Week 12 : Moulding and Casting

Assignment

design a 3D mold, machine it, and cast parts from it

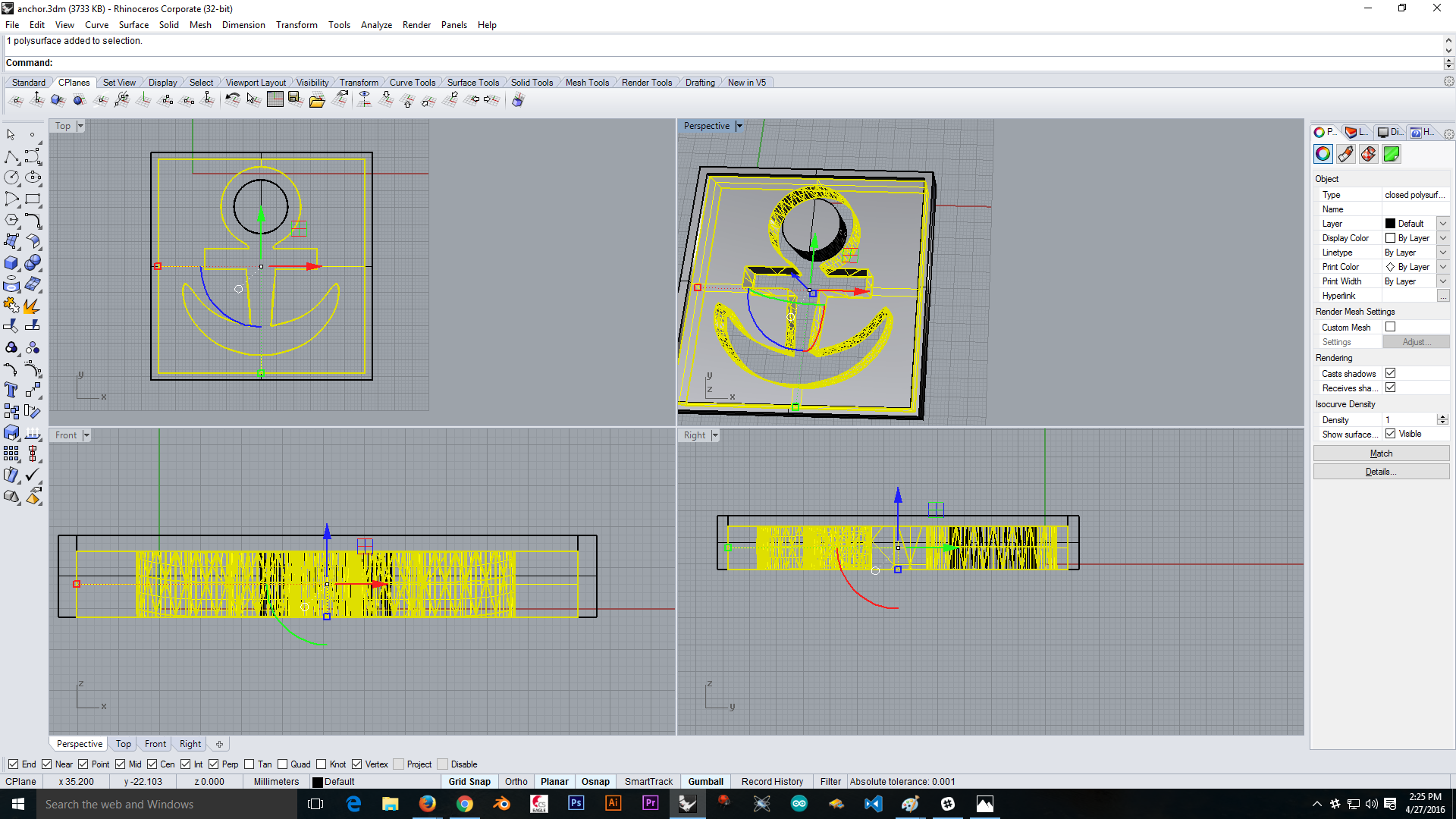

Designing in Rhino

For the Designing parpouse i used Rhino software.another one is before the Designing we want to understant our Project is 3d mold for that we want to design a negative molt design or a postive mold.in hear i used a negative mold design.

Rhino Screenshots:  Rhino Screenshots:

Rhino Screenshots:

Milling in Wax mold

After the Designing i start the milling process.I Milled the design in a

wax block using modella.moreover i used two bits in this milling process one is

1/8 rount bit and another one is 1/8 finishing cut bits.

