In this week I've try several things. Even how to Unscrew the screw with end mill.

I might had lose my eye if I did more mistake.

Always, Safety First!

You have to wear at least goggles when you operate CNC Router. When something fly right in to your eye while work on something it may make you blind.

Also there will be a lot of noise while you cutting and run Dust collector so, wear the ear protection to protect your ears. and the Mask is highly recommended. ;)

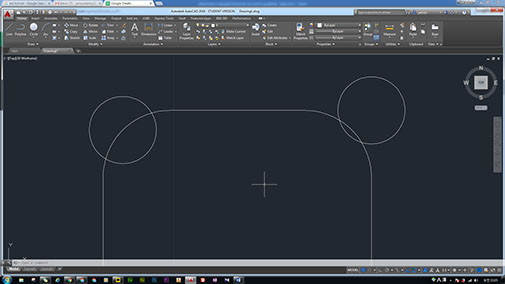

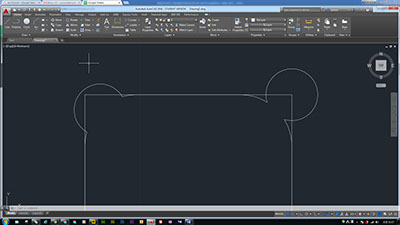

First thing you have to do is design something to cut.

I was working on with Auto CAD 2016.

And I've try something like this.

making a 3mm hole first and change the mill and cut out the hole profile. It makes beautiful pieces but though I don't have auto tool change. It was really annoying when ever I change the tool path.

I cut the OSB panel and Cheap ply wood in this week.

OSB is too weak to make some joinery. It breaks very easily but since OSB is weak I can cut 1.5 time faster than normal plywood. Twice faster than birch plywood.

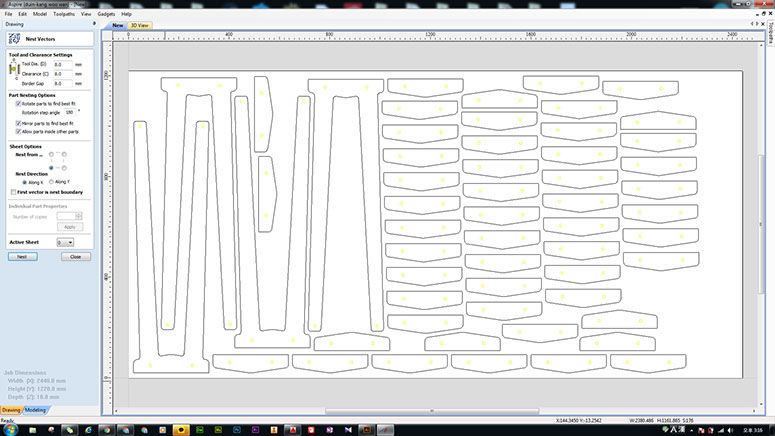

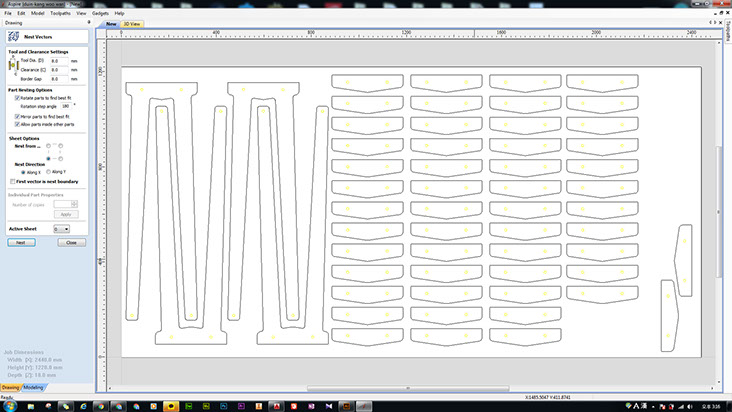

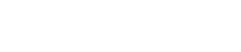

To save the material use Nest.

It organize as the tool diameter,

clearance and border gap.

doesn't matter how you put the pieces, It shows you a magic!

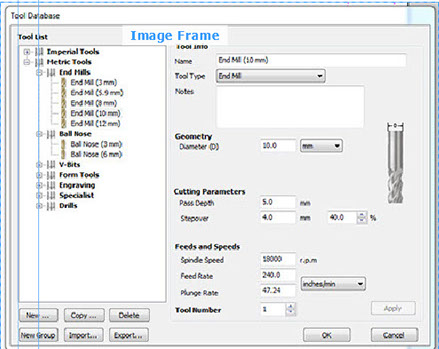

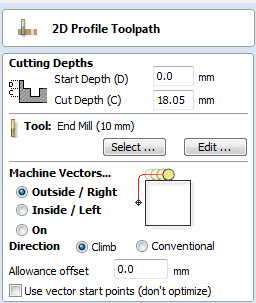

Set the Cut Depth.

I usually give 0.05 or 1mm more than stock thickness.

To not do more job after cutting.

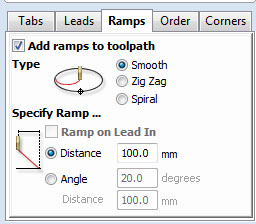

This is important!

Always, check Ramp on is checked.

If you don't check your going to lose your mill faster.

I'm using 2 flutes, so, this going to be work!

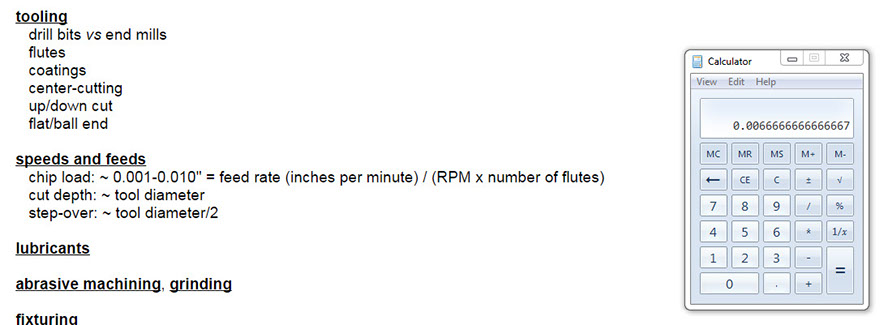

For better output look at the Chip-load Chart.

For more information click the click button below

Click

OSB is really Crappy plywood but one of my favorite wood.

because it is cheap and crappy no one gonna blame you if you make any mistake on it. ;p

Electric Sander is most big enemy for OSB...

This was my Ski rack for home but I've found that my ski doesn't fit and it is too heavy to put this OSB rack so now it used as a spray paint shelve.

Very nice!

And the OSB that I use was used for

Fab Pavilion in 2015.

for the platform.

It can be said as "Recycle".

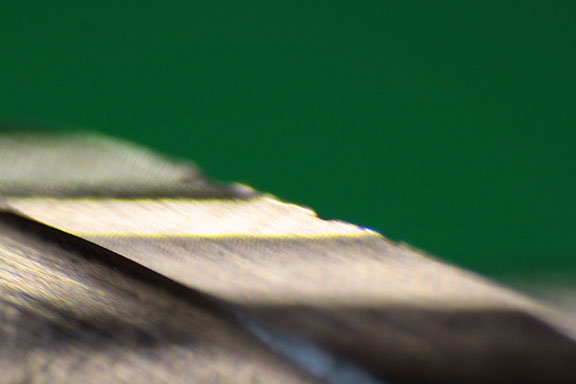

I've Deign another thing and I make the try out file and try. and this kind of thing happened.

It is very good to watch this and always check more than twice everything. Especially Boarder gap.

AS you can see the screw hit by the mill and edge of the mill has broken little. Just a little...

You should put more than 15mm border gap to prevent unscrew accident.

I have tried Down cut mill It manufactured in Onsrud company and dit is 1/4' endmill.

It uses imperial not a metric one.

So, you have to prepare 1/4" collate not 6mm

Here what different between 6mm and 1/4" collate.

Always beware of inch and millimeter.

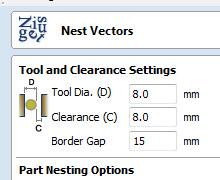

And here is cutting.

It seems it does cutting and sanding at the same time. it just gorgeous!

The cut lines are not connected in the middle of the stock.

This kind of thing can happen when the stock itself is not perfect flat or the spoil board is not flat or both.

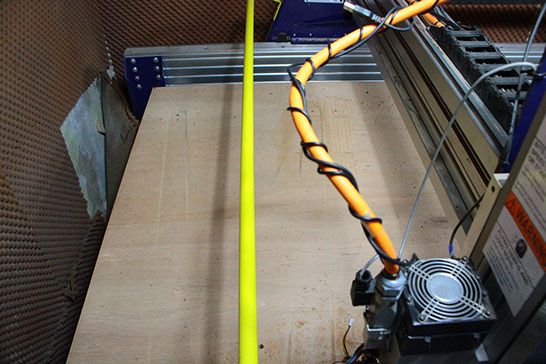

When I cut something with different endmill I make separate file to make sure that I change the endmill.

After cut every thing out let's sand.

and there was almost "0" amount of sanding.

And It's time to assemble everything!

Make sure that one end tighten first.

You can mix the steps to make another furniture.

After that apply some wood glue and clamp it and wait until dry.

Tada!

1000mm tall

Standing mini table.

I think I should tighten the

bolt under the leg also.

It actually wobble. just a little...

And my ski rack is now paint rack.

And I was so touched by the mill.

Thank you OSRUD!

The Best Mill Ever