Thermal study

The first step is to check the feasibility, and advantage, of having the freezer nested into the cooler. We therefore need to calculate the heat power involved in the process.

There are different sources which give information about peltier devices and support the necessary calculation. I first surfed through a very well made blog on the subject Peltier Device Information Directory.

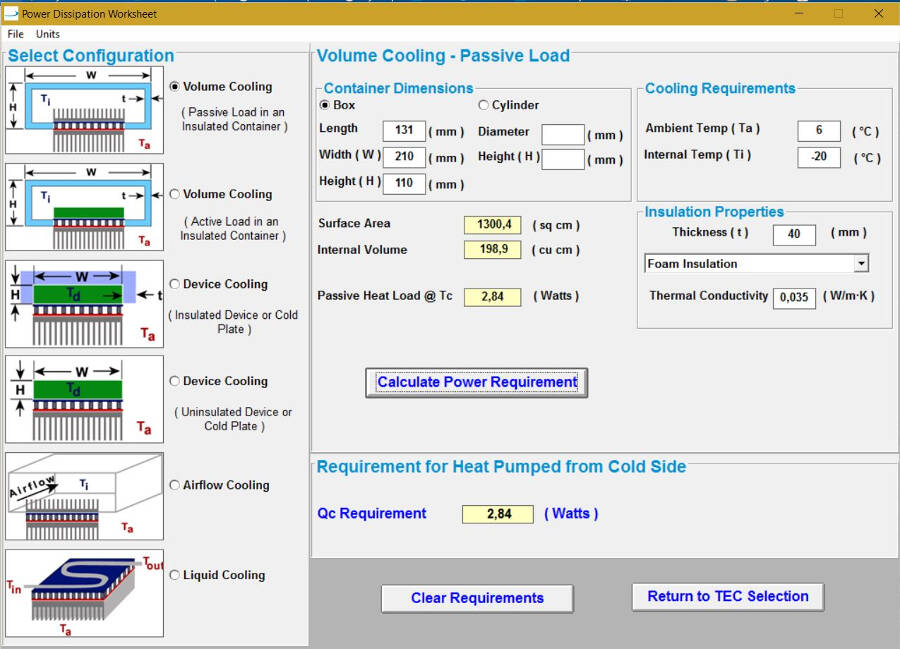

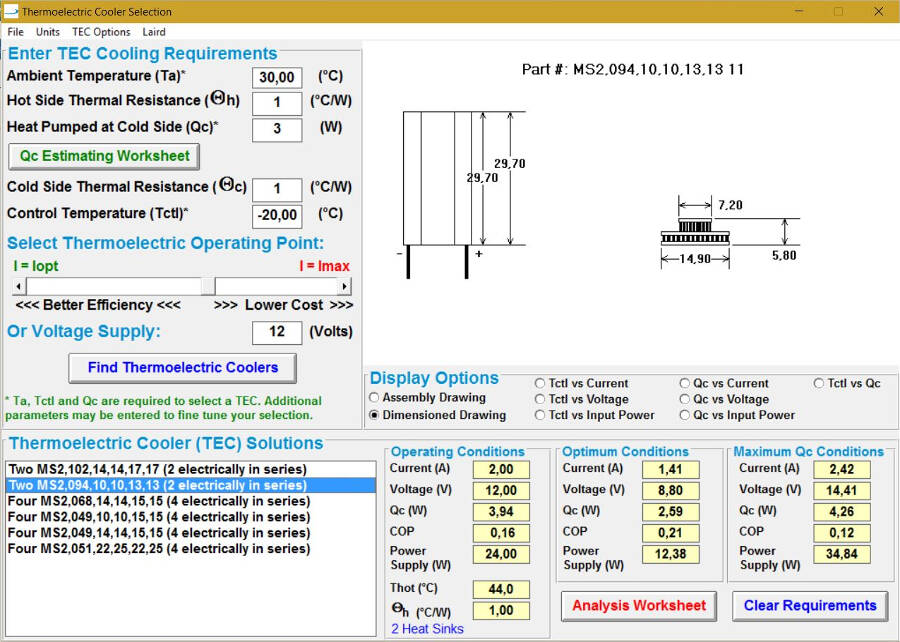

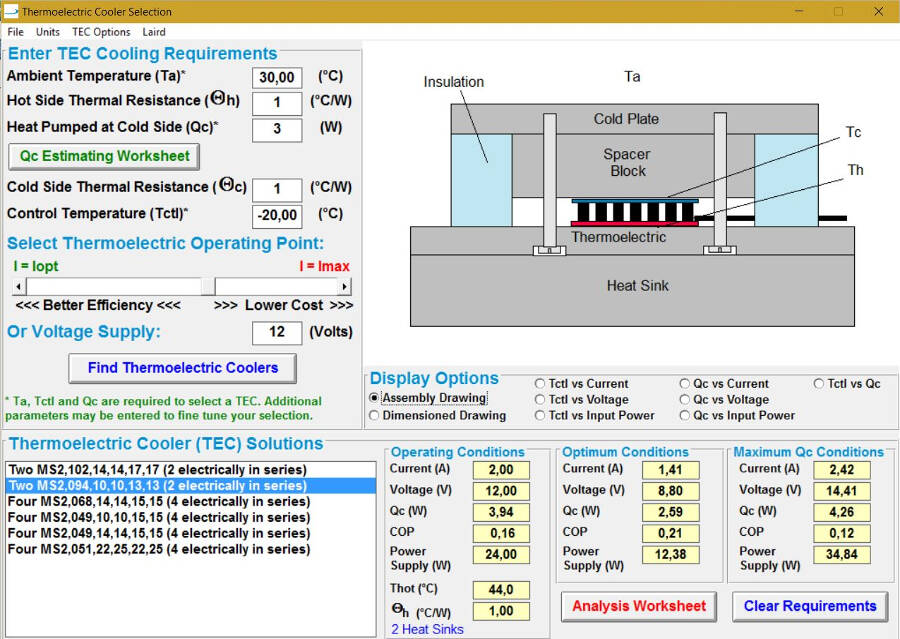

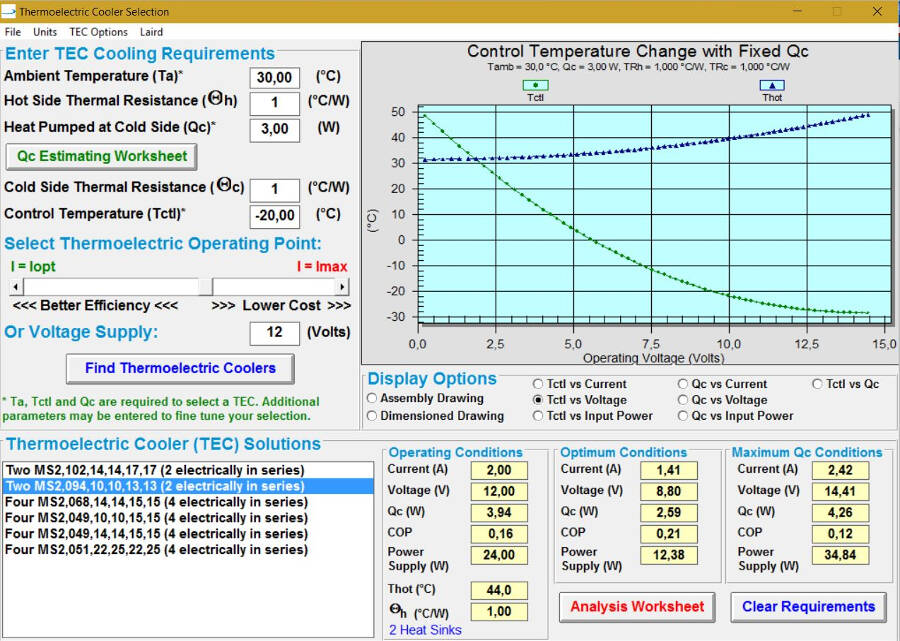

From there, I found a company which makes available an online tool to get a first idea of the heat energy that must be drawn from cooler and freezer in a stade stade operation:

TE Technology, Inc. - Cooling Assembly and Heat Load Calculator.

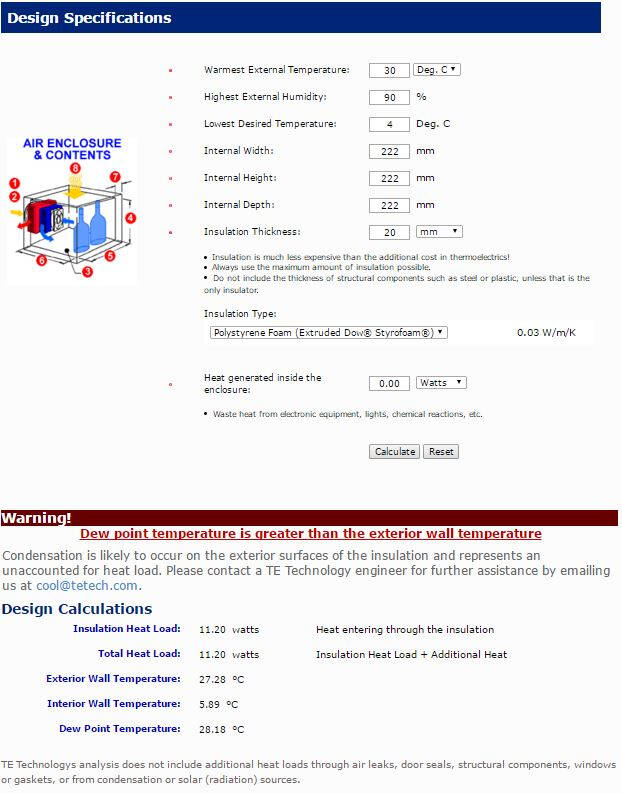

This is the data needed:volume of freezer: the freezer size should be sufficient for four tube racks, stacked two by two.

