Date

4th week

CLASS

Electronics production

Miling a PCB

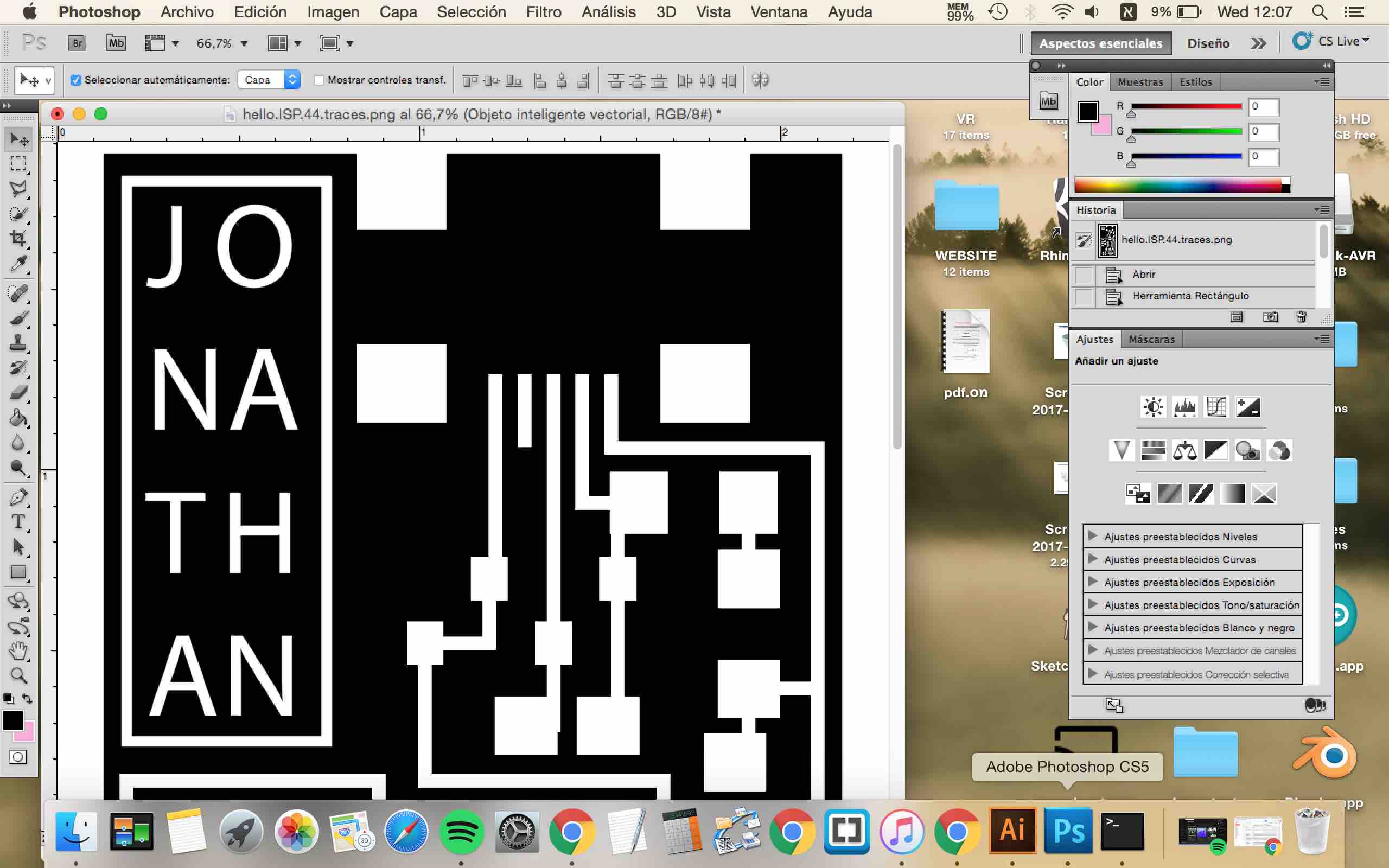

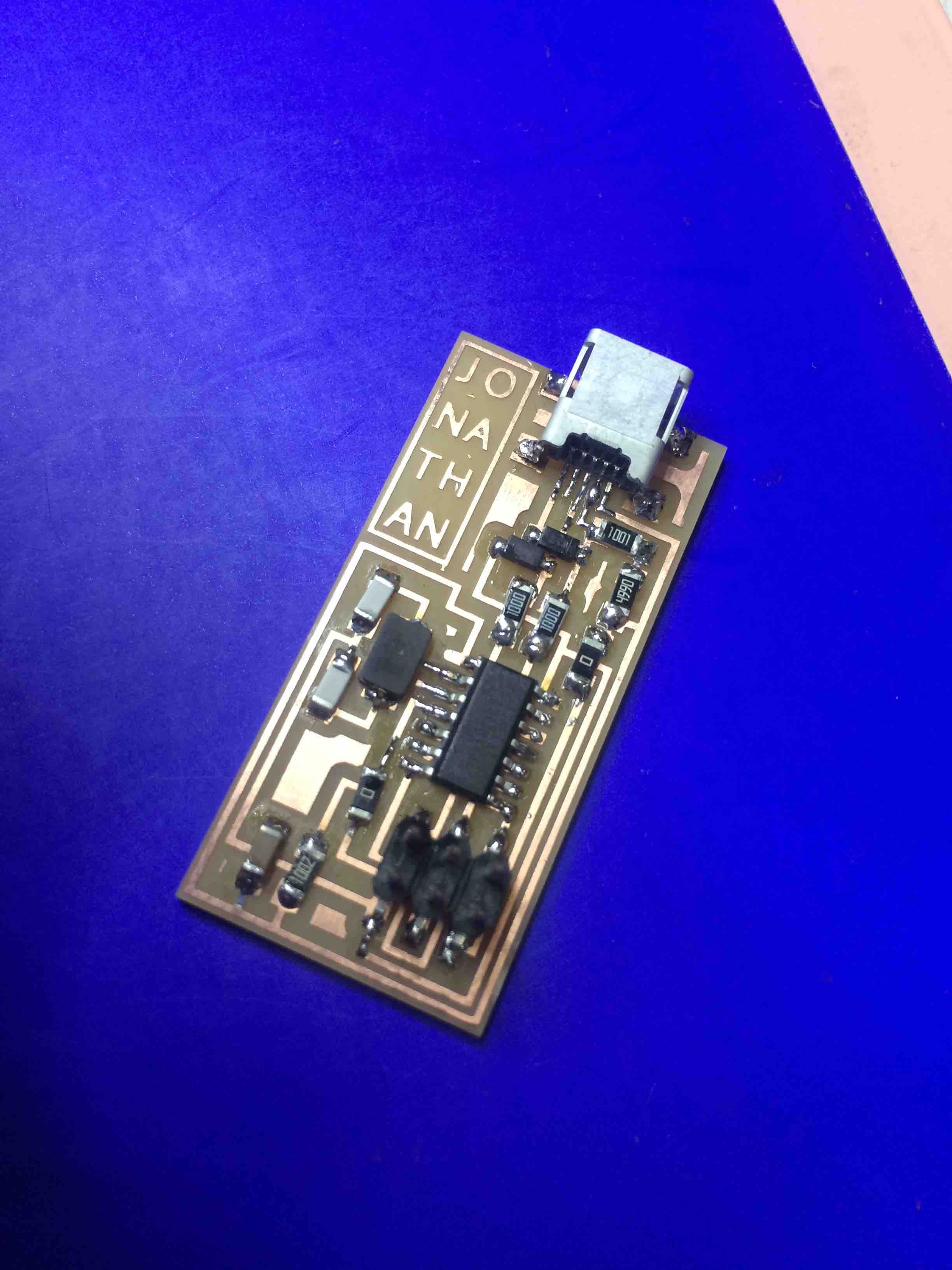

This week i started with undertanding how the electronics board works, get famililer with the materials and the type of borad exsiting and after that we jumped stright away into miling. I download the traces png files of neil´s bored and as first step i made it a bit personal by writing my name on it using photoshop

