Week 12::3D Molding and Casting

Learning outcomes: Design appropriate objects within the limitations of 3 axis machining. Demonstrate work flows used in mold design, construction and casting. Source Files.

Design appropriate objects within the limitations of 3 axis machining:

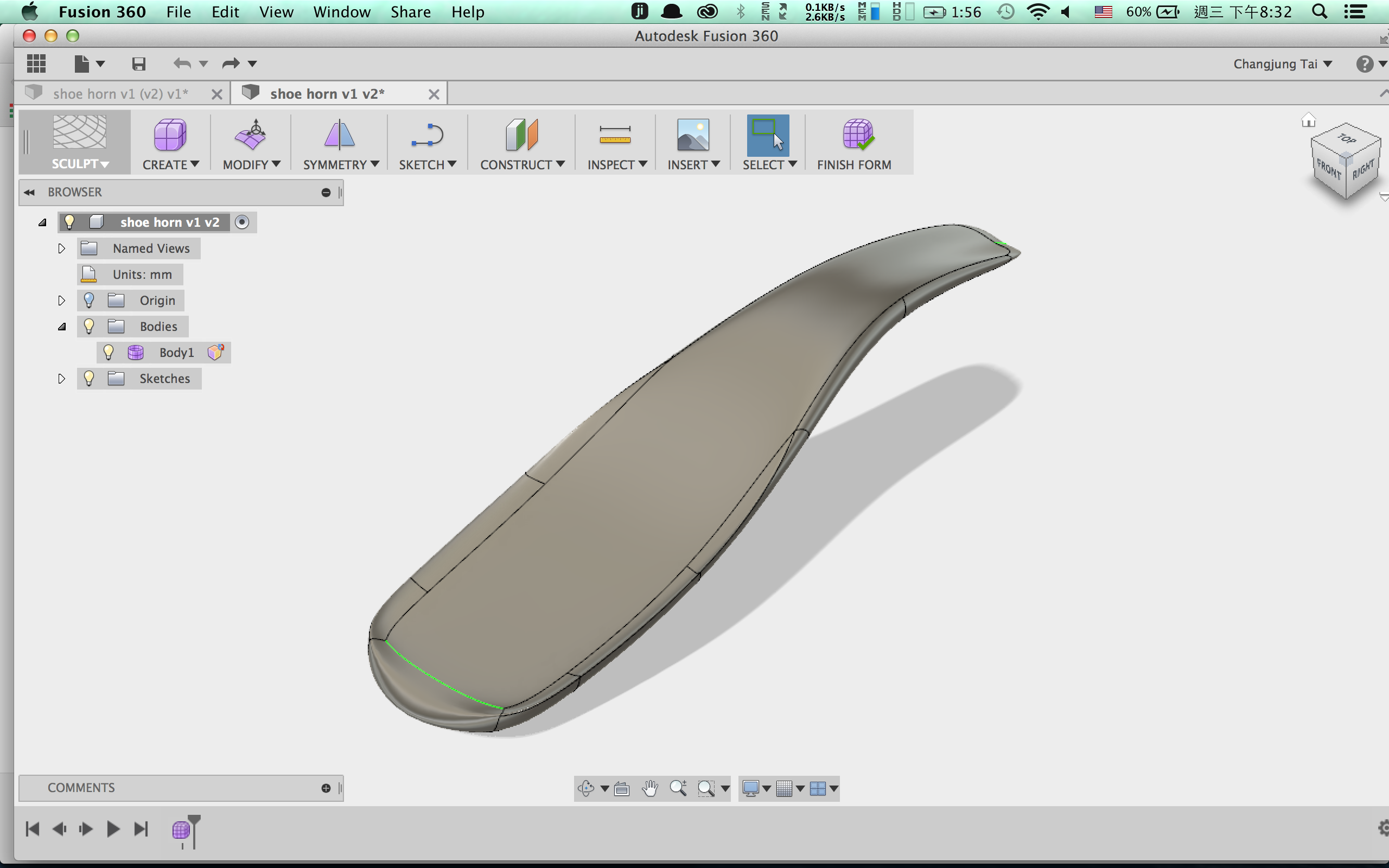

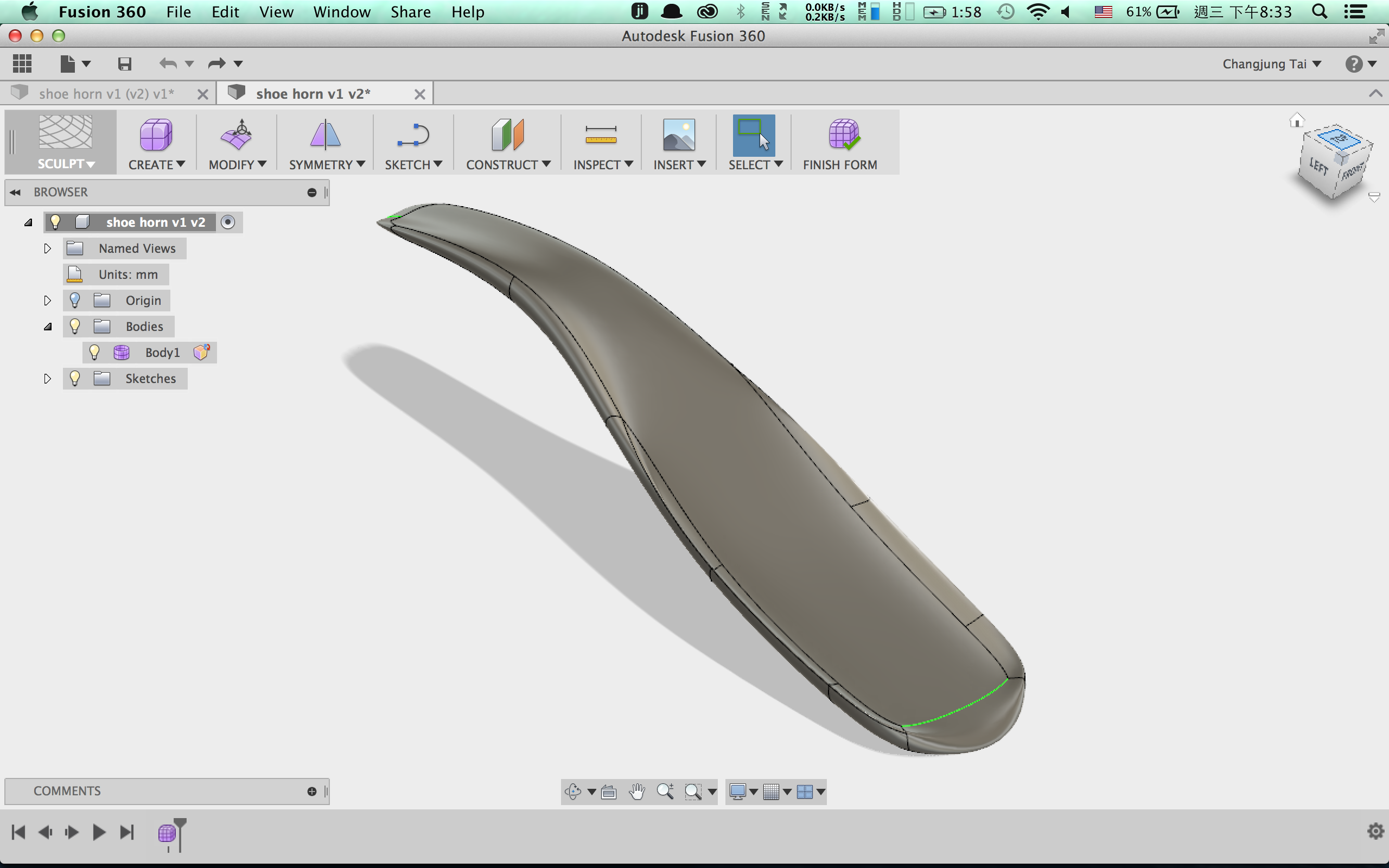

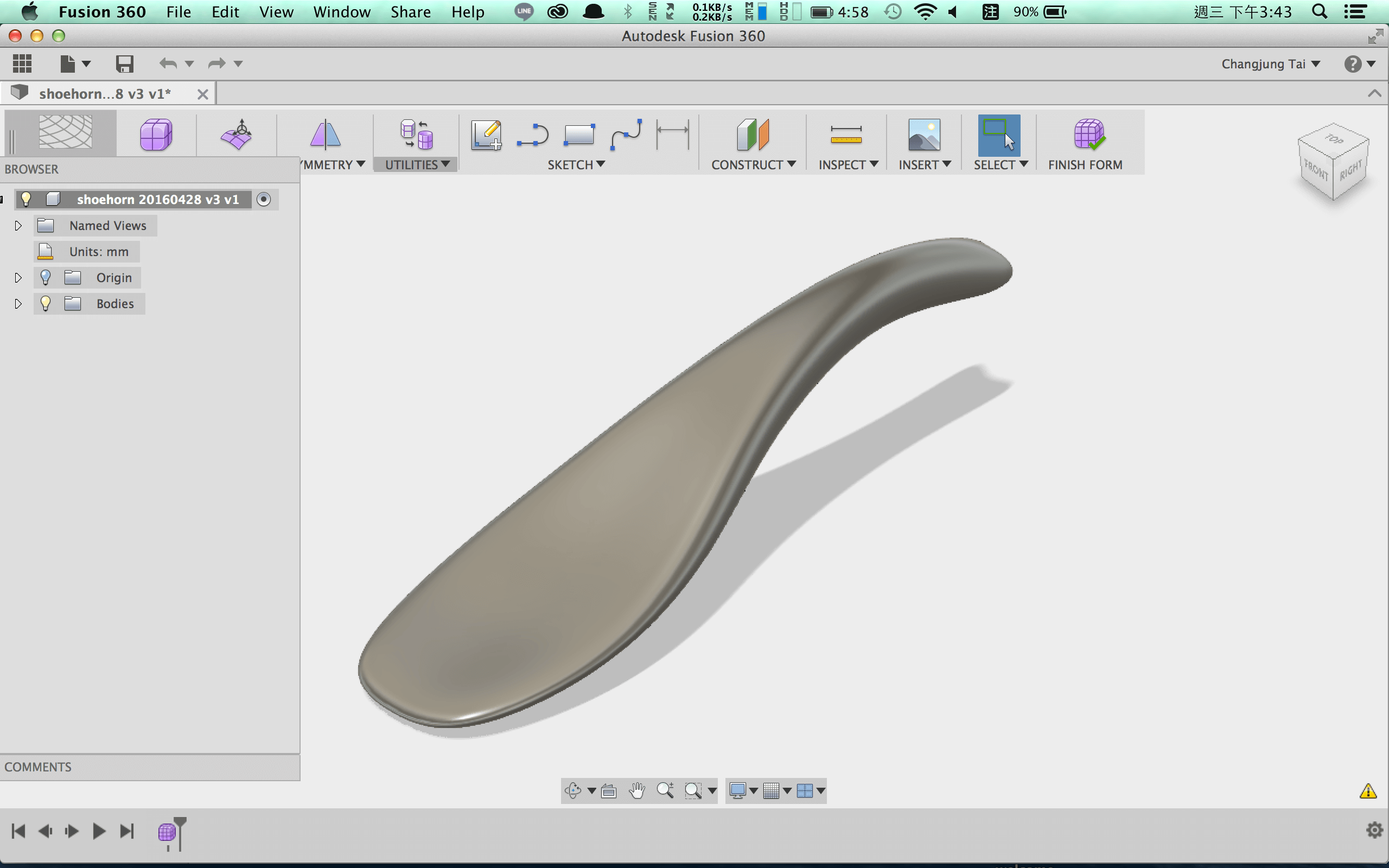

Because I was used the shoehorn every morning, so I want to make a shoehorn for myself and my