The available volume should be mm 131x210x110 = 3.0261 dm3

The cooler size requirements are mm 291x300x160 = 13.968 dm3

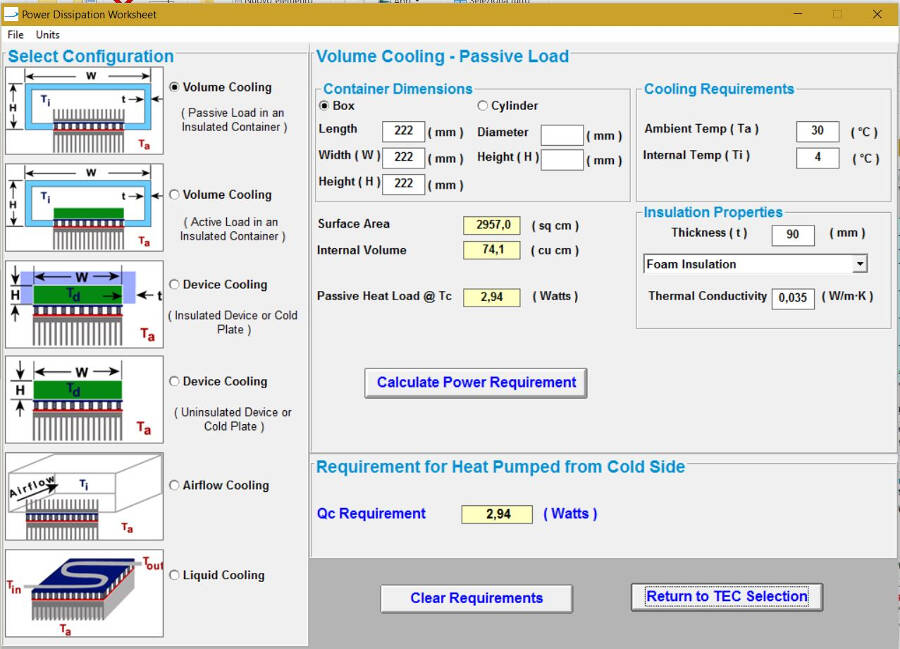

Effective volume of cooler, if the freezer is embedded: 13.968-3.0261 = 10.9419 dm3 which is equivalent, for calculation purposes, to a cube of mm 222x222x222.

