Applications and Implications

OverviewLast updated: 03/07/2016

Objective Propose a final project that integrates a range of units covered. Projects can be separate or joint, but need to show individual mastery of all of the skills. Where possible, you should make rather than buy the parts of your project. Learning outcomes 1.Define the scope of a project;2.Develop a project plan; Have I... Answered all of the questions? Preface In this project I took a critical approach to what I have been doing and the way I have been conducting my work in this past semester at FabLab Toscana. It is a project that is in line with what I usually like doing and aims to be a little provocative. In these last months I’ve been noticing that the more I was getting acquainted with the digital fabrication world, the more I was letting behind the traditional craft techniques. Gradually I found myself abandoning the use of my hands to spend time preparing files on my laptop with specific softwares. Both in digital fabrication and traditional handicraft, creativity and technique mastery are necessary skills. They lead the process at different levels and their combination determines the final result. The main difference among them lies on the ficontrol that artisans have over the process. Clearly this does not mean that digital makers do not have it at all but clearly the traditional artisan, from the very first moment of the process to the very last one, has his hands directly involved in the making. Digital manufacturers have to deal with the alternation of softwares and the “dead moments” in which the machine is executing the task, before accessing the final result. It’s a discontinuous process that creates sudden interruptions during the creativity flow, often estranging the maker from its own craft. That made me believe that re-establishing a process that still involves the machines but integrates them into the crafting part in a more continuous way was an interesting direction.

Could machines evolve into something more co-creational that gives the maker more of a sense of control?

I took this as my research question and I came up with the idea of a machine that could guarantee the maker a continuous direct input so to co-create with it at any time, if wanted.

What will it do? EMI will allow the artisan to combine the expressivity of hands with CNC routing. It is a touch tablet with pressure sensors that can be used as a controller for the Roland SRM-20. A matrix of 12 x 16 sensors will detect the location and the intensity of the pressure applied and will move the spindle there. The x and y-axes are mapped to the location of the finger on the tablet. The z-axis is mapped to the pressure applied. The spindle would always be spinnning at 12000 rpms and the material to be milled shuld be soft.

EMI is a prototype and the first step of a much more ambitious project, that is creating an interface for refining digitally manufactured objects.

Who's done what beforehand? As far as I could get from Google, the combination of CNC routing and expressive interfaces is a rather unexplored territory. On the two separate fields, though, I could find something. Hacking a milling machine and, in my particular case, hacking a Roland SRM-20 is quite well documented. Three projects mainly inspired my work: 1. This project shows how to hack the spindle with an arduino. 2. Chocolate millin machine is a nice and creative project where a touch screen was attached to the Roland in order to "draw" on chocolate pieces. 3. This project shows an interesting customisation of both the hardware and software of the Roland. 4. Fiore's project is an example of software interface for the Roland.

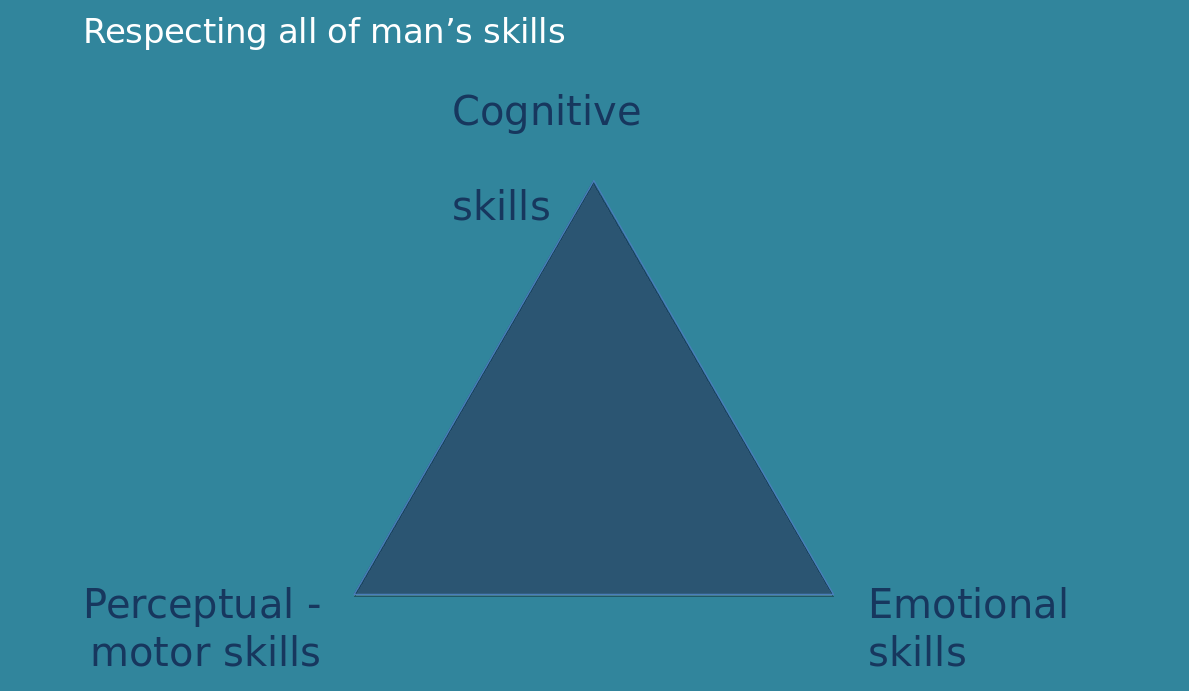

The concept of "expressivity" in the field of interaction design has largely been discussed, even though little applied to industrial machines. In defining expressive and aesthetic interface design I mainly refer to this article of my professors back at Eindhoven University of technology. There, three relevant aspects are necessary for interfaces in order to be aesthetic, as summarised in the diagram below.

What materials and components will be required? Were will they come from? How much will they cost?

| Component | Vendor | Quantity | Price |

|---|---|---|---|

| liquid silicone Sorta37 | shop.smooth-on.com/ | 10 grams | 2$ |

| 2mm aluminum | harware store | 30 x 20 mm | 2$ |

| 6mm plywood | harware store | 30 x 20 mm | 4$ |

| 3mm plywood | harware store | 40 x 20 mm | 5$ |

| copper sticker | 60 x 20 mm | 10$ | |

| Velostat | http://www.ebay.com | 15 x 15 mm | 1$ |

| satshakit micro | github.com | 1 | 7$ |

| Multiplexer HE4067BT | www.rs-online.com | 2 | 4$ |

| Arduino Uno | www.rs-online.com | 1 | 25$ |

What parts and systems will be made? The system can be abstracted in three parts:

. INPUT: the interface will be totally manufactured. I will make the casing, the sensors and the PCB

. COMMUNICATION: wired serial communication

. OUTPUT: an Arduino Uno will be attached to the roland and move the spindle

What processes will be used? . Moulding and casting for the touchpad

. Vinyl cutting for the sensor matrix

. Lasercutting for the plywood frame

. Milling for the aluminum frame

. 3D printing to make the handles of the tablet

. electronics production to make the sensor board

What tasks need to be completed? There are four main tasks that need to be executed:

. Hacking the Roland SRM-20 and controlling through the laptop with Arduino serial communication, at first

. Producing the sensor board and calibrating it

. Designing and manufacturing the tablet

. Manufacturing the PCB

What questions need to be answered? . Will the sensor matrix actually work as fluent as expected or will it generate a noisy signal?

. Will the spindle actually move around the x and y-axis with a sufficient speed or will the interaction be too slow and frustrating?

. How many people does Matteo have to bother in order to design the shell of a snail?

What is the schedule? . May 8th-May 10th: designing and producing the sensor board

. May 10th-May the 15th: hacking the Roland SRM-20

. May 15th-May 20th: connecting the two systems, testing, preliminary evaluating

. May 20th: presenting, drinking a beer or two afterwards

. May 20th-July 8th: bug fixing

How will it be evaluated? Having a fluently working interface is way too ambitious for the time I am given. Hence I consider my project only a demonstrator of a concept. In my opinion it will be successful when I will be able to move the spindle through the touchpad in all three axes. An extra point for me would be to manage to trigger debate around the thoughts I had in mind when I came up with the concept.