1. Liquid Deposit Drawing machine

For the Machine design assignment we have decided to build two machines: a LDM printer with X/Y axes freedom and a Pick and place to create mosaics. This week I've been working to understand wich kind of mechanism we could use for the LDD syringe extrusion that can be even adapts as vacuum mechanism. I found 2 main way to do it: a simple linear extruder mechanism or an Auger Valve mechanism as the LDM wasp printer.

The Auger extruder

-

Useful links

- Auger mechanism

- Wasp extruder

- Wasp extruder CAD files

Linear Extruder

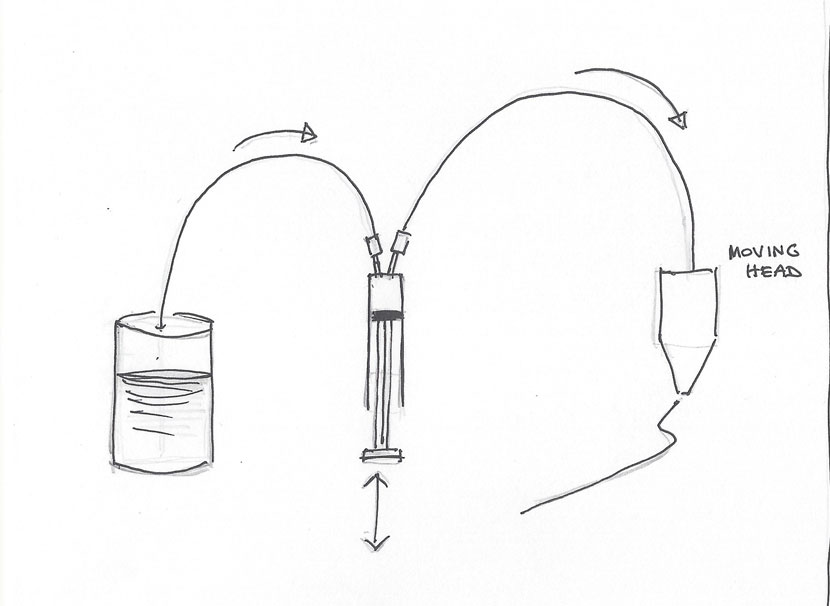

A more simple mechanism to build is a linear extruder with a syringe. The only issue with this system is the limited tank of a syringe, that not occurs in the auger valve system. But thinking a bit about it I imagined to make a system with two non return valves one for printing, one for refill the syringe from a tank. I wanted to test if this system could work so I decided to try this one instead of the auger method.

2. The project

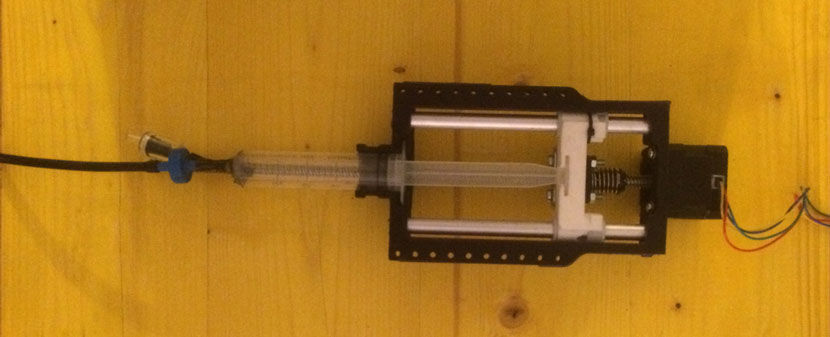

Looking on instructables I've found a good project for a linear extruder of a syringe: Instructables link.

I've modified the body of the extruder to fit it inside the Prusa's printing plate (max 180mm).

And behind you can see the idea of how the refill system should works.

