Awesome Makers

Intro

First week, we had a intoduction class with our instuctor. We learnt about basic machine mechanism and did research work all together.

Role distribution

Fablab Seoul students have various background, from designer to engineer. Project group is devided in 3 parts; Mechanical& Machine design, Software programming and Hardware design.

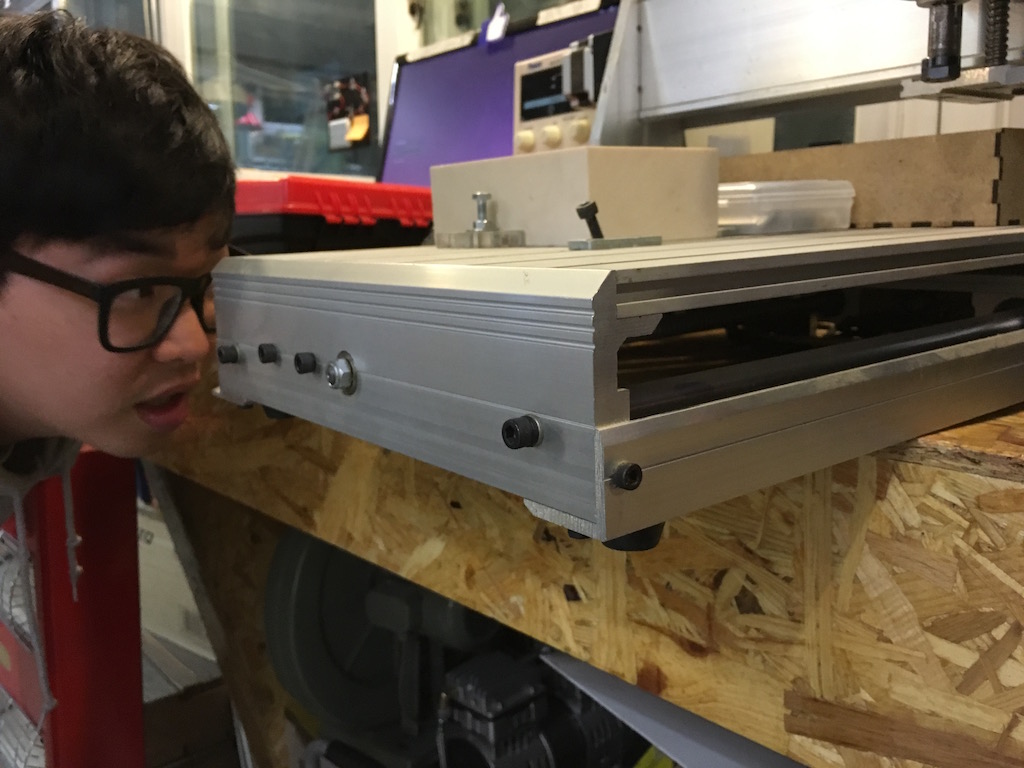

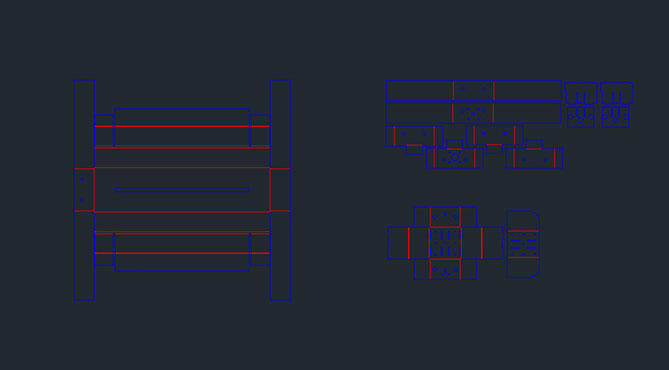

