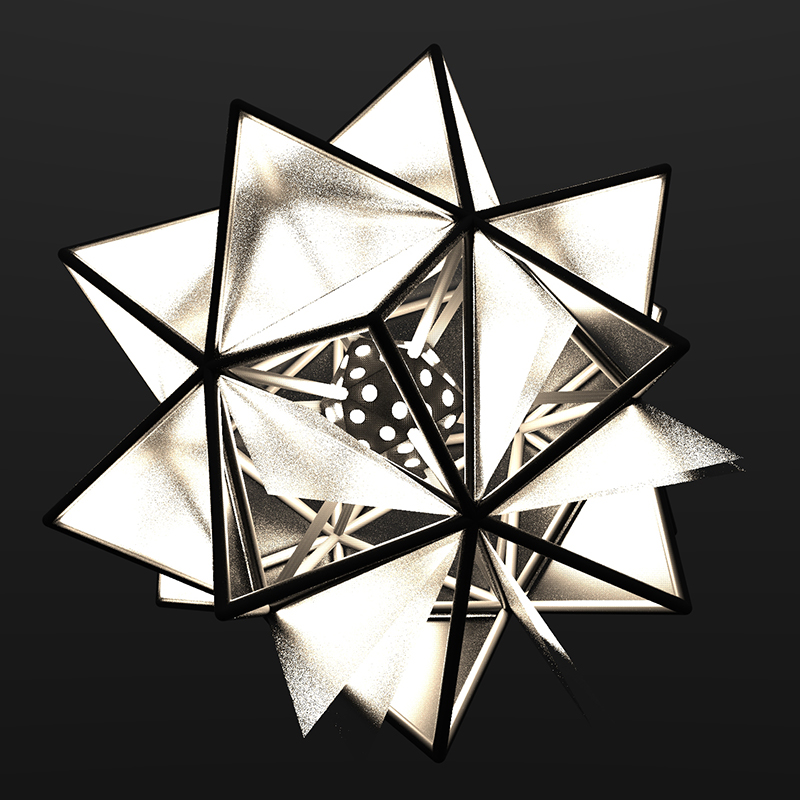

Spore is a sensitive lamp and for me is a double challange. Firstly because I have no prior experience neither with electronics nor with programming, and secondly because it needs to be an aesthetic object. The real goal is to embed everything it needs hiding it inside the structure of the lamp. So I had to face the problem of miniaturization, in order to obtain the lower impact in terms of mechanical and electronic presence.

The production of Spore has been programmed since the mid of April. Thanks to this I had the time to produce some parts that were high in number. For me this production phase has been extremely satisfying. Above all I enjoied the most producing all the tips via moulding and casting process.

What will it do?

Spore has a semi-transparent shell made of "flaps", touching the structure produce these flaps to open just around the touch position.

Who's done what beforehand?

This is not inspired by a particular project I have seen rather is a first experiment to measure myself with the theme of sensitive objects. In the future I would like to produce more and more experimentation on this topic.

What materials and components will be required?

I need aluminium profiles for stucture (12 with circular section and 60 with square section), PP semi-transparent sheets to build 30 flaps, a 40w lamp, 12 3D printed parts for structural joint, 8 3D printed small parts for motor fixing, a spherical 3D printed central core, a mould for tips, resin, fishing rope (nylon wire), 4 dc motors, 1 satshakit, 2 h-bridge, 4 capacitive sensors and one voltage reducer.

Where will they come from?

Aluminium bars are bought in 1m leght, as well as the lighting lamp (a small 40w hooven lamp) and PP sheets (3 sheets 100x50cm). Everything else is autoproduced.

How much will it cost?

Resin 18€, aluminium bars 15€, lamp 2€, PP sheets 15€, nylon 3€, Satshakit 8€, electronics 2€. Totally 63€.

What parts and systems will be made?

I produced the mould for tips, I 3D printed joints, DC motor fixing parts and the spherical core. I laser cutted PP Sheets to obtain flaps. I produced the satshakit as well as the extra electroincs needed.

What processes will be used?

CAD design, lasercutting, molding and casting, 3D printing, electronic production, programming.

What tasks need to be completed?

All the electronic and programming activities.

What questions need to be answered?

Since flaps are pulled and automatically return to their closed position once tendons are de-twisted, I need to value empirically wich is the right voltage needed to properly pull tendons without stressing too much DC motors.

What is the schedule?

I'm finishing to produce all the structural parts. In the last weeks I need to build the lamp and to avaluate empirical aspects to fix electronics and produce it. I sheduled 7 full time days (18h on 24h), for the final assembly plus test plus programming.

How will it be evaluated?

Sufficient: The structure is made and the lamp is aesthetically good.

Good: The Lamp is aesthetically very good and movable parts works properly with the tendons system.

Very good: Sensors and actuators are properly embedded and respond to a simple program that cycles opening and closures of "flaps".

Super: everything is implemented in every node of the lamp, it means it respond wherever you touch it. The product is aesthetically very well defined with all the electronic components well hidden inside the structure.