Milled in a wax block using Modella

Fab module:  Bits:

Bits:  Mould:

Mould:

Casting

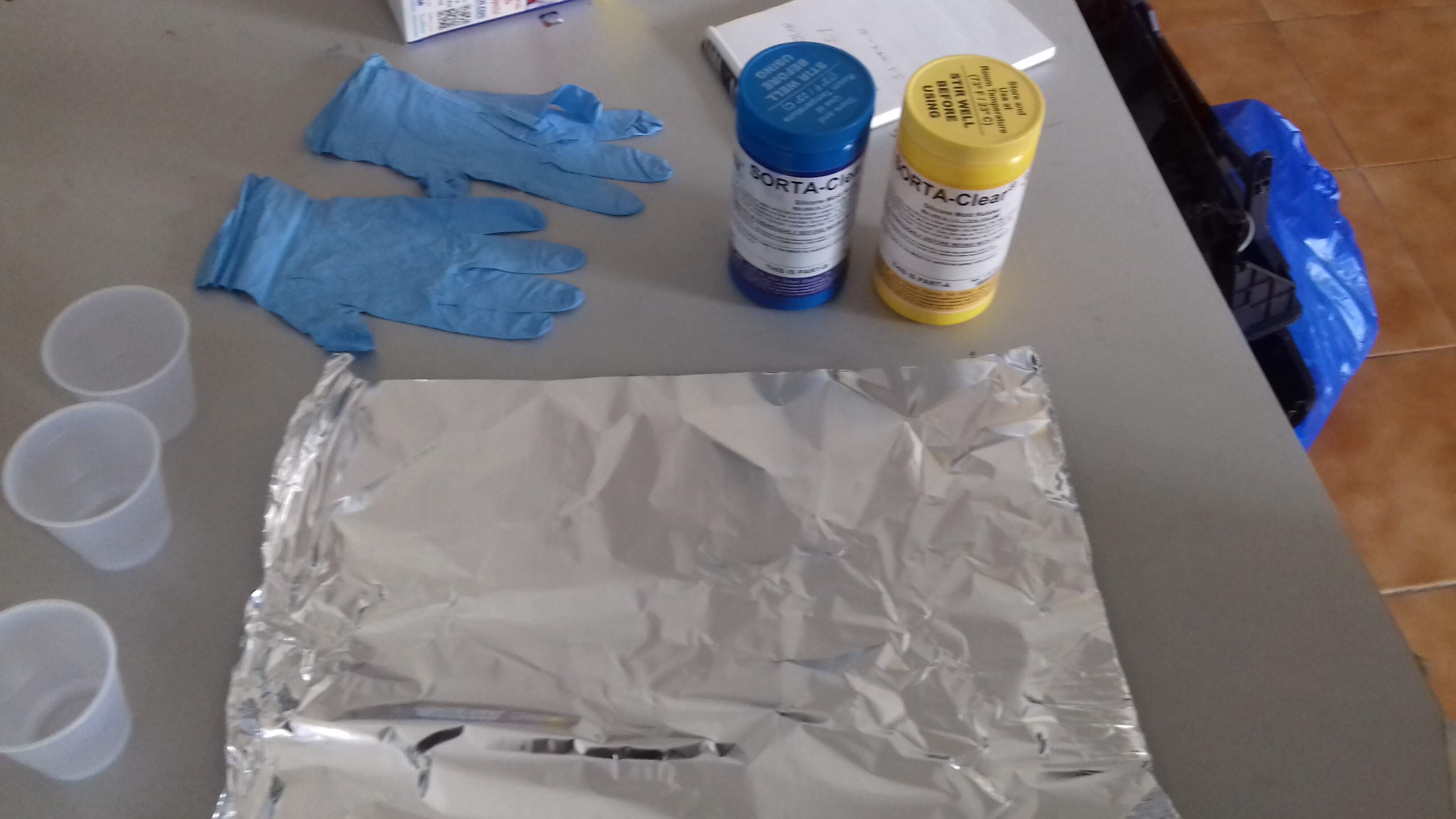

next step was casting the silicon mold.for the casting i used sorta-clear and silicon rubber.which is mixing (solar-clear and silicon rubber )1:1 ratio.first i take the volume required by pouring water in to the molding wax after that i epmtying water in to a cup.then i took the equal volume of part A and partB In a seperate glasess and i try to add colour for that i mix blue colour in partB . dont mix colour with part A.after that i mix part A and part B in same glass,mix it 3 to 4 minute very well.then the siloicon mixture part A and part B Poured in the Wax mold.

Materilas Used

Casting Materials:

Coloring Agent:  Coloring Agent:

Coloring Agent:

the colour mix with the part B and shake it very well.

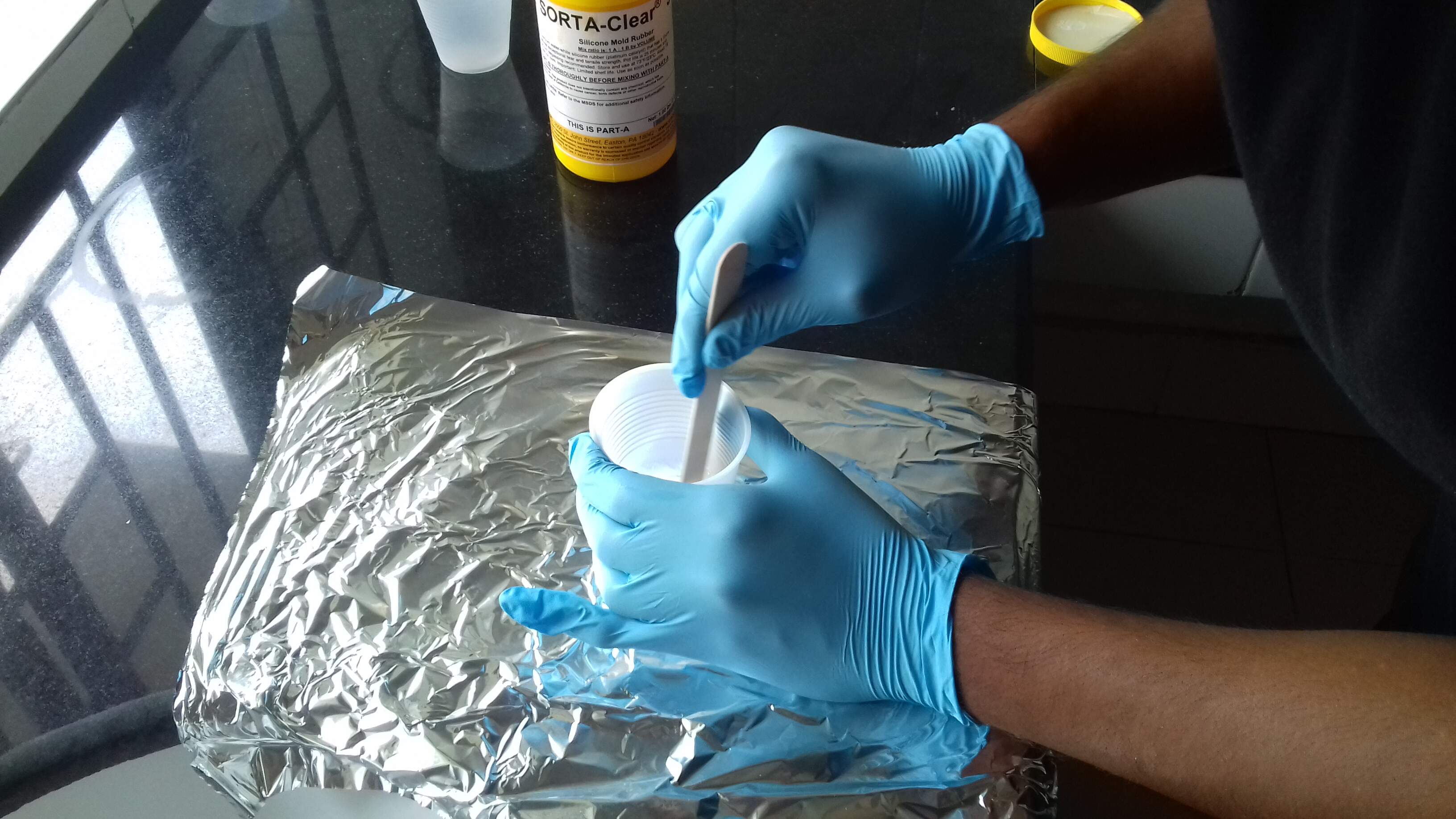

Casting Process

for the casting process mix part A and coloured part B 3 to 4 minute,

It is ready to mold

Process:

After 4 Hours

for the well setting process it should take 4 hours.then it keep 4 hours safely. after it take out inside the mold.

Final Out:  Final Out:

Final Out: