14.COMPOSITES

May 5, 2016

This week's assignment is to design and to make a 3D mold (~ft2), and to produce a fiber composite part in it.

In this assignment, I decided to make a mask such as the Venetian mask.

14-1. Making molds & sheets for composites

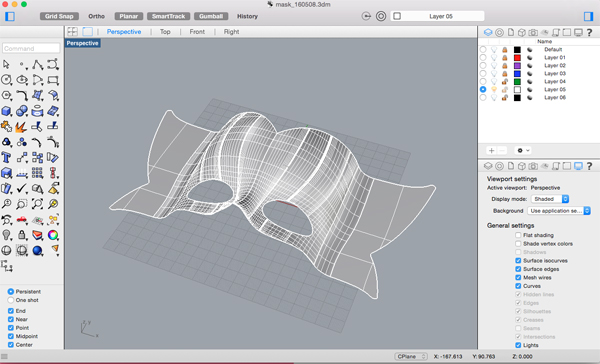

[Tool]Software: Rhinoceros (MacOSX), Adobe Illustrator CS5

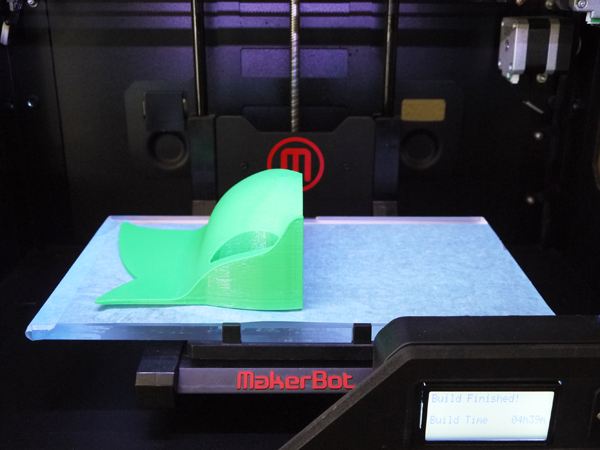

3DPrinting machine: Makerbot Replicator2

Laser cutting machine: trotec speedy100

[Material]

Molds: PLA, PVC sheet(W:450mm/H:450mm/D:0.5mm)

Composites: Felt (polyester 100%), Epoxy resin

[Proccess]

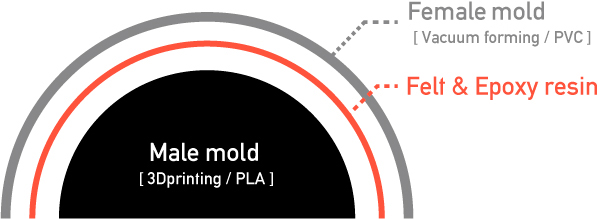

1.Making molds

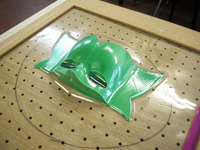

I made a male mold with 3D printing machine. And I used vacuum forming for the production of a female mold.(Vacuum forming is a method of molding sheets of plastic into 3D shapes using the force created by an air vacuum.)

Rhinoceros Data > mask_160507.3dm

[Setting]

- Resolution: 0.3mm

- Infill: 20%

- Number of Shells: 2

- Support & Raft: off

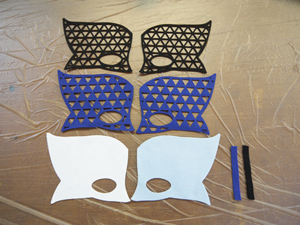

2.Making sheets for composites

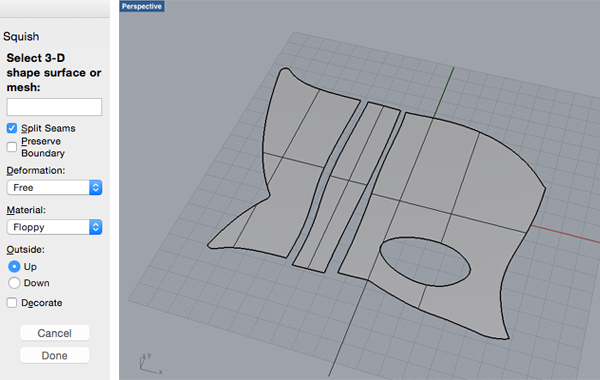

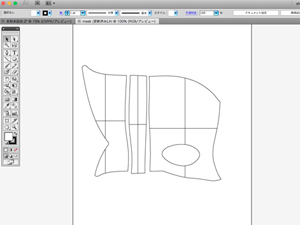

I used "Command:Squish" for a male mold data. (The Squish command flattens a non-developable (curved in two directions) 3-D mesh or NURBS surface into a flat 2-D pattern.) And I saved it as data of Adobe Illustrator.

Data > mask_160508.svg

[Setting]

- Power: 12%

- Speed: 2%

In addition, I made square parts(W:10mm/H:80mm) to join right and left of a mask together.

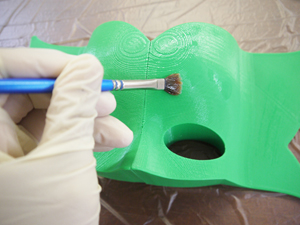

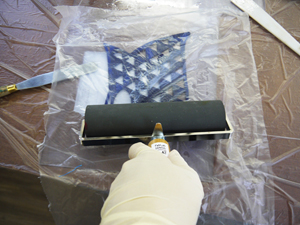

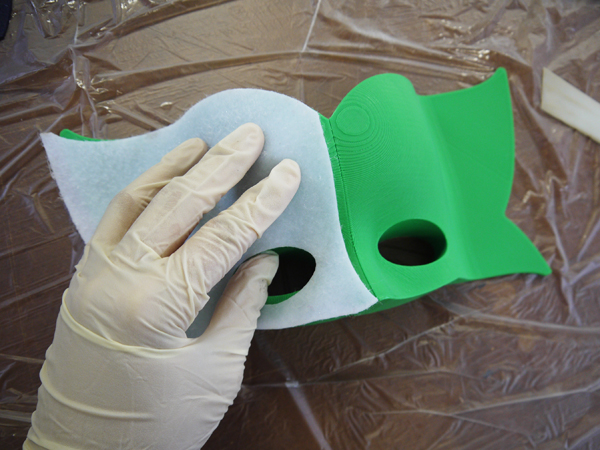

14-2. Creating the composite

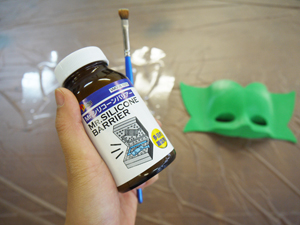

(The epoxy resin I used is this. > Epoxy resin & A hardener.)

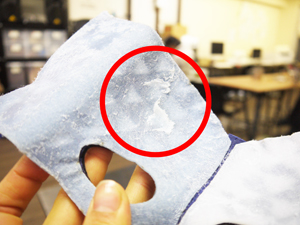

A bag was broke, and water leaked... I excluded a mask early to dry it.

---

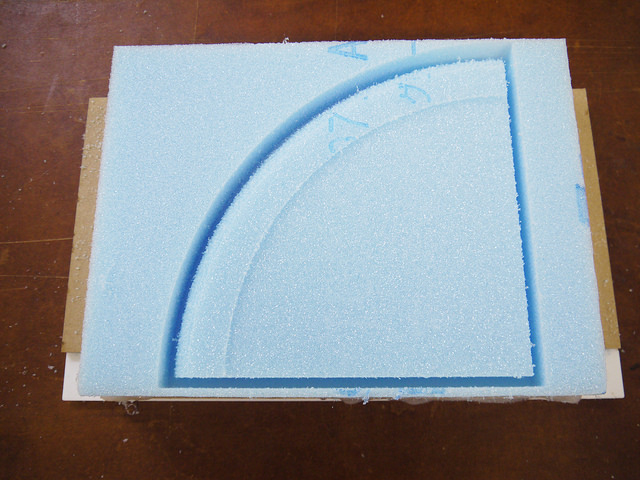

And, I tried making another one.

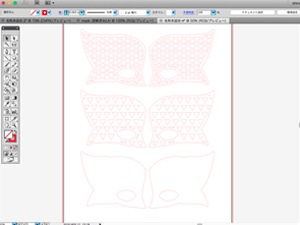

[Material]

- Mold: Styrofoam

- Sheets: Felt x2, Cotton cloth x1, Linen cloth x3

[Tool]

- Roland MDX-20

[Data]

- flyingdisk_160706.3dm

[Photo]

- [FabAcademy2016] Week14 Composites

Please refer to this photo page for how to make.

Felt x2 > Linen cloth x3 > Cotton cloth