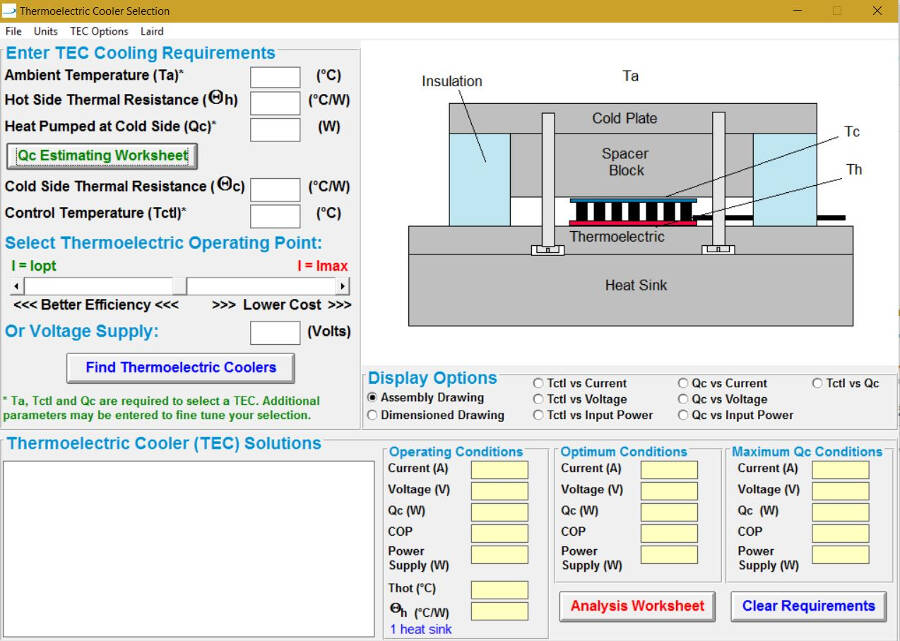

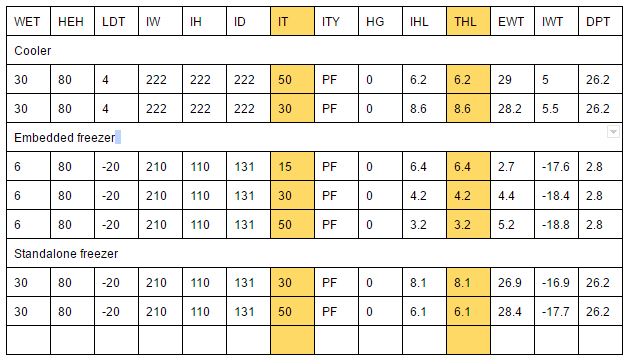

When using the online tool it is immediately clear that insulation thickness greatly influences the heat energy that must be pumped out by the cooling system and, in turn, the type of peltier element. It is necessary to run different iterations to set the correct system design.

Let's quickly draw two design scenario:

- Individual cooler and freezer;

- Freezer nested into cooler;

WET= warmest external temperature (°C)

HEH= highest external humidity (%)

LDT= lowest desired temperature

IW= internal width (mm)

IH= internal height

ID= internal depth

IT= insulation thickness

ITY= insulation type

HG= heat generated inside the enclosure (W)

IHL= insulation heat load (W)

THL= total heat load

EWT= exterior wall temperature

IWT= interior wall temperature

DPT= dew point temperature

PF= polyurethane foam

Power requirements cooler and freezer: 6.2 + 6.1 = 12.3 W

Power requirements cooler with embedded freezer: 6.2 W.

The second solution halves the power requirements. Moreover, it only needs a single thermoelectric block instead of two.

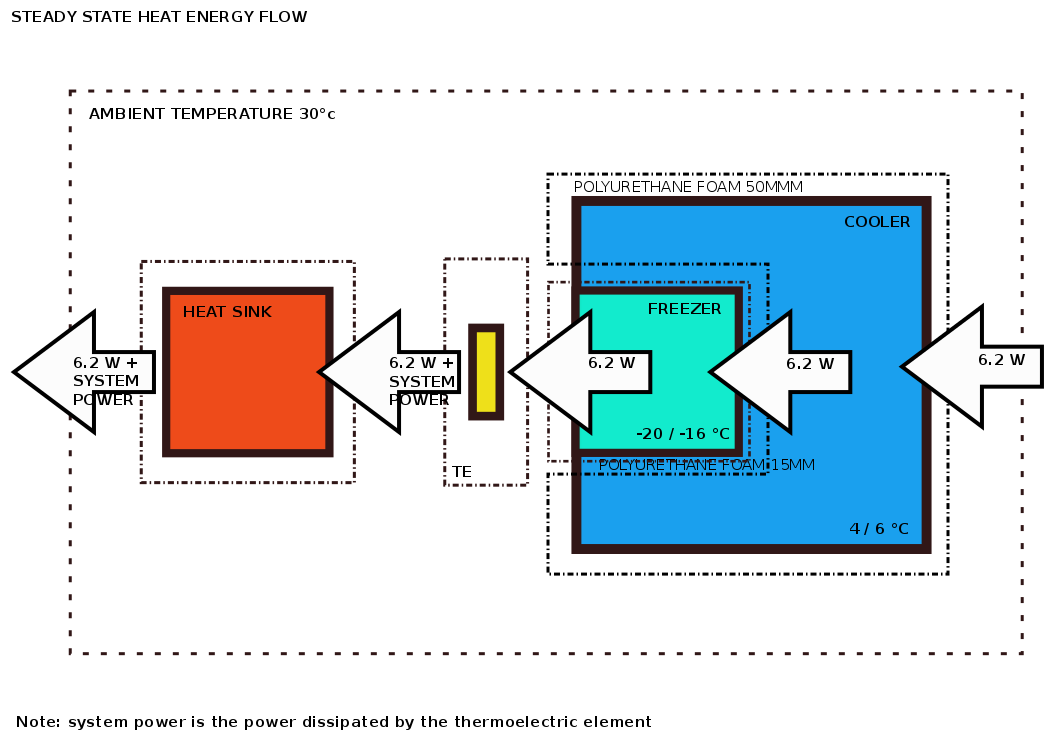

In this case, to get a correct thermal balance, the heat energy flowing through the cooler must be the same as the thermal energy flowing through the freezer and through the peltier element. The freezer insulation must be adjusted accordingly. However, the final insulation thickness and the corresponding thermal power, will be set with the selection of the peltier element.

The thermal balance scheme is the following: