Applications and Implications

Week 17: Assignment

The assignment for this week is to propose a final project that integrates the range of units covered, answering the following questions:

- What will it do?

- Who's done what beforehand?

- What materials and components will be required?

- Where will they come from?

- How much will it cost?

- What parts and systems will be made?

- What processes will be used?

- What tasks need to be completed?

- What questions need to be answered?

- What is the schedule?

- How will it be evaluated?

Also, as per Neil's instruction following points should also be kept in mind.

- Projects can be separate or joint, but need to show individual mastery of the range of skills covered.

- Where possible, you should make rather than buy the parts of your project.

Final Project and What will it do?

As a final project for FabAcdemy 2017, I decided to make Automatic Food Dispensing machine for fishes in aquarium.

Reason, I decided to make this is because, One of my friend stays alone and loves fishes. So, at his place he is having a fish aquarium. Whenever he stays out of town for more than one day I have to feed his fishes. I am sure most of the people worldwide faces this same problem, which restricts them from going out. So, to overcome this problem, I planned to develop a mechanism which need to be attached with the aquarium and it will dispense fish food automatically at the programmed time. Also, as a added feature to this mechanism, I have decided to show, time and temperature of the room on the LCD.

Who's done what beforehand?

To the best of my knowledge, no one in FabAcademy has created anything of this type. But, when I googled for similar products, I found some automatic food dispencing machines are already available in market ranging from Rs. 1000 to 5000, available on ebay and amazon.

What materials and components will be required?