friends.As usual, I use Fusion 360 to draw the shoehorn and use i3 printer to printout.

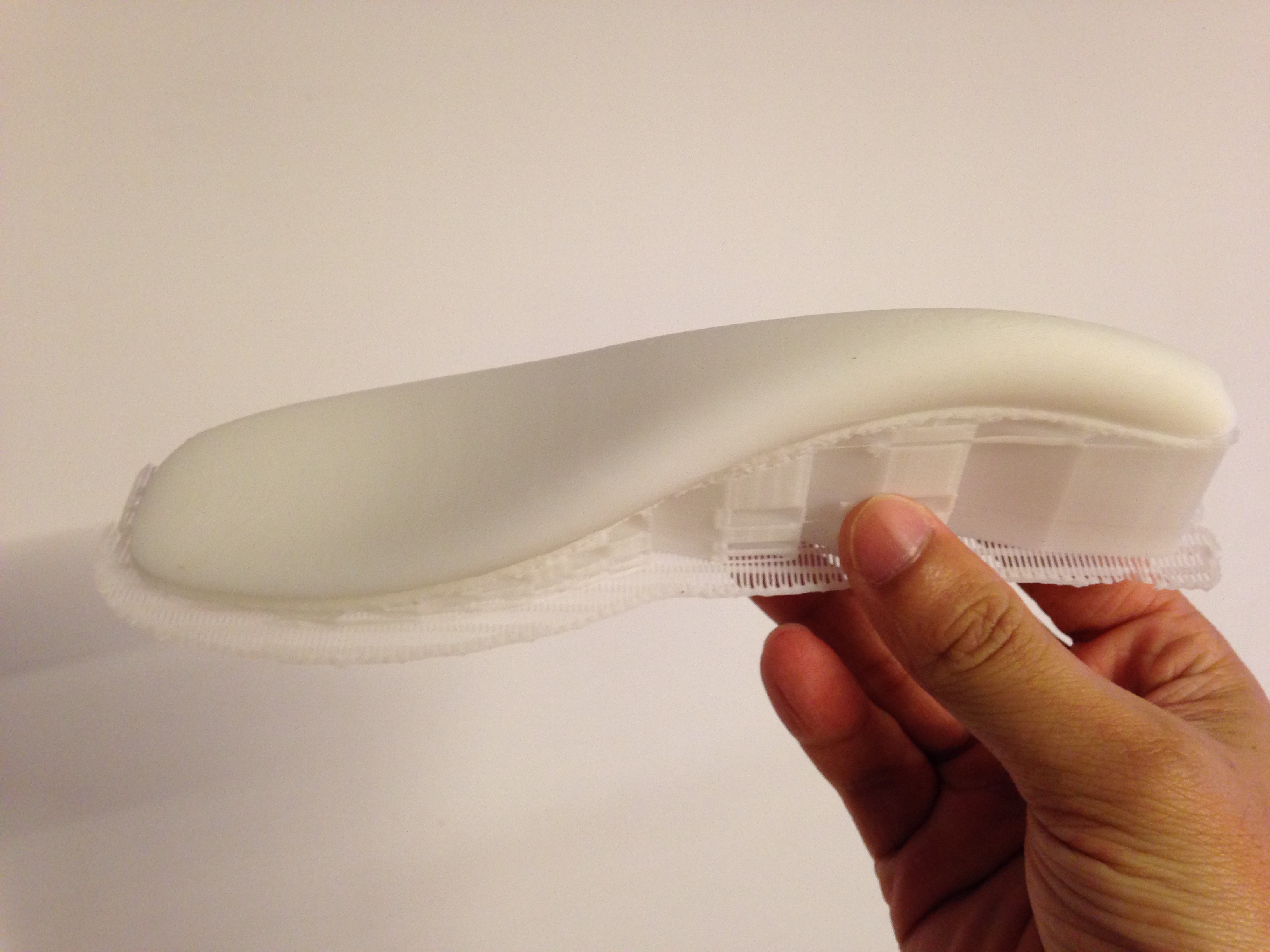

Use 3D printer to printout and use some putty(we called it butterfly) to smooth the surface.

Repeat sanding and use putty to smooth it and repeat.

But my final project was made a fishing sinker with my fishing float. So finally I am not yet casting shoehorn, but I will do it as soon as possible.

Demonstrate work flows used in mold design, construction and casting:

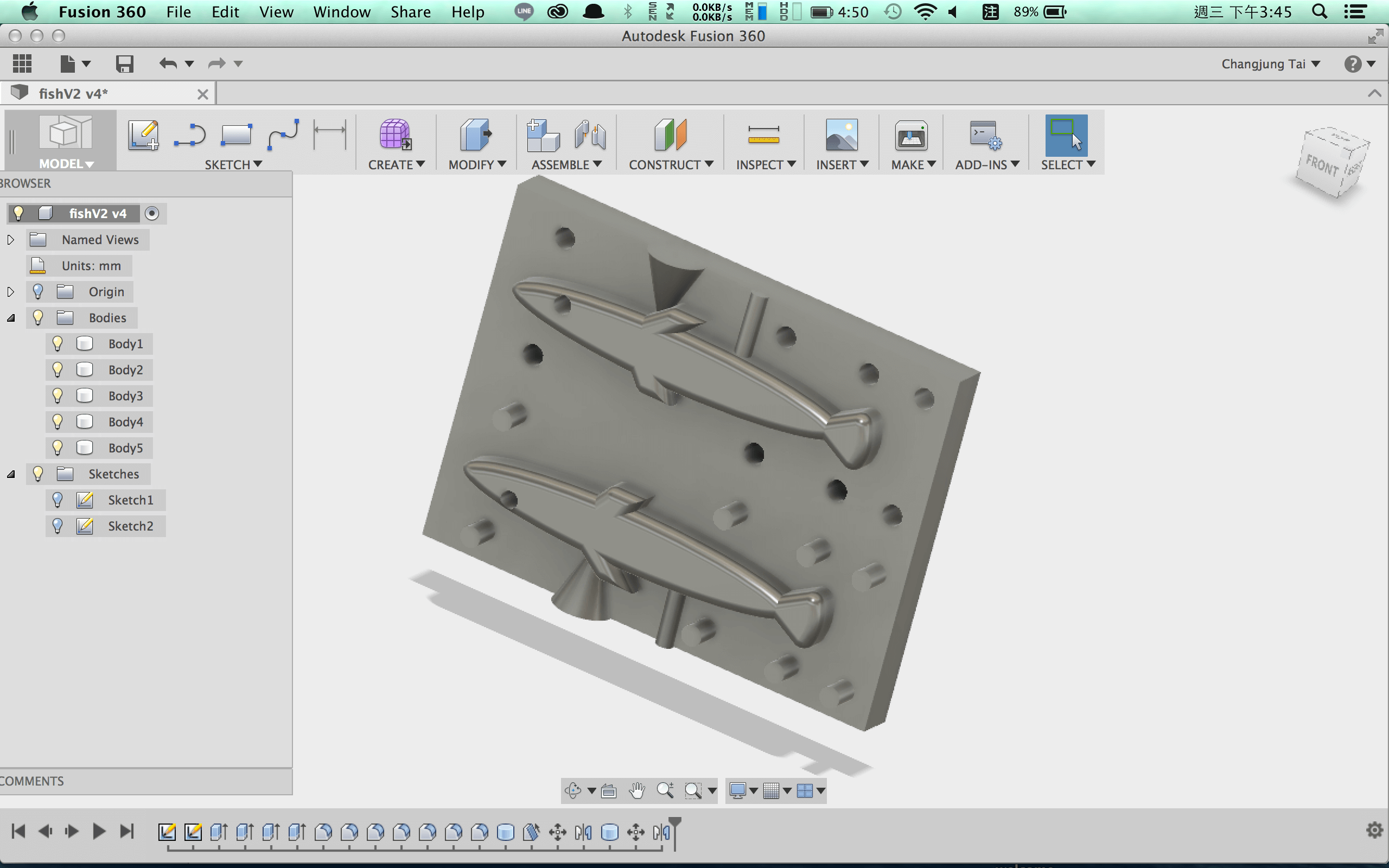

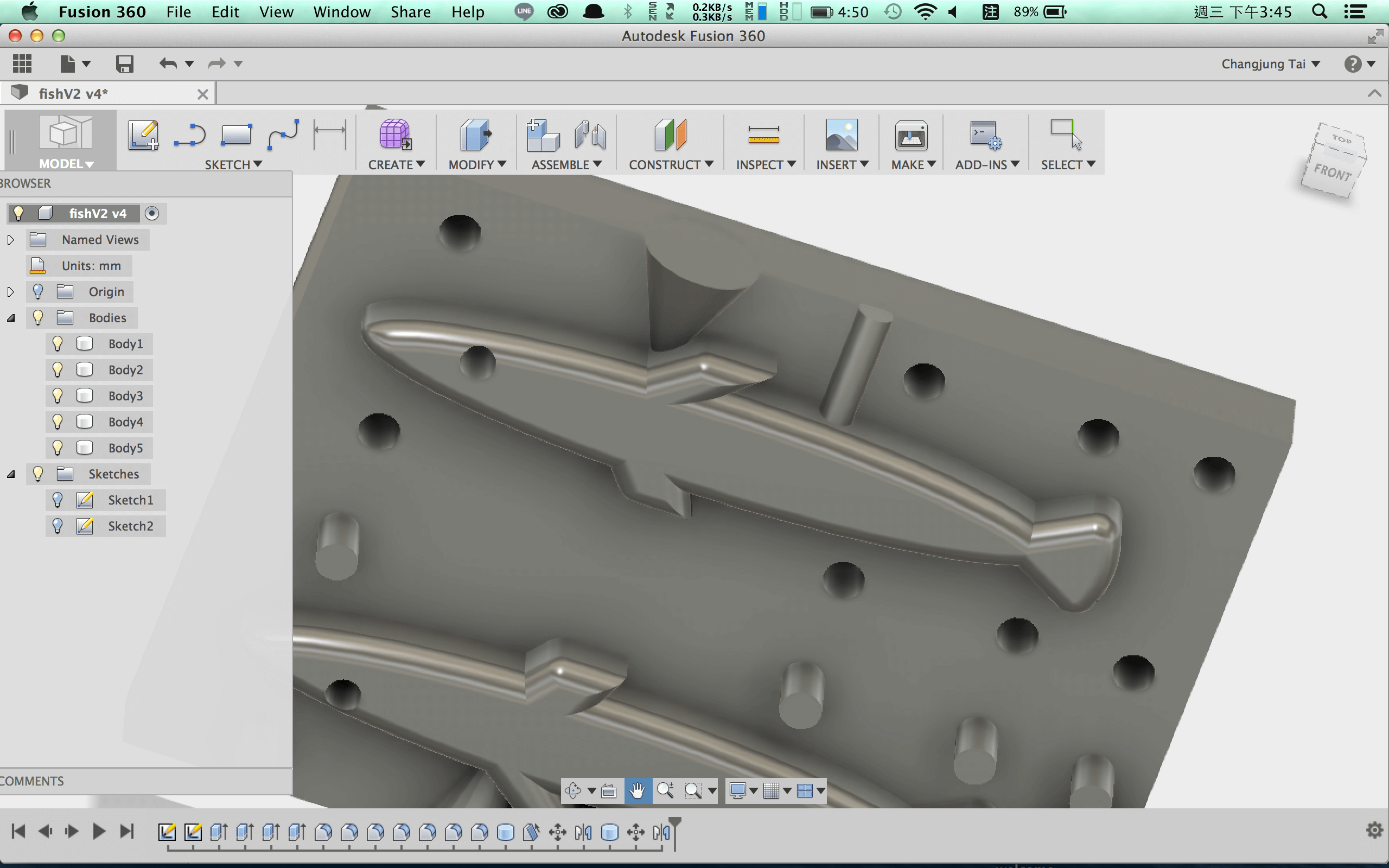

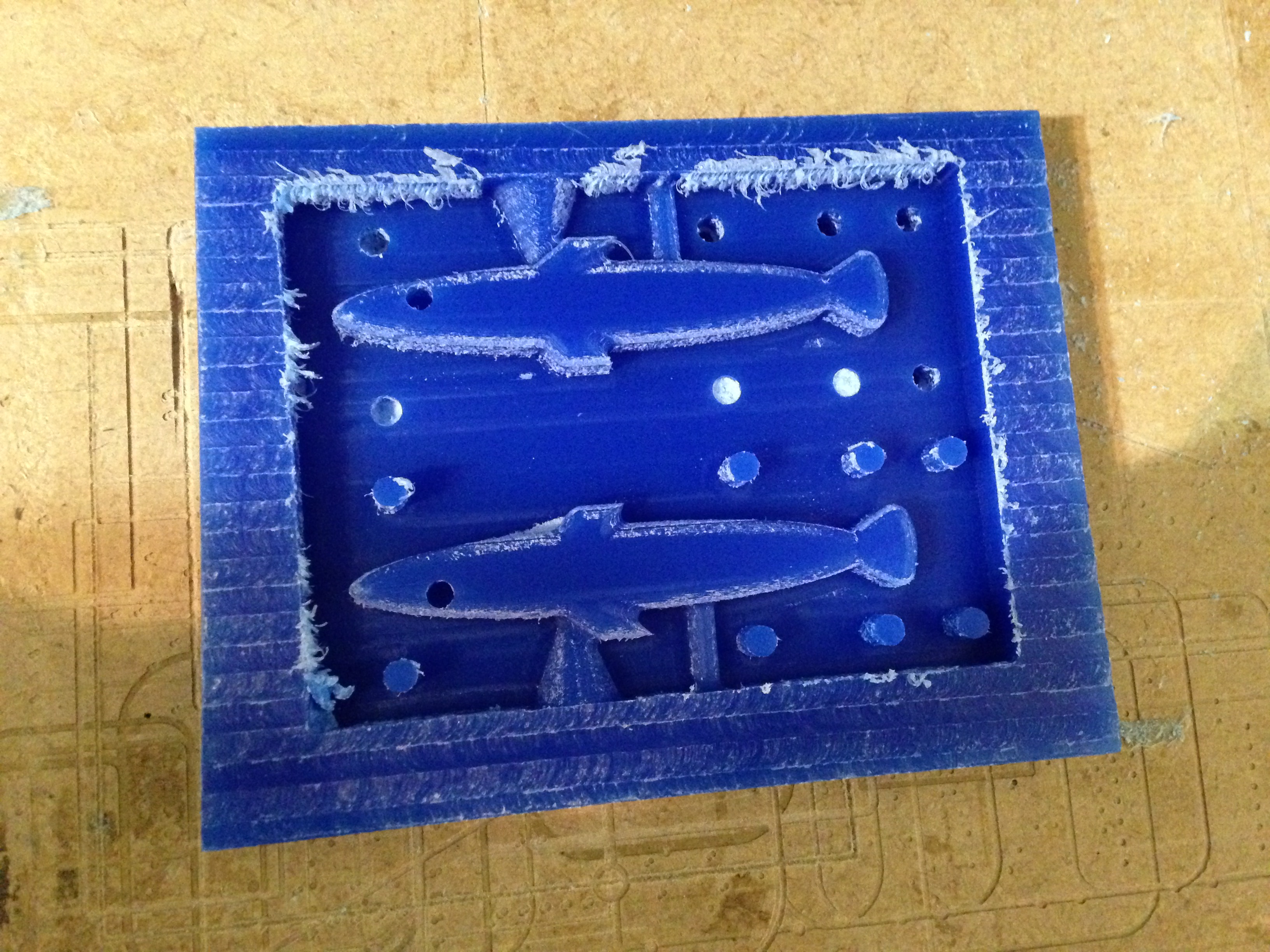

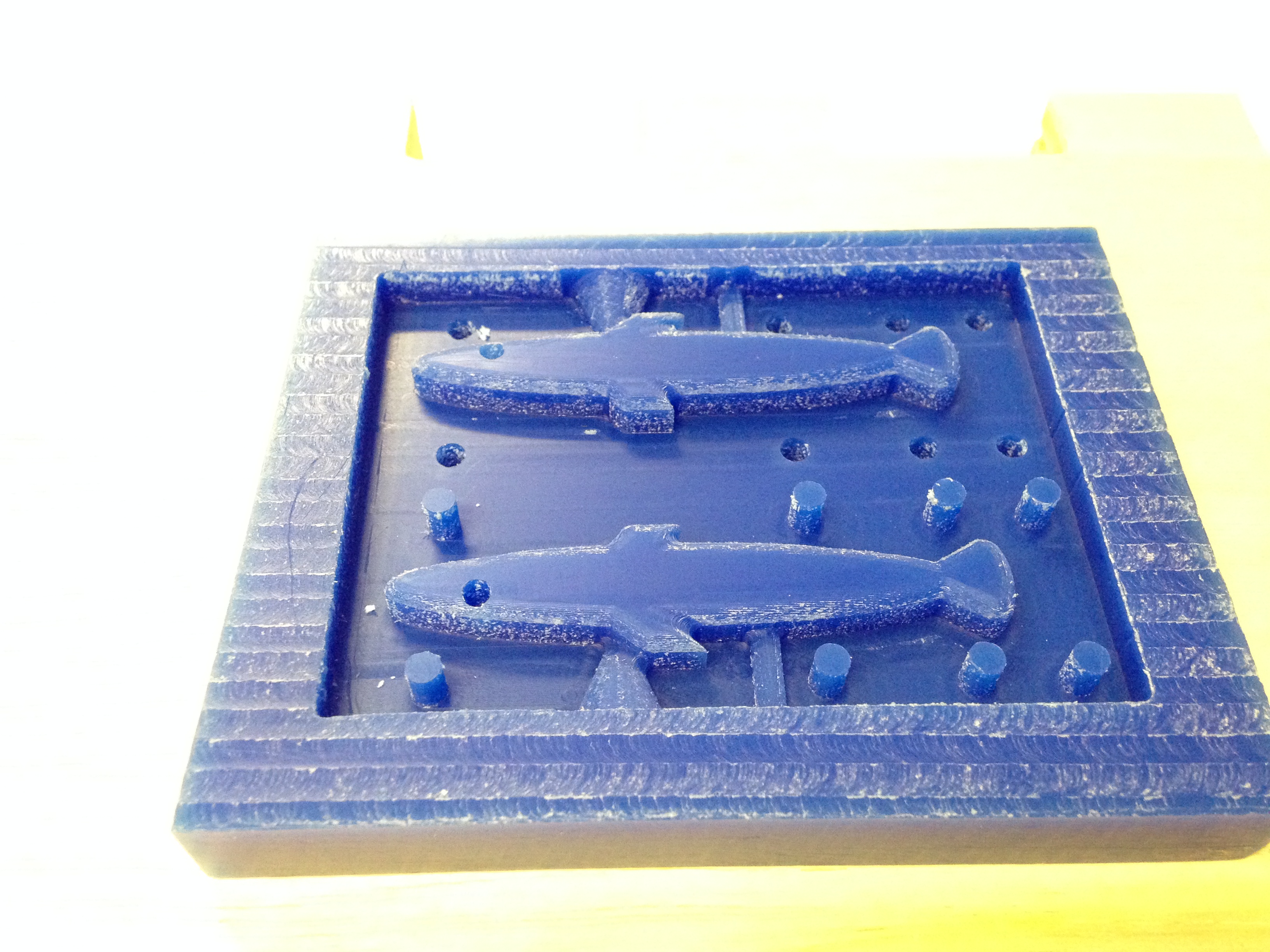

I used Fusion 360 to draw a fish be a fishing sinker for molding and casting.

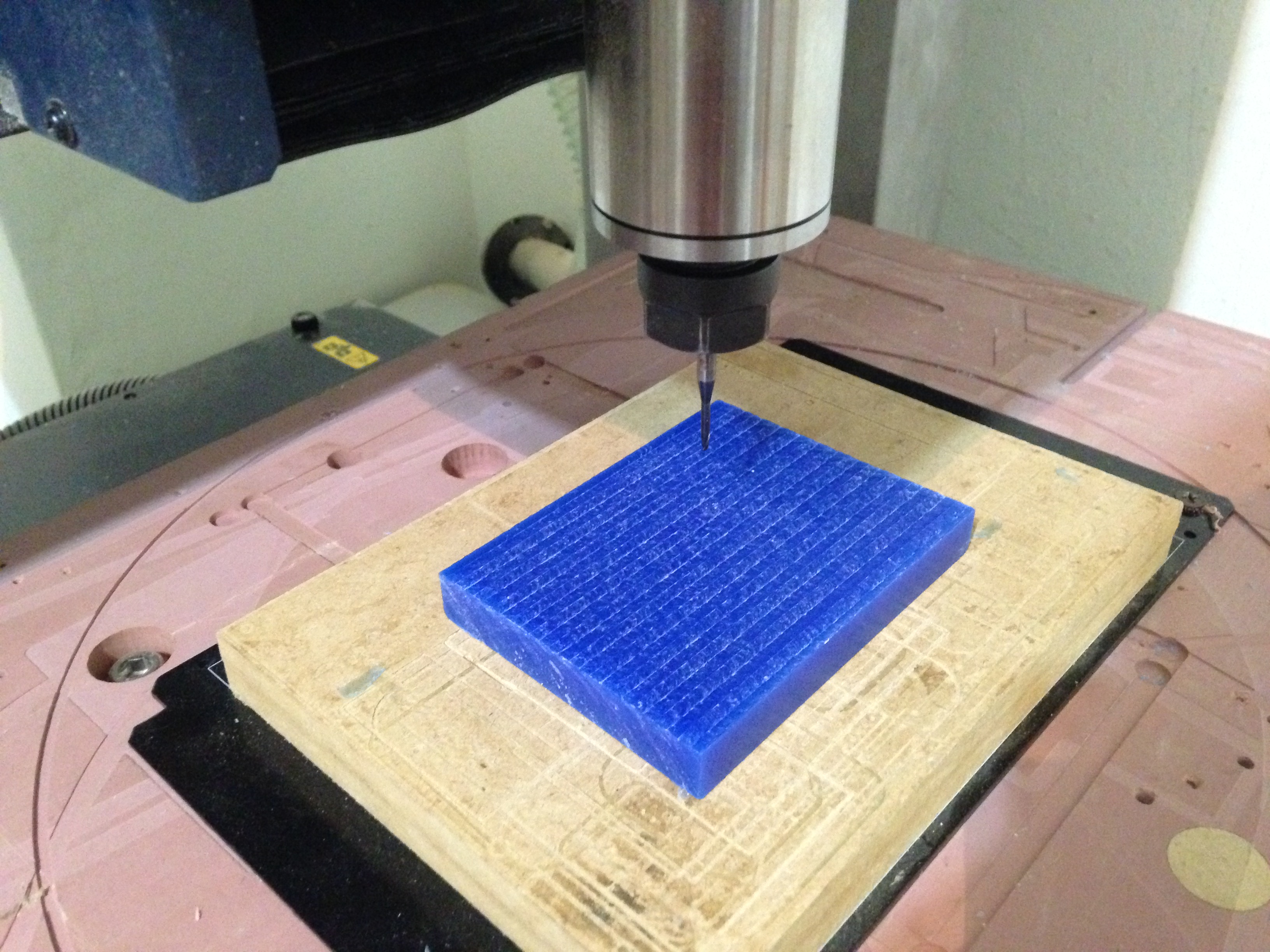

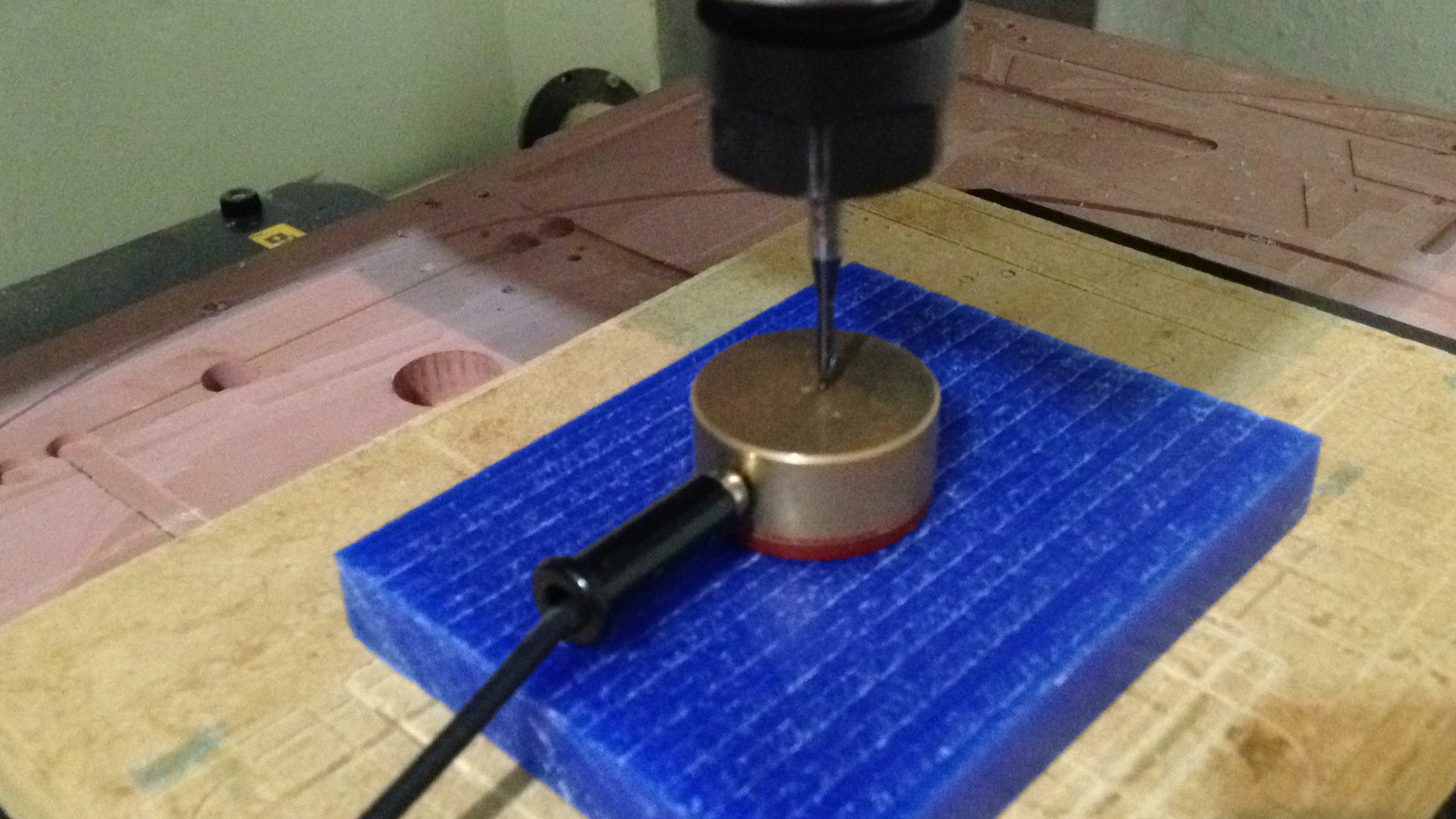

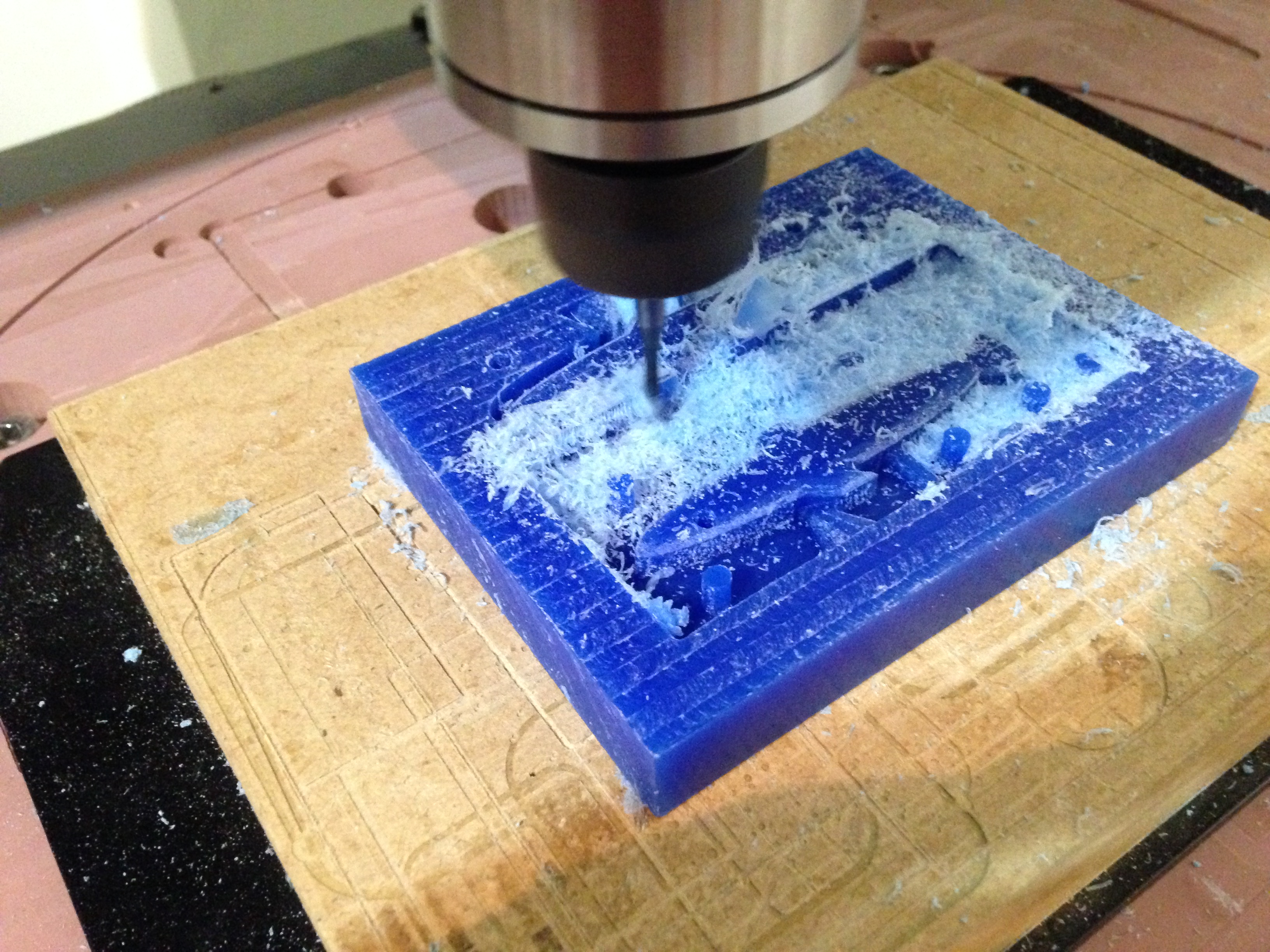

Then I used machinable wax、CNC machine to mill my mold.

