Clicking on the picture you can see the group documentation! my individual contribution were the group webpage, the photos, the design and assembly of the rotary axis.

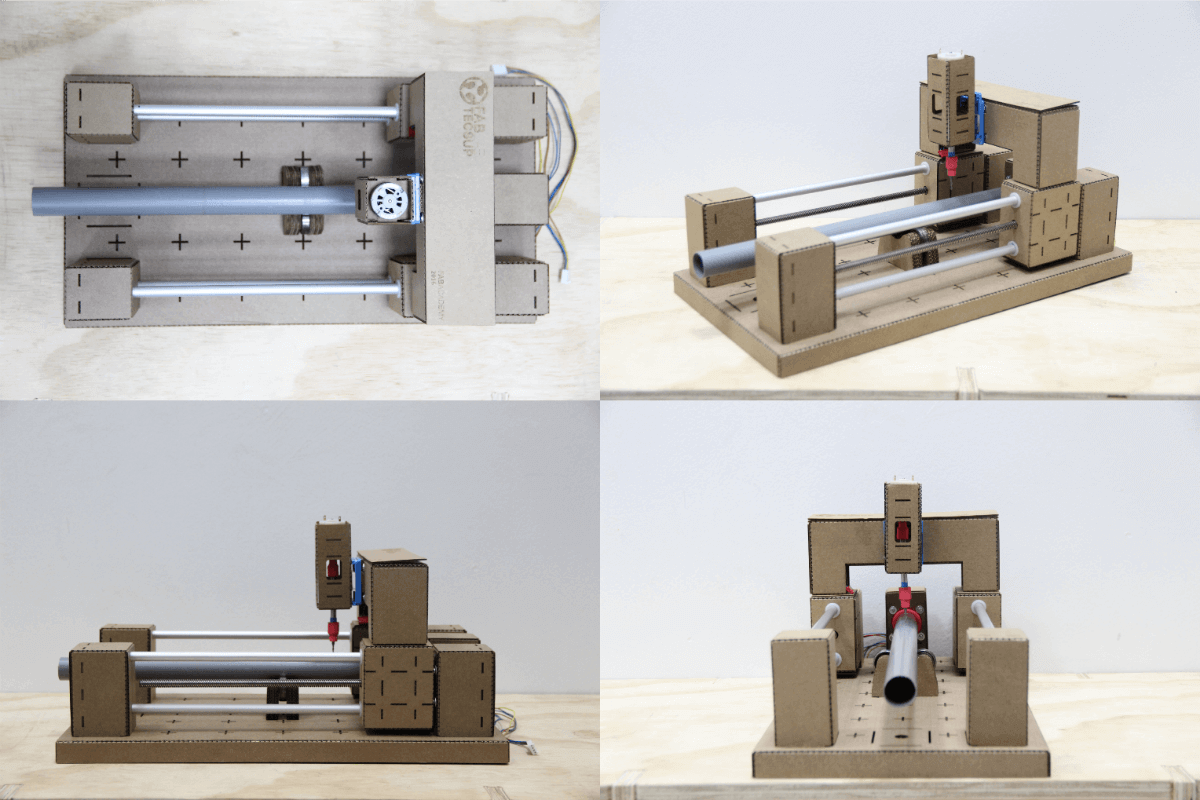

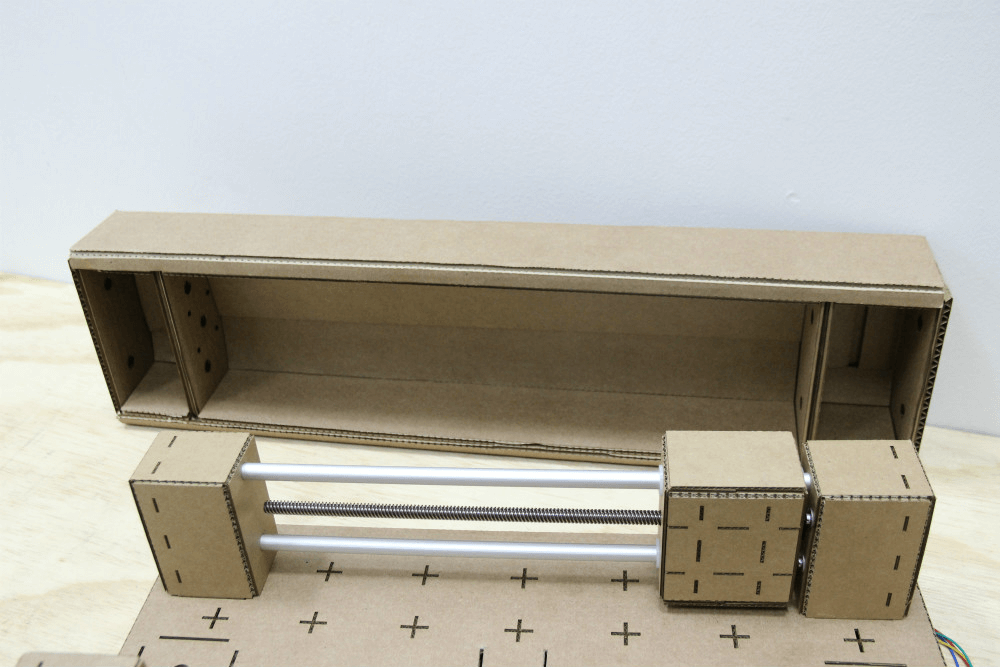

This week, we had a grupal work for machine design. First with a brainstorming, we had decided to design a CNC tube cutter, when downloaded the files of [modular] Machines that make. With my partner we decided to redesign the model, to reduce the size and material use, while maintaining the necessary stiffness.

Each one had a task in this assignment,in my case i was responsible to designed the rotary axis section. The documentation with the camera, and make the group page web.

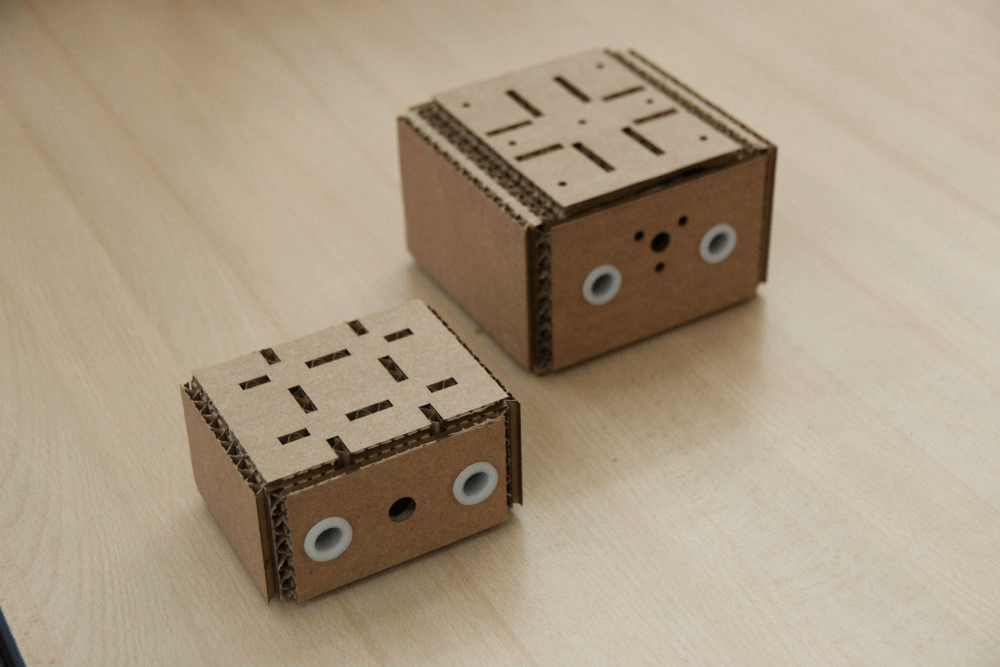

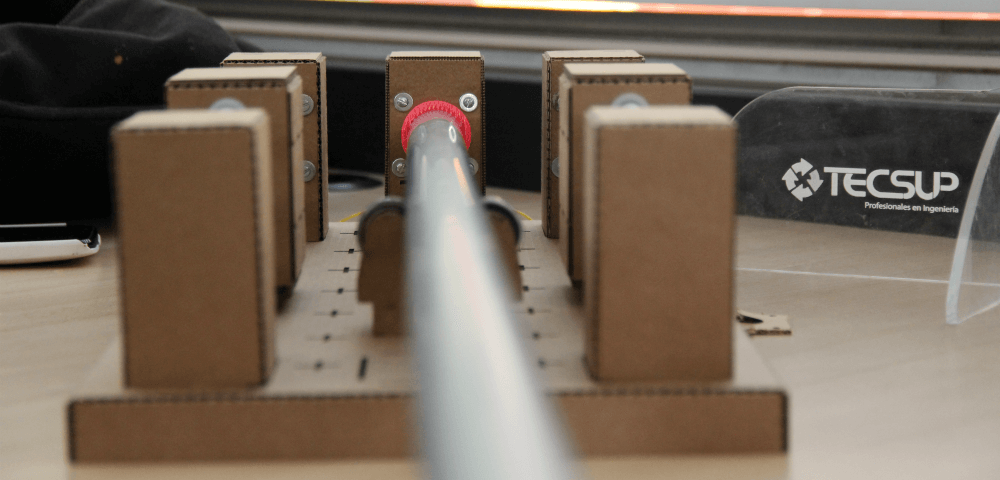

To the rotary axis section, we decided to use bearings to assist the tube rotation. For support the bearings, we needed two axis. The tubes were a superior diameter of than we needed, so we resorted to a lathe machine of Tecsup. Then with Autocad, designed the cardboard section for assembly de bearing module.

Also designed a 3D printed piece to support the extreme of the tube, this is connected to stepper driving rotation. For this piece i was modified the cardboard module.

By building the machine, I worked in the assembly of some parts, also I photographed stop motion that allows us to see how official the machine manually.