In this group assignment I am charging on the make the main frame.

I try to make the modular frame just as mtm gestalt node machine but somehow my design not allow to disassemble that easy so, It's half modular frame. If you want to check my design you can find it end of this week page.

I try to use high density polyethylene which is quit expensive but really good for make machine with it. If you want to buy this material in Korea you have to follow the link bellow and it's called UHMWPE. made by German manufacturer.

Here is the link for the HDPE.

HDPE is material that suit for robotic projects or make something need to be rigid but also elastic.

If you want to know more about HDPE here is the link to the wikipedia.

I try to cut the frame from MTM webpage. Gestalt node frame but it was in inch which only American use. So I have to multiply 2.54 to make it right size.

but! there was some serious problem.

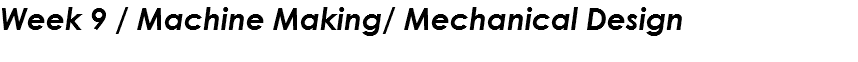

Whenever I try to cut with our Laser cutter it shows this kind of stressful sh....

I try to figure it out why it happens and it was the broken lines.

If you draw 3d model with rhinoceros and after that make it 2d and import or open with auto cad usually all the line are broken wherever has anchor point before in Rhino so,you have to select each of them and hit "j" and space bar or enter to join the lines to gather.

>>>>>>>>>>>>>>>

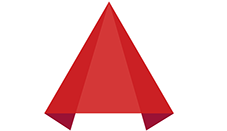

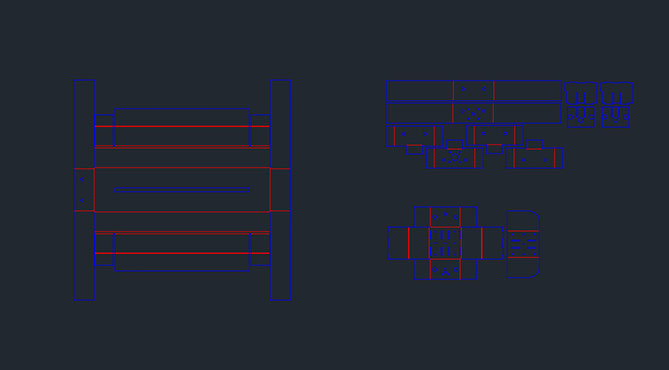

While I try to fix this I have changed my mind and start to draw new stuff which can work with HDPE.

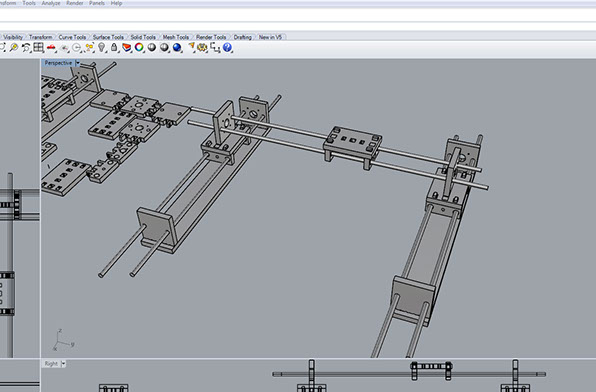

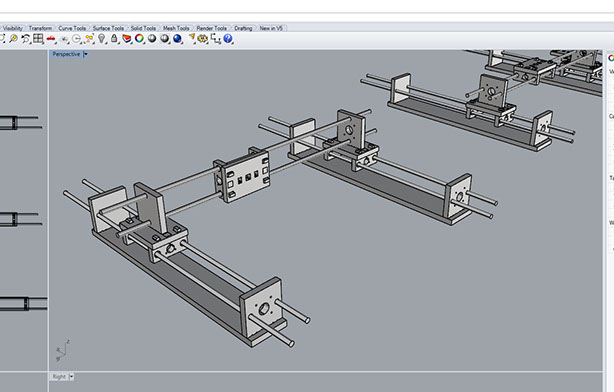

After I made the plan with Auto Cad and I made the 3d model to test it out.

so if there is any mistakes in there and I have found that I have to rotate the middle bar to face the front of the machine.

Like this.

Now it looks okay.