For milling machinable wax. The MDX540 variable what is set:

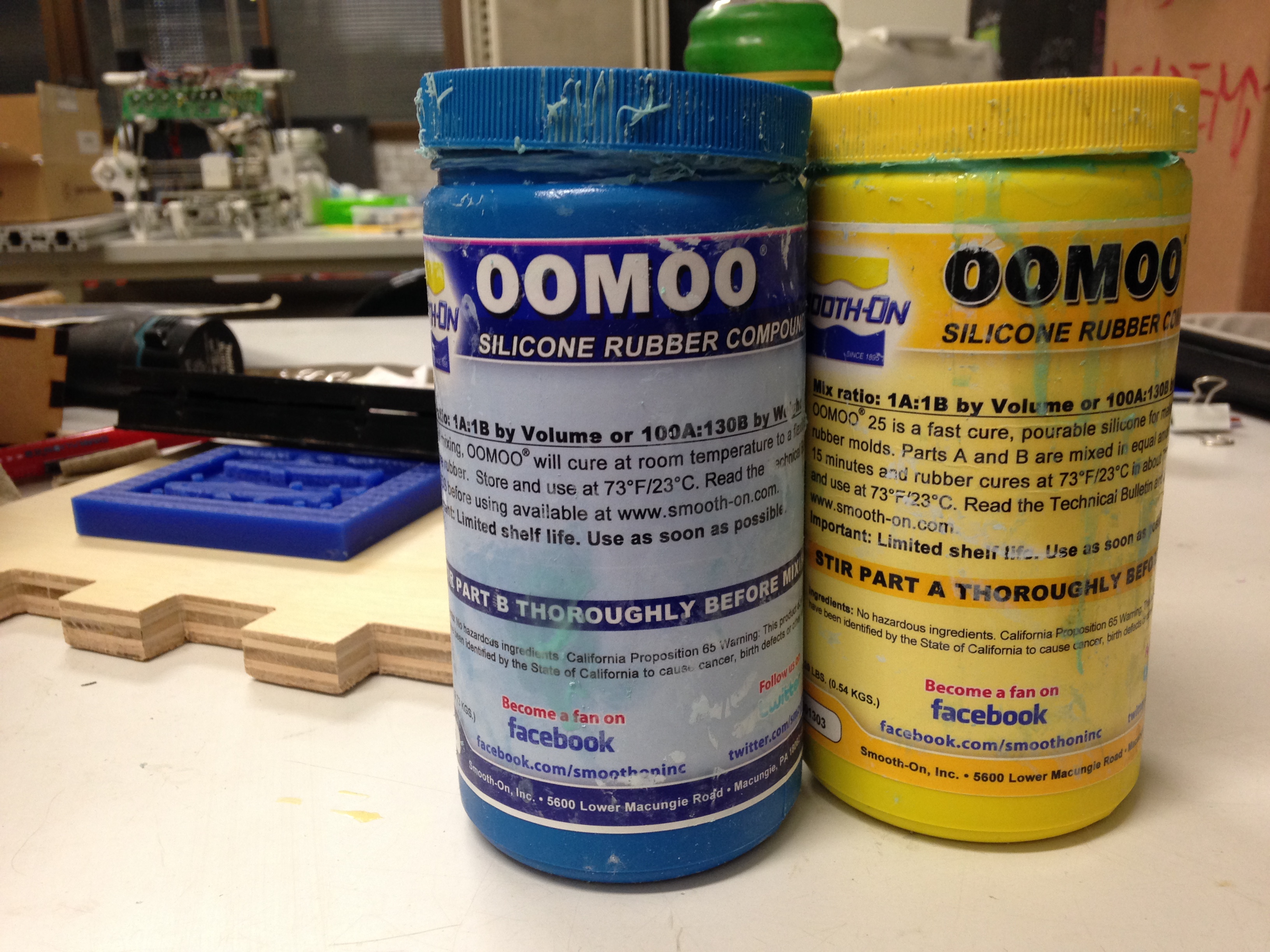

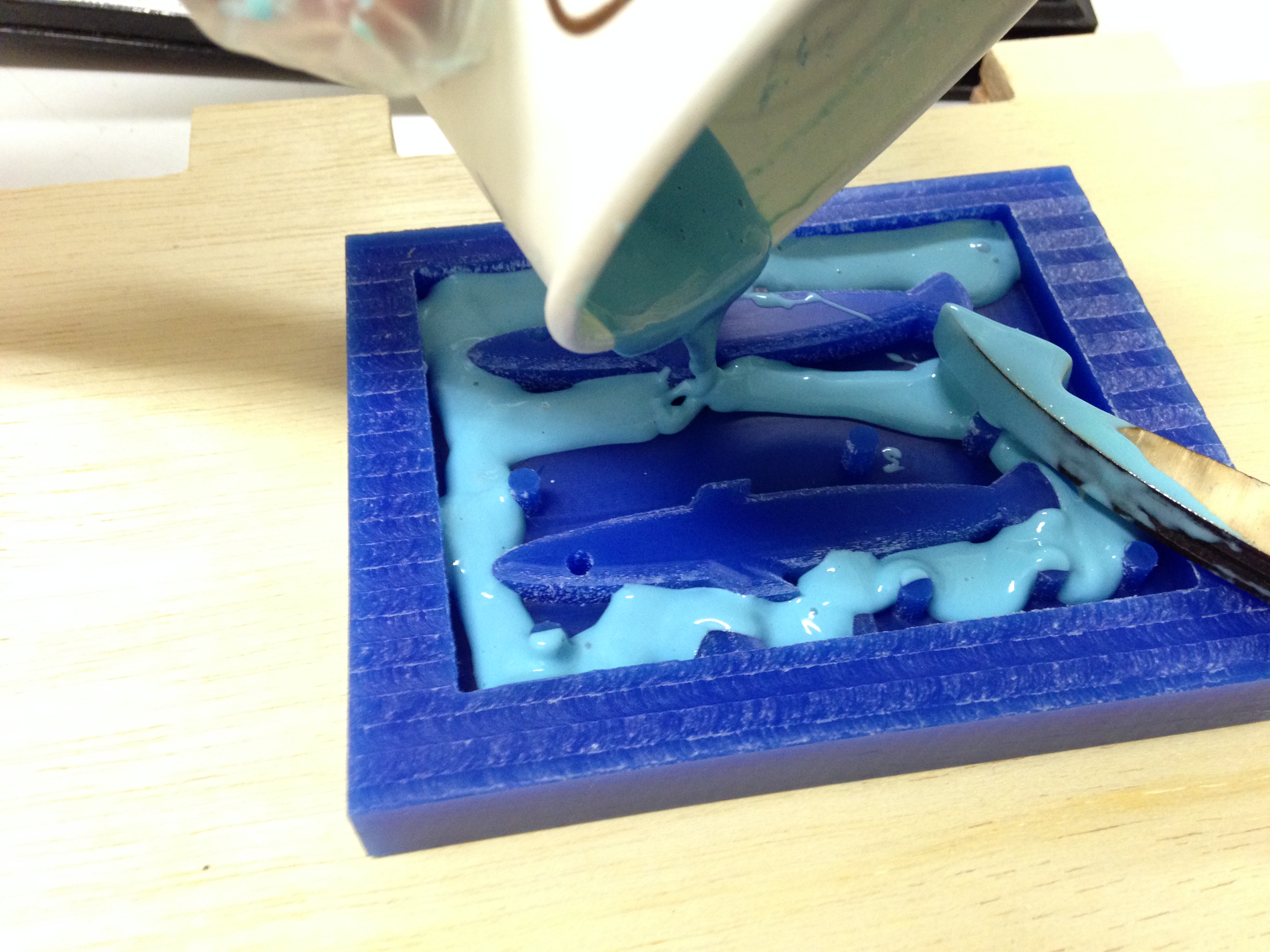

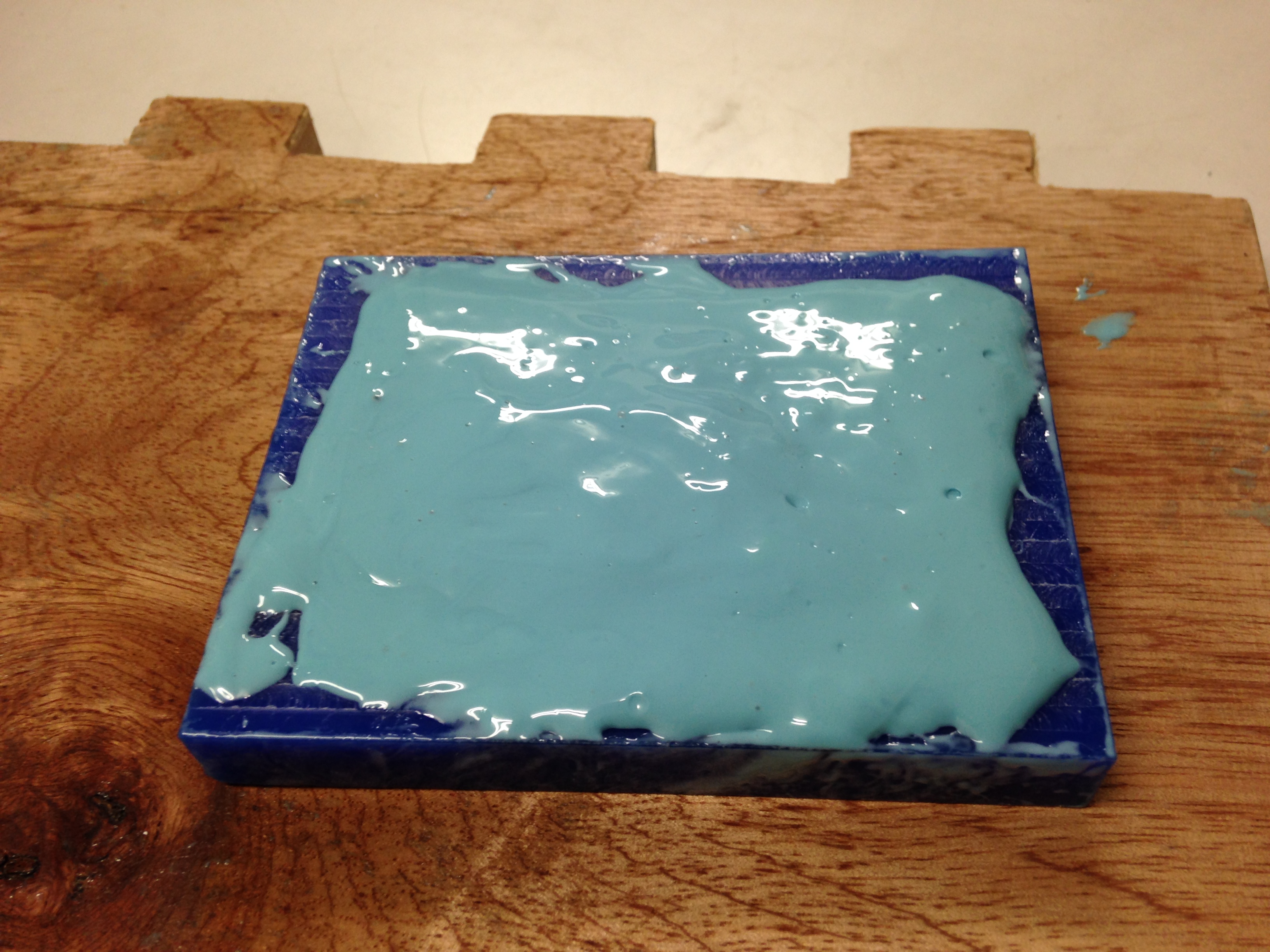

Then I used oomoo to make a mold.

Equal parts oomoo A and B by volume. Then Mix, mix and mix it.

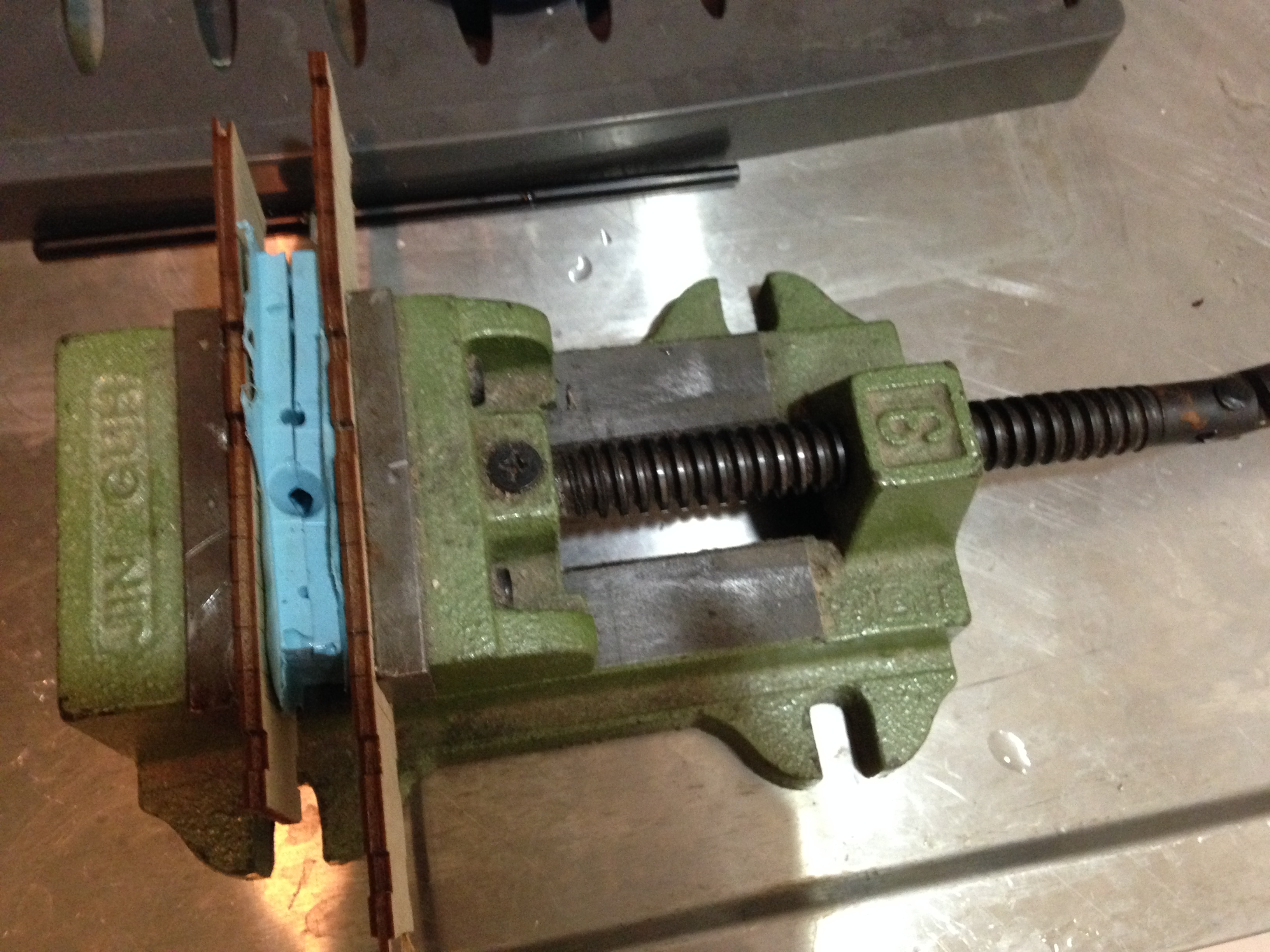

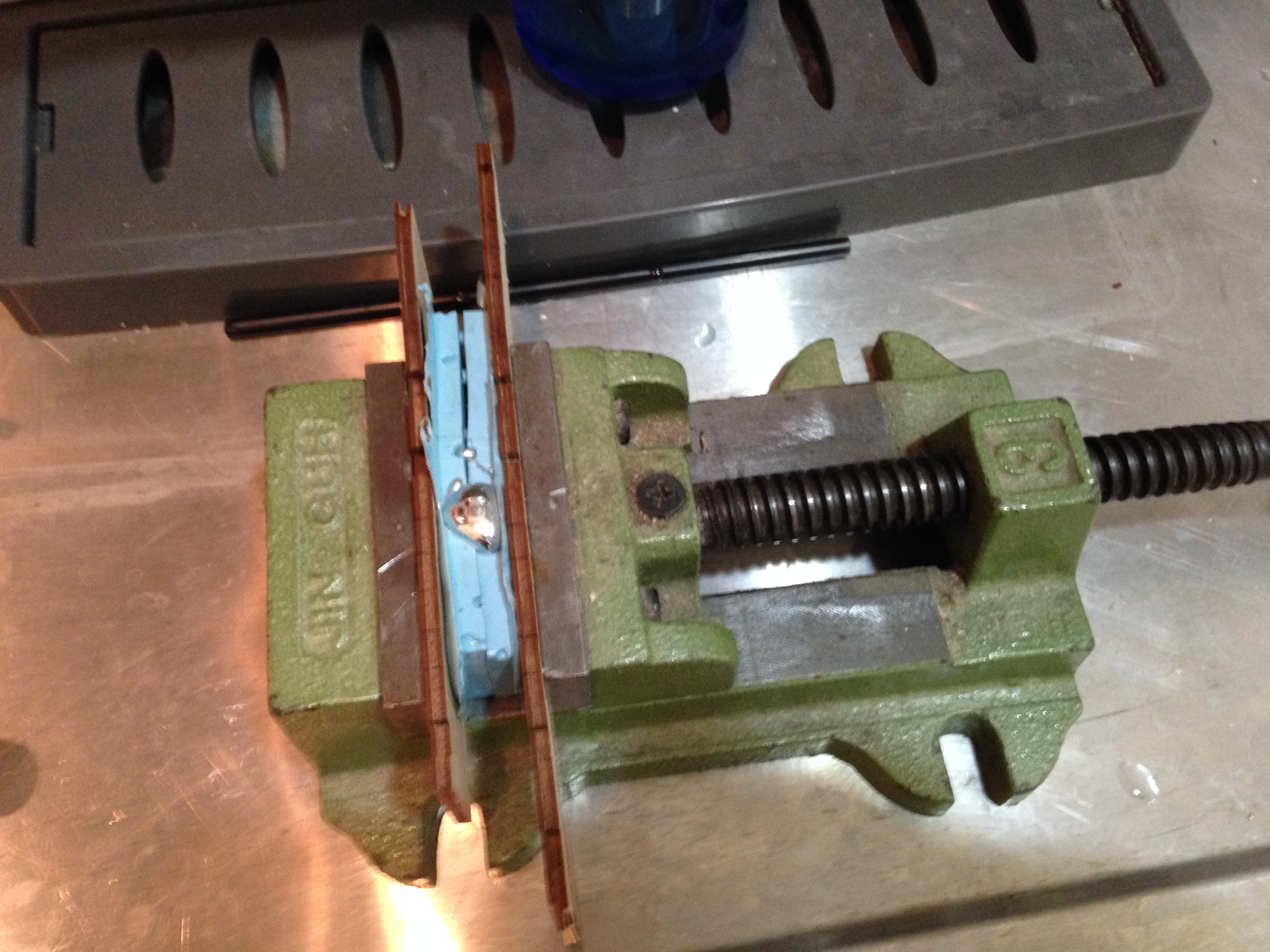

JC told me how to melt down alloy and I used two pieces of MDF and metal clamp to fix the mold. Pouring of the liquid metal into my mold.

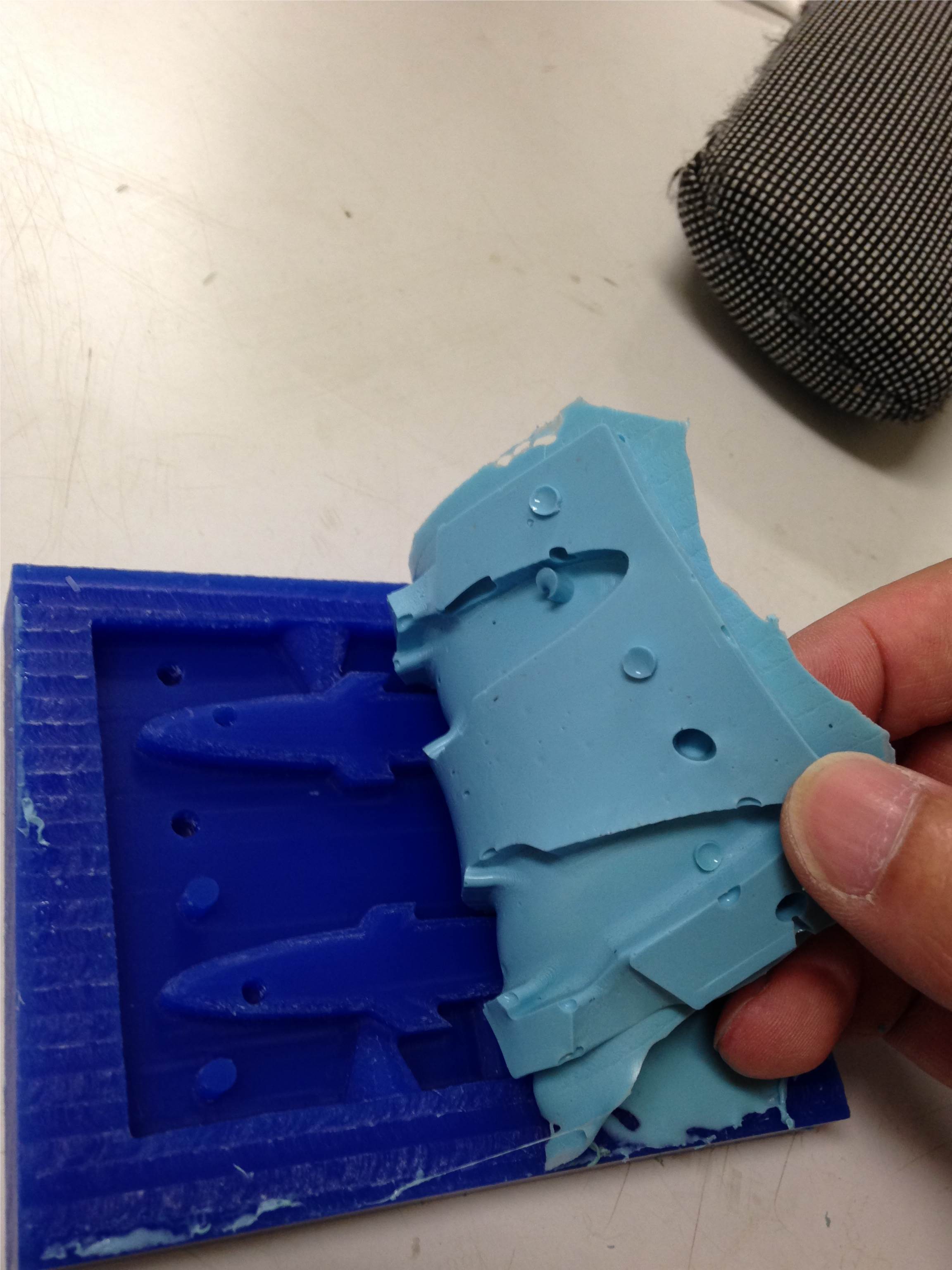

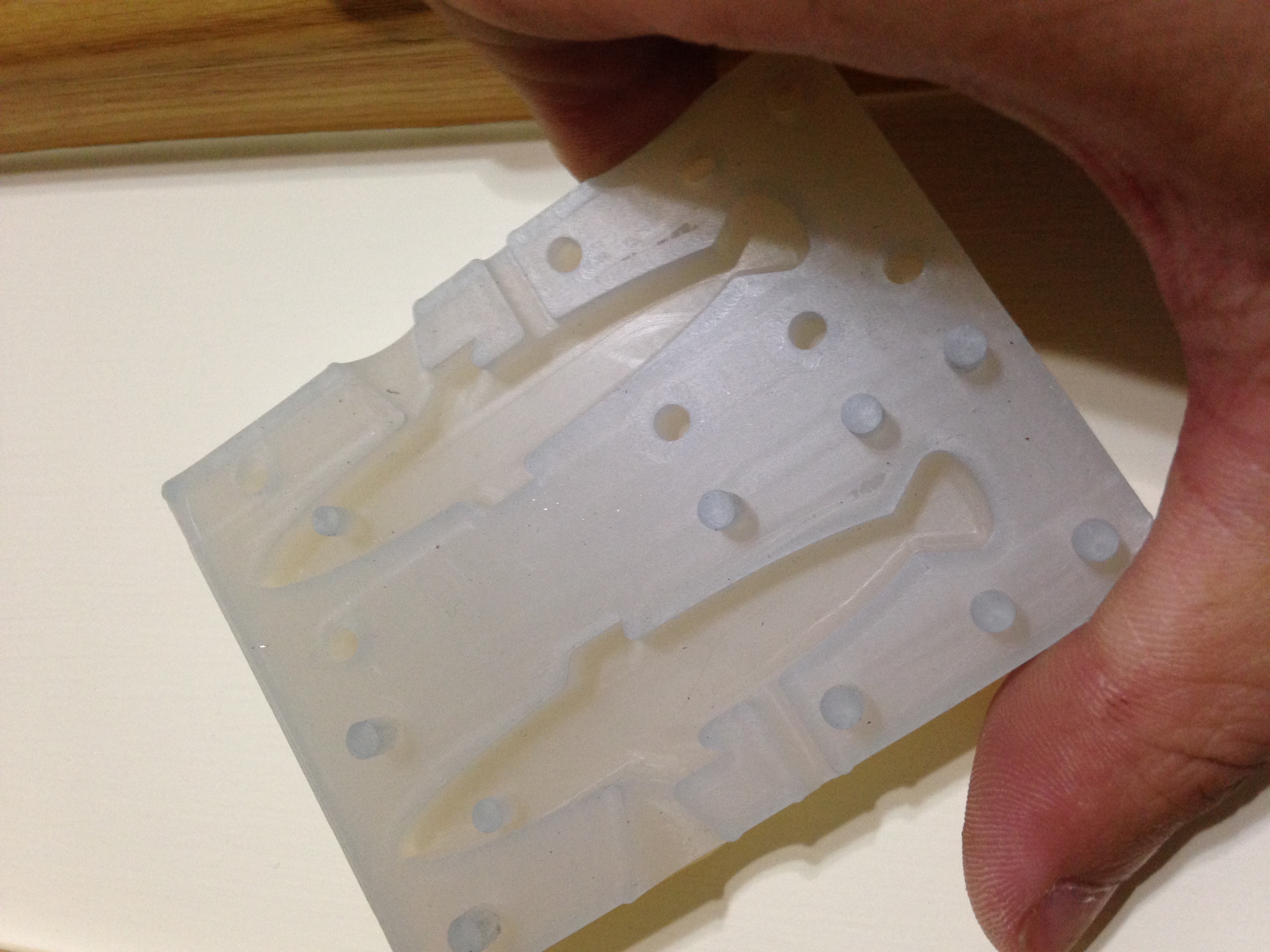

Try to make another mold with silicon.

To cut the mold into two symmetric pieces.