Week05

Introduction to this week

1. 3D scanning

I was trying to do 3D scanning task by using a 3D scanner from XianLin Tech, which is an chinese 3D scanner provider.From the picture, it obviously shows the outlines of the object. But it's so kind of rough for further using case. So we need to build our owe 3D model.

2. 3D Modeling

For 3D design, I want to make laser gun to be used in my final project. And I regard this is a good example for 3D printing, as both sides of the gun are not flat. If we make it by subtractivly, it will become very difficult to cut or mill it in both sides. So I think 3D printing is the best choice to make this laser gun.(Why it cannot be made subtractively)?

Well, indeed the laser gun can theoretically be made subtractively. But it becomes more complex in implemention. The resons showed below:- 1. The laser gun is a double-sides model. If it be made by milling machine, it is difficult to be realized

- 2. The surface of laser gun anomalous and has many details. If will takes much time made by subtractive methodes.

- 3. The size of the gun is not small. From my personal experience, doing it subtractively takes more time then 3D printing. I have milled a mold onece before, to finishing the milling I spent 8 hours for the size around 6*10 cm. While this time, the size of the laser gun is aroud 15*24 cm.HOW LONG IT WILL TAKE?...

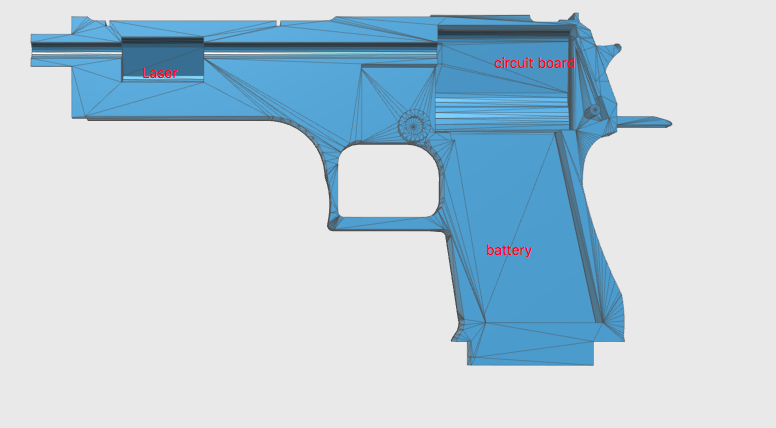

To make this laser gun, I am thinking that it should have a gun shape, and it has the capability to shoot a laser ray.

So I used an openSource gun shape model from internet. I cut the gun model into 2 pieces from the middle. Then in order to fit my application, I leave some space from inside to lacate circuit board, battery and so on basiclly used Subtract Intersect command to do the modification. And then it shows like the picture below:

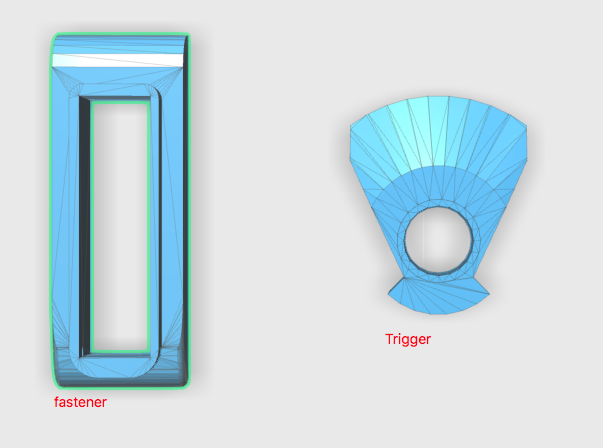

And some opnent for laser gun.

And some opnent for laser gun.

3. 3D Printing

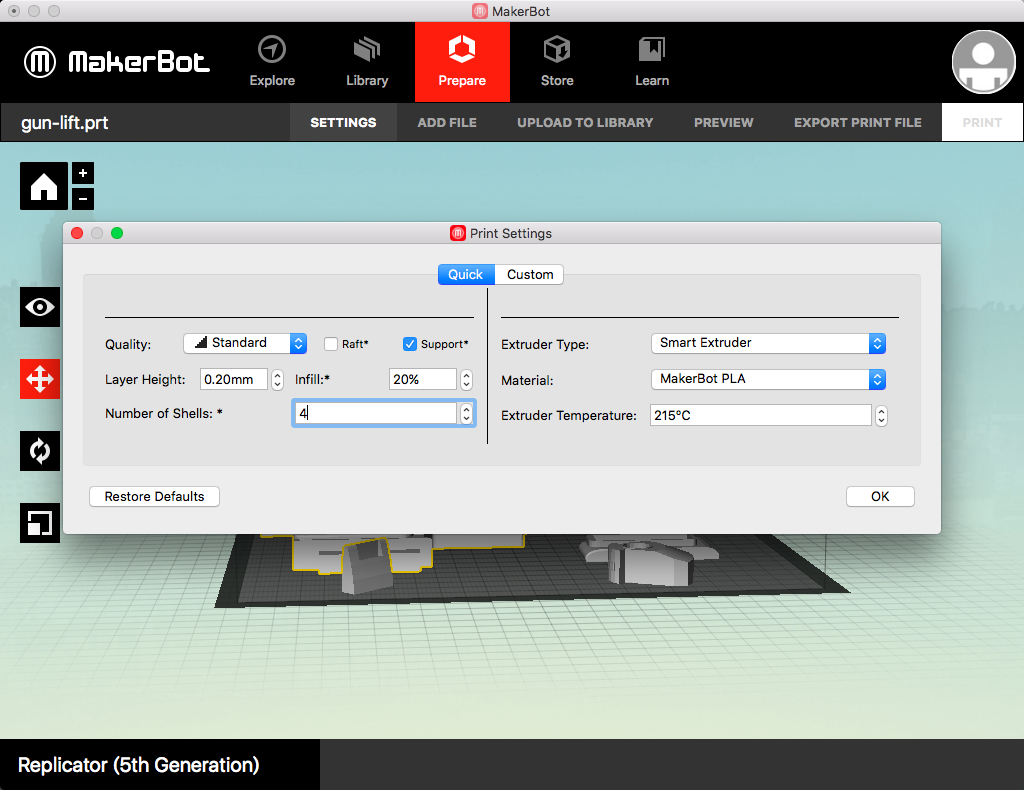

I use MakerBot to print the gun, one thing we should do before printing is to set up some configuration.