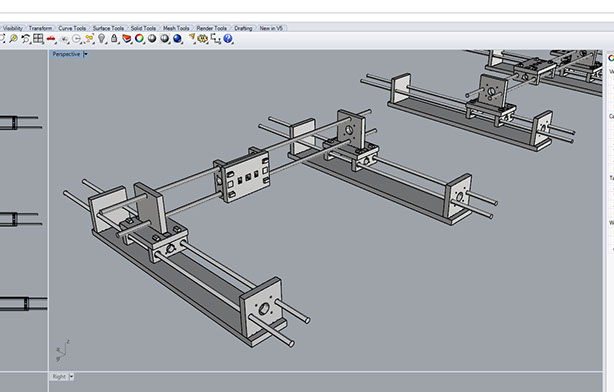

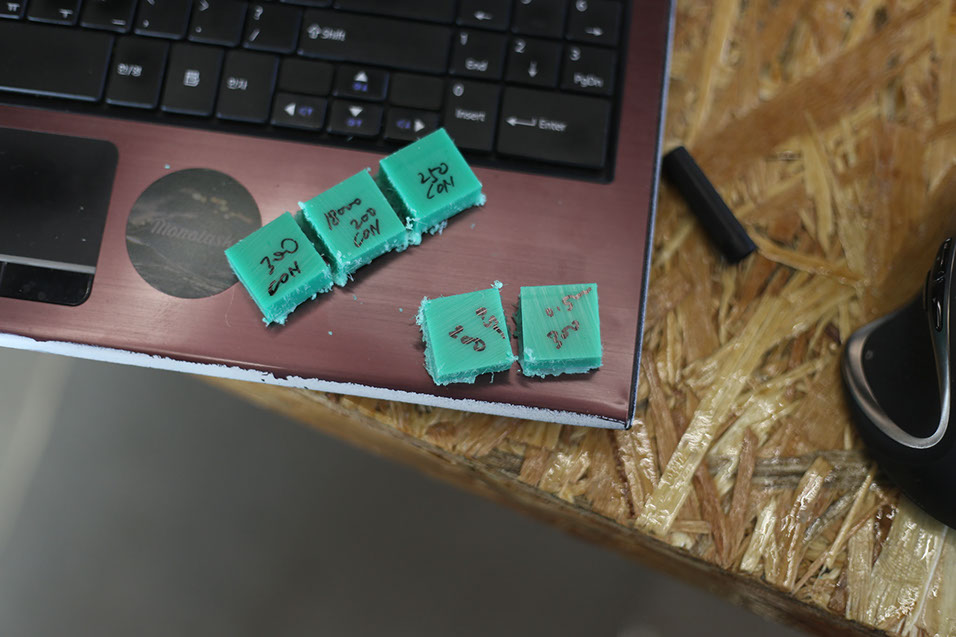

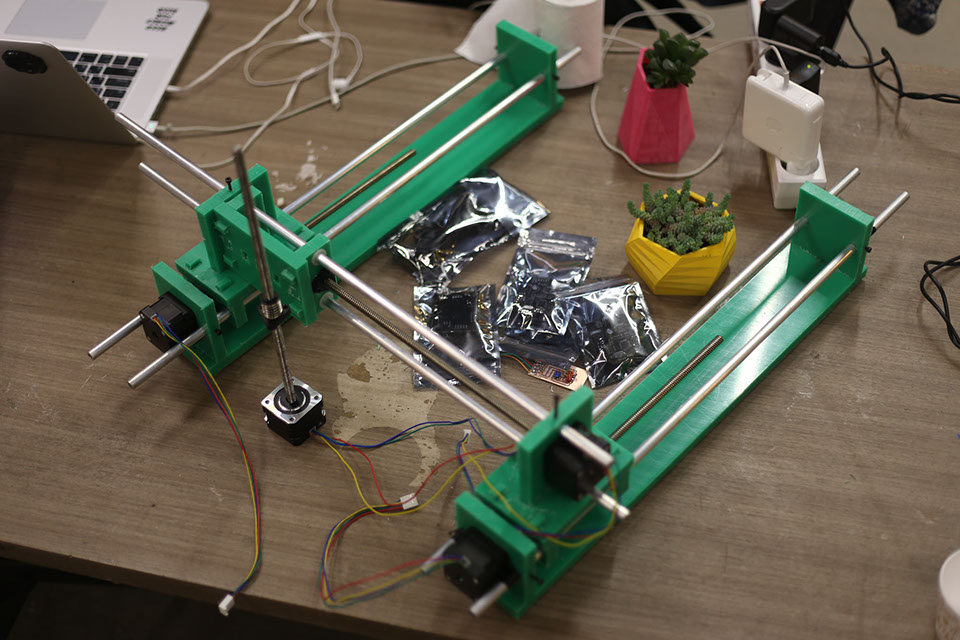

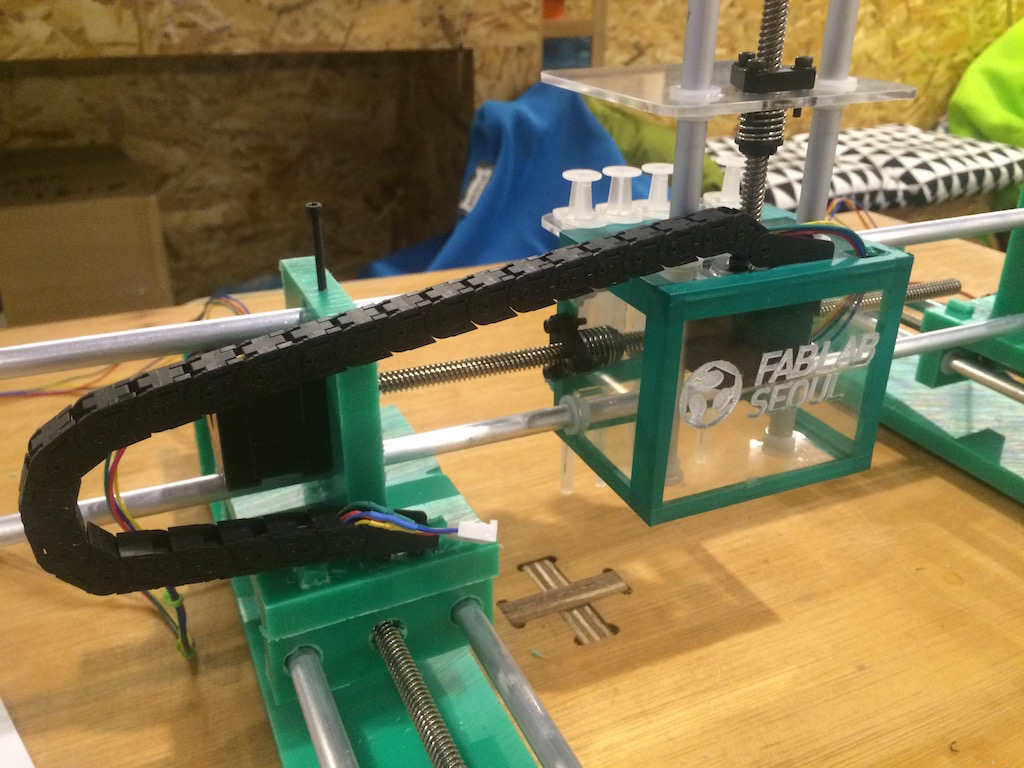

Machine Design

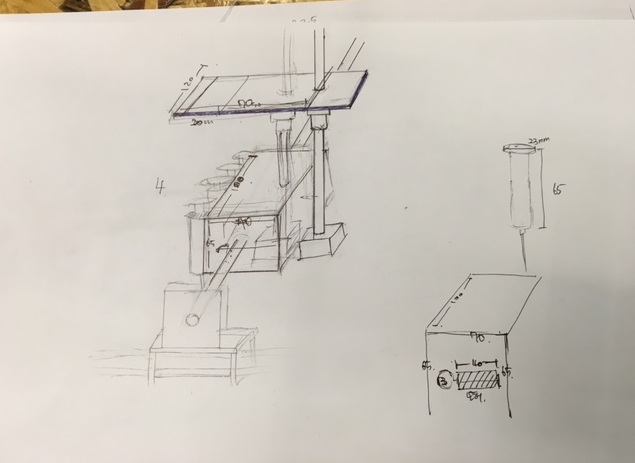

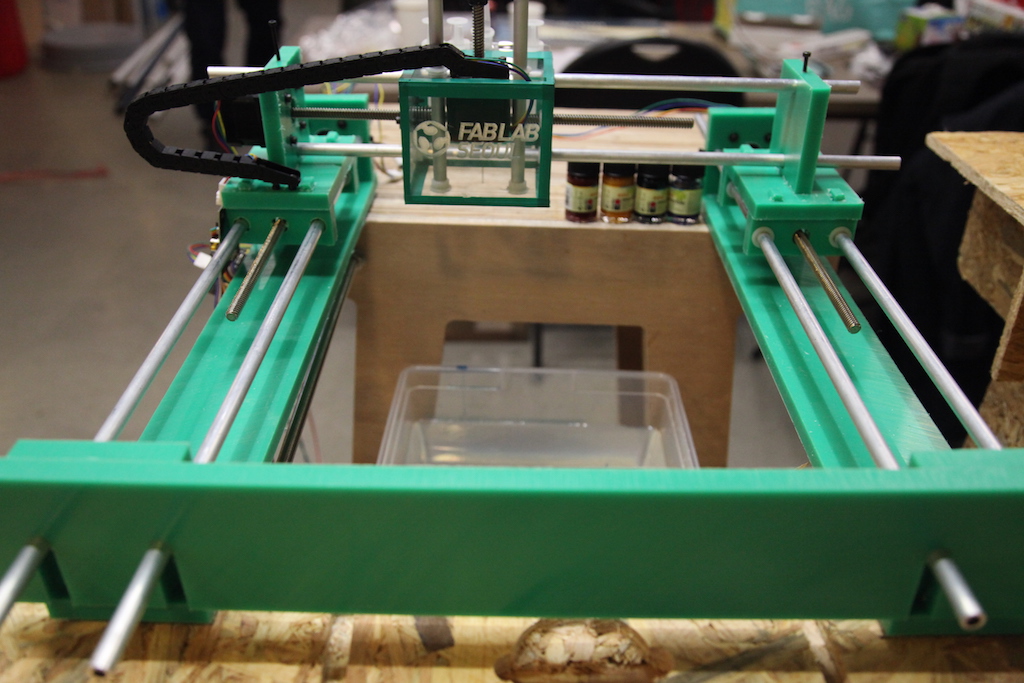

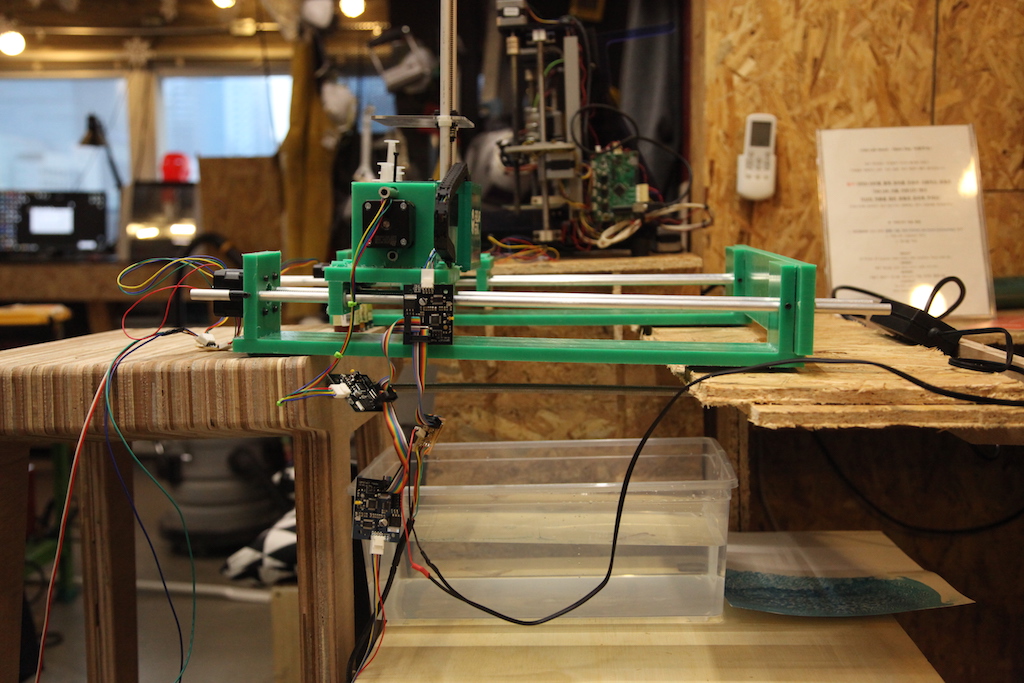

Yousun started design main frame. He tried to use HDPE(high density polyethylene) which is quit expensive but really good for make machine with it. Frist, he did 2D design and tested with laser cutter. After he made the plan with Auto Cad and I made the 3d model to test it out. He tested holes, step motor holder, linear bearing, triangular thing and aluminium post. To make clean cut he've done few test. He figured out the best was 18,000RPM / 200 Feed Rate (inch/min) / 2mm cut depth (3mm endmill 1 flute) for cnc machine i fablab seoul.

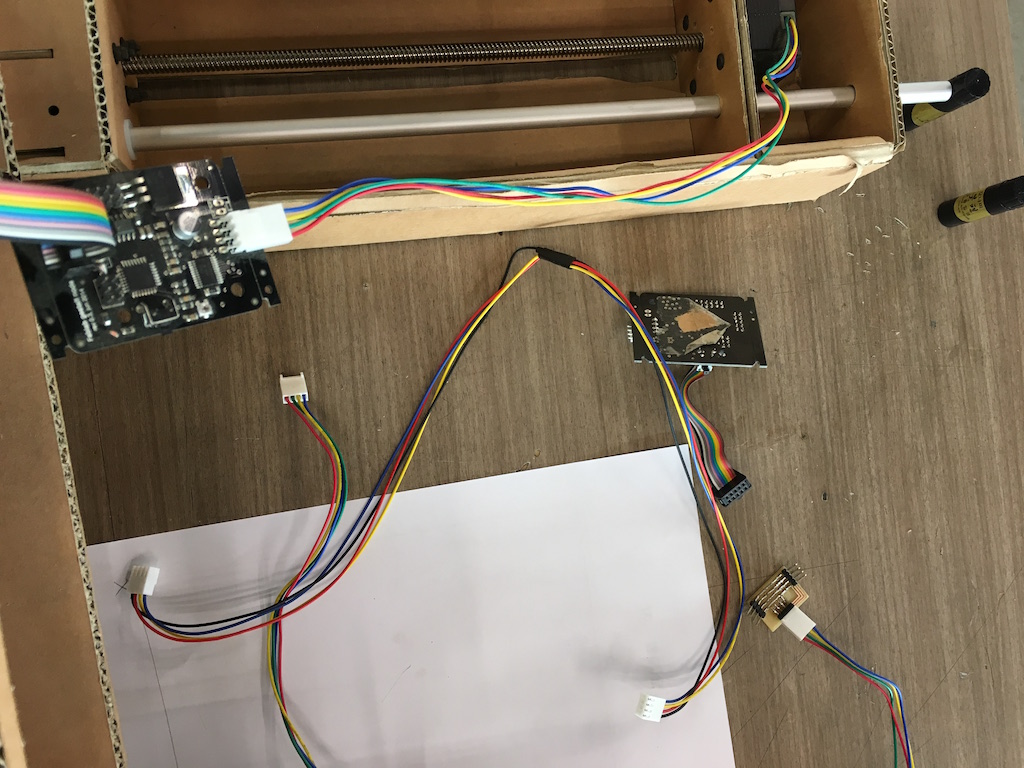

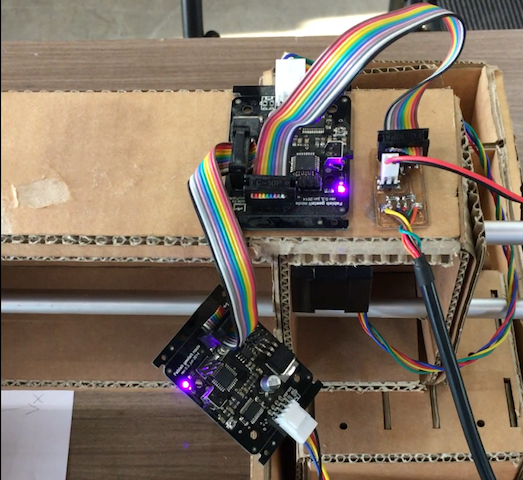

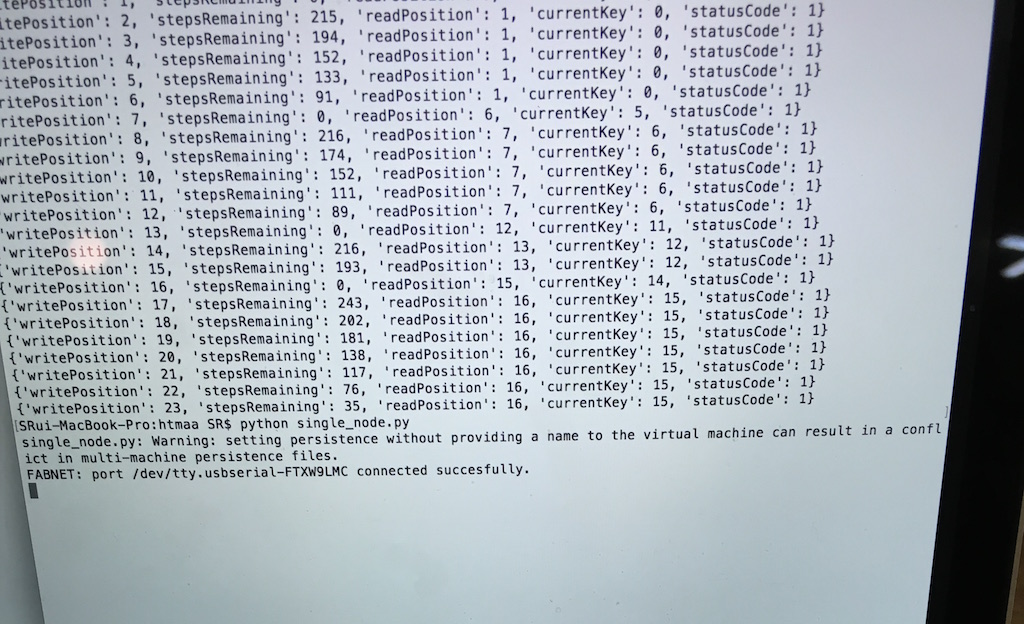

Software Programming

Heereen was the only student who has engineering backgorund. And thankfully she had some experience with python. She started test example codes with machine that previous students made.

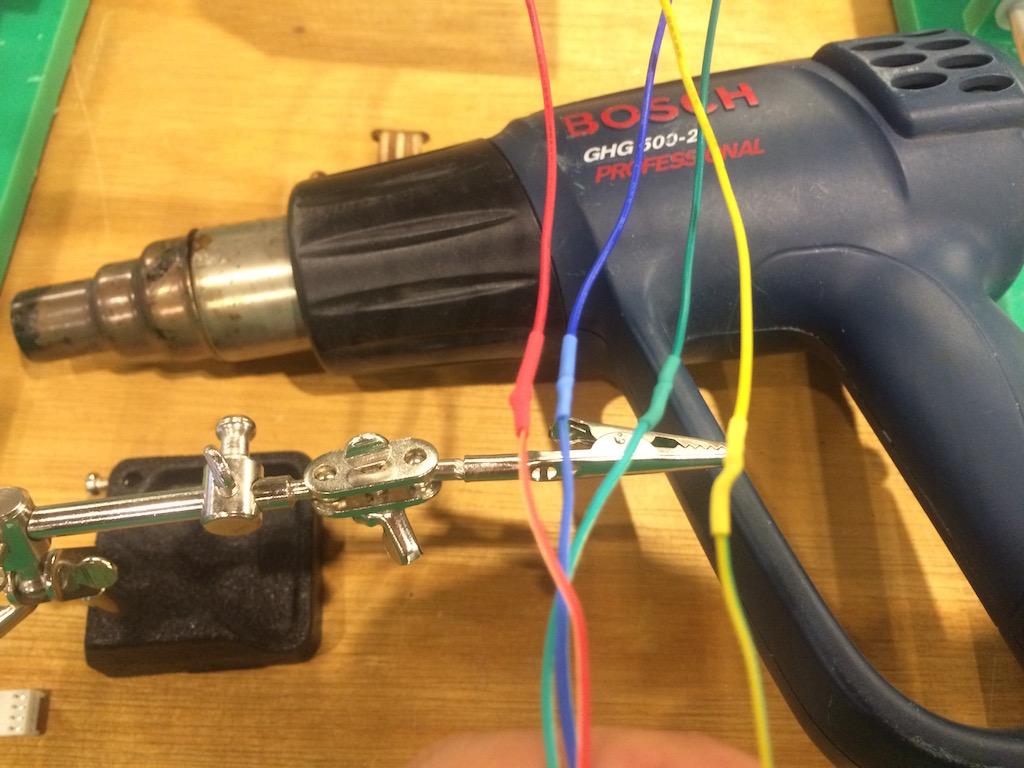

Hardware Design

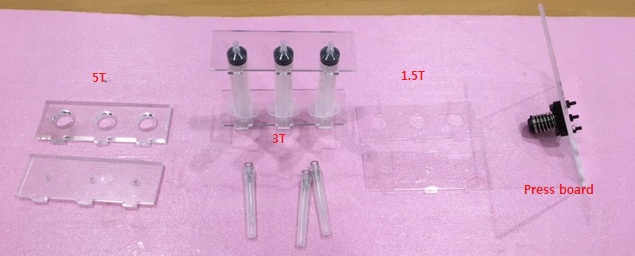

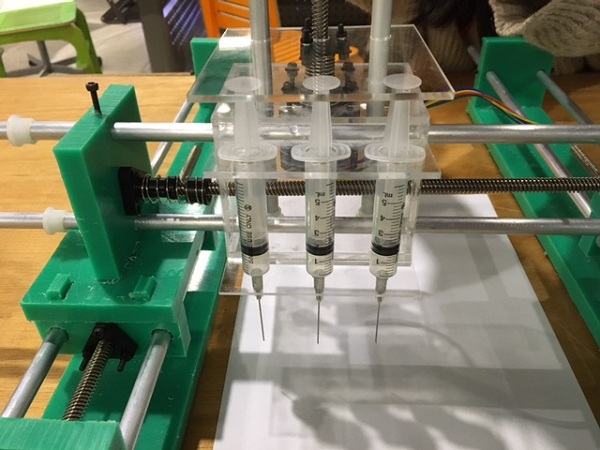

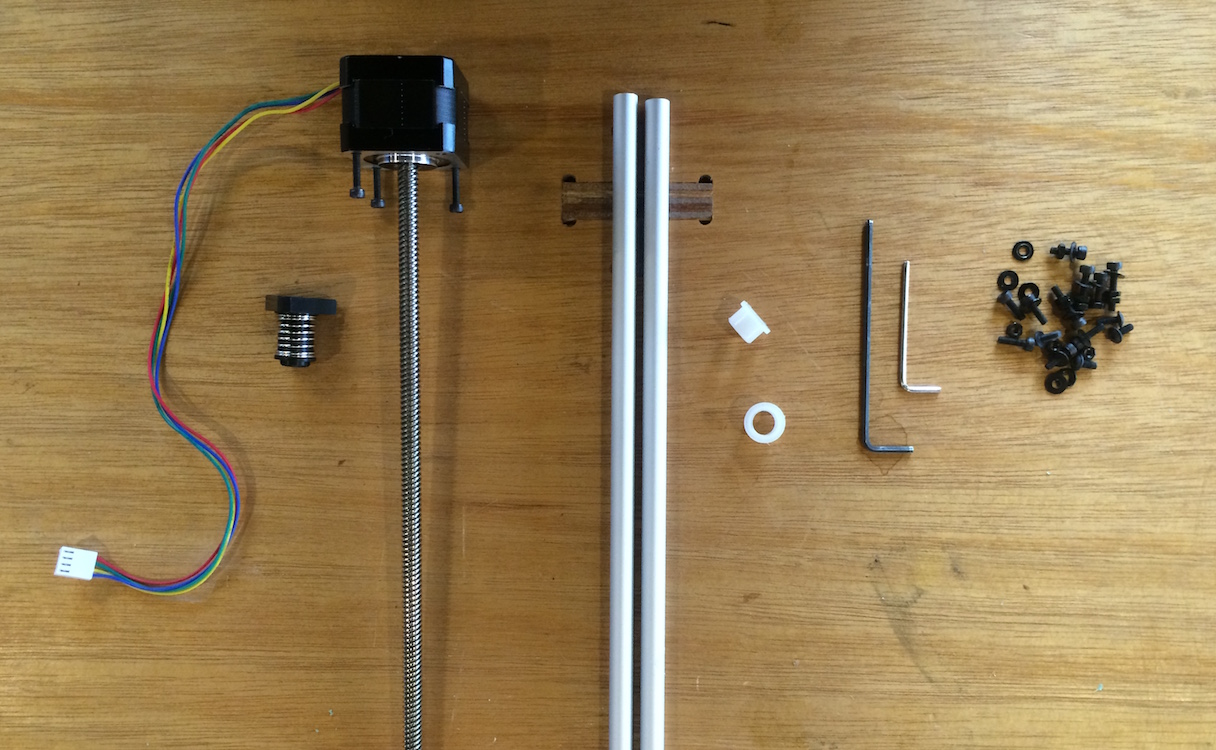

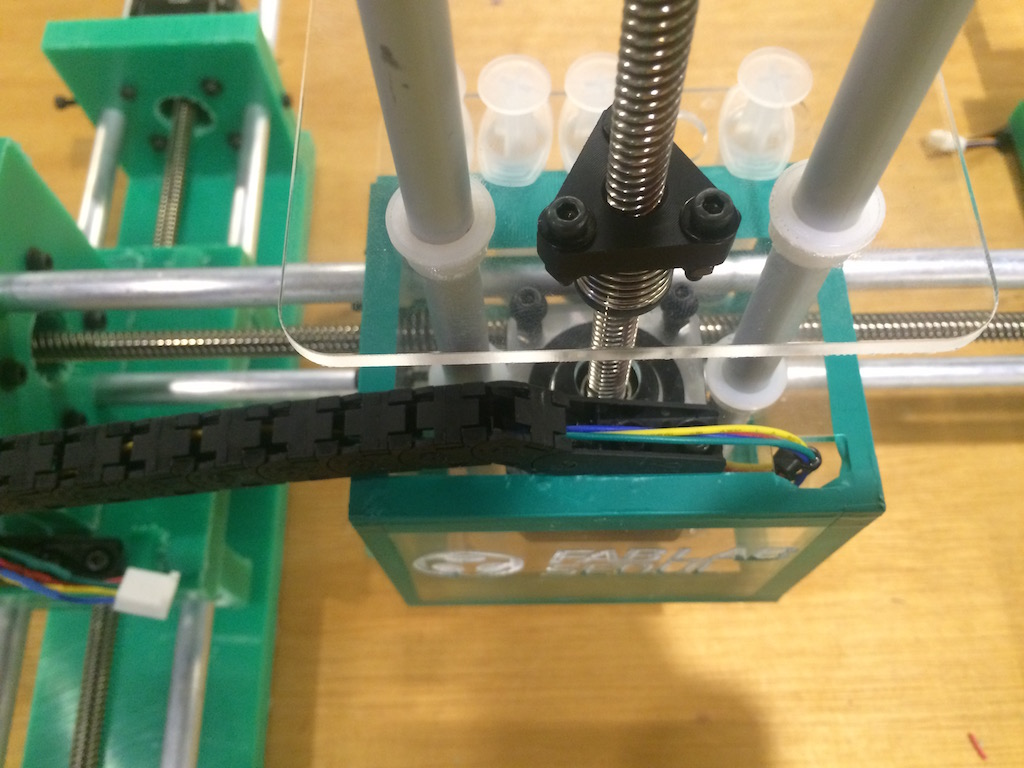

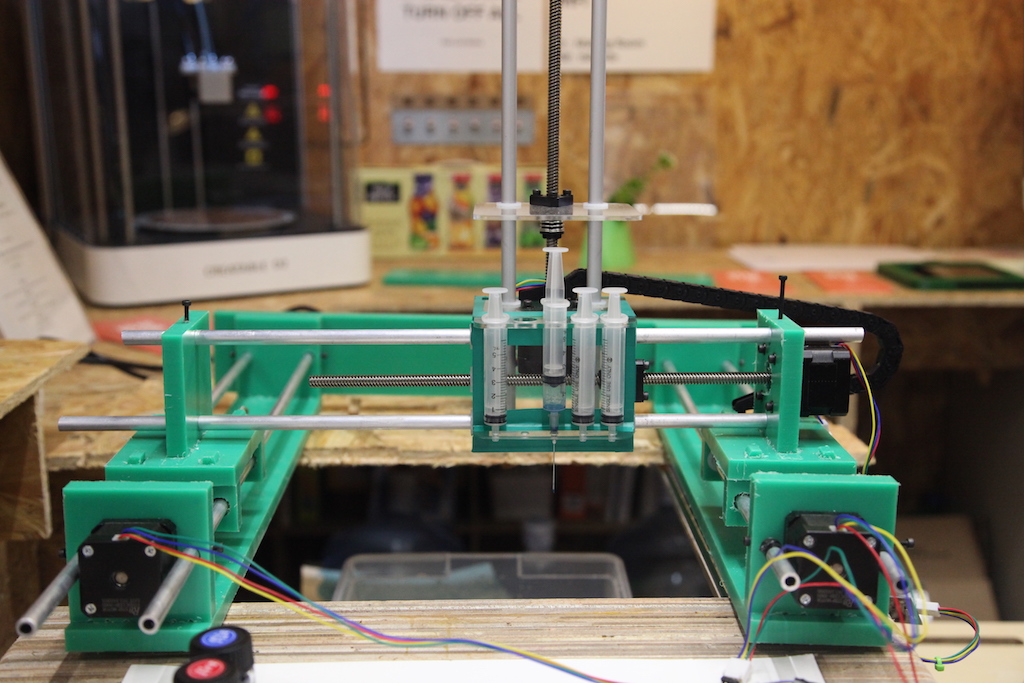

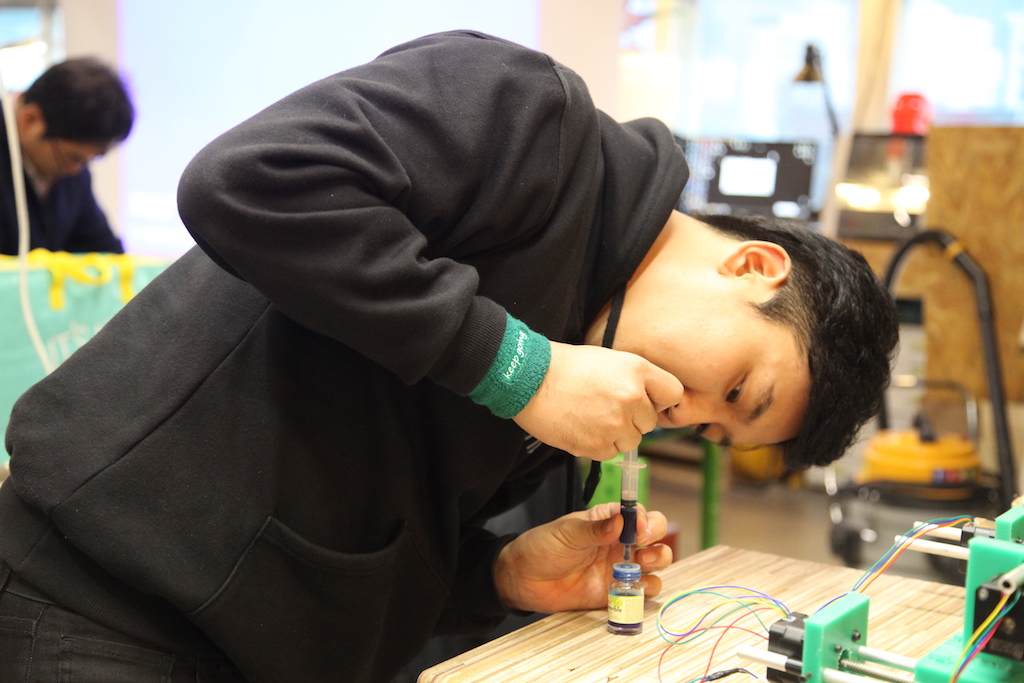

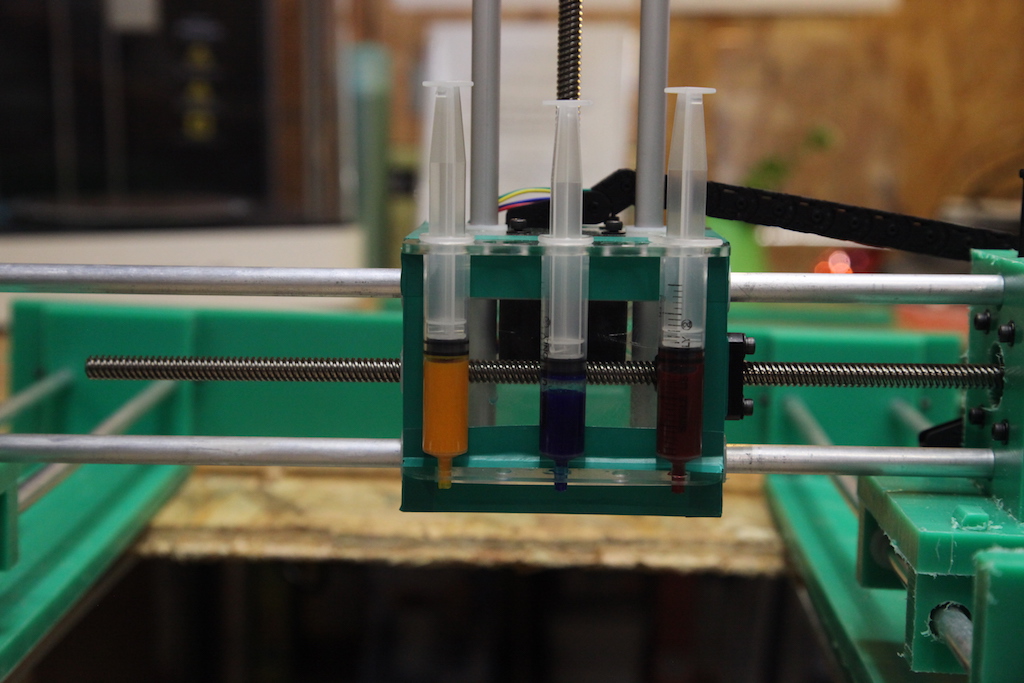

Suhyun, Hyebin and Mirae took a charge of end effector design. They chose to use syringes to drop the paints and make piston move with stepper motor with Z axis movement. IT press down plungers of the syringes. THey tried several times and made three different holders. They found that the best way is making two holders; one is in Luer-Lock tip and the one is under the finger flange, with using different thickness of acrilic.

Mechanical Design

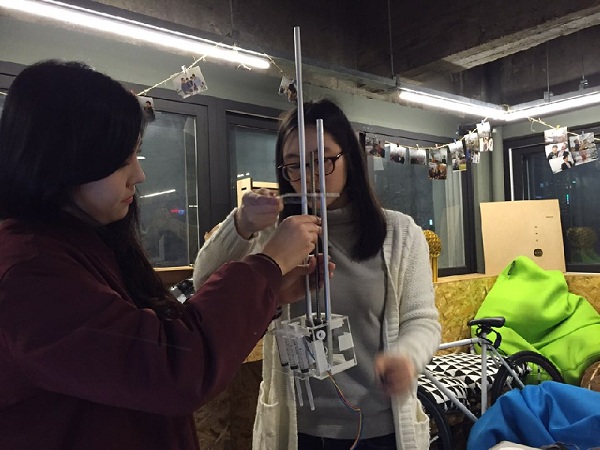

Hyungu worked with Yousun and helped hardware group. He modified some design for better movement and assembled the end effector and main body. He also did practical works, such as finding materials and buying stuffs we need.

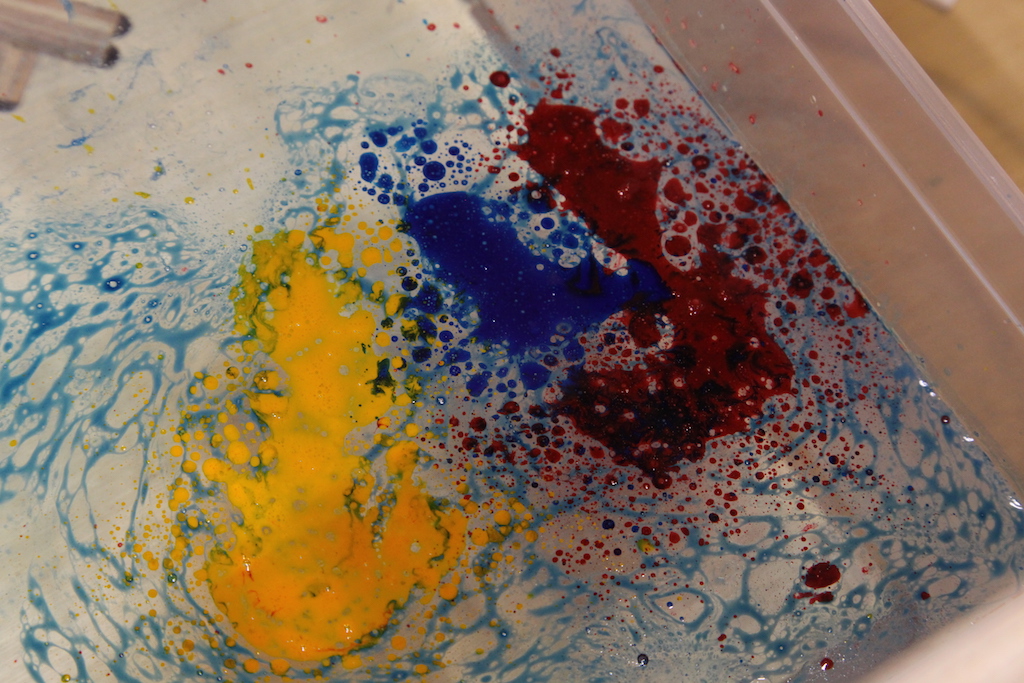

Result

All shits are done!! Lest try out !

fabacademy from Shim92 on Vimeo.

Download code