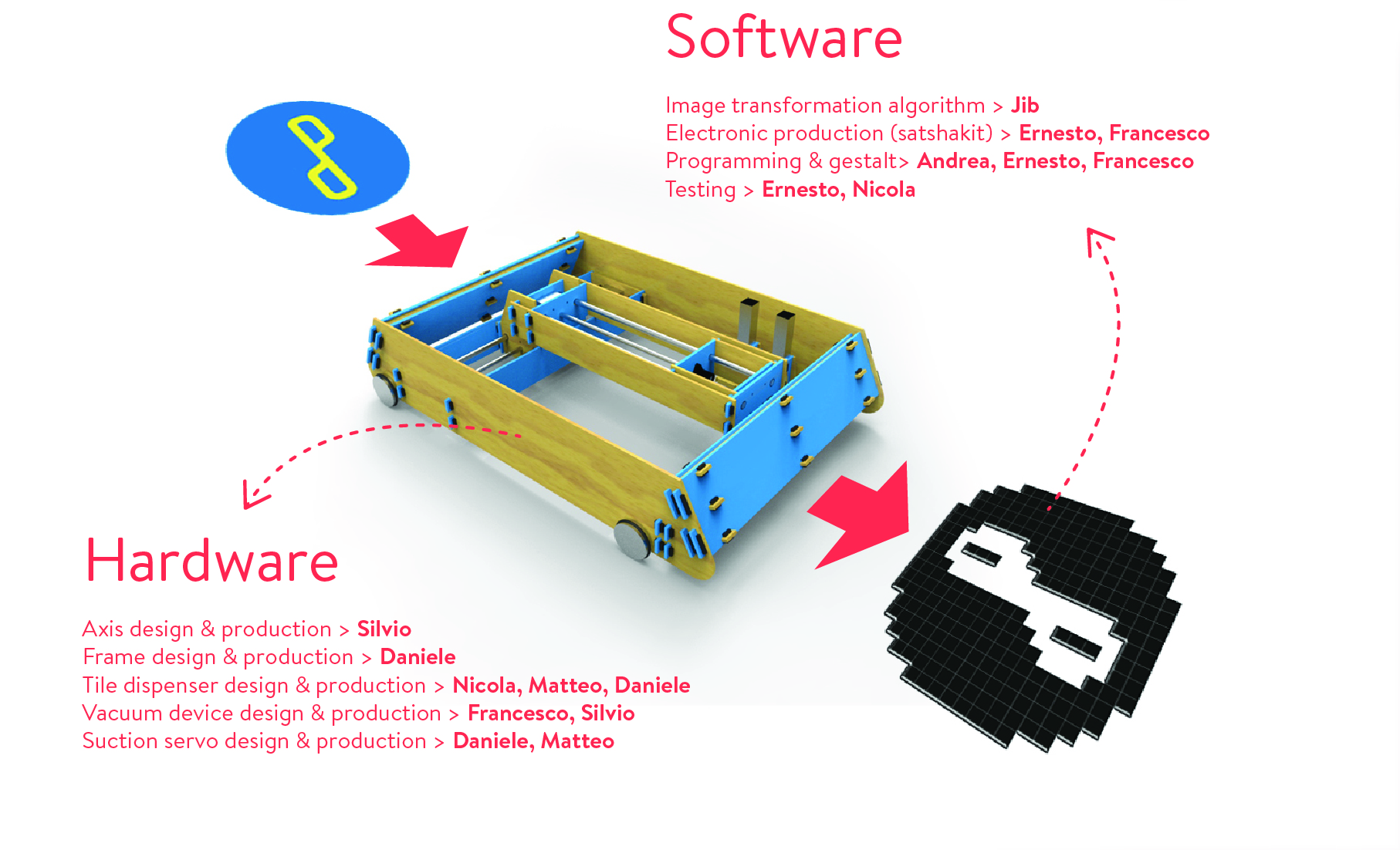

This week we seated togather at the designing table to decide what machine we were going to build. The 9 people at opendot divided in 2 teams and decided to build 2 distinct machines. I was in charge for the machine design of the first machine. It is a pick and place machine for mosaics.

We togather decided for an orizontal layout of X and Y axis, attached to a frame structure. The frame was provided with wheels to make the machine move and create longer mosaic strips.

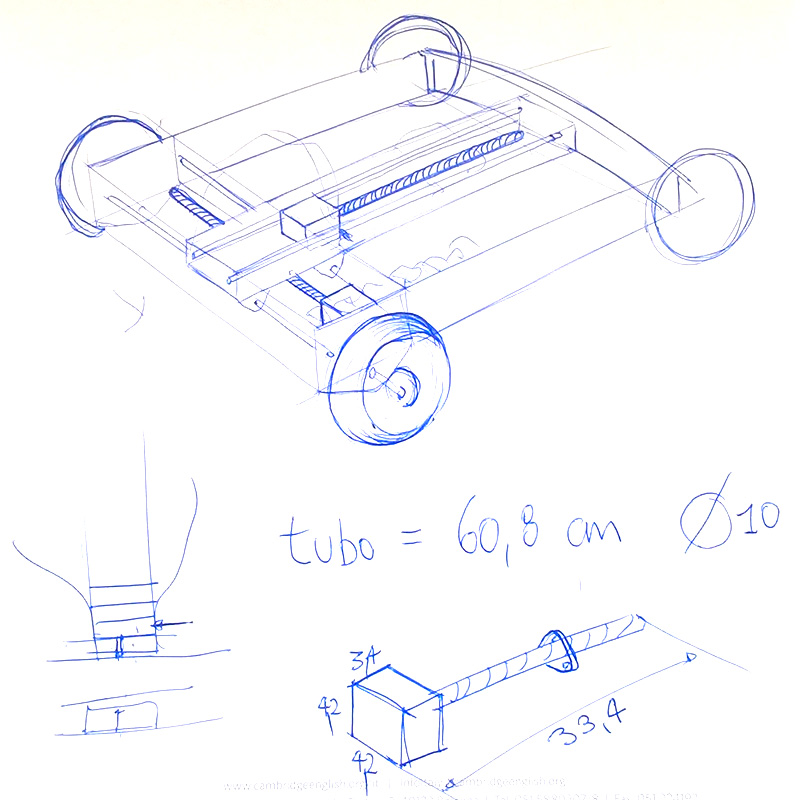

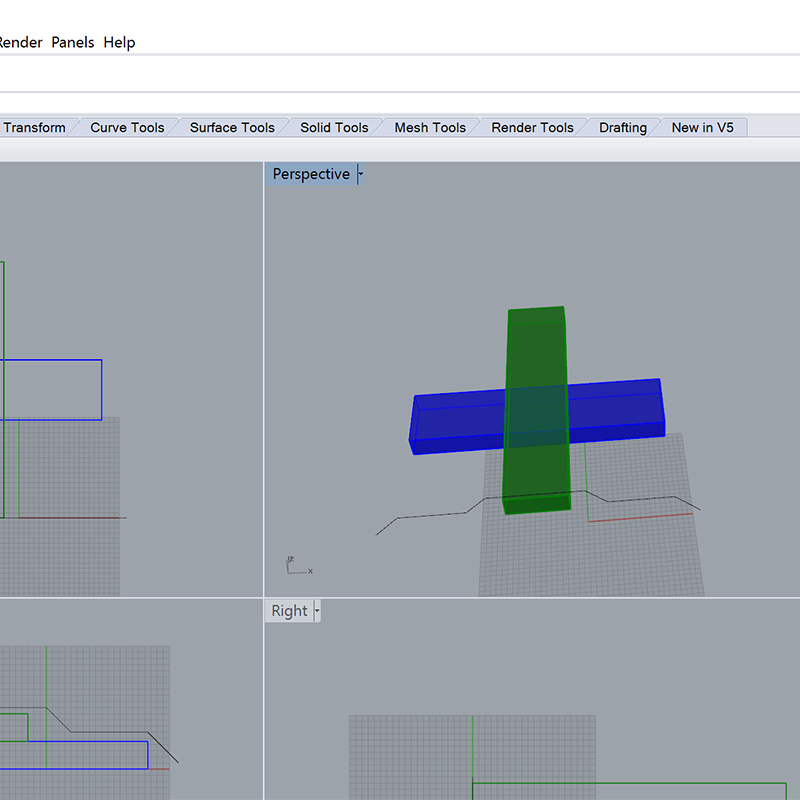

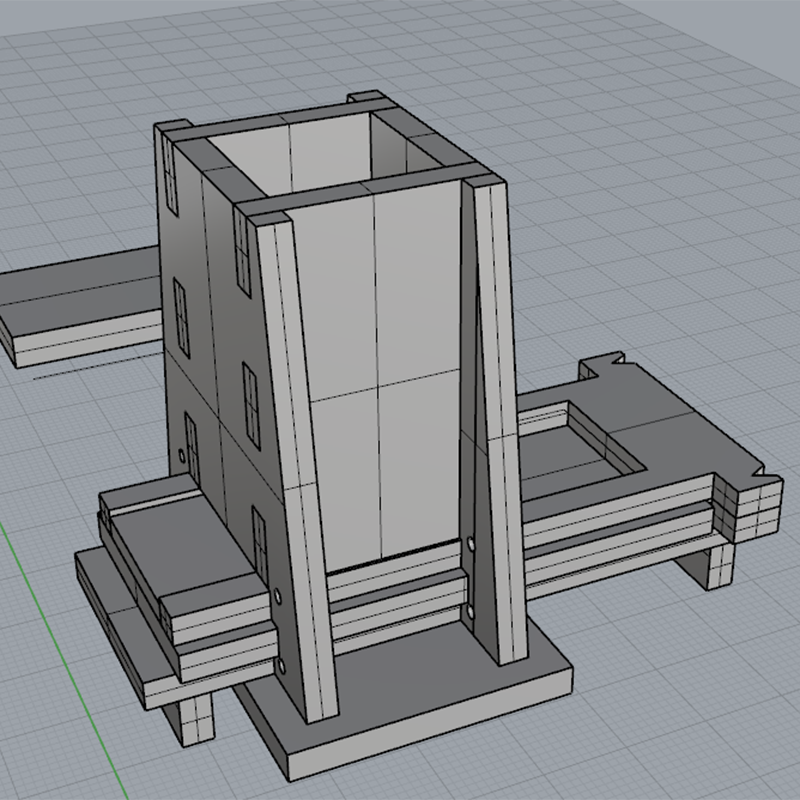

So I started designing the Frame structure in Rhino while Silvio was designg axis boxes. Everithing was designed to be built with 4mm lasercutted plywood.

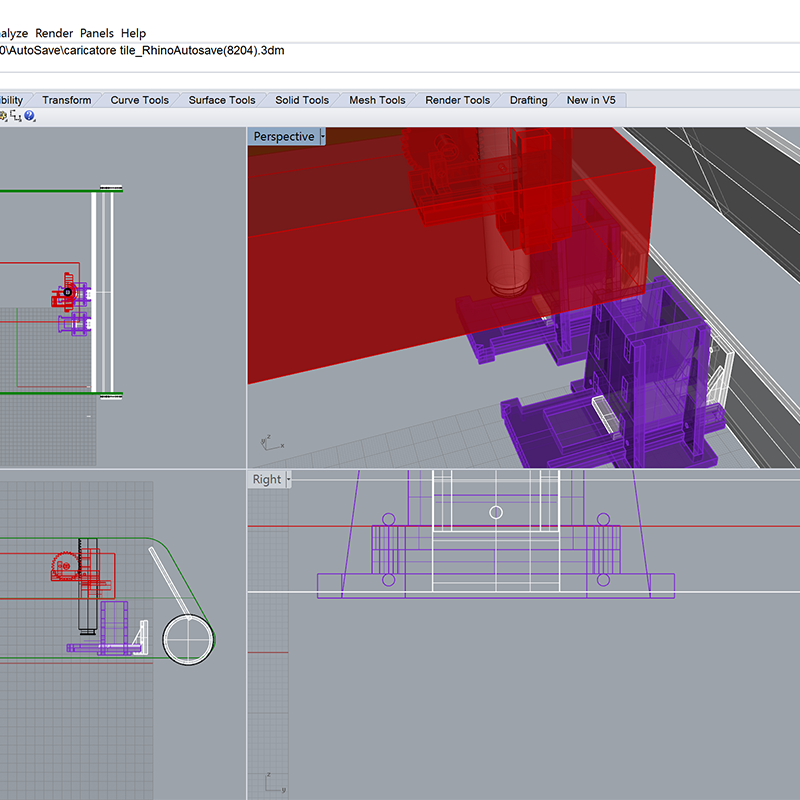

Matteo and Nicola were in charge to design the tile dispenser of the machine. They came out with a smart idea I placed inside the machine frame. We togather canghed some measurements to fit the machine design.

This is How the tile dispenser look like now.

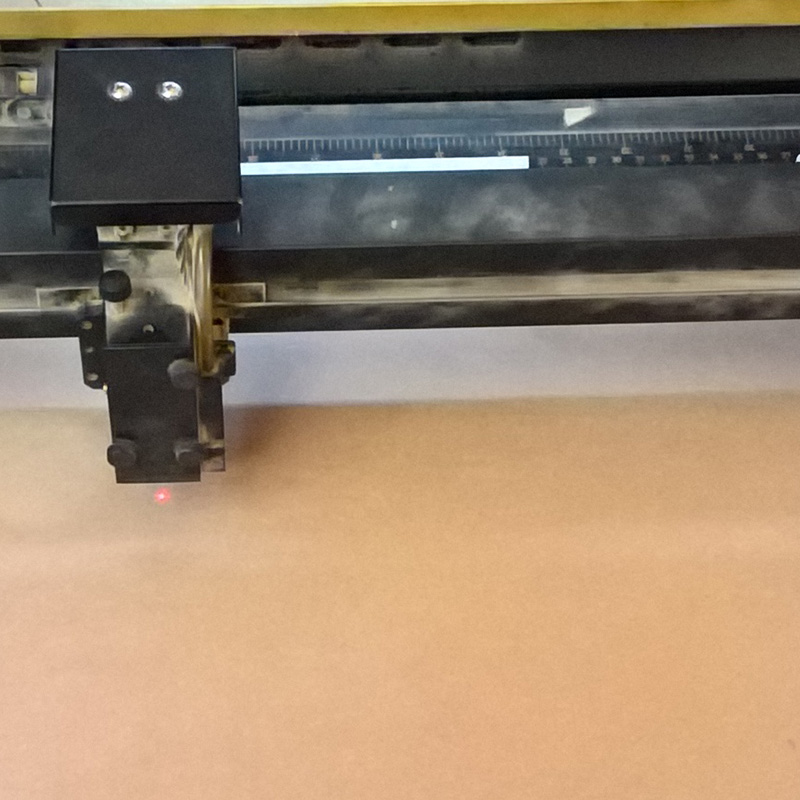

We created cut traces and laserctted the piece.

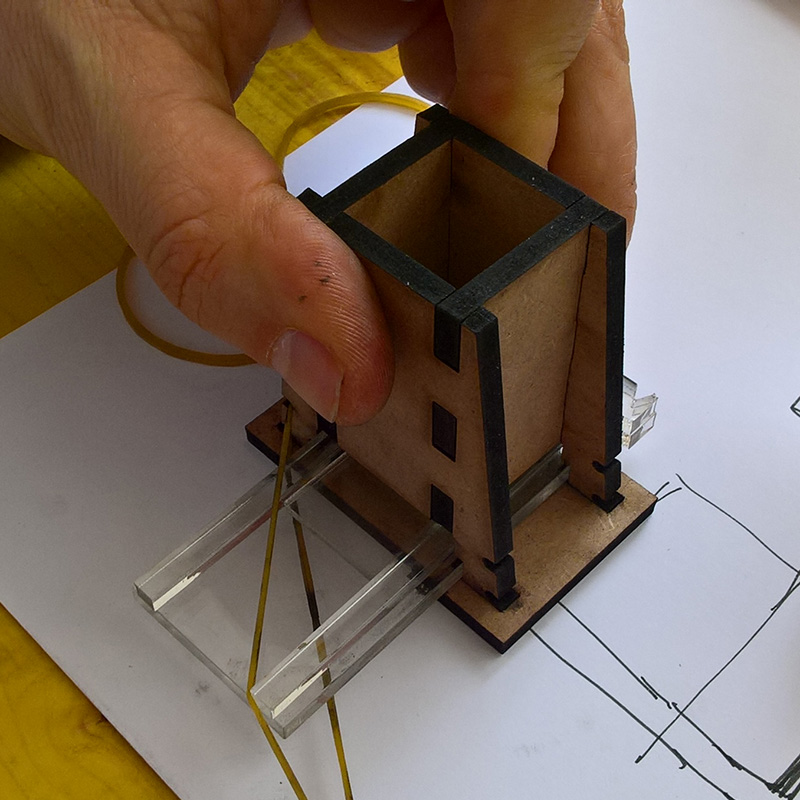

Some pieces are made with 4 mm MDF but the sliding parts are made in plexiglass just to obtain a smooth sliding performance.Elastic was used to activate the sliding movement that picks tiles.

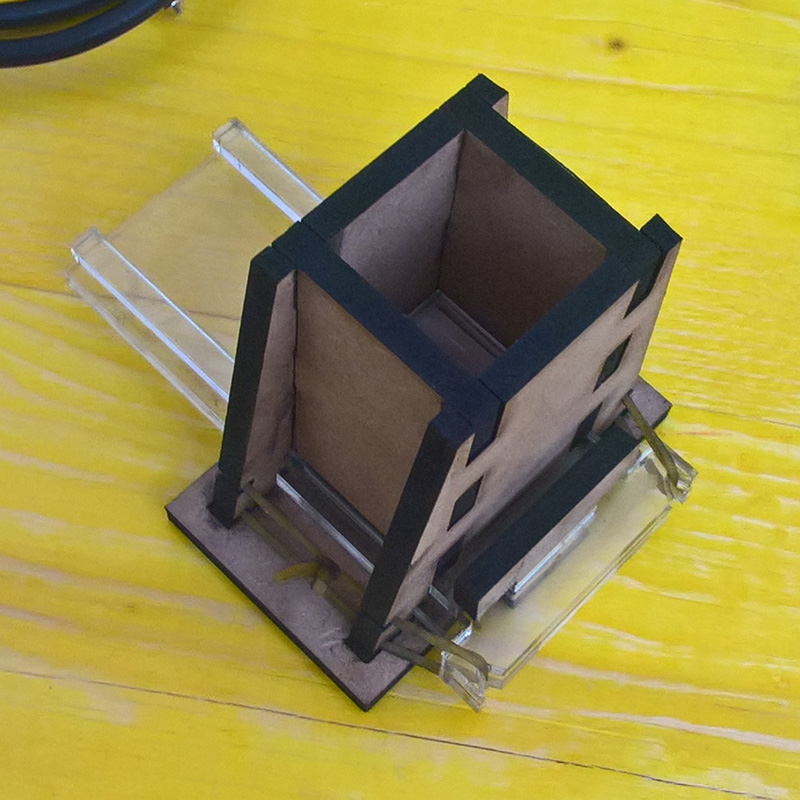

Here is the part complete and working. From this piece we made oservations that produced a second version better designed and capable of storing more tiles.