Composites

Assignment

design and make a 3D mold (~ft2), and produce a fiber composite part in it

what is composite?

composites are formed by combining two or more material; it changes significantly the physical or chemical properties and it forming an overall structure, that is better than the sum of the individual components, in this type of process is called composites.

plan

I am plan to make star fish 3D cmposite structure .for this composite I have used

textile fabric and jute. For the resin i choose Araldiate Aw 106 Resin.

Design

Rhino is used to start my design work, and I have completed the starfish 3D structure. For the mold designing, I have to take the boolean difference in my design structure and material structure.

making the Mould

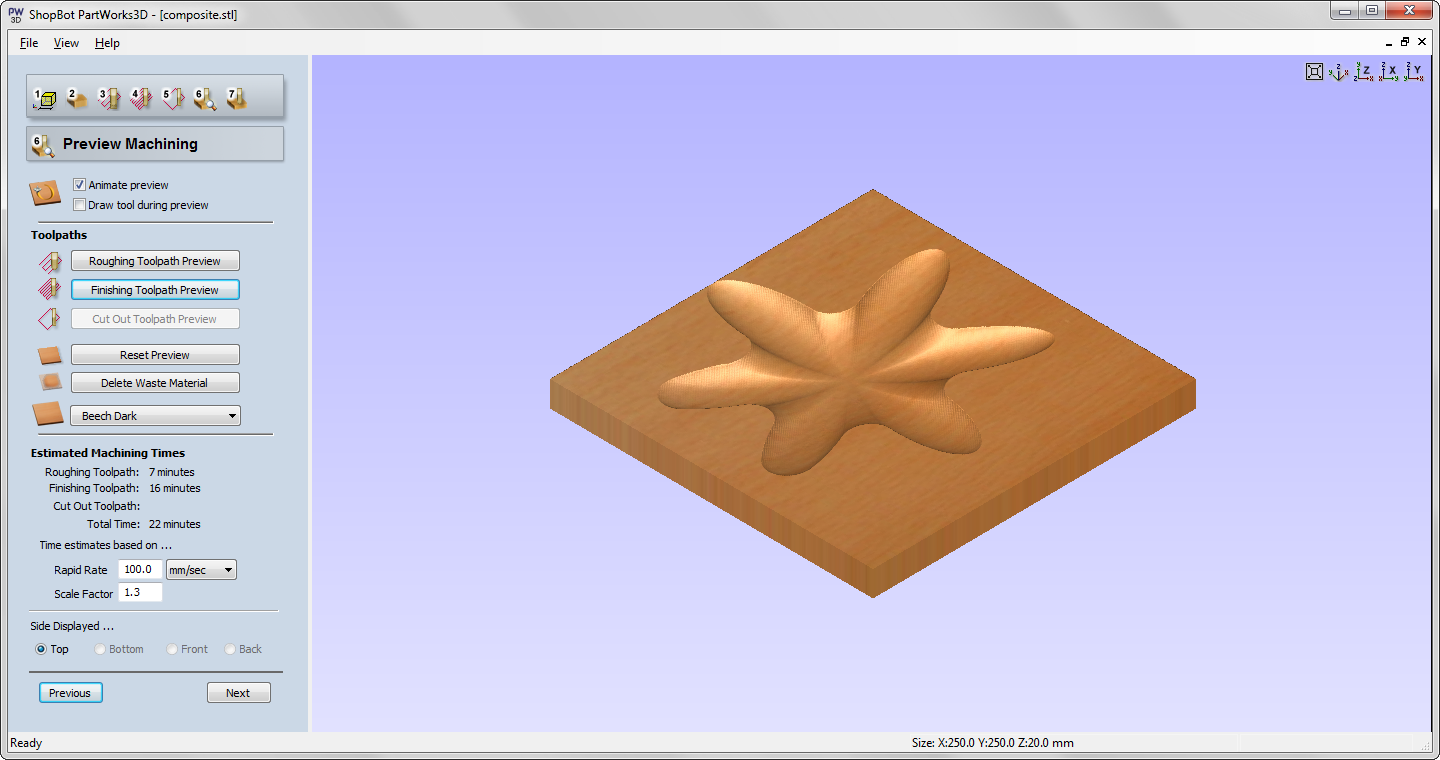

for the making of mould i am used the shopbot.for the 3d work we used partworks3D i opened the .stl file in partworks and check the size after that i gave the meterial size and margins.the 1/4 upcut and finishing cut bit are used for the mouldmaking

After the setting process, i saved this file into shopbot file(.spb) and started the work using Shopbot

mold making is done successfully

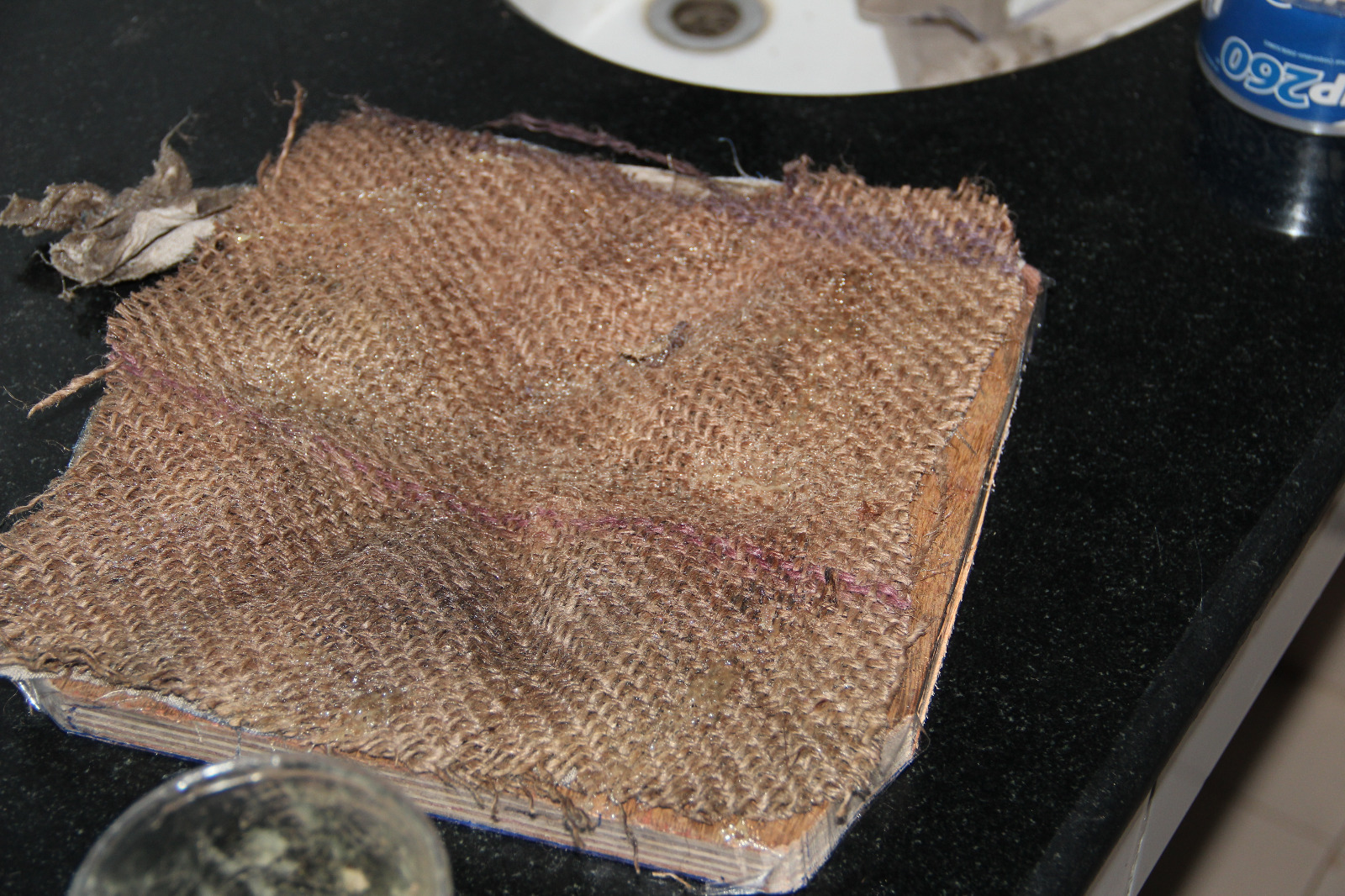

Making the composite

For the composite making, I have used textile fabric and jute. For the resin, i choose Araldite Aw 106 Resin. For that, i cut fabric in the shape of mold after that packing tap is used to cover the mold, the purpose of using packing tap is, when we removing the composite inside of the mould if not to using packing cover, the composite will stick the mold and we can not get the composite inside of the mold.

MAKING THE RESIN

the two syringes used to take the equal volumes into a cup then it mixed

setting the composite

totally I am using 3layers two cotton and jute fibers.the up and down layers I have used the cotton fibers because the cotton is smooth surface that is why we can get a smooth surface in our composite.

firstly, spread the cotton fiberic and to paste the mixing of resin.do does not use the resin more when we pasting use very less and paste all the part slice.

secondly, I spread the jute and paste the resin

finally, the cotton spread above the jute

vacuum bagging

the well setting process we want compress it for that plastic wrap is used to covered very tightly, and it kept inside of the plastic cover

then the covering mold kept in a plastic cover the vacuum tube is used to compress it

for the setting composite will take some time, then I keep it eight hours

Result