3D scanning and printing

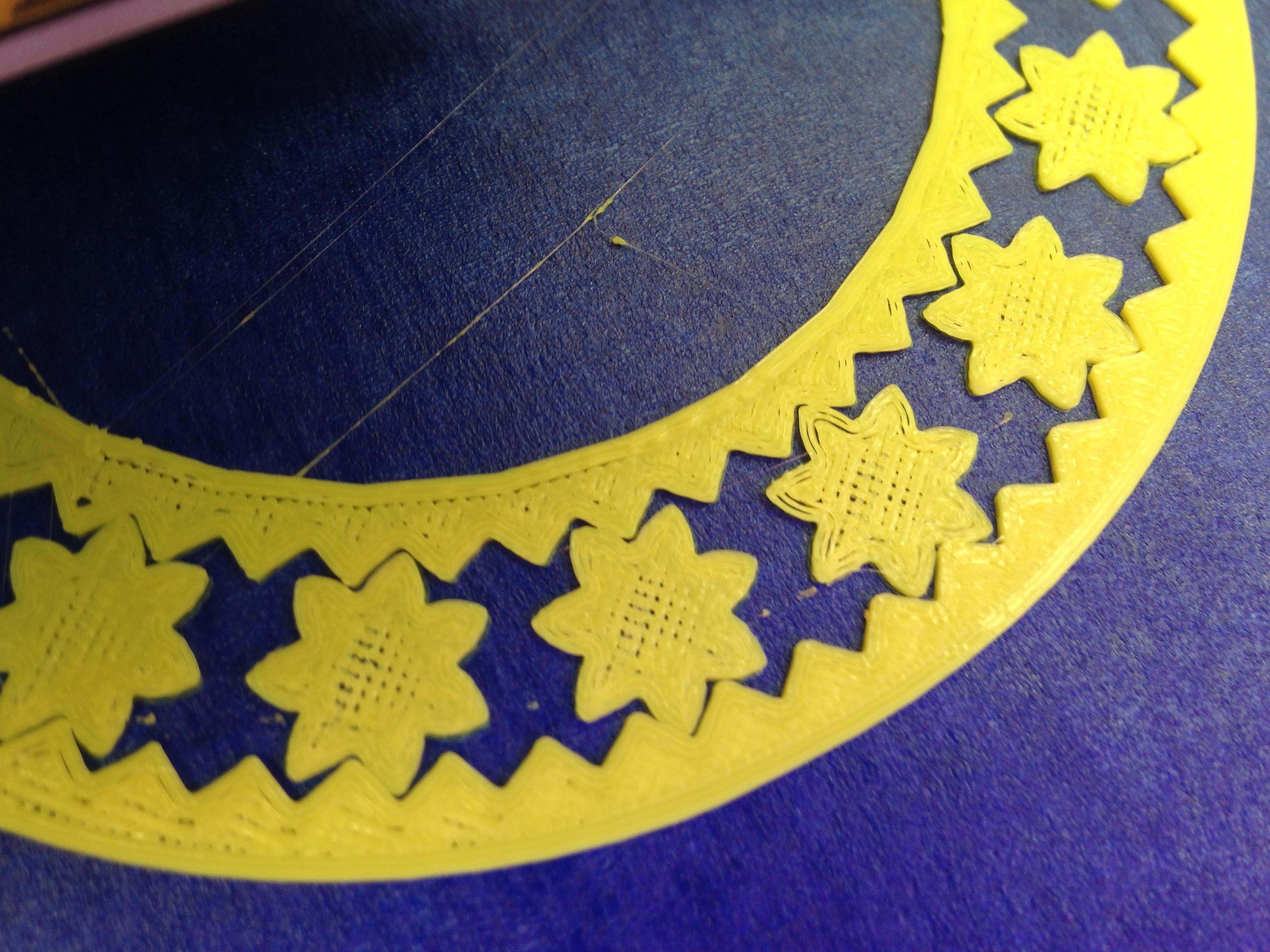