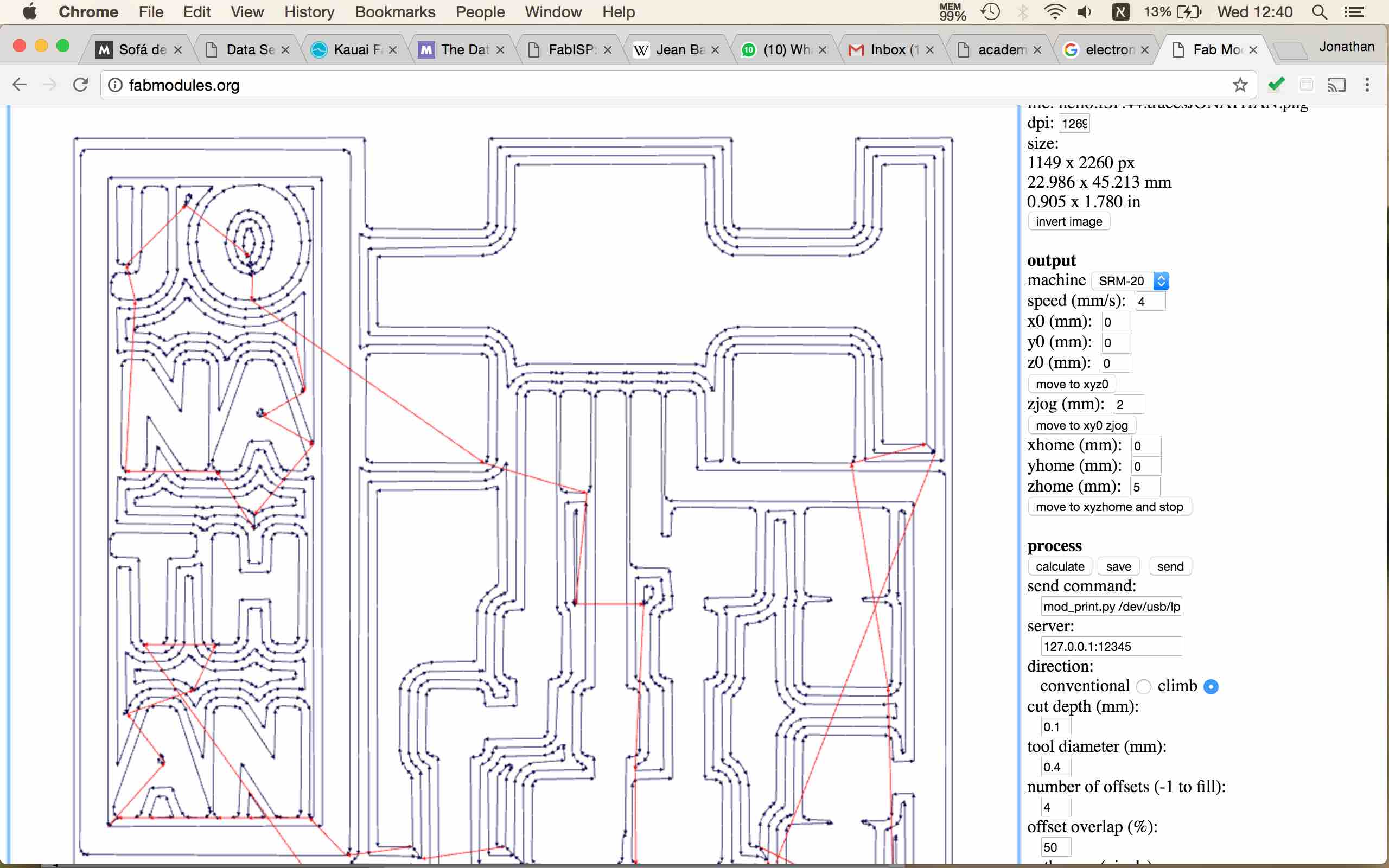

After doing that i uploaded the file into the fabmodules site and followed the instruction by calculating and prepering the tracing file for the SRM20 Ronald miling machine we have here in the lab.

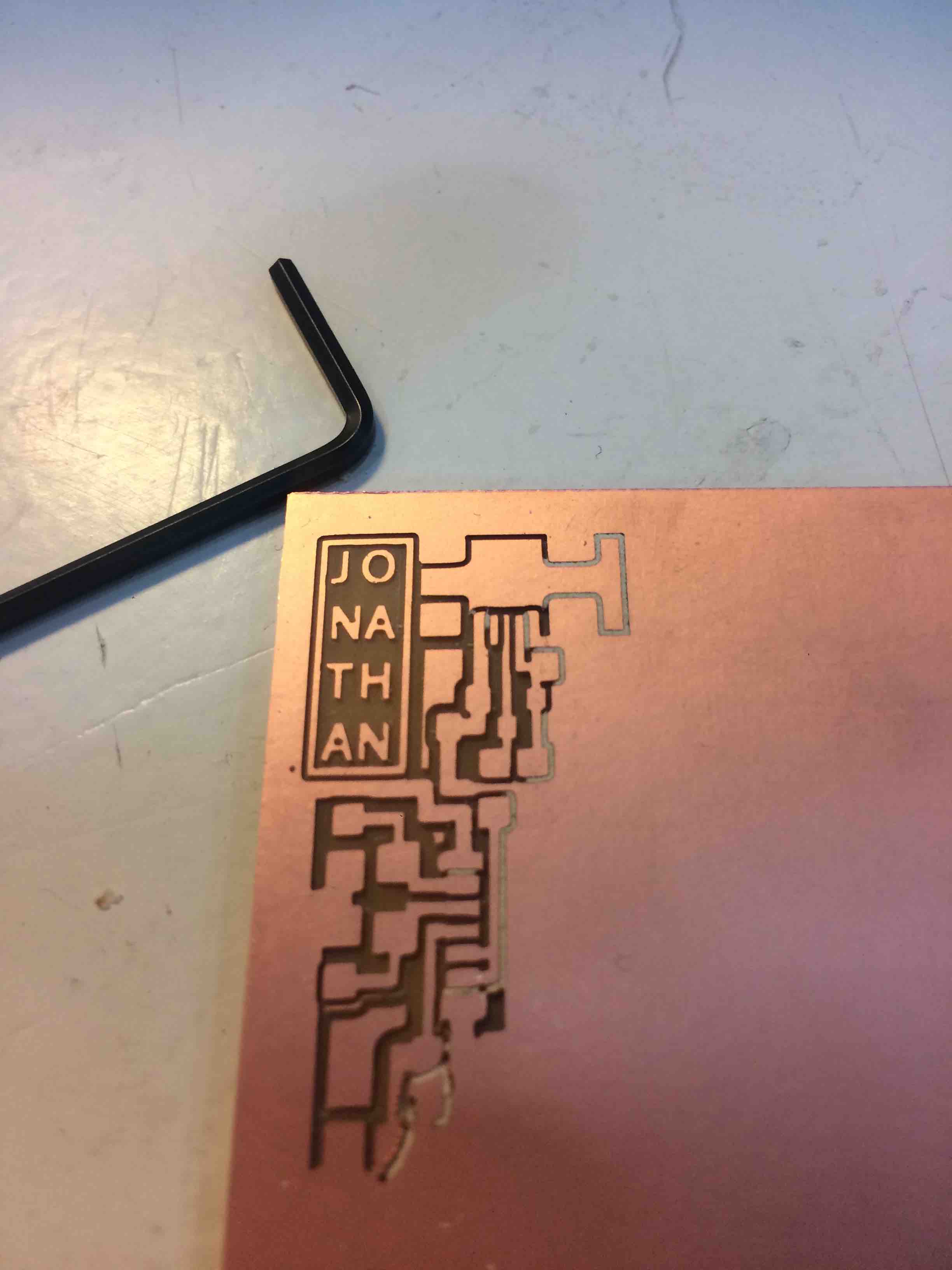

The first attempt failed, i probobly didnt put enough tape on the buttom of the borad and while mining the board moved a bit and i stoped imidiettly the procses.

i restart the X Y and Z values and started again, this time i assume i didnt configured right the Z value or the surface wasent flat enough and the miling got worng as you can see in the picture:

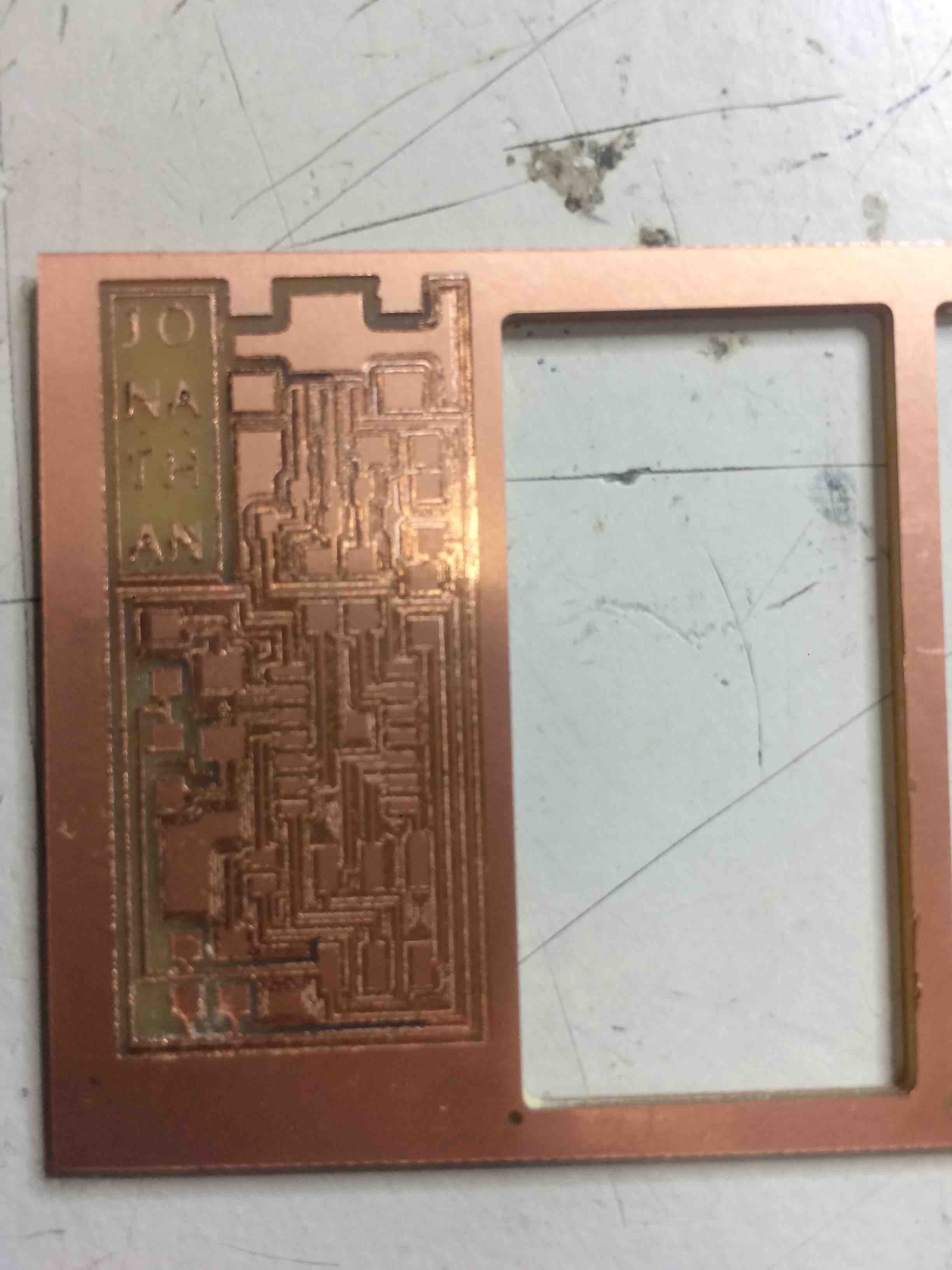

in the third attempt everything works right and the borad came out from the machine exacly as it needed to be. then i started to collect the components needed for the solding part.

Solding the compenents

The first time i was looking on the companents i really didnt understood how its posible to sold correctly such a tiny companents but after watching some of my class college doing it i got more confidence and started with the work. surprisely it wasent as hard as i thought and in couple of hours i finished solding all to components to the borad.

Testing and Programing the borad

After finishing with solding the board i started to to test with the circuit tester that all the circuits are made well and the electricity can pass from each component to another