Fab Academy 2017 at Fab Lab Barcelona By Trinidad Gomez Machuca

Define the scope of a project.

Develop a project plan.

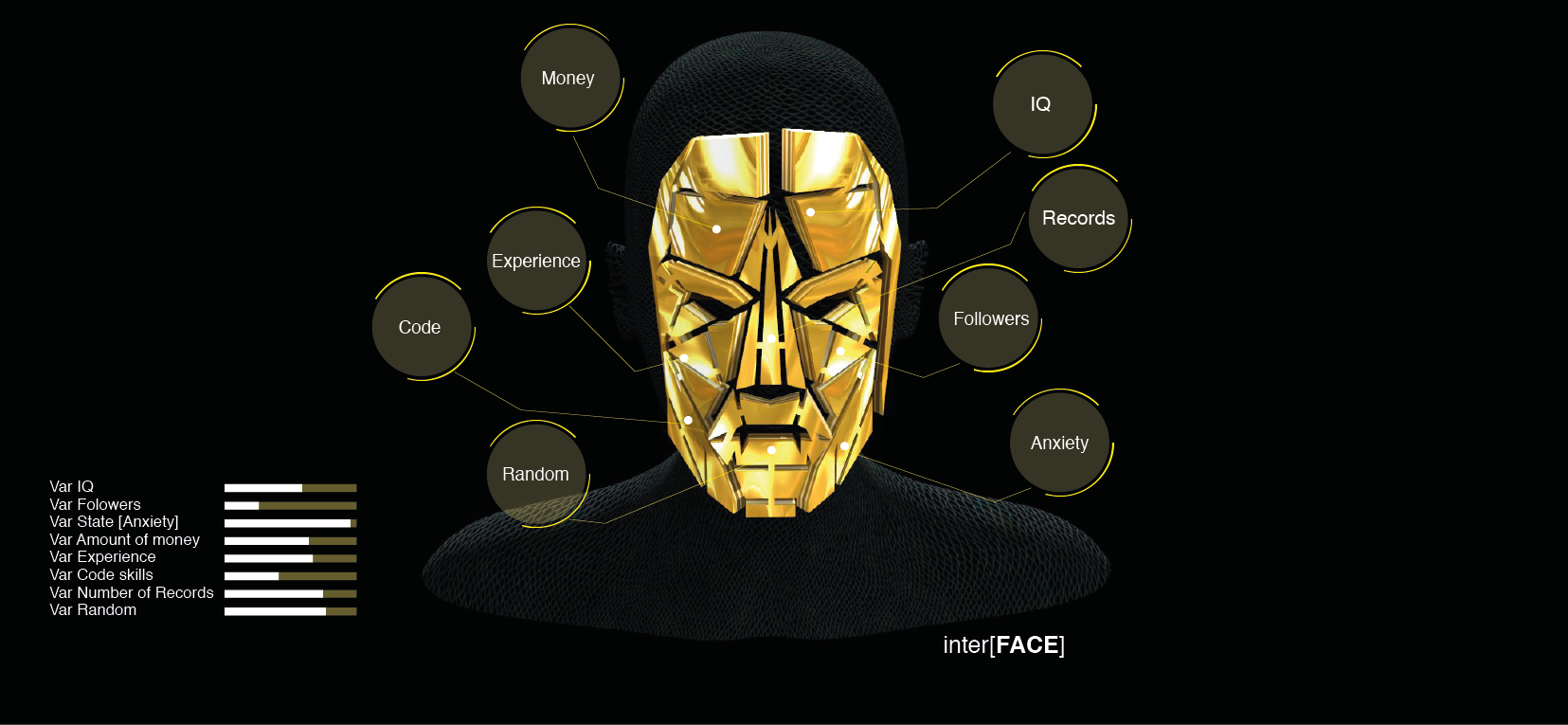

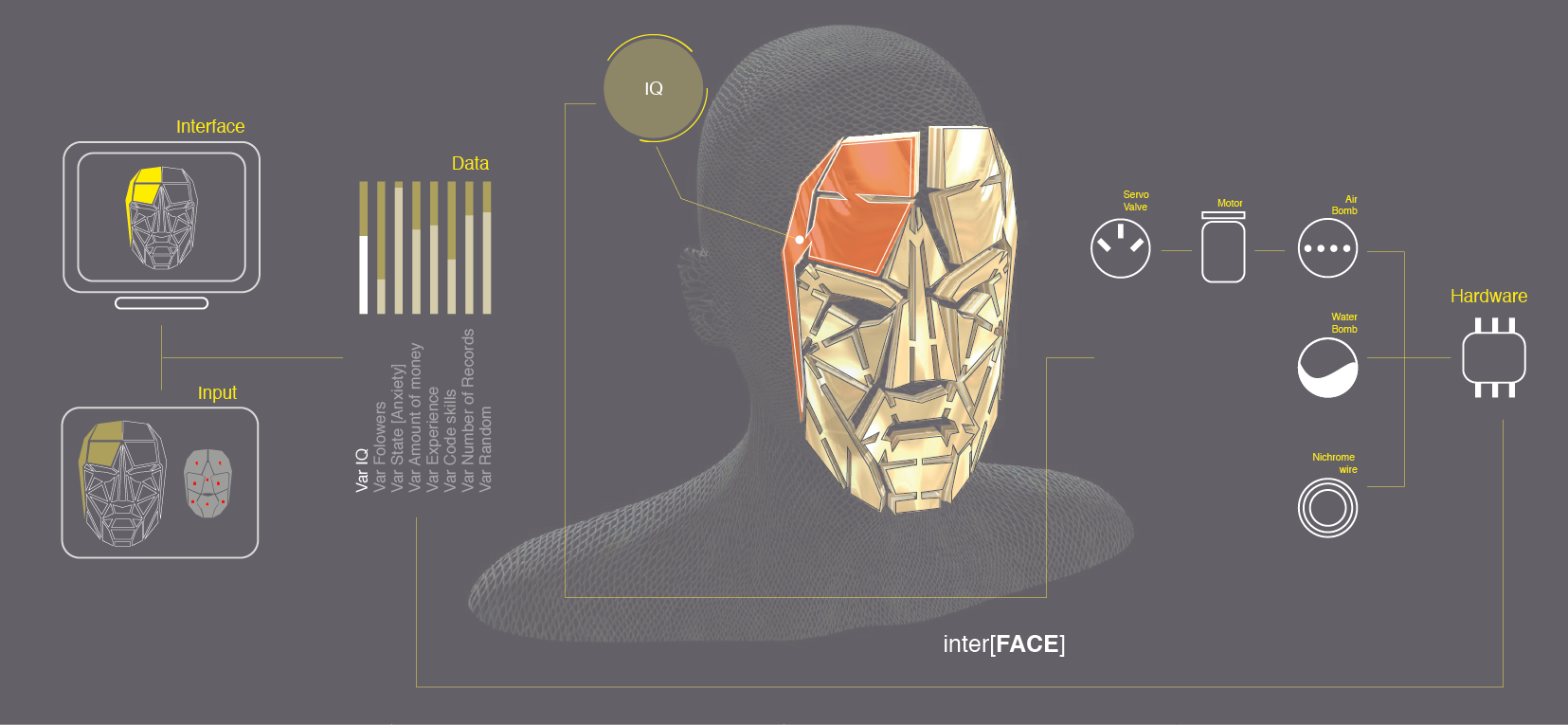

For my final project I want to fabricate a mask that interact with the data that I decide to show through the face. Depending on the variables that you choose to quantify, it will expand, change color, activate some sensor, etc., as you can see in the video. This mask will be divide by 4 areas, every one will be controlled by a physical inteface(capacitive sensors) and digital interface (processing). When the user choose an area this will trigger an output. The purpose is fabricate a tech wearable with thte principles of soft robotics to show information that we can want in the face.

I found a lot of examples of masks that have been made them with the process of digital fabrication. 3d print are the most common but the purpose of all of them are the same, only to play with the algorithm of the data of the 3d images and show a parametrics or aesthetic result. Only one of the examples that I found was interesting. The Facial Weaponization Suite because they are against the face recongnition algorithm that governments use to identify infractors in the street since they are looking for maintain their anonymity, the only thing is that theire result still being aesthetic.

For the fabrication I will need only the ecoflex combined with thermochromic dust that will allow to change the color of the ecoflex depending on the temperature. I will do the mold in the CNC or the 3d print.

Ecoflex 00-30 the ecoflex is the most flexible, I researched what kind of material and the most common one was this kind the 00-30.

