Concept

graNulo is a big plastic pellet extruder, to use it with the 6 axis robot arm.

I chouse to develope a a pellet extruder in order to allow to mix materials,

to print at a big scale faster and stronger and became less expensive than using a filament

extruder.

For this project I was inspired from:

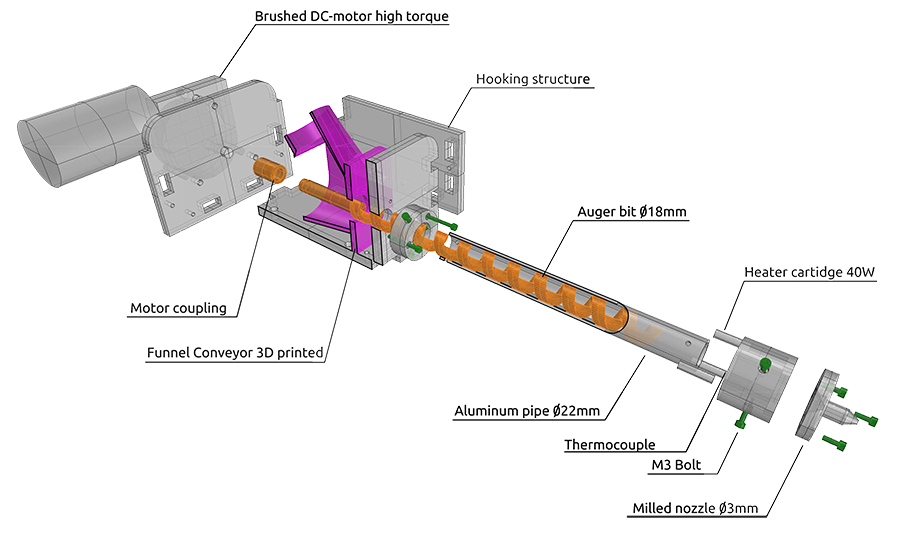

Main Parts

- Nozzle

- Pellet Transporter

- Conveyor

- Hooking Structure

- Motor and Controller

Mechanics

The pellet is pushed into the heating chamber through the use of a classic

auger bit normally used to drill wood beams.

The bit is connected directly to the motor (a high torque, 5Nm) using an

home made aluminum motor coupling.

Structure

The main part (the hopper) will direct the pellet to the auger bit, it

is filled using an external tank directly attacked or remote and connected

through a pipe.

The structure will be attached to the robot using a laser cutted flange

of plexiglass.

Hotend

The hotend will heating the pellet to become fluid, using 3 ceramic heater cartidge and a thermocouple to control the temperature.

Electronic

The control board will receive the commands trhough the serial,

and control the motor, the temperature and cooling system.

The board will be based on an ATMEGA328p C programmed

through Arduino library.

Software

The firmware for the board will control the motor, the heating

and the cooling system; the board will receive the command through

the robot using the serial port an RS-232.

The generation of the robot movements will be generated using a

grasshopper components, developed togheter with

digifabTuring

the group that are working on the robot arm to the Fablab Torino.

The component will generate the .pdl code to control the robot from the

inverse kinematics.