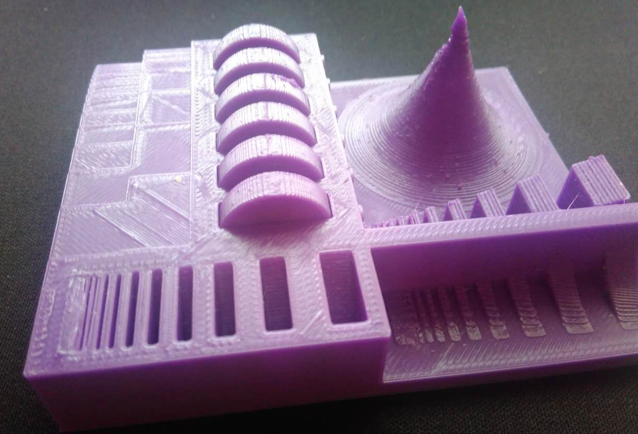

1. 3D Printer Test

This week's main purpose is to use the 3D printer and 3D scaner. First our group print a test module to test the 3D printer.

Here is some of our test parameters.

Machine: MakerBot Replicator 2

Material: PLA

Layerheight: 0.2mm

Temperature: 210 degrees

Number of shells: 2

Fill: 10%

The progress of using 3D printer:

1. Generate stl format;

2 slices using software slicing. makebot can use its own slice software.

3. The following sections generated files into sd card, take an English name.

4. Insert the sd card into the slot in the printer, select print files in the interface, and so the nozzle heating is completed, you can start to print.

In the process of printing, there have been a lot of accidents. Print accuracy is not high in some places, from a large range of movement will be some voids in the movement, these gaps can cause some residue on the front of the print is applied to the back of the printed matter, the formation accuracy is not high.

In addition, in the case when the print head will be clogged, then refill material can cause a disruption before printing, which is the final cause of printing failure.

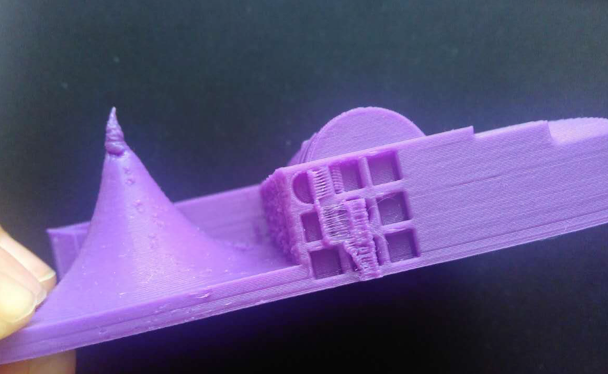

We use this to test tip, curvature and cracks. We use standard quality and print 6 hours. Maybe we should use high quality to get a high quality. You can see from the photo that the tip is bad.

And for the coins, we cannot pull out even one coin. It has big error. For the bridge, it may crash down.

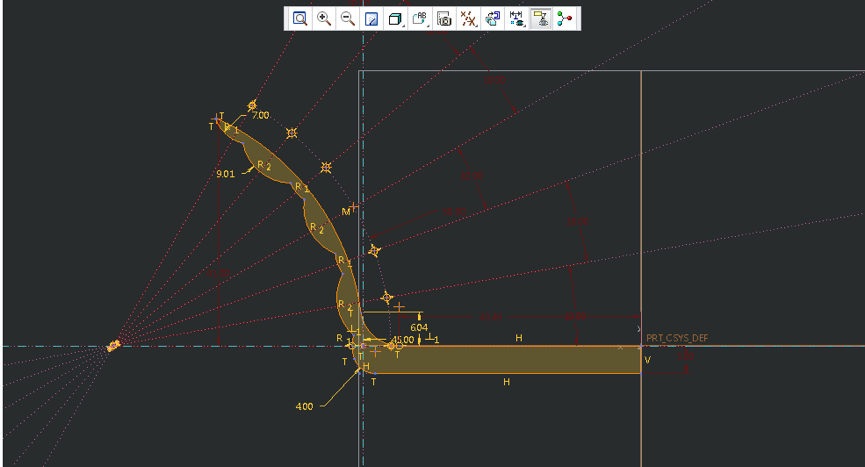

2. 3D design and 3D print

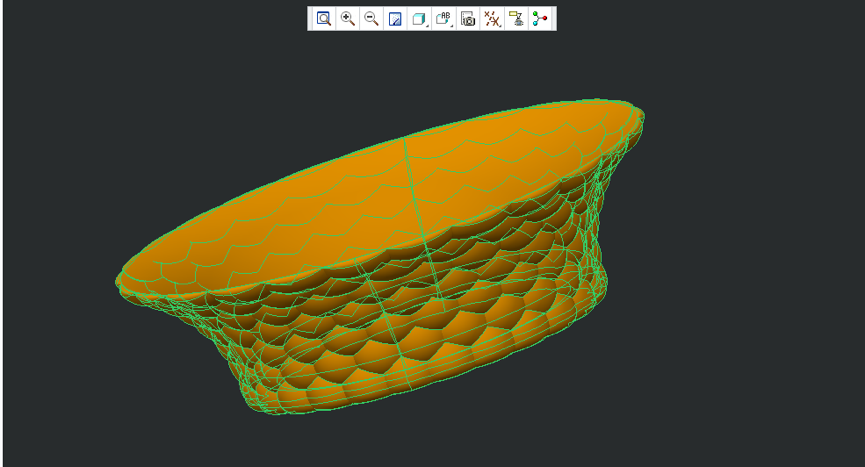

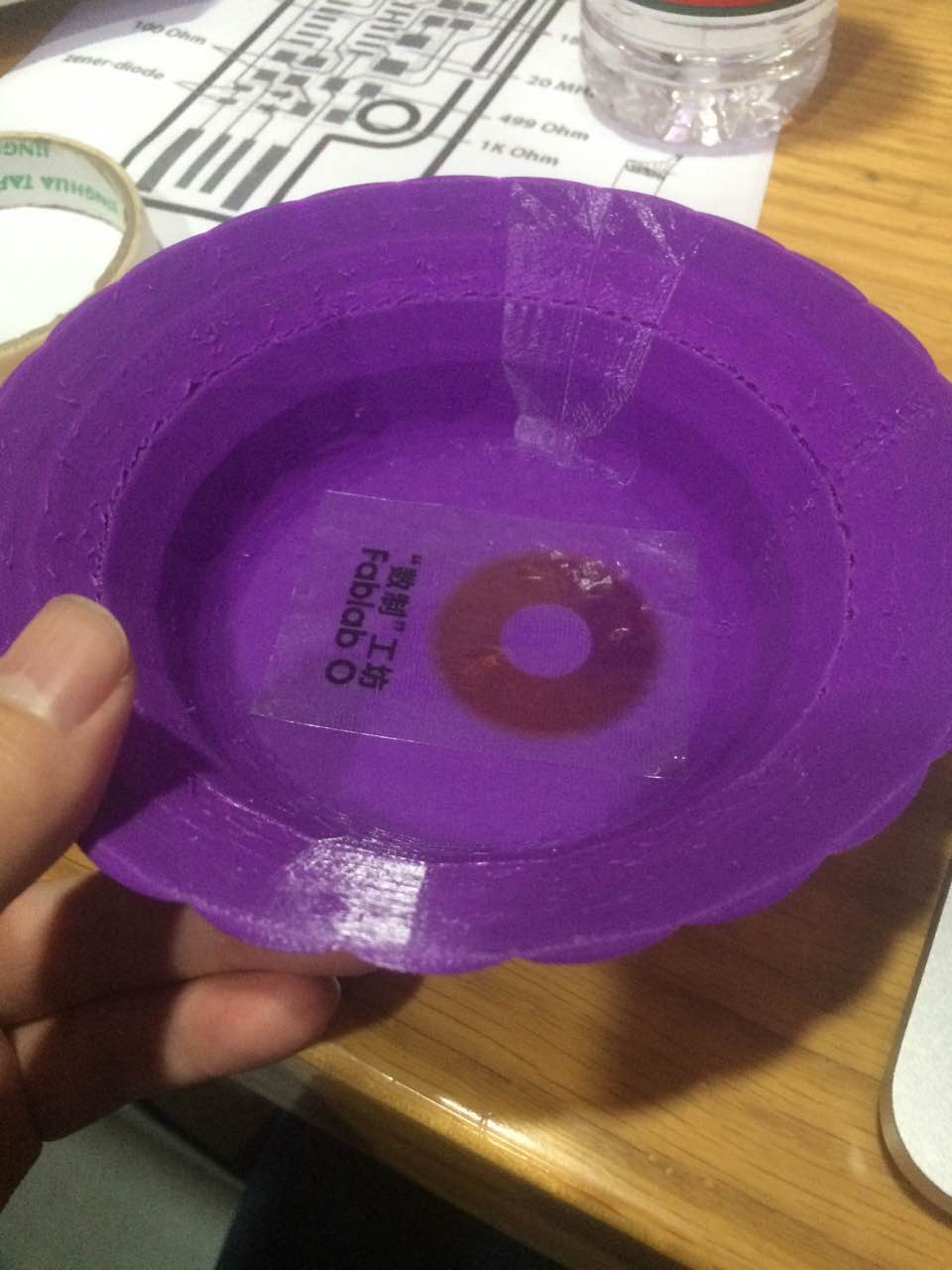

For 3D printer, i use Creo to design a bowl with a complex figure. Because this bowl has some indent figure so that it cannot be mold.

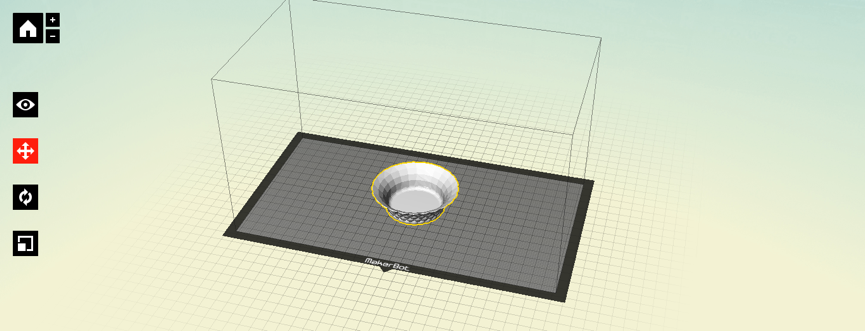

Send it to the 3d printer.

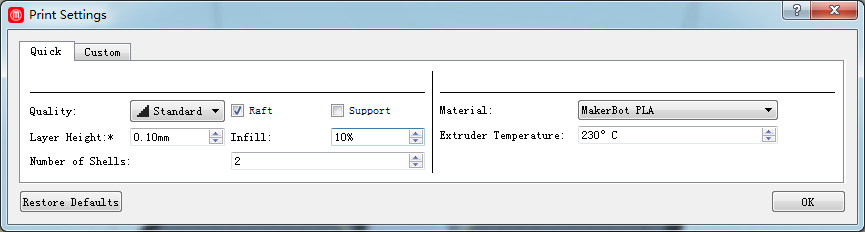

Here is my parameters.

Here is my parameters.

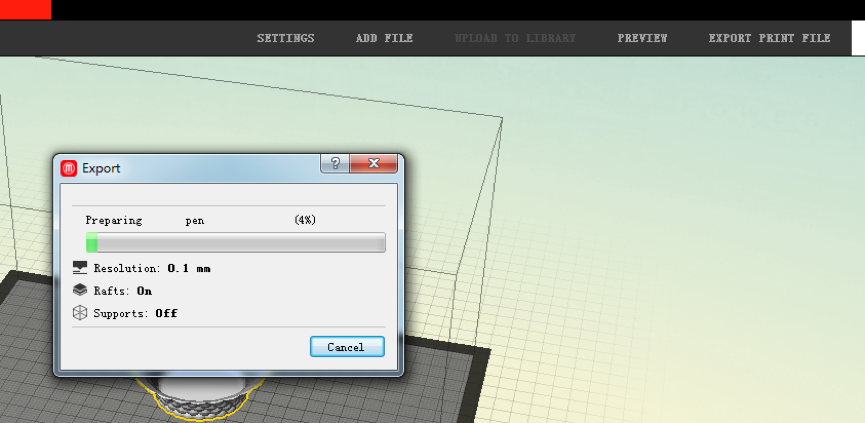

Finally, get the output file and print it.

Here is my 3D printer.

And here is my stl file. Download and Creo design file.

3. 3D scaning

For 3D Scaning I use makerBot Digitizer.

I use clay and mold to make the scaning thing. I think if I can scan my clay and print it, it's one kind of 3D design. But I am doing very bad on art. So I use a mold.

I use clay and mold to make the scaning thing. I think if I can scan my clay and print it, it's one kind of 3D design. But I am doing very bad on art. So I use a mold.

Here is my clay.

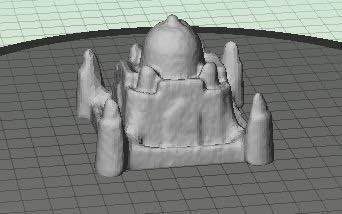

Here is my 3D scaning result.

Here is my 3D scaning result.

And here is my stl file. Download

Problems

When using makebot, its head is often blocked. Under normal circumstances, we can solve the problem by way of elevating the material. However, due to the nozzle configuration, and sometimes the material will fill the entire nozzle block, this time you need to remove the nozzle from the inside with a small Knife go blocked material. The probability of this happening is so large.