Thermocrhomatic aditive. This material is expensive and hard to find but it is very cool to try.

Nichrome wire this one you can find it in a Stationery, is commonly used for cutting foam materials, depending on the volts that you used can be very hot and cut or only change the color of my ecoflex.

Hardware OUTPUTS

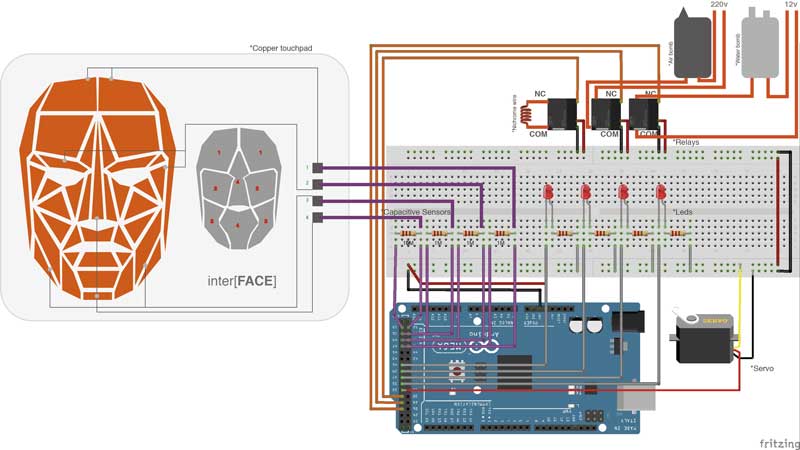

As you can see I'm planning to have only one kind of input, in this case i will use capacitive sensor, a touch pad that triggers something, and for the outputs i want to have leds, servos, air pomp, water pomp and heat a nichrome wire.

// Servo: is for moving something in the mask or make a servo valve that allows to inflate different parts of my mask with only one air bomb.

// Leds: is for see a fast output in the site is readting because the bomb air will take some time.

// Nichrome wire: is for heat the material that I will use for the change the color of the mask. I will mix the ecoflex with a special dust that has Thermochromic properties, this will allow my mask to change the color depending on the temperture.

// Bomb air: is for inflate the mask

// Bomb water: is for put cold water inside so i can reverse the reaction of the nichrome wire.

// Iot: I really want to experiment with this but i will do it only if i have time, honestly i don't know nothing about electronics so i hope i can do it.

The purpose of having a lot of outputs is to show different data. Every part of the mask will mean something. For example, if one part change the color it will mean that this area is activated because the person is happy. Yeah, something like this hahahahaha.

Everything i will get them from the lab, the only thing i bought was the thermochromic additive, and air and water pump.

In total i have spent like 152 euros, the most expensive thing was the thermochromic additive. Everything else i found them in the Fab Lab.

ECOFLEX 40 EUROS

NICROME WIRE 5 EUROS

THERMOCROMATIC ADDITIVE 20 EUROS

ACRILIC 20 EUROS

AIR POMP 10 EUROS

PIPES AND CONNECTIONS 5 EUROS

POLYPROPYLENE 5 EUROS

CARDBOARD 20 EUROS

ELECTRONICS 27 EUROS

-I need to to the mold of the mask wish I was planning to make it in the laser cutter.

-I need a head that I will do in the CNC that i'm not sure yet if I will do a mold with the Thermoforming machine.

-And finally i'm working on my final board that I will fabricate in the rolland machine.

-Design in Eagle

-Mill in the Modela machine.

-Solder the components.

-Design in rhino the mask.

-Laser cut the mold for the mask.

-Add the fabric layers.

-Add the nichrome wire.

-Make the Mask holder in the CNC.

How to control the air to inflate and deflate the mask.

How long the properties of the ecoflex and the thermochromic additive will last?

In which way can this prootype used as a product?

Week One: electronics, design, mill, solder and pass the code that i have in my Arduino mega to the Atmega32u4.

Week two: Fabrication, will laser cut the mold of the mask and put the ecoflex for the soft mask.

Week three: finish with the details of the mask and write the documentation.

When i finish the Mask i will show how all the parts work through the interfaces. The mask will show how all outputs that are trigger and makes the interaction with the information.

Nothing for this week

Nothing for this week

| Fab Academy 2017 | Fab Lab Barcelona | Trinidad A. Gomez Machuca |

| IAAC | trinidad.gomez@iaac.net | |