Electrical Installation

My personal contribution was to implement all electrical installation.

In our FabLab was impossible to use the Gestalt Nodes becouse we don't have the RS-485 transceiver for develop FABNET PCB. Remember that FABNET is the physical layer and if you don't comunicate every physical node with the computer is impossible to control the cnc machine.

The electronic components of the printer are:

In our FabLab was impossible to use the Gestalt Nodes becouse we don't have the RS-485 transceiver for develop FABNET PCB. Remember that FABNET is the physical layer and if you don't comunicate every physical node with the computer is impossible to control the cnc machine.

Ramps 1.4 is a shield for Arduino Mega.

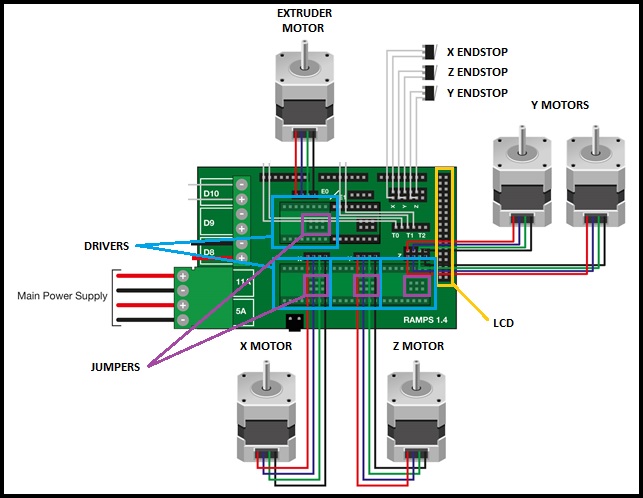

First, I connected steppers, endstops, drivers and LCD on the shield (RAMPS 1.4). Is important to connect all jumpers on each driver for maximun resolution. Next image is an schematic of connections.

Our printer is a replica of Falla 3D printer thus I downloaded firmware here.

For this printer I used Single Extruder Falla firmware. After to upload firmware on Arduino is necessary some changes:

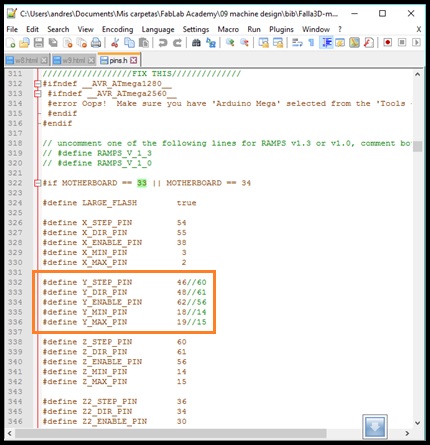

- Check pin assignments in "pins.h" file.

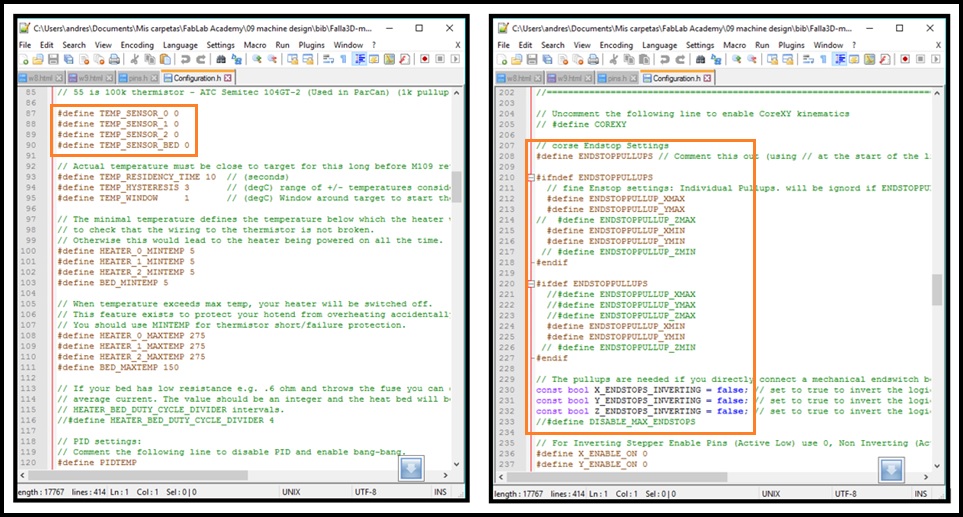

- In "Configuration.h" file disable all temperature sensors and eneable End Stop Pullups becouse the printer has mecanical switches.

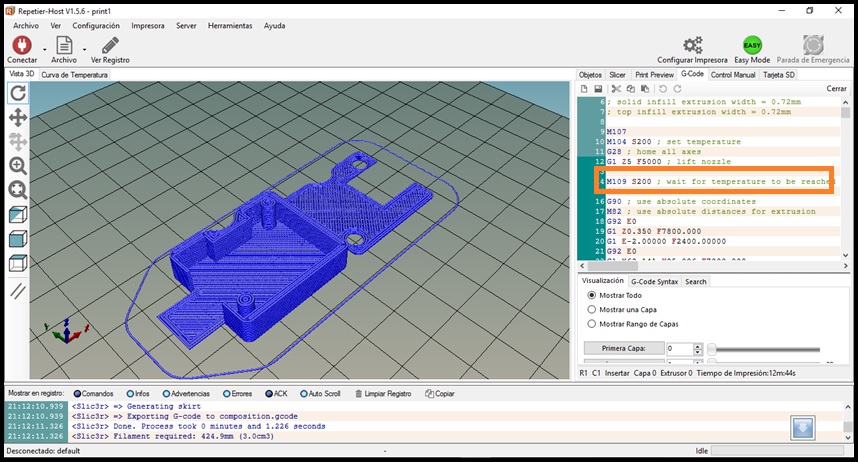

I used Repetier Host software to generate G-CODE.

Before starting printing a file is necessary edit G-CODE. Is important to delete the code "M109 S200" (wait for temperature to be reached) becouse the printer doesn't have sensor temperatures.

These were my personal contribution and this video is the test of the electrical installation of the printer.