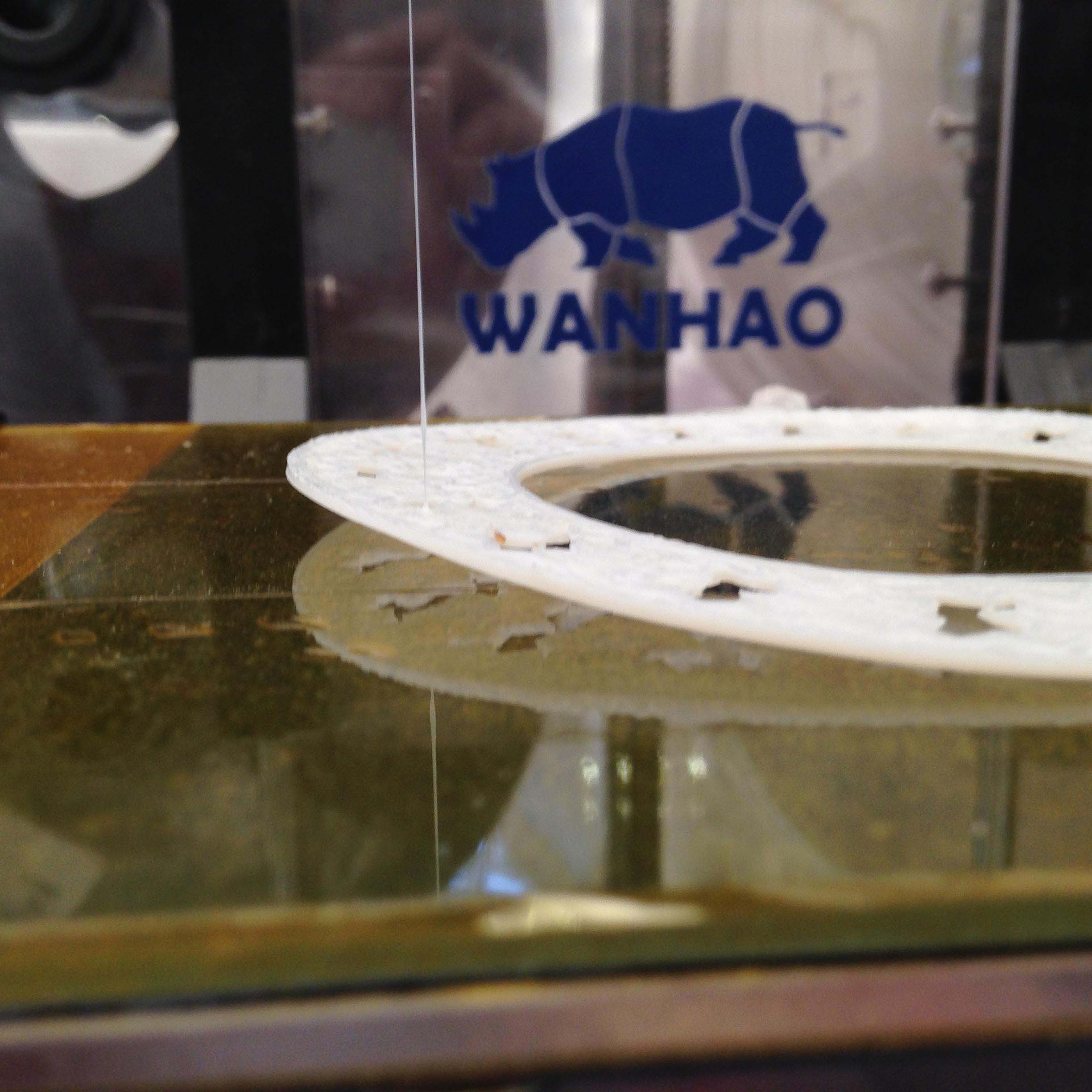