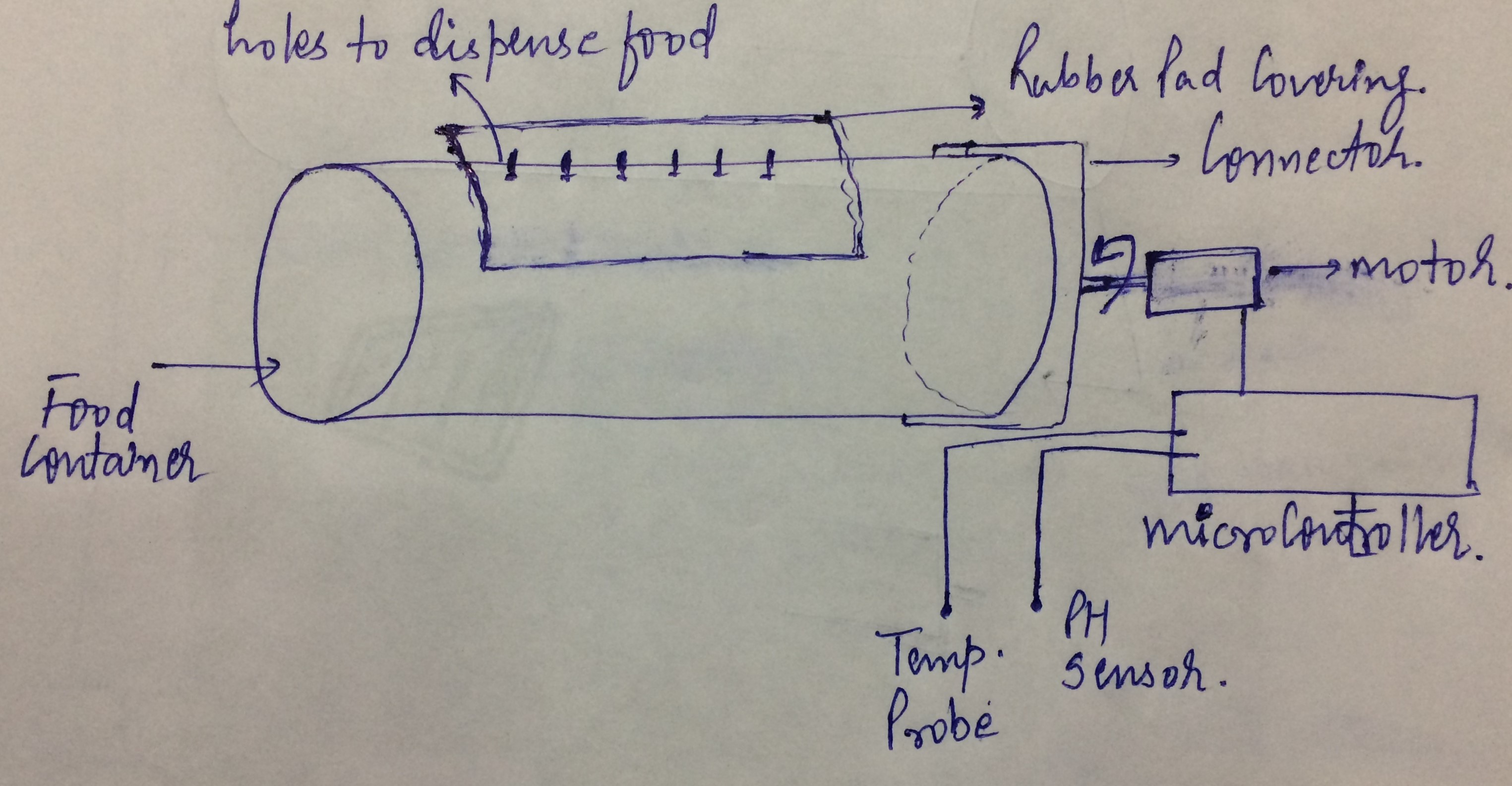

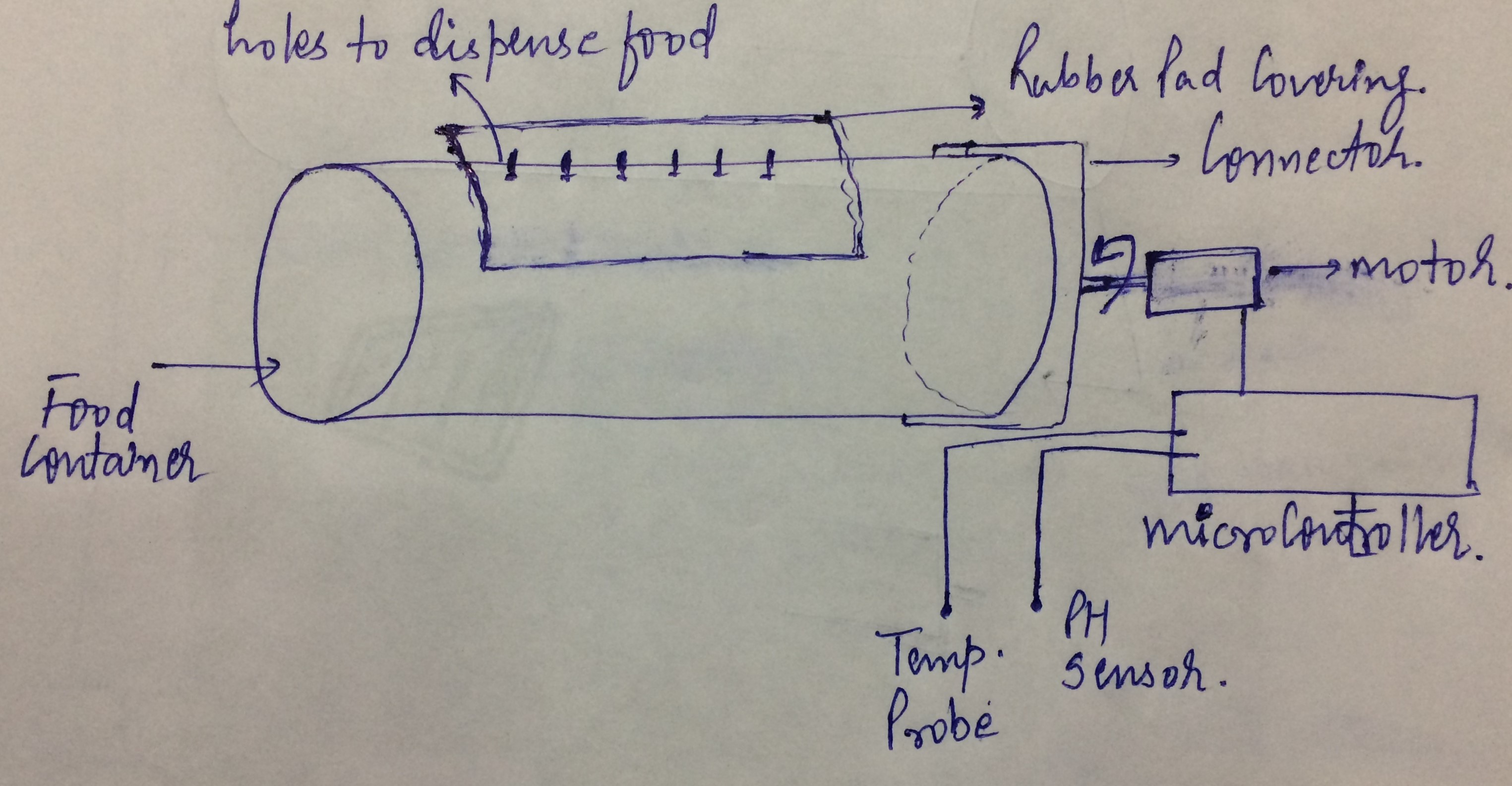

Following is the rough sketch of my final project, from the sketch itself one can make out what are components required for the completion of my product.

List of material and components, will be using for completion of my project:

List of material and components, will be using for completion of my project:

- Roland SRM 20 PCB milling machine for milling the PCB board.

- Copper clad board for making PCB.

- SMDs to stuff my board.

- 3D printer for printing the rotating cylinder.

- Servo Motor to rotate the cylinder.

- ATMEL MEGA328P microcontroller.

- Soldering station.

- DS 3231, real-time clock (RTC)

Where will they come from?

All the above mentioned material and components are available in our lab.

How much will it cost?

The approximate cost of the above mentioned material and components is as follow:

- pH sensor: Rs. 950

- Roland SRM 20 PCB milling machine for milling the PCB board: Rs. 2,60,000

- Copper clad board for making PCB: Rs. 200

- SMDs to stuff my board: Rs. 200

- 3D printer for printing the rotating cylinder: Rs. 1,50,000

- Servo Motor to rotate the cylinder: Rs. 150

- ATMEL MEGA328P microcontroller: Rs. 150

- Soldering station: Rs. 2000

- DS 3231, real-time clock (RTC): Rs. 190

What parts and systems will be made?

I will be making following parts:

- Rotating Cylinder: I will be making a 3D model for the rotating cylinder and will 3D print it on Ultimaker 2.

- Printed Circut Board: After making the schematics on the Eagel, will mill the board on Roland SRM 20 and thereafter will stuff all the SMDs on it.

Following parts will be used directly:

- Servo Motor

- DS 3231, real-time clock (RTC)

What processes will be used?

Following Softwares and machines will be used to make the final project:

- Solidworks is used to make 3D model of the rotating cylinder.

- Ultimaker 2 is used to 3D print the 3D model developed using Solidworks.

- Eagle software is used to make schematic of the circut board.

- The developed board of the circuit by Eagle software is theirafter milled using SRM20 Roland machine.

- Arduino software is used to write the program and burn it in the microcontroller.

What tasks need to be completed?

Following tasks need to be done:

- Designing of the 3D Model.

- Printing the designed model on 3D printer.

- Make desing of the controller board on Eagle software.

- Milling the board on Roland SRM 20 machine.

- Writing a arduino program to take input form RTC and rotate the cylinder.

- Writing a C program to drive the servo motor at defined intervals.

What questions need to be answered?

Accuracy of the machine is main concern to me and also how the utility of the machine can be incresed.

What is the schedule?

I want to finish my final project in 2 weeks approximately and will start working on my project from 01/06/2017 and try to windup everything by 10/06/2017.

How will it be evaluated?

My machine can be evaluated by comparing it with the already available machines in market on the basis of Price, utility and accuracy. This machine is a proof of concept for much grander product. Various setups of this type, could also be used simuntaneously for putting calculated and precise amount of various spices for making dishes. For now, While developing this machine I will get an idea of the problems and areas of improvement. Also, once my machine starts fulfilling it's basic function successfully, I can think of adding some more features to increse it's utility and value.

List of material and components, will be using for completion of my project:

List of material and components, will be using for completion of my project: