Week07

Introduction to this week

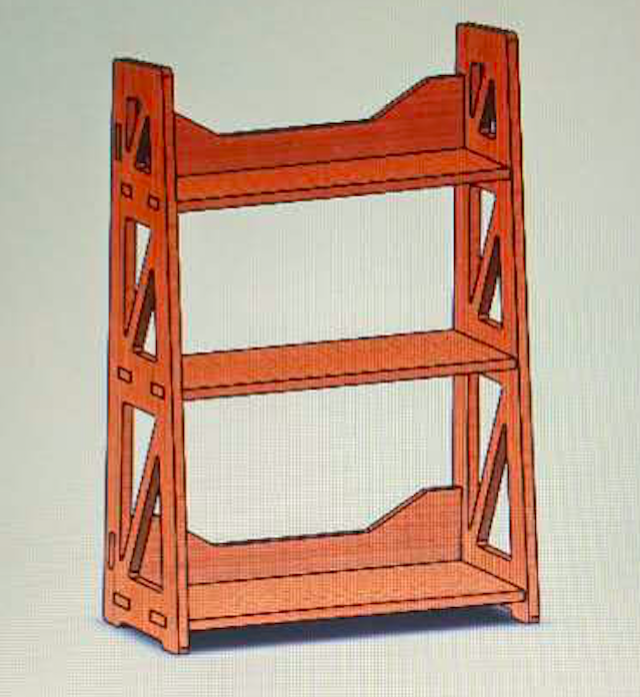

For this week assignment is to make something ‘big’. I am going to make a bookshelf which I think is big enough.1. 3D design

To design the structure of the shelf, I used Solidworks to design 3D model for better preview of my product. I didn’t use this software before, but after looking some tutorials from YouTube ,I can use it to build some easy object.Then I have tried to build easy shelf model by solid works.

2. cutting design

As we are going to cut the shelf by using a CNC machine and assembling. I have separate this 3D model to several pieces 2D boards. In my case, I generate it in AutoCAD. And because the thickness of wood block is 15 mm, which have been set in file.3. Lasercutting for preview

To check the design I first laser cut the book shelf by scale the file. And it seems everything works fine.

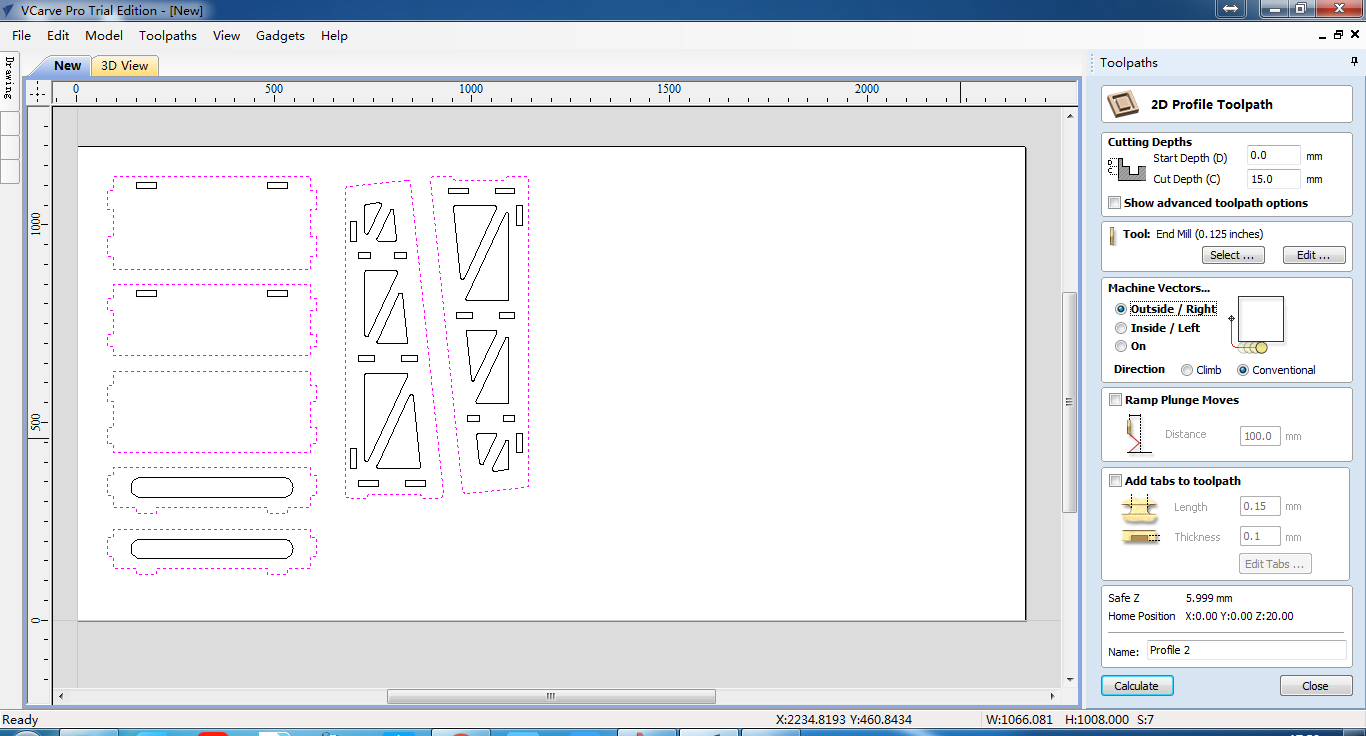

4. VCarve

Then to cut it in CNC, we have to generate gCode and tool path before real cutting. I chose VCarve Pro. VCarve Pro and VCarve Desktop provide a powerful but intuitive software solution for cutting parts on a CNC Router. There are tools for 2D design and calculation of 2D and 2.5D toolpaths and along with the ability to import and toolpath a single 3D model (STL, OBJ, SKP etc.). There is also support to import multiple Vectric Clip Art 3D models (V3M) to create advanced 3D assemblies.[ http://www.vectric.com/products/vcarve.htm] Calculate the cutting path.

Calculate the cutting path.

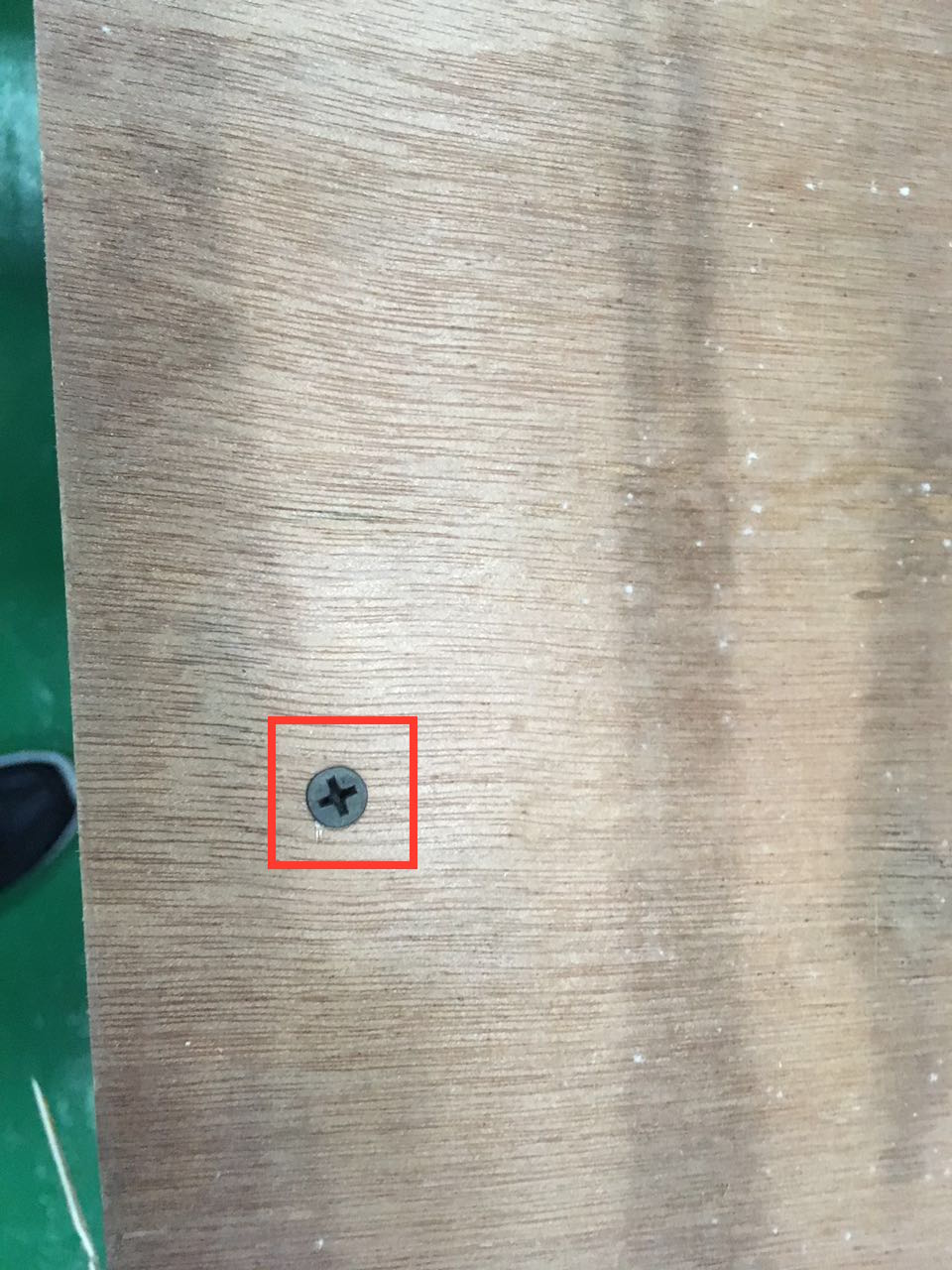

5. Cutting and Assembling

Durring Assembling, I found it is very hard to insert one part to the other part. I think it's because their rough edge. Next time the speed of CNC movement should be lower.