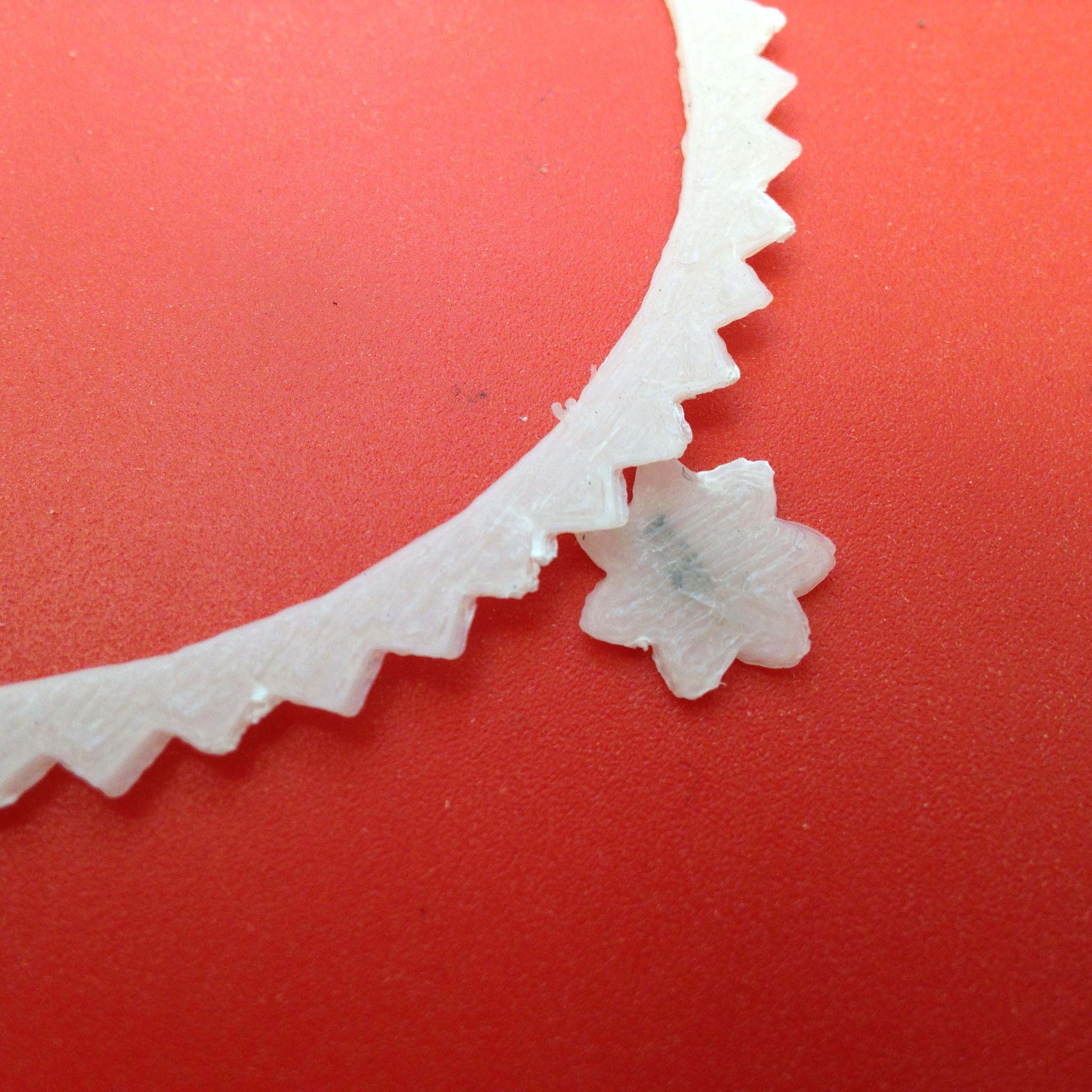

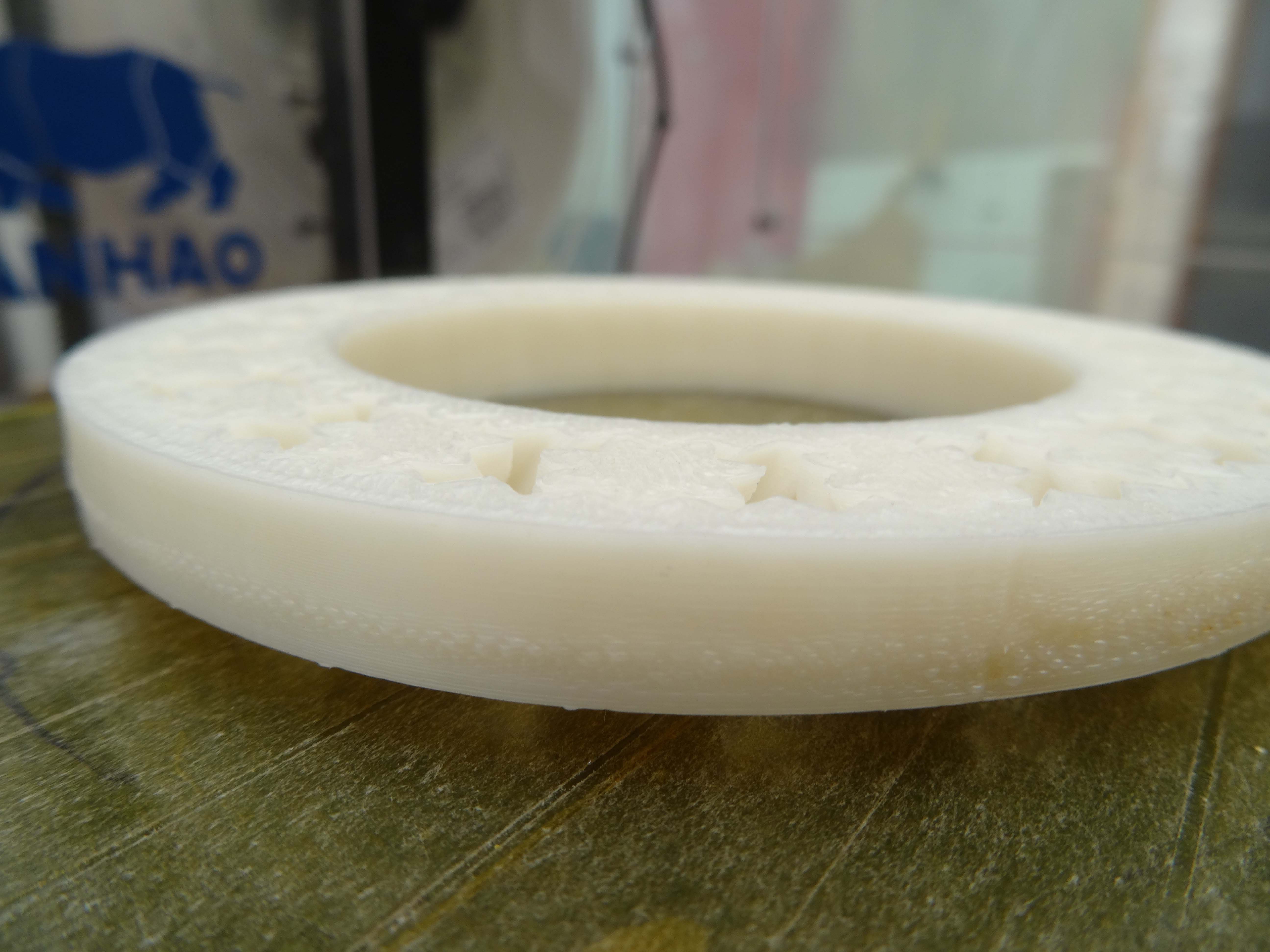

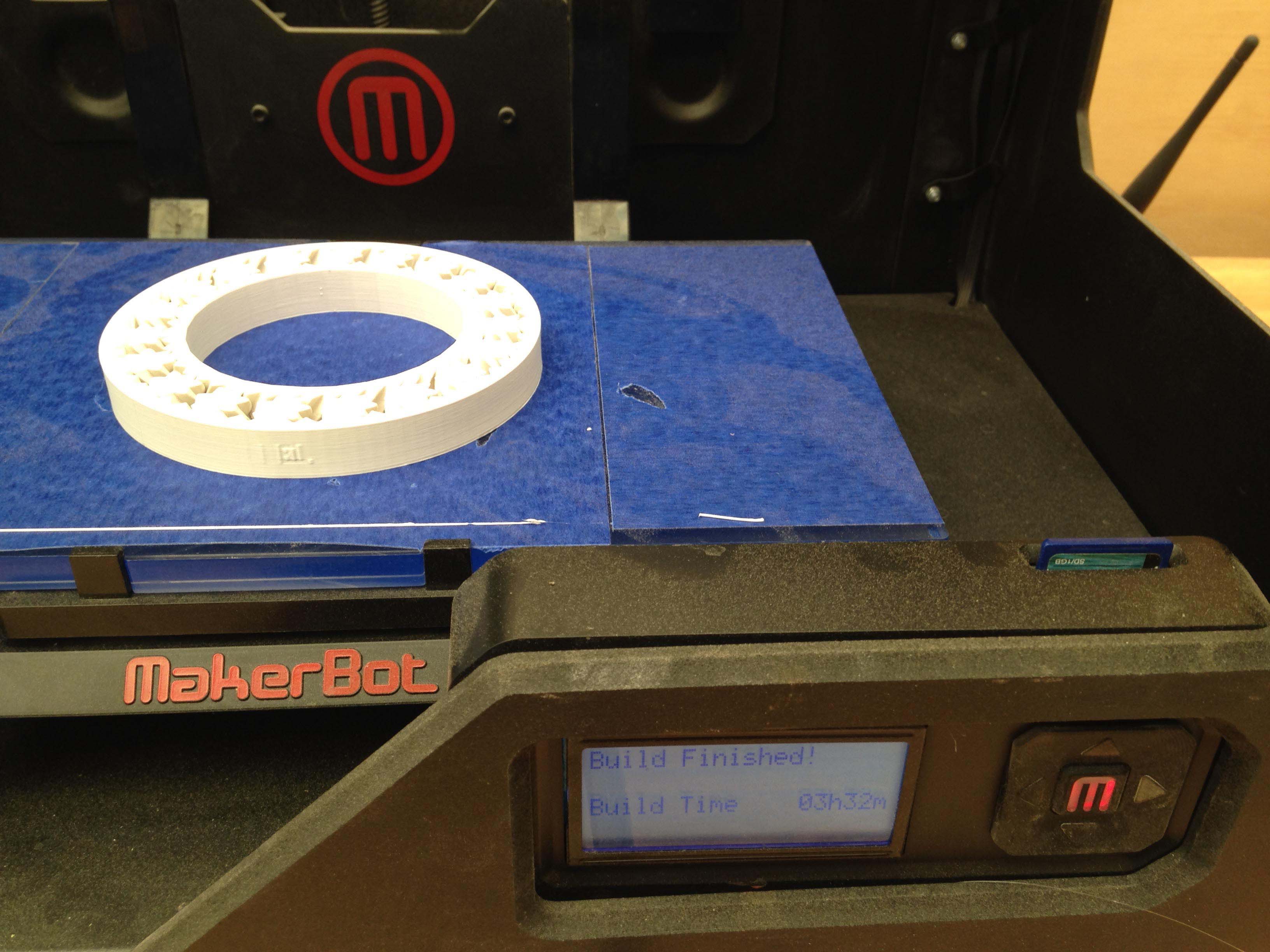

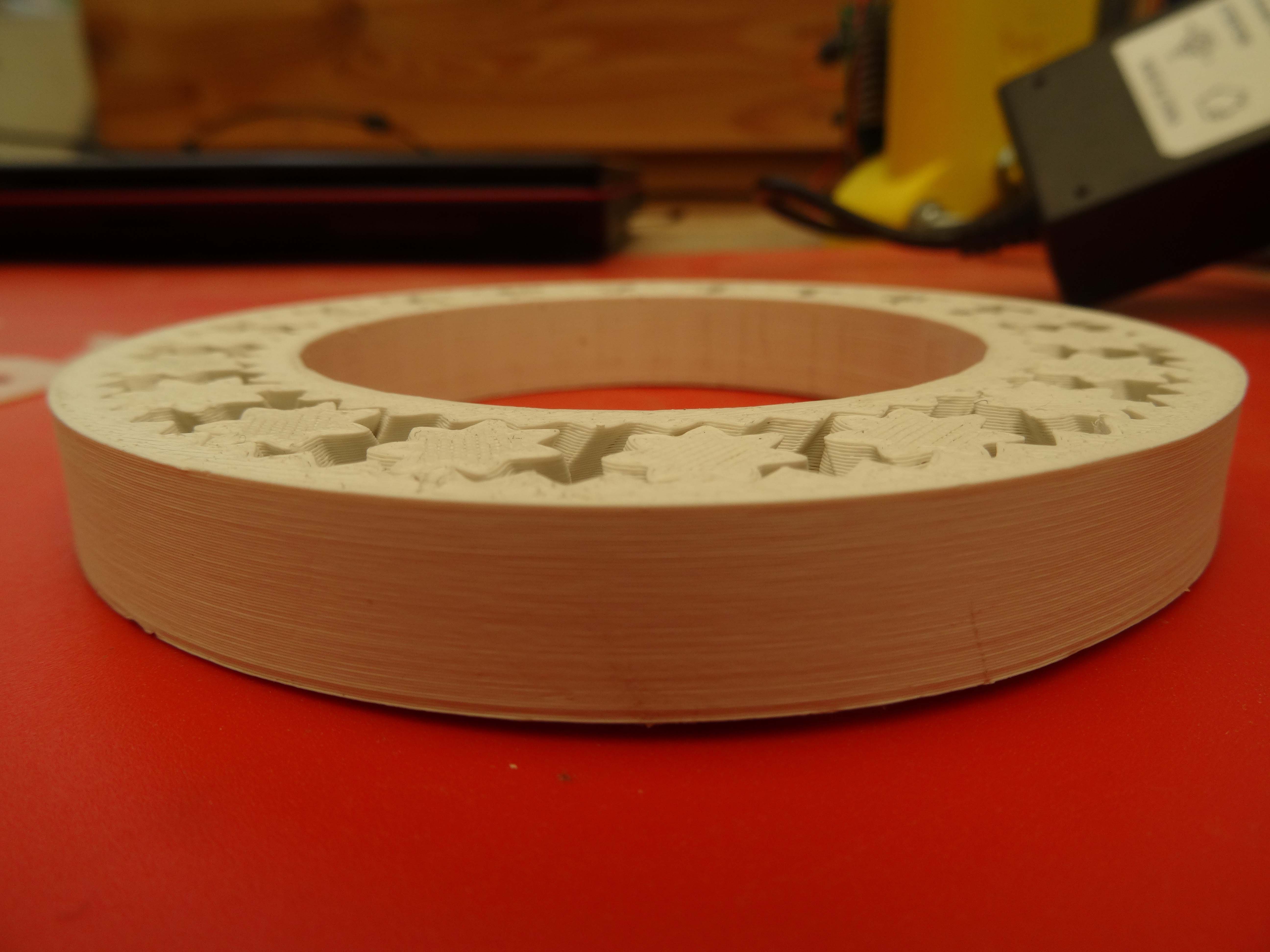

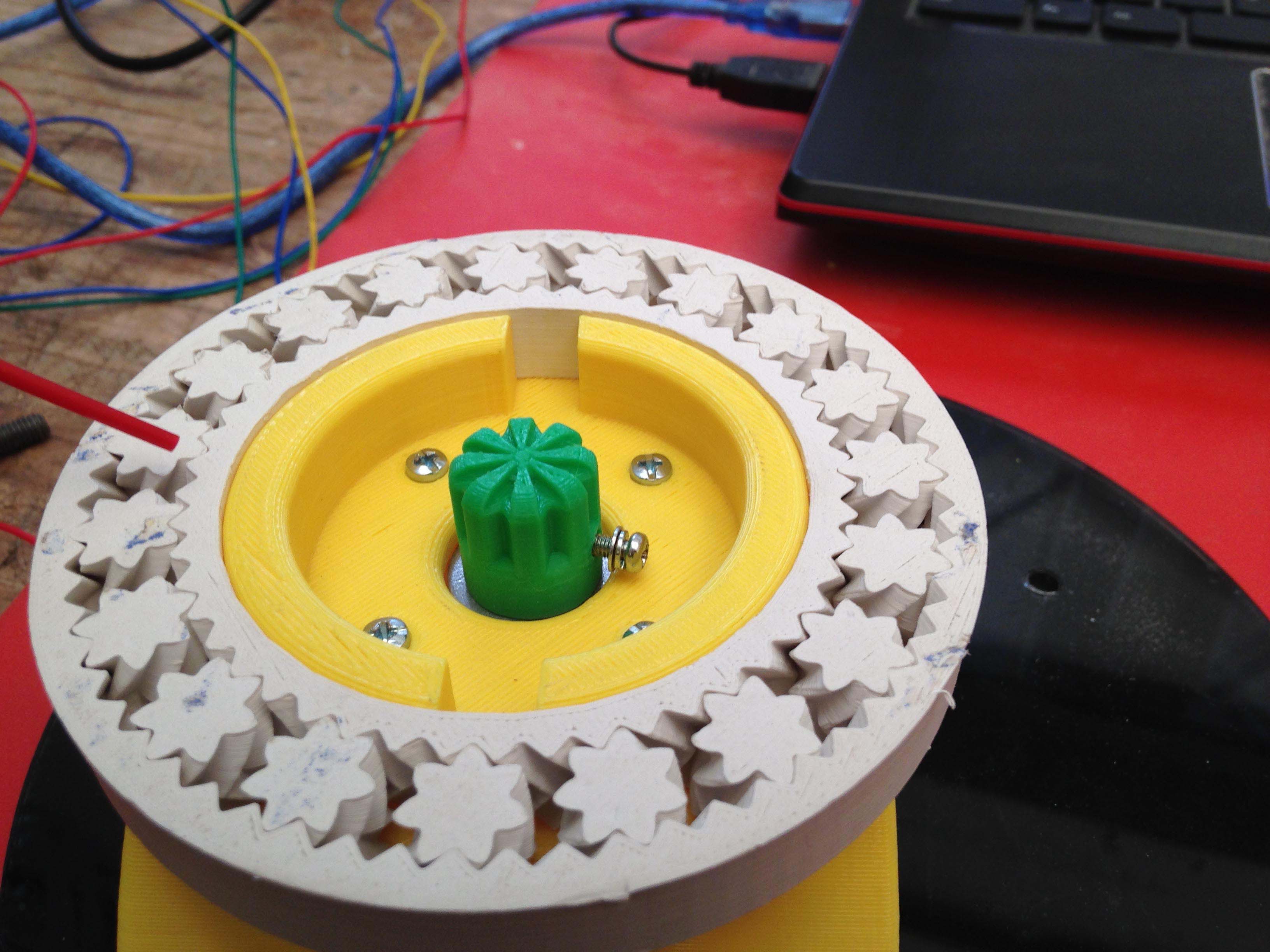

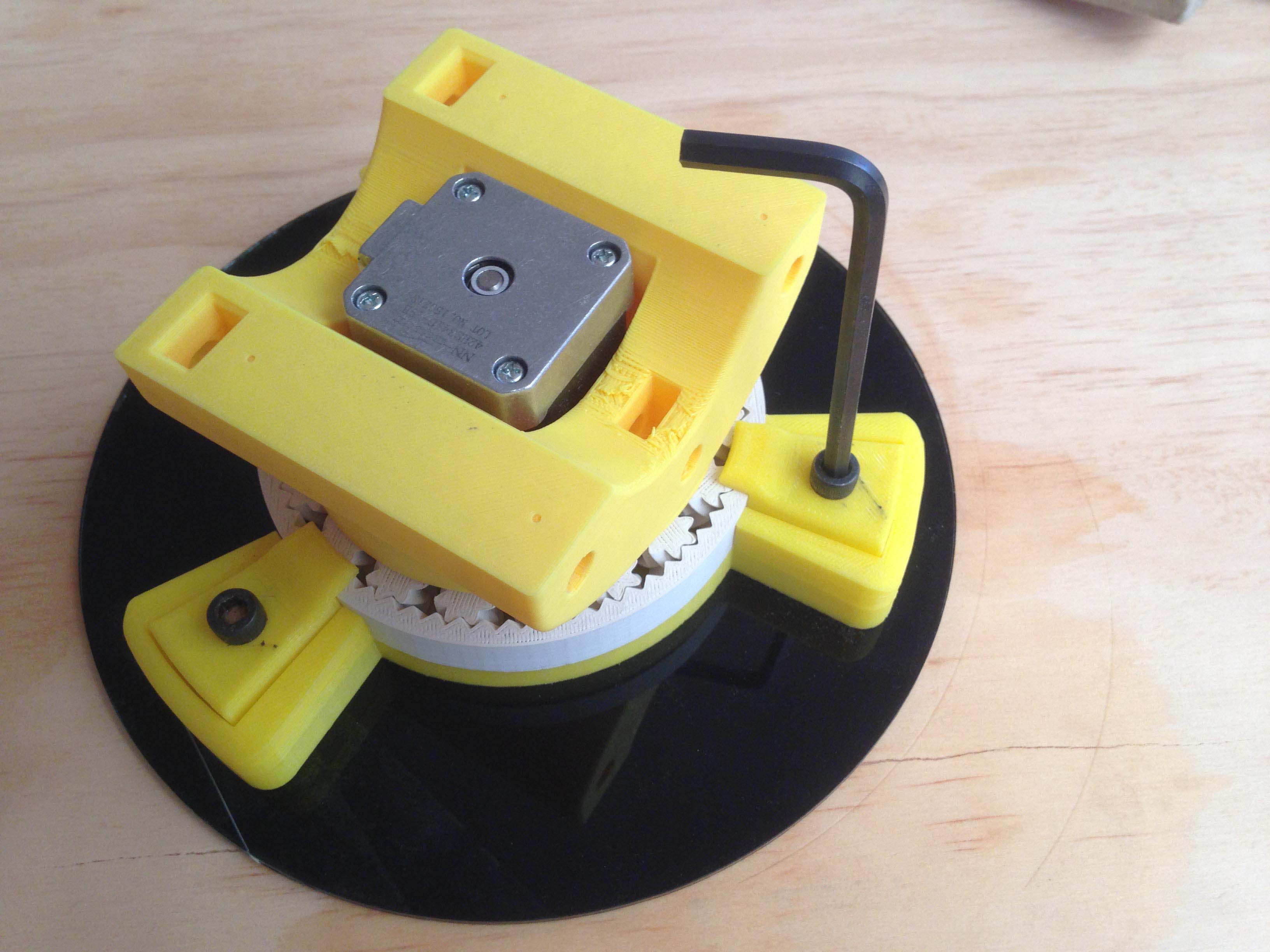

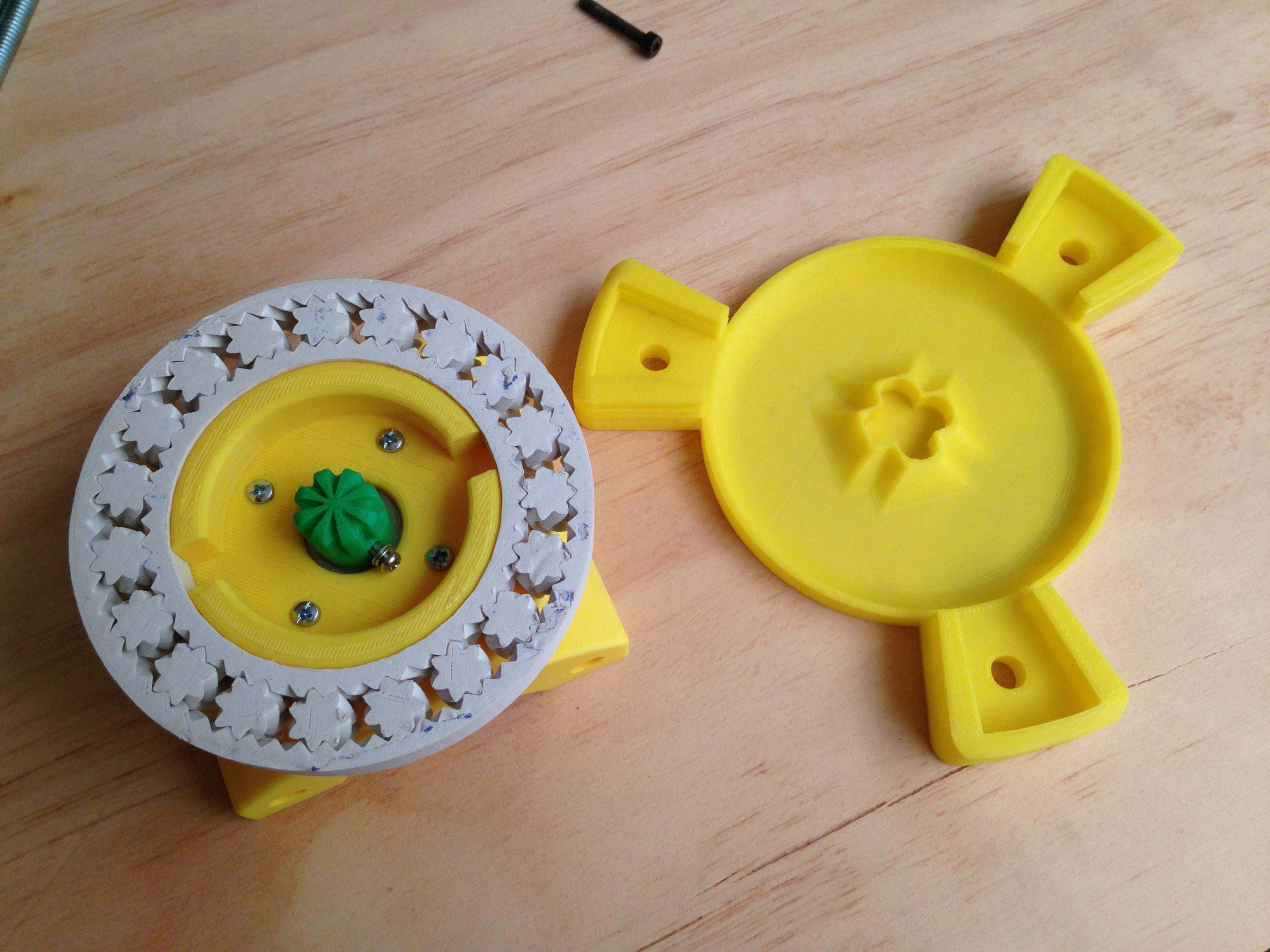

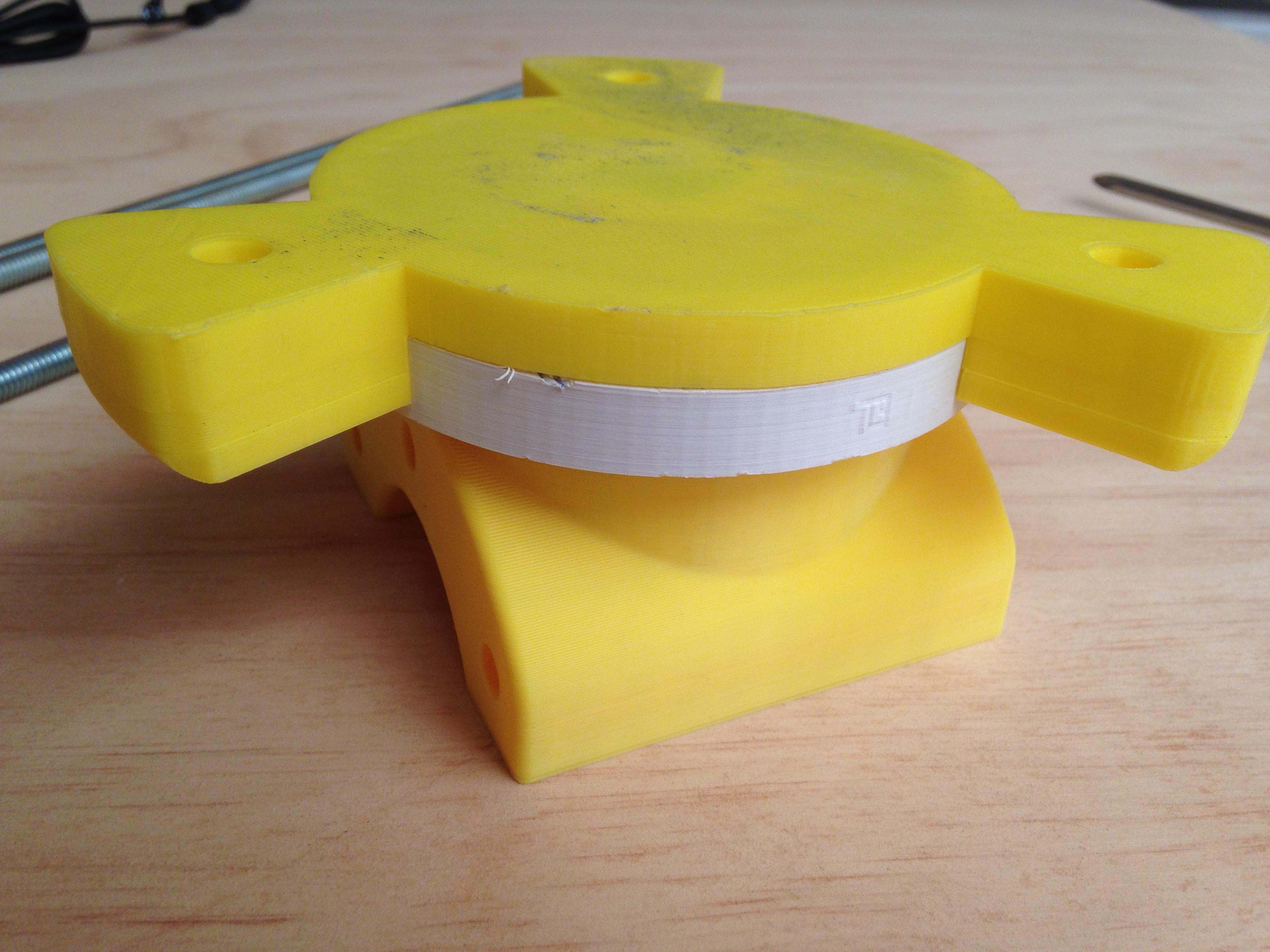

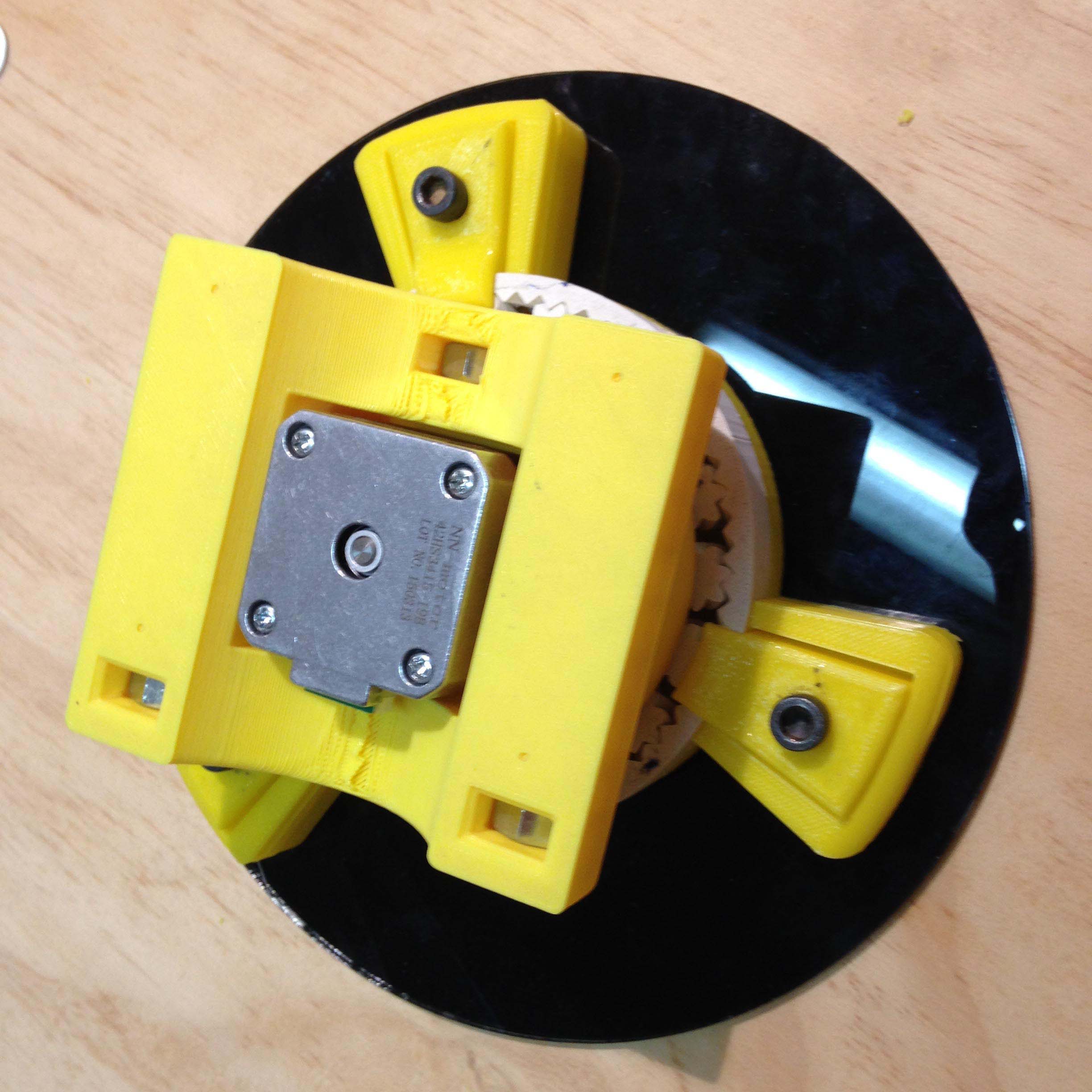