Thanks to Nicola for the drawing

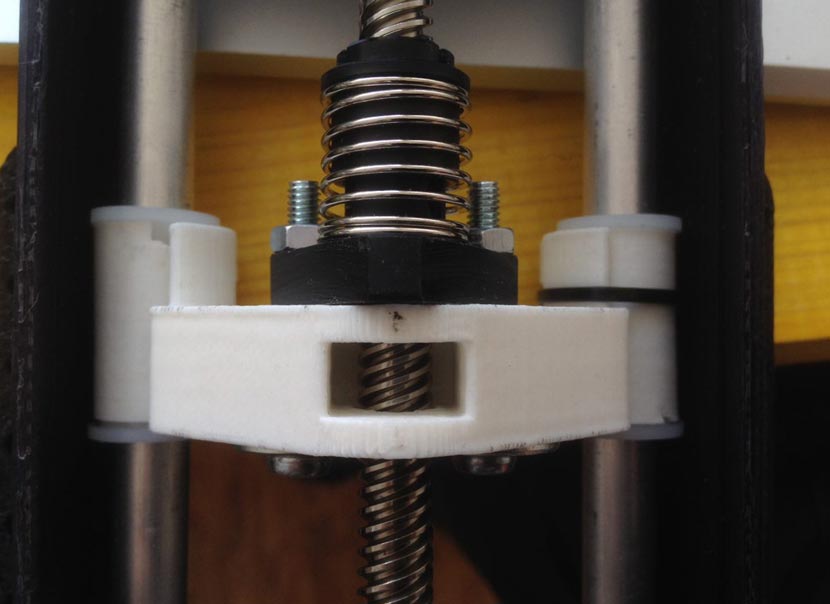

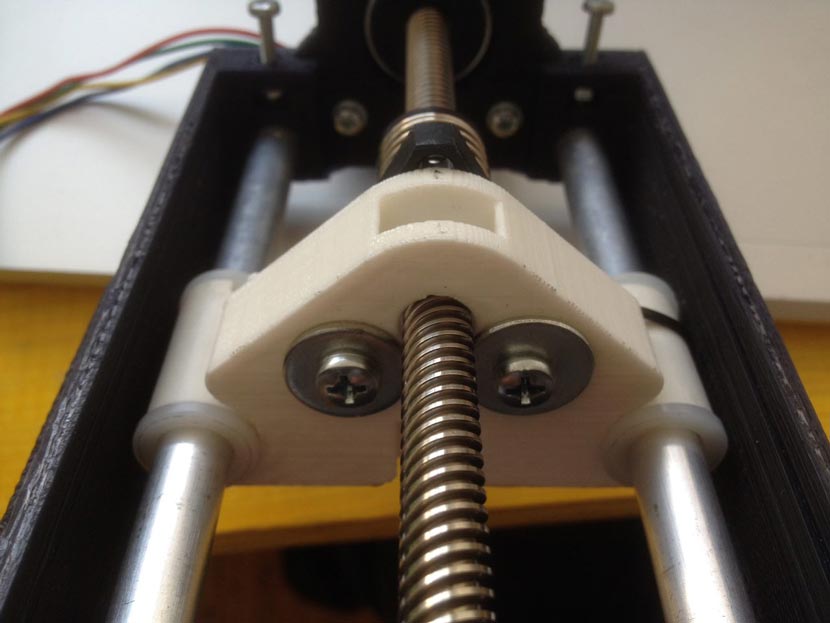

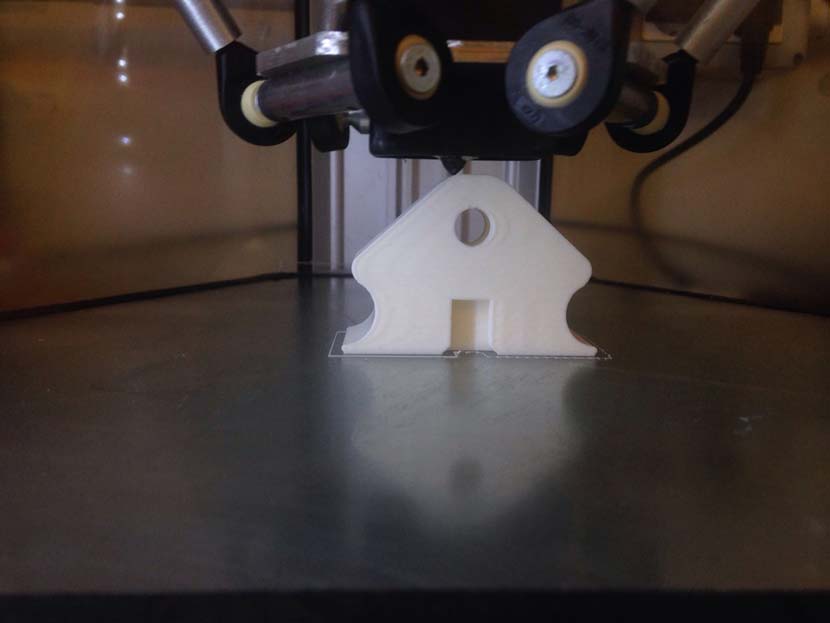

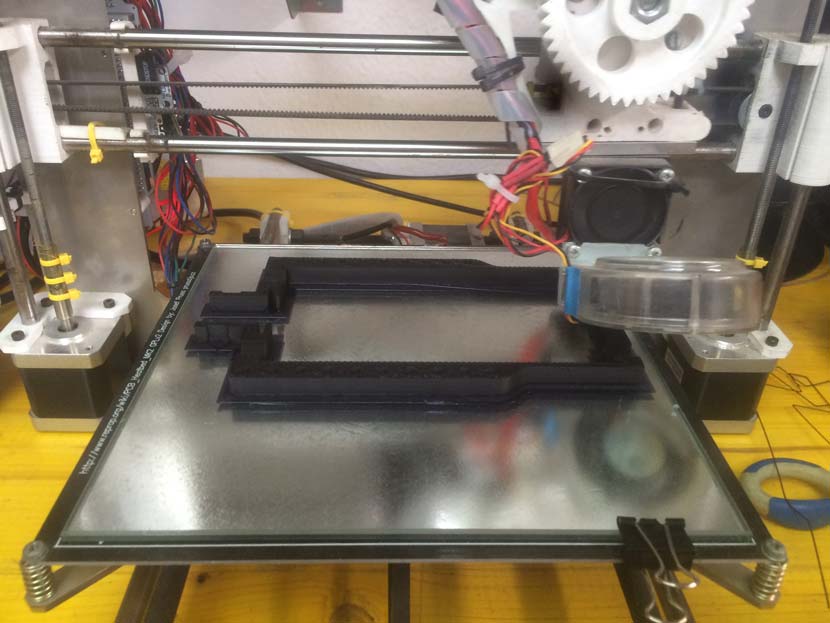

3. Printing the body, ram and bearing joiners

I've printed the ram using the Delta wasp and the body using the prusa (in order to decrease the printing time). It took 50 min to print the ram and 2 and half hour to print the body

- Cad files

- Body

- Ram

- Bearing joiners

4. Assembling of the extruder