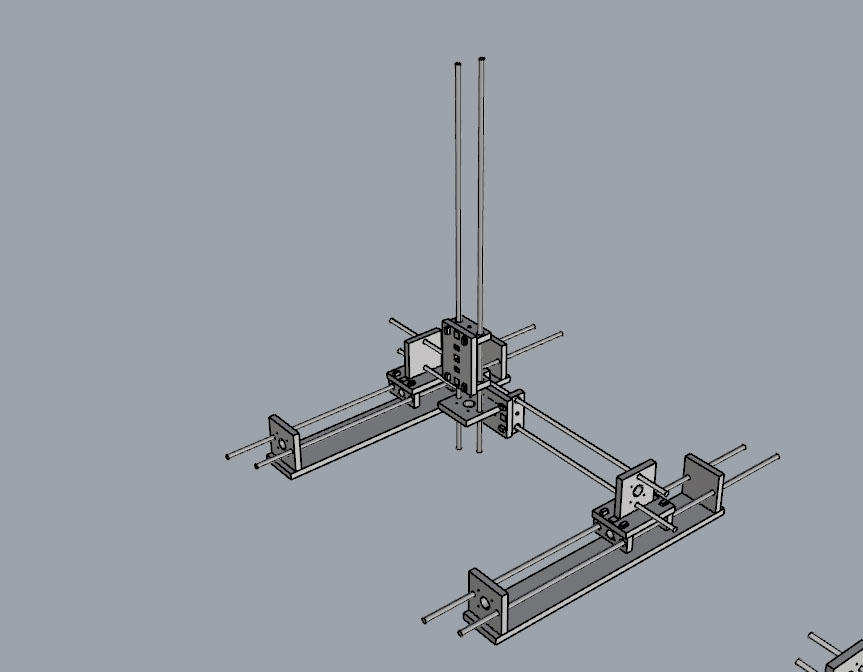

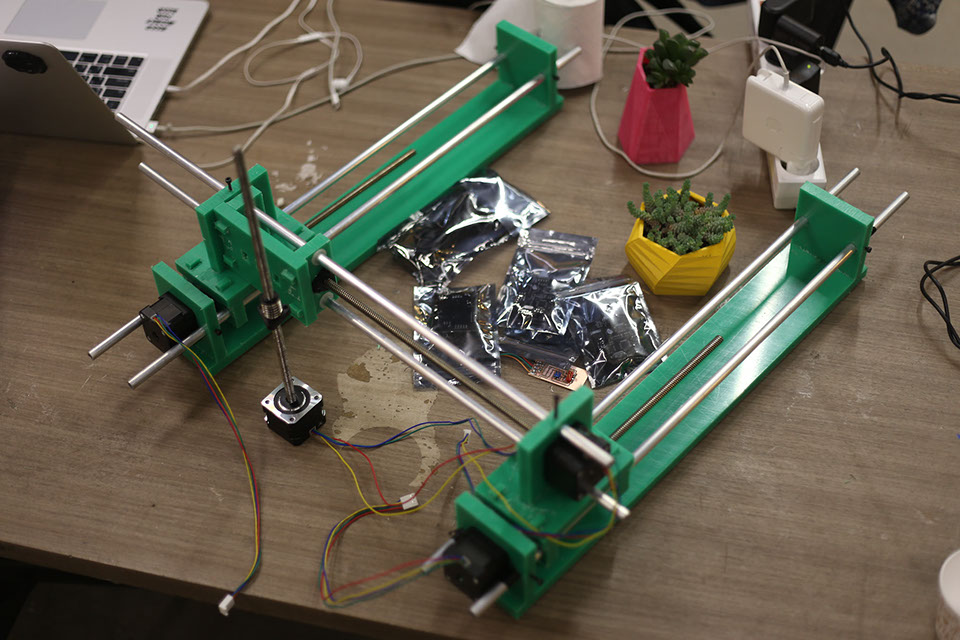

This will be the how machine finally looks like.

more or less..

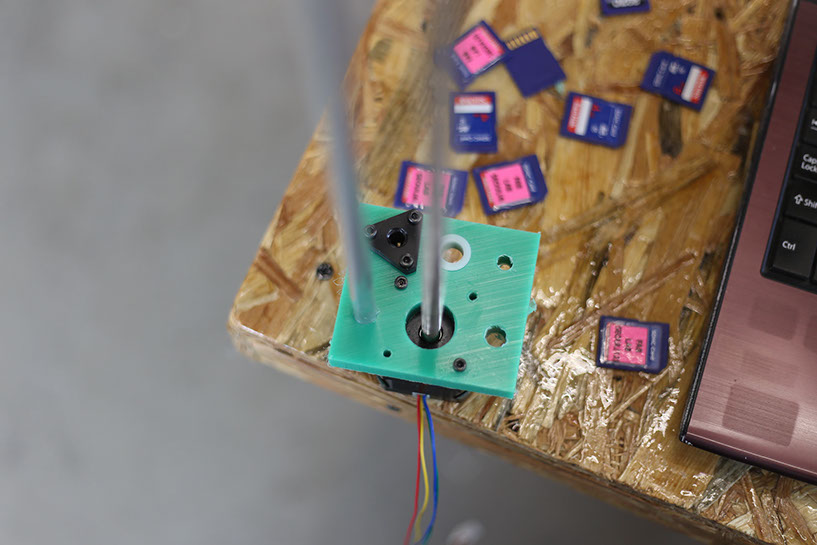

Testing the holes.

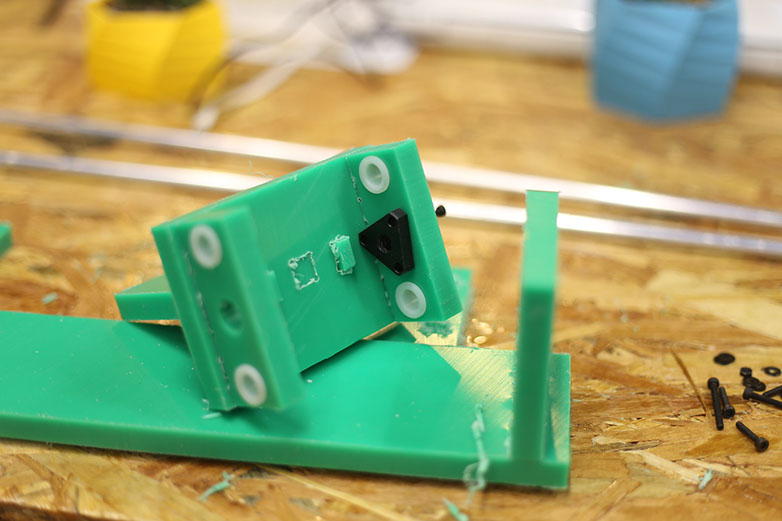

Step motor holder, linear bearing, triangular thing, aluminium post.

After I did the few test actually the size of the hole or everything was set in the original frame file which doesn't work well with our laser cut software,

You have to look through the Step motor's data sheet to make perfect hole and I didn't do it. ;P

but it works fine.............

It need some force to fit it to gather. and It will helps to prevent loosen off while use the machine.

Professional way to testing hardness and flexibility.

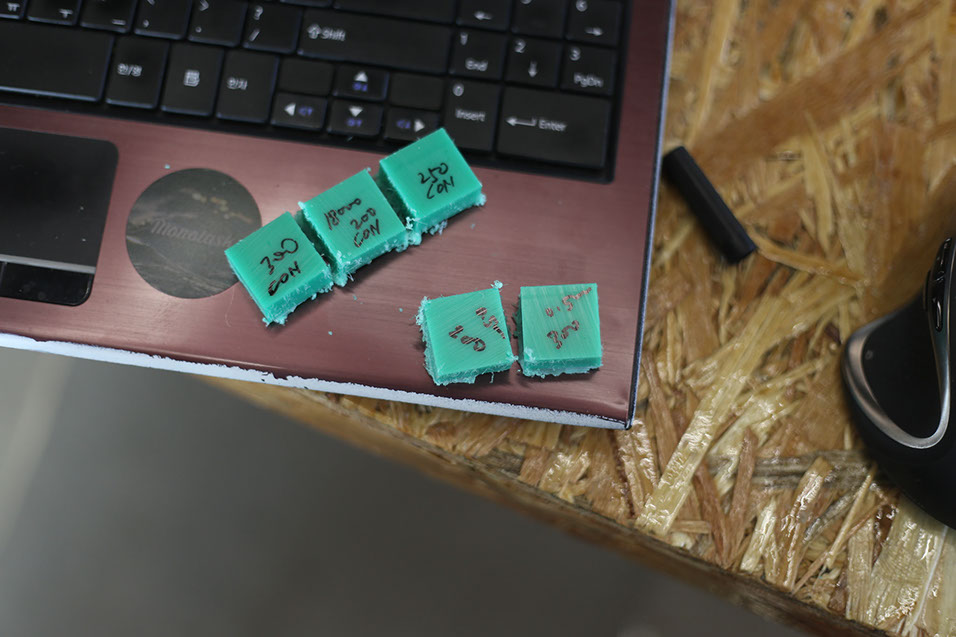

To clean cut I've done few test and the best was

18,000RPM / 200 Feed Rate (inch/min) / 2mm cut depth (3mm endmill 1 flute)

But you should try it with your machine first.

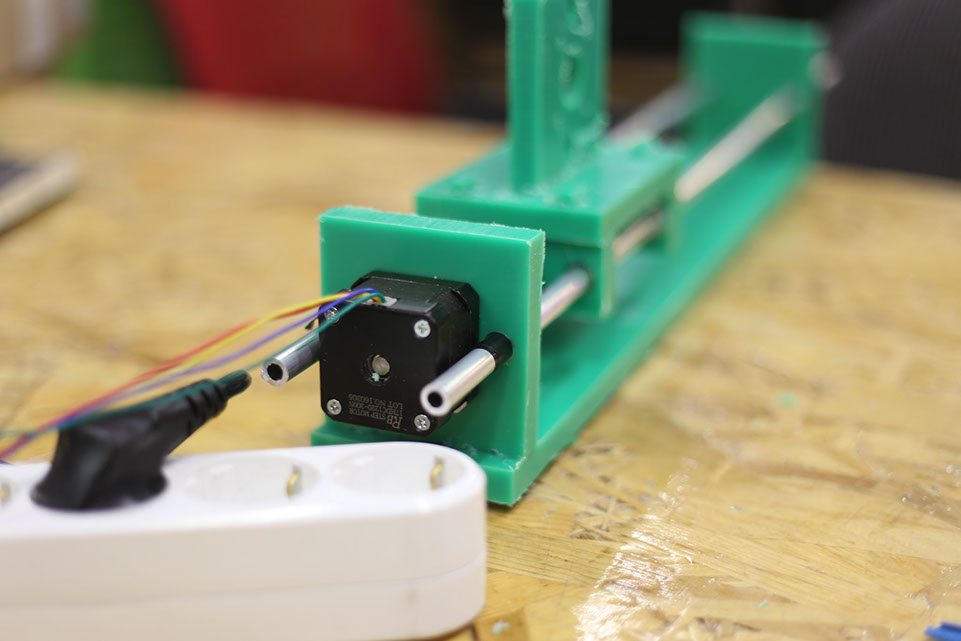

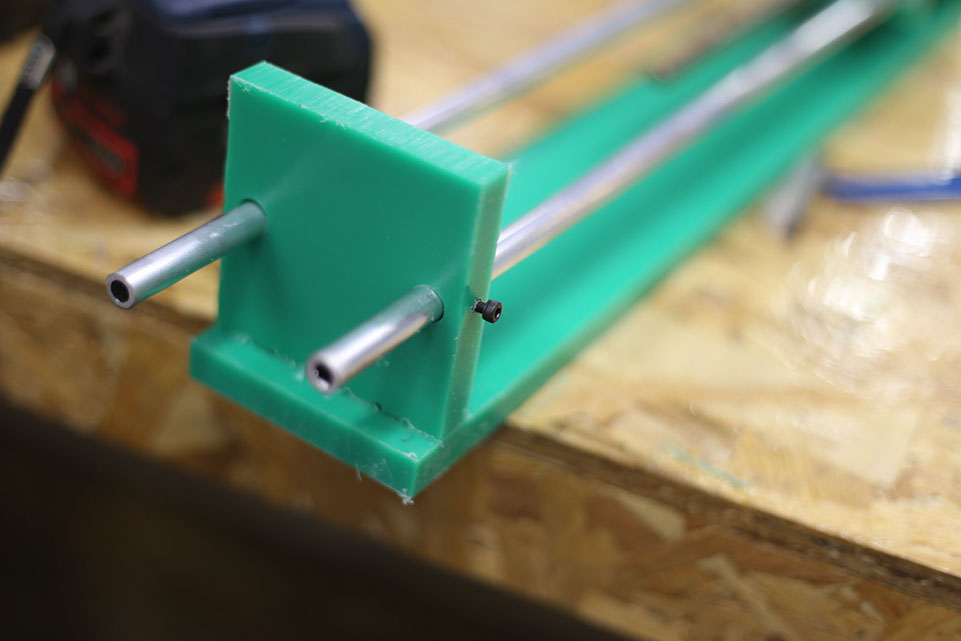

Assembling.

At first I just use the tape to hold the post but It was too easy to move it so I've change it to the bolt.

M3 bolt / T3 allen tool / 3mm tapping bit / 2mm drill bit

make the hole through hdpe and aluminium pipe with 2 mm drill and make the 3 mm tapping hole and screw it with m3 bolt.

Now It's time to make this machine alive.

files

frame auto cad file

frame 3dm file (rhinoceros 5.0)

HDPE TEST CUT file

home