Week 3 : Computer Controlled Cutting

assignment

Cut somthing on vinyl cutter design,make,and document a parametric press-fit construction kit.

Vinyl cutter

vinyl cutter is a type of compyter controlled machine.the computer movement is a sharp blade.the blade is used to cut out shape and letter from sheets of thin-adhesive plastic ,it is used to we can make sticker moreover,it is used to we can make flexible circuit in a flexible copper sheet.In our FAB LAB has using CAMM-1 ROLAND VINYL Cutter.

what i did

I desided to plan a logo in my project,for that photoshop software is used to completed the logo and I started to the vinyl cutting process.

here is the orginal

Working with vinyl cutter

first I take a small piece of vinyl sheet then I kept it inside of the vinyl cutter.vinyl cutter has a sensor in one end when we kepting the sheet,the sheet kept above the sensor otherwise the loading time the machine will be show ………..

Then power on the vinyl machine and select which type of sheet will be loaded I mean roll or piece then arow key is used to change the selecte sheet,in here i am using piece type of sheet that is why i am choose piece then I enter the “enter” button,that time the vinyl machine read the size of sheet

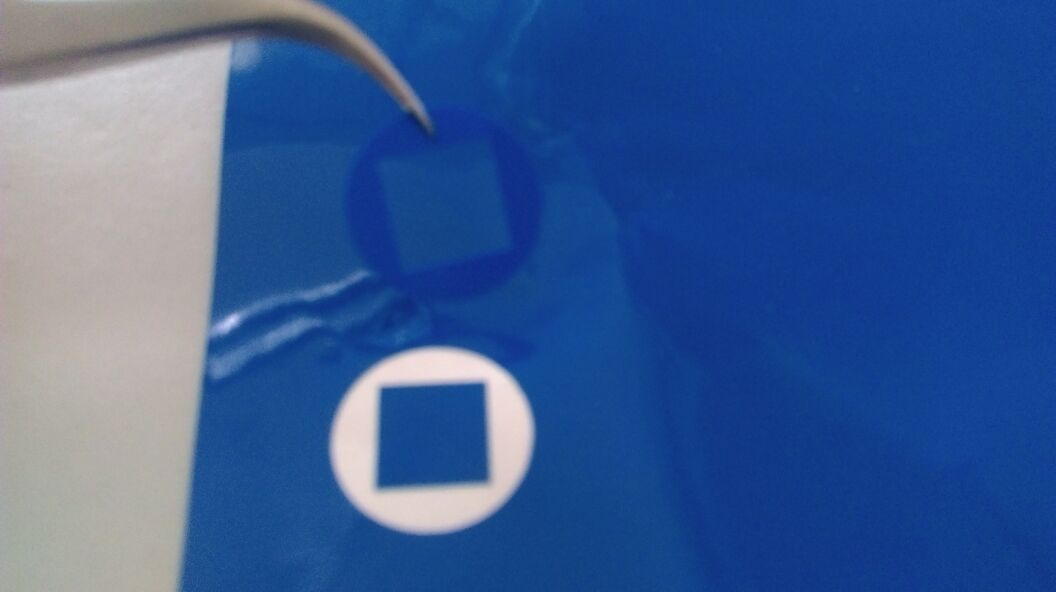

then we check our designed file is fit or not in this sheet.if it is ok we have to test the machine is working good or not ,how we can test? Just press the test button 5 second at a time we can get a sample cut the twezer is used to remove the rount if it is get correctly the cutting process is ok otherwise adujust the blade or force

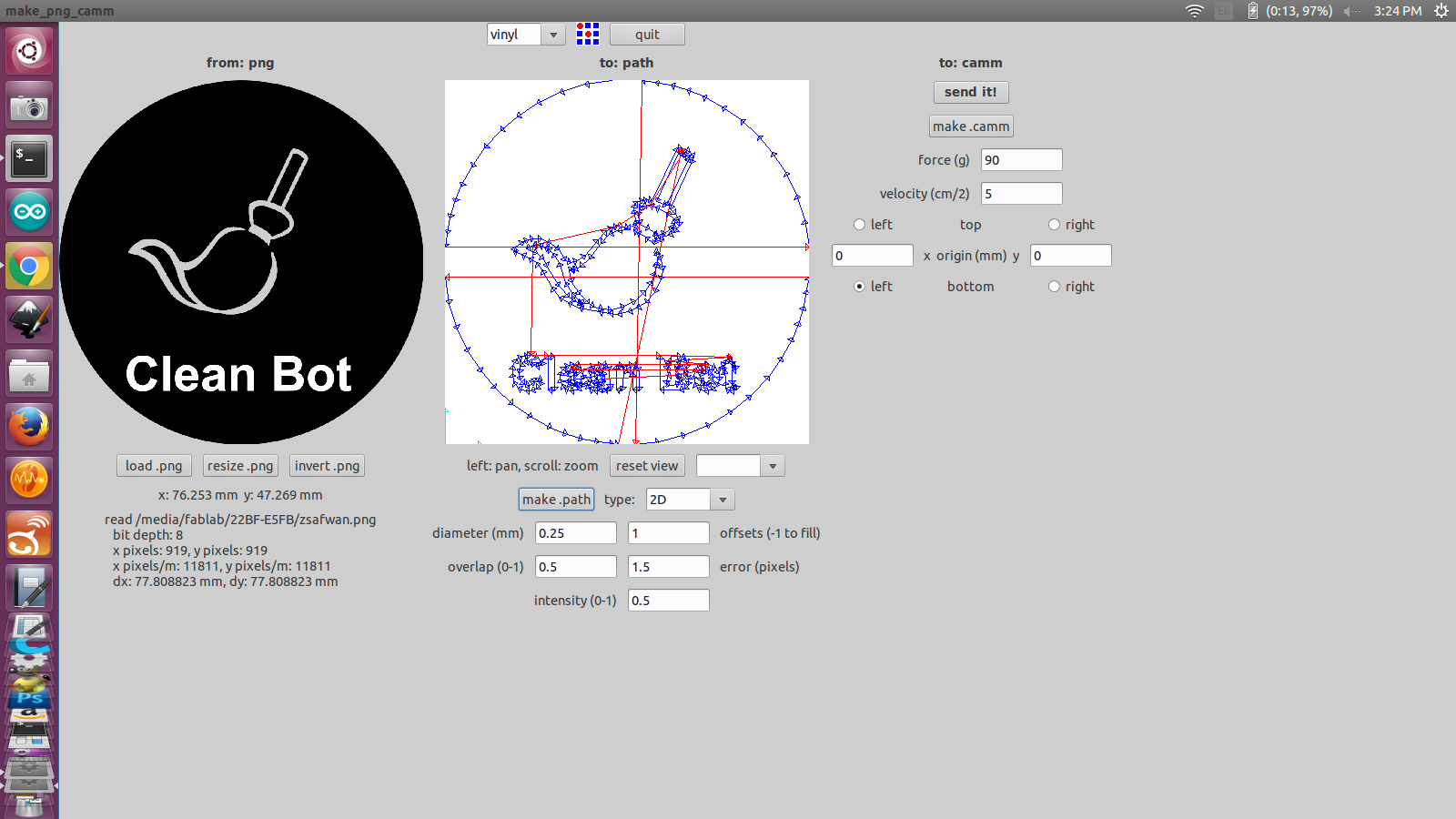

working with fab modules

fab module is the software part of the viniyl cutter for that install the fab modules in our system after the installetion of fab modules,

1)type “fab” in terminal

2)the upcomming box

3)then the new window select “vinyl”

4)load butten is used to upload our designed files

5)click “make.path”(that time the right side of box shows the cutting path,check it get clearly or not)

6)click “make cam”

7)click “send it”

that time the vinyl cutter start to the cutting process.after the cutting process we remove the unwanded things when we removing the unwanted sides,twizer is used for the removing process also we should care for the removing time.yup I got it correctly

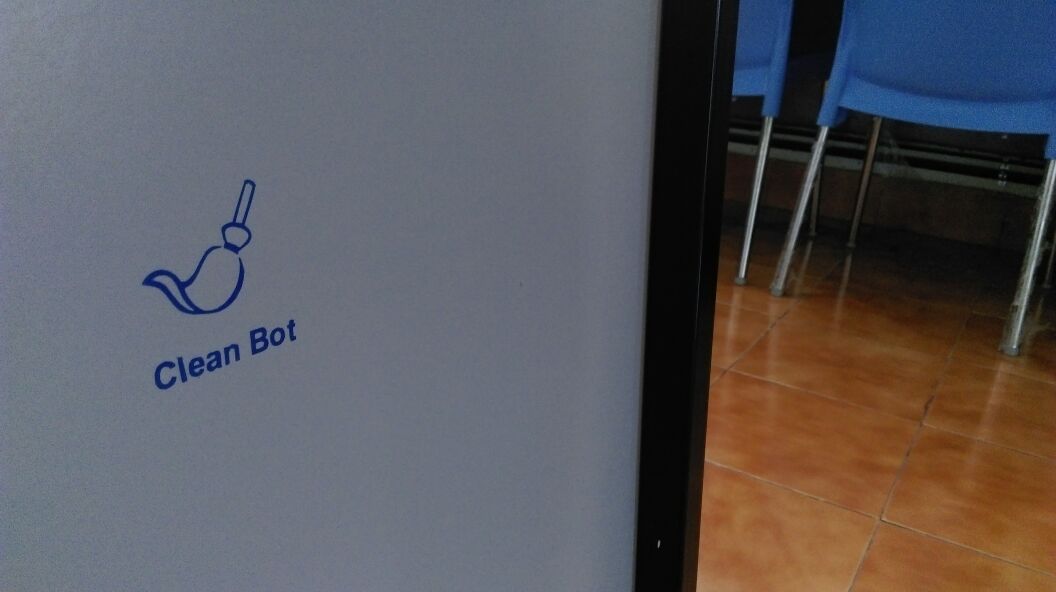

Then masking tape is used to stick over the sticker then we take it and to stick where we want,I stick it over on my table and I rub it some times then i remove the masking table my logo is stick very well in the table.

Then masking tape is used to stick over the sticker then we take it and to stick where we want,I stick it over on my table and I rub it some times then i remove the masking table my logo is stick very well in the table.

fainal out

Laser Cutting

Laser cutting uses a high-powered beam to cut material based on computer-controlled parameters.i our fablab using Trotrc Speedy 100 Laser Cutting Machine

Inspiration

Desgining

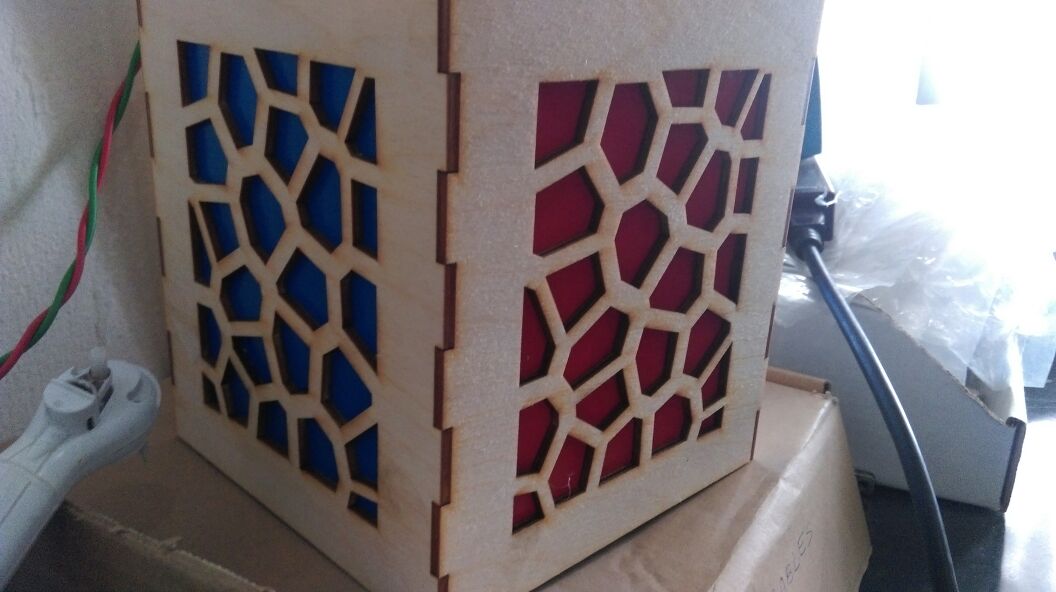

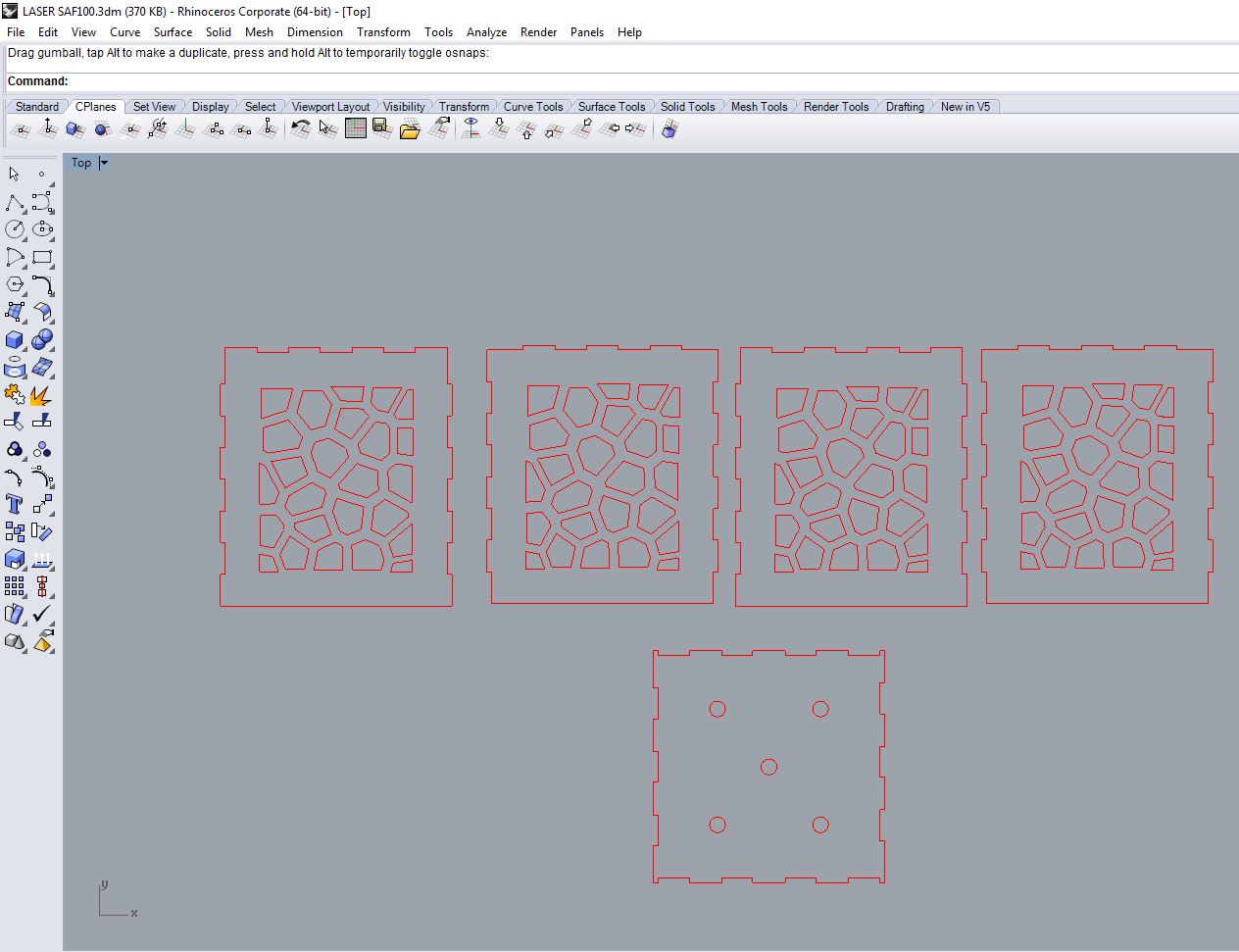

Rhino software is used to start the design process, and the grasshopper is used to complete the Varano structure.

my design is over

laser cutting

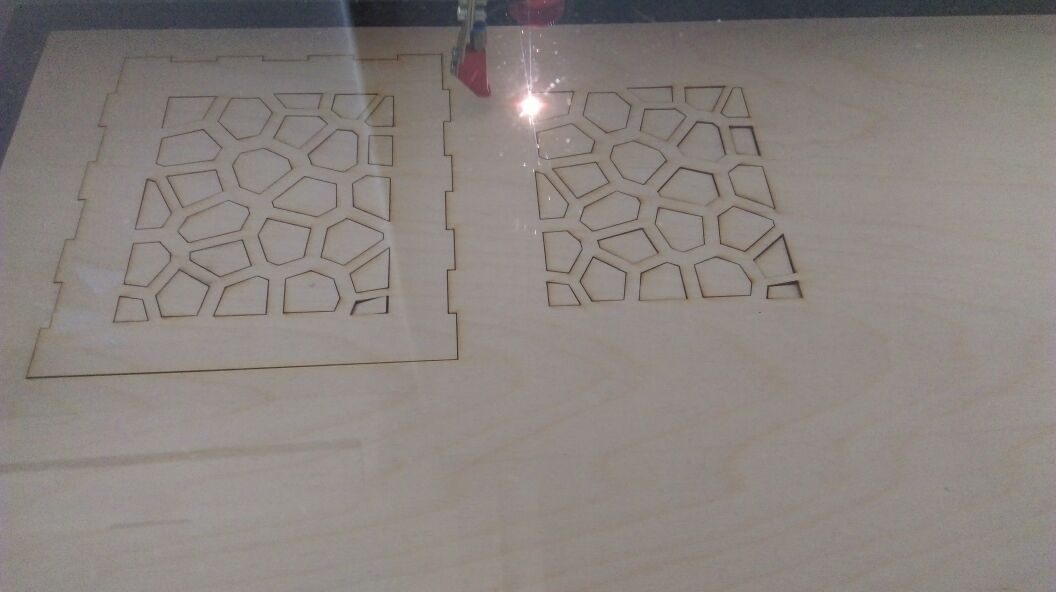

For the laser cutting process, i choose the 3mm craft plywood.Then first I set the position of the laser point into the material .then after designing purpose I am open the 3dm file in the system then I selected my cutting desgin.then to get the print option in that I have changed the properties material type and width, length of design files.

In here I am using the trolec job control software for the laser cutter controlling process in that set the job position and to click the ready button

Result