Propose a final project that integrates the range of units covered.

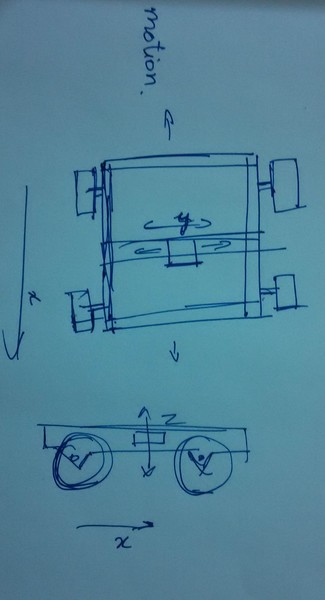

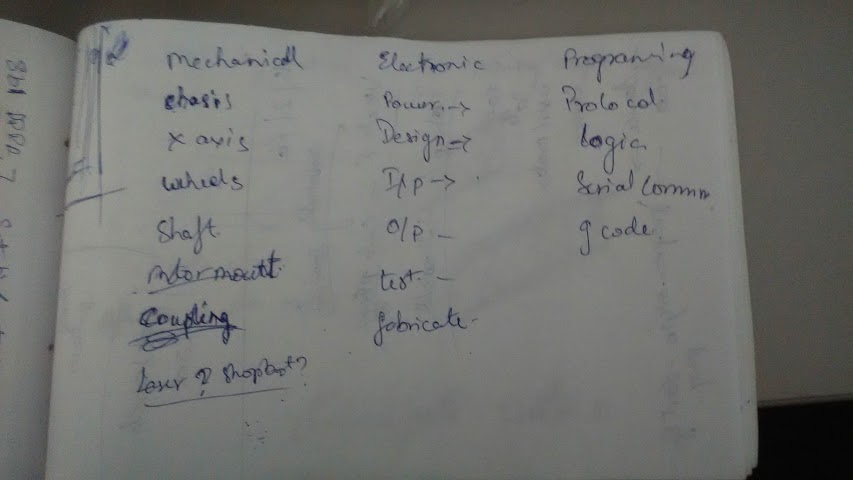

I’m going to make a CNC on wheels, the simplest version of it. What it will do is that it will move in a straight line and draw, paint or 3d print as it goes. Essentially the one of the axis is replaced by powered wheel.

My final project page is soon coming up, which will explain the design and process in detail as I go about making it.

I have name it Infinity CNC, because it can work over large length as compared to a conventional fixed cnc.

What will it do?

For now it will do pen plotting over a large length. There will not be any steering, it will move in a straight line back and forth. Any non contact end effector can be attached to it including, inkjet nozzel, lASER and 3d printer nozzle.

Who’s done what beforehand?

DIY CNC have been made for various functions and of different variety. I was aware of this type of cnc and always wanted to make one. I didnt find much reference in google, I guess the concept is not very popular in the diy community. I’m sure this type of cnc would have some application but I dont know the technical term so that I could look for details on it. Often my while research I've seen it getting mixed with portable CNC concept. A portable CNC has a complete different function and meaning.

Penplotters on robotic chassis have been done, but in my project I am implementing a whole gantry on a moving platform, to my knowledge I haven’t found anyone who has done it.

What materials and components will be required?

Mechanical body of the cnc will be laser cut from 6mm Acrylic and press fitted.

It will use ultrasonic sensor or proximity sensor in order to detect obstacle and stop.

It will be driven by stepper motor. For transmission I might use, capstan mechanism using fishing line or a timing belt.

Motor will need couplings, this will need 3d printing.

I will initially test it with marlin firmware and arduino mega and ramps 1.4 combo. But I want to create a network of the motors and sensor and write a simple g code interpretor for it.

Where will they come from?

Most stuff came from fablab, the cost and BOM will be worked out.

I will use 6mm acylic for chasis and gantry.

I bought some stuff like timing belt and 8mm shafts online from ebay and amazon.

BOM

Mechanical.

Acrylic clear 2 sheet3 1ftx2ft, smal pieces of 3mm acrylic()(Fablab).

M3 nuts bolts and nuts and washers about 20 Nos.($3.38)(ebay.in)

Timing Belt 2mm pitch 1M length.($2.06)(ebay.in)

Roland Broken End mills with 1/8th inch shank and 35 mm length- 5 Nos.($0)(Fablab)

7CM Wheels for hobby robotics-4Nos.($3.69)(ebay.in)

6mm shaft dead axle - 2Nos($0.81 )(amazon.in)

Electronics.

PCB FR1 small - 5 Nos(Fablab)

Resistors SMD 10K R,1K R some(Fablab)

Capacitos SMD .1uF , 1uF, 10uF some(Fablab)

Attiny 44 SMD. 4Nos(Fablab)

5x2 pin jumper SMD and header . (Fablab)

Ribbon cable.(Fablab)

1.2mm wires for power transmission for motors.(Fablab)

A4953 Half bridge SMD IC(Fablab)

5V FTDI USB device.(Fablab)

Motors bipolar/unipolar converted to bipolar 3 Nos.(Fablab)

12V 3A SMPS.(Fablab)

2M twisting cable with appropriate gauge for carrying 230V power supply to smps.(Cheap)(Hardware store)

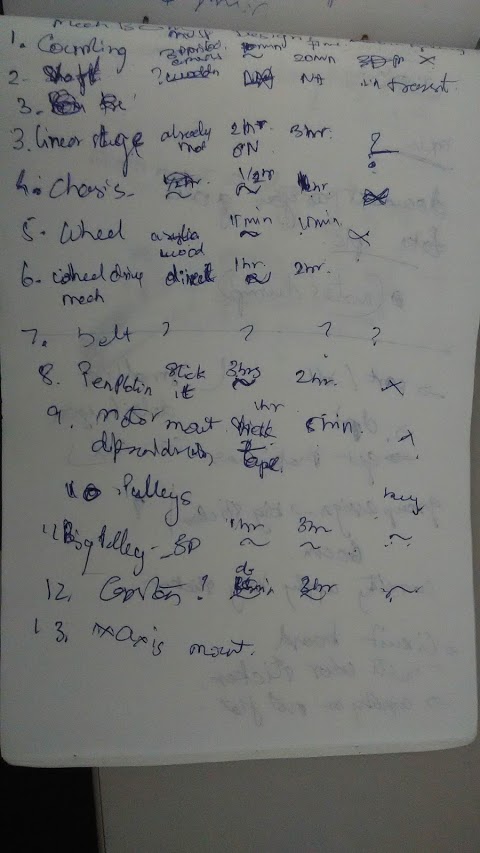

What parts and systems will be made?

Chasis.

Gantry.

Penplotter/Z axis.

Electronics.- stepper driver, infrared proximity sensor network nodes.

Rough sketch

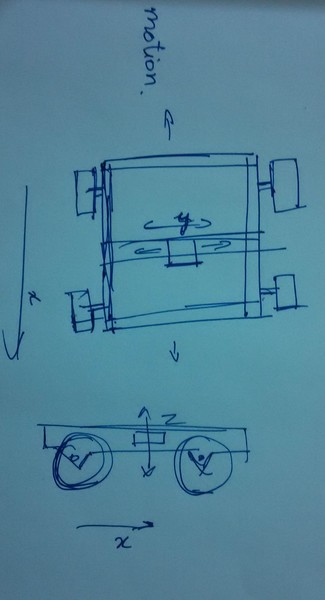

I list down Assemblies and parts required and what and if the minimum viable product of each of those component is. I also list down my estimates of design and fabrication of the components.

What is the schedule?

In the above parts list I have noted down the approximate time, it would take to design and fabricate each component. I got an idea what comes before what, what all can be fabricated in parallel and what all are to be developed later.

I listed the possible minimum possible implementation of an assembly to reach fabrication as quickly as possible. Which will give me enough time to iterate better.

Broadly I want to finish this by 2 weeks and assigned tasks and goals on day to day basis.

What tasks need to be completed?

First the mechanical assembly will be fabricated. The design and fabrication will take place in parallel. Some mecahnical components are scheduled to be manufacture after another one, depending on the importance and ease of design and fabrication of the component and depending on whether it depends on design of any other component and availability of materials(some are ordered online).

The electronics design production will come after the mechanical fabrication and assembly.

The logic will keep evolving, I have to get an idea about the working over time and depending on features I want to include and confident about.

What processes will be used?

3D Designs will be in Onshape, I’ll be using it mostly for designing part for 3d printing, later on the entire machine build for simulation etc. Most part of the designs will be in 2D and with my favorite tool Draftsight. I’ll be using press fit and snap fit techniques for quick prototyping.

What questions need to be answered?

The accuracy and precision of the machine are unknowns here, how these will get affected by motion and the make and working of the machine.

The progamming is something I’m not sure of, I have the basic structure in my head, but What problems will I face while implementing and debugging them will be cause of my worry and I feel is the critical part. Networking is new to me and electronics too so getting to make these work and debugging them is a cause of concern.

How will it be evaluated?

Speed, Price, compared to machines available already, usability.

This machine is a proof of concept for much grander product. This could be used for painting on buildings if it has proper set of wheels(wall climb ability). It could be used for LASER engraving over a large area, BIllboards etc.

For now if the machine is able to prove it is working and gives me an idea of the problems and areas of improvement and what area need what extent of development it has done its job. There unexpected goods and bads in it. How fast it can go and what will be its limitation s, all these questions could be answered by this prototype.