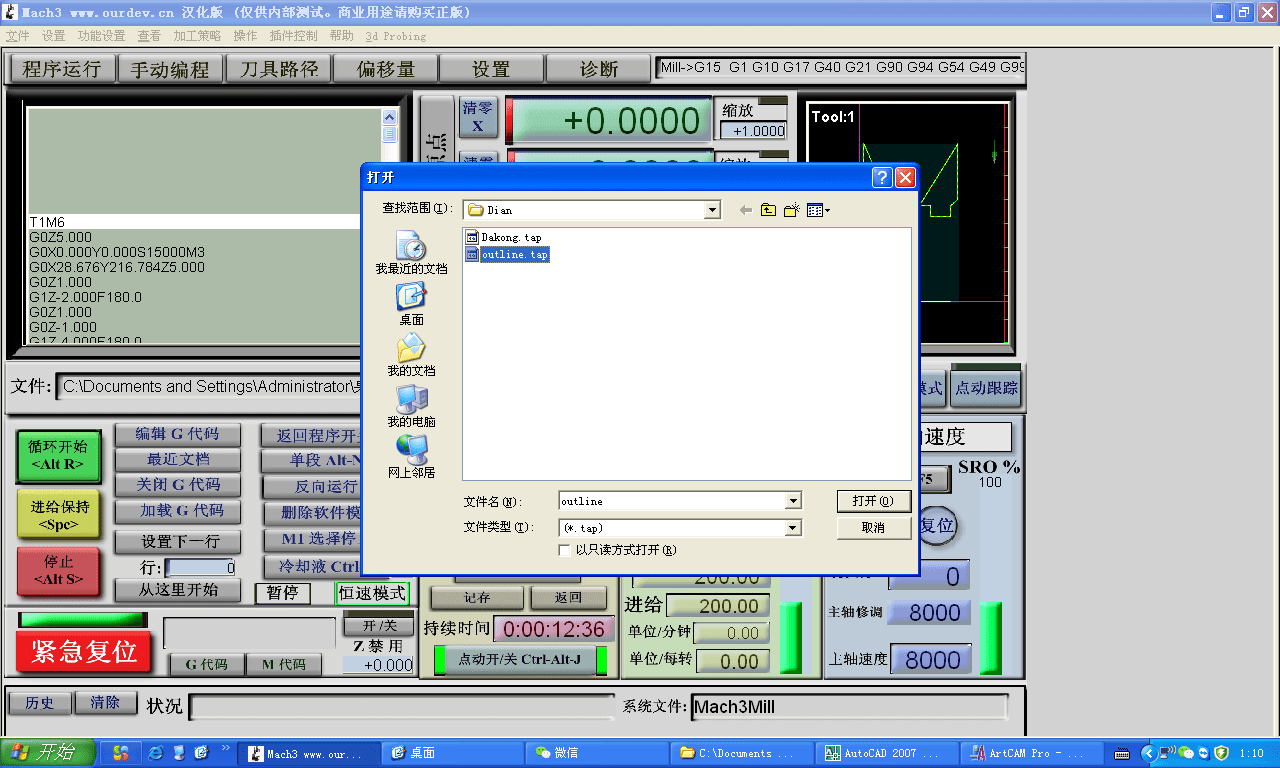

Open Mach3 import the G-code file (.tap)

Roll the machine from the remote control and start mill!