05.- 3D Scanning and Printing

Feb 22

group assignment:

individual assignment:

-Design and 3D print an object (small, few cm) that could not be made subtractively

-3D scan an object (and optionally print it) (extra credit: make your own scanner).

- Introduccion 3D Printer

- Pices for final project prototipe

- Aneurysm

- Kinet Scan

- STL thumpnail previw

More content related: Upgrading my prusa i3 and My Thingiverse

Introduction 3D Printer

- Possibilities of 3d printing technology (FDM).

- About 3d printing technology as open source business model.

- Testing the design rules for ours printers (group project)

I have to say that in the lab I am considered an expert in 3d printing because before the fab academy I was managing the 3d printing room as intern.

I have tried to help and advise my colleagues.

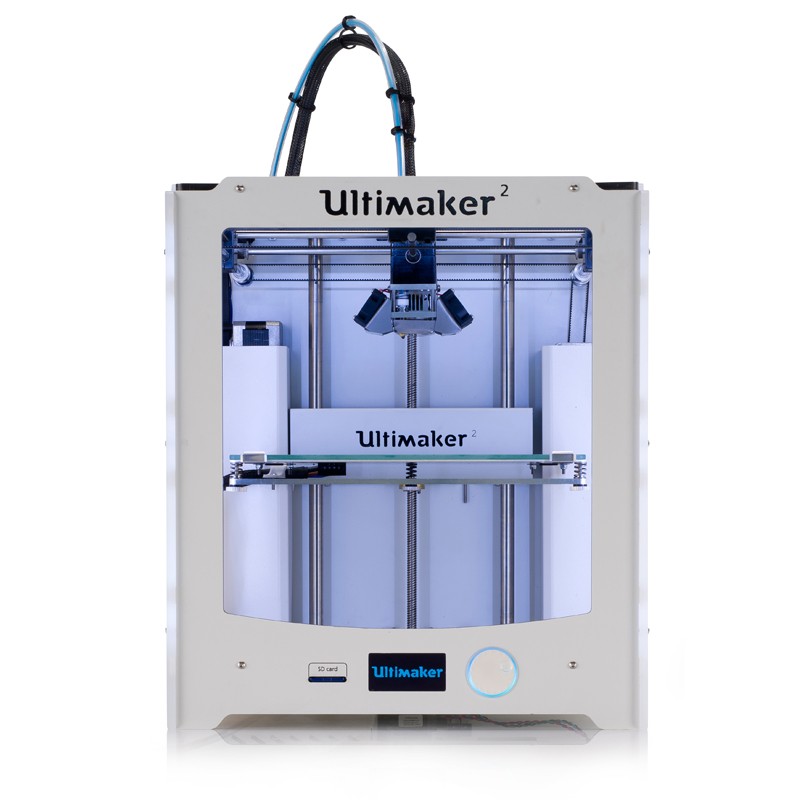

Now we have available 3 RepRapBCN and 1 ultimaker 2 and my Prusa i3 hephestos.

I recommend one of these slicer sofwares Slic3r Prusa Edition or Cura 2.4.

This is presetings for 3d printers available in the lab:

cura profile prusa i3

cura profile Reprap_4

cura profile Reprap_6

cura profile Ultimaker_2

Possibilities of 3d printing technology (FDM).

I collaborate with my instructors to create a document of references and designs of thinguiberse to show the possibilities offered by 3d printing.

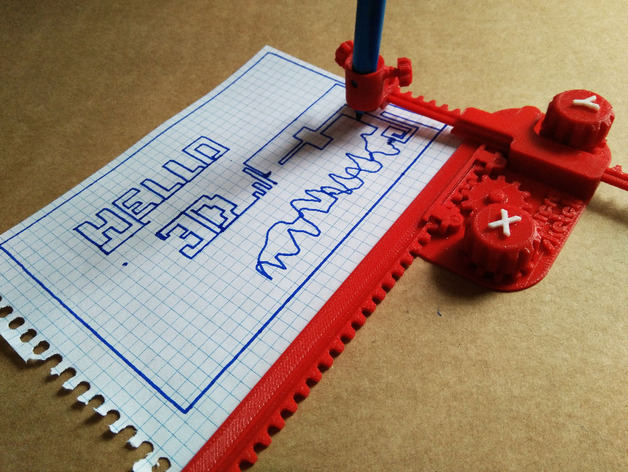

Mechanisims

There are many examples of relatively small mechanisms because FDM technology is well suited to prototyping and making physical mechanisms difficult to understand. This allows you to detect faults and improve the object.

In fact most of the examples are improvements of previous versions or have been improved already.

An example made by me related to this topic Gear dodecahedron.

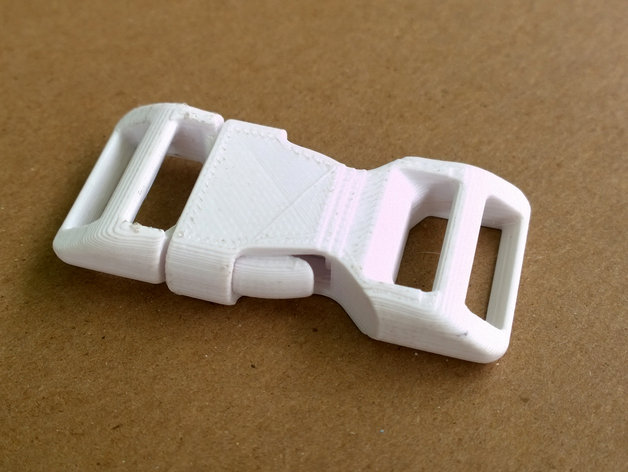

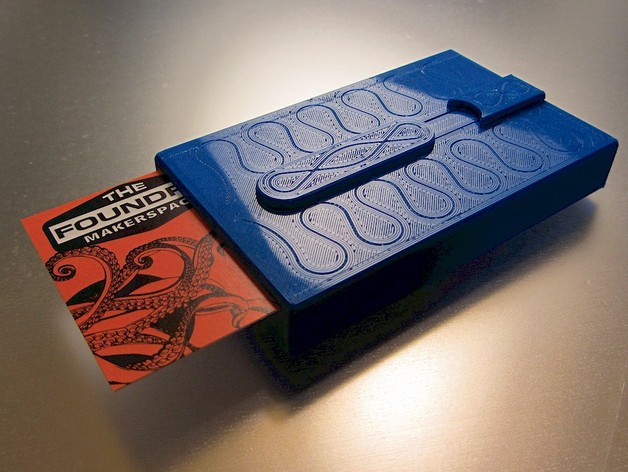

Pre-assamblet Models

One of the techniques that allows the additive manufacture is to create 2 or more parts connected at one time.

To do this one must take into account the tolerance between the parts. According to my experience 0.3 mm is a good number to start to try.

An example made by me related to this topic 5 tetrahedron star.

Springs

The continuous communication and spirit of improvement has allowed the community to have access to very elaborate designs and with the use of springs and gears.

Vase Mode

This printing mode is available in most slicers, it consists of printing only the outer surfaces, eliminating the layer concept, it is a continuous press where the z axes progressively rises as the nozzle travels the perimeter.

This method is much faster and the possibilities are interesting

Furry experiment

This concept is born of an error. the idea is to approve the effect of objects with overhang parts without supports. The result is to print in the air and that is why the plastic becomes in the form of hair.

An example made by me related to this topic.Unfortunately I do not keep the files for this object.

About 3d printing technology as open sourse model.

The true potential of FDM is that it is a technology of rapid prototyping that is why there are not many end products with this technology but, This technology is open sourse, that means that there is a community very interested in using and developing 3d printing. Also because it is fast prototyping is very flesible to improve parts and so you can adapt your printer to the new improvements that are appearing. It is a design tool that allows you to do some iterations to get an end product.

A very interesting interview from Thomas Sanladerer to different companies related to 3D printing on OpenSource concepts."Open source" is more than a marketing term!

Testing the design rules for ours printers (group project)

In this window is the page of the group assignment

Pieces for final project prototype

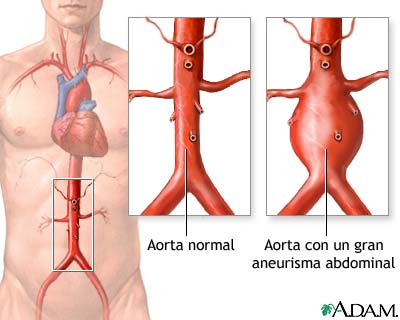

week02 Rhinoceros exerciceAneurysm

One of the fabprobcn projects with the hospital Hospitalet is to try to reproduce an aneurysm of a real patient thanks tag and scaners

One of the files is the inside of the artery and the other the exterior. I used meshmixer to smooth surfaces and get the final shape with boolean operations

This is just a 10 minutes sreen video with music, It is me working in mexmixer a you can get an idea how a did.

pictture taked in the hospital before operation

In this case the main advantage is that the 3d impression allows reproducing replicas of areas of the human body that are going to be operated.It will help the doctors to make a better strategy for the operation and even to simulate the operation with the printed piece.

The impression is made with filaflex to be able to simulate the operation

Download the files of this section here:

inside

outside

final shape

Kinet Scan

We have 3 kinect in the lab, I used one to scan my hand. I have used the free version of skanect and a driver from this link.

In Meshmixer is very easy to clean mesh

And blender is very useful to finish sculpt the form since the free version of scanet does not allow much definition

Download the files of this section here:

blender file

STL file

STL thumpnail previw

Windows 10 does not bring by default the option to view the STL files before opening them.

I have many STL files and I would be very useful.

After searching for the solution that has worked for me:

If the STL files are very heavy the browser will need some time to show the previw but only the first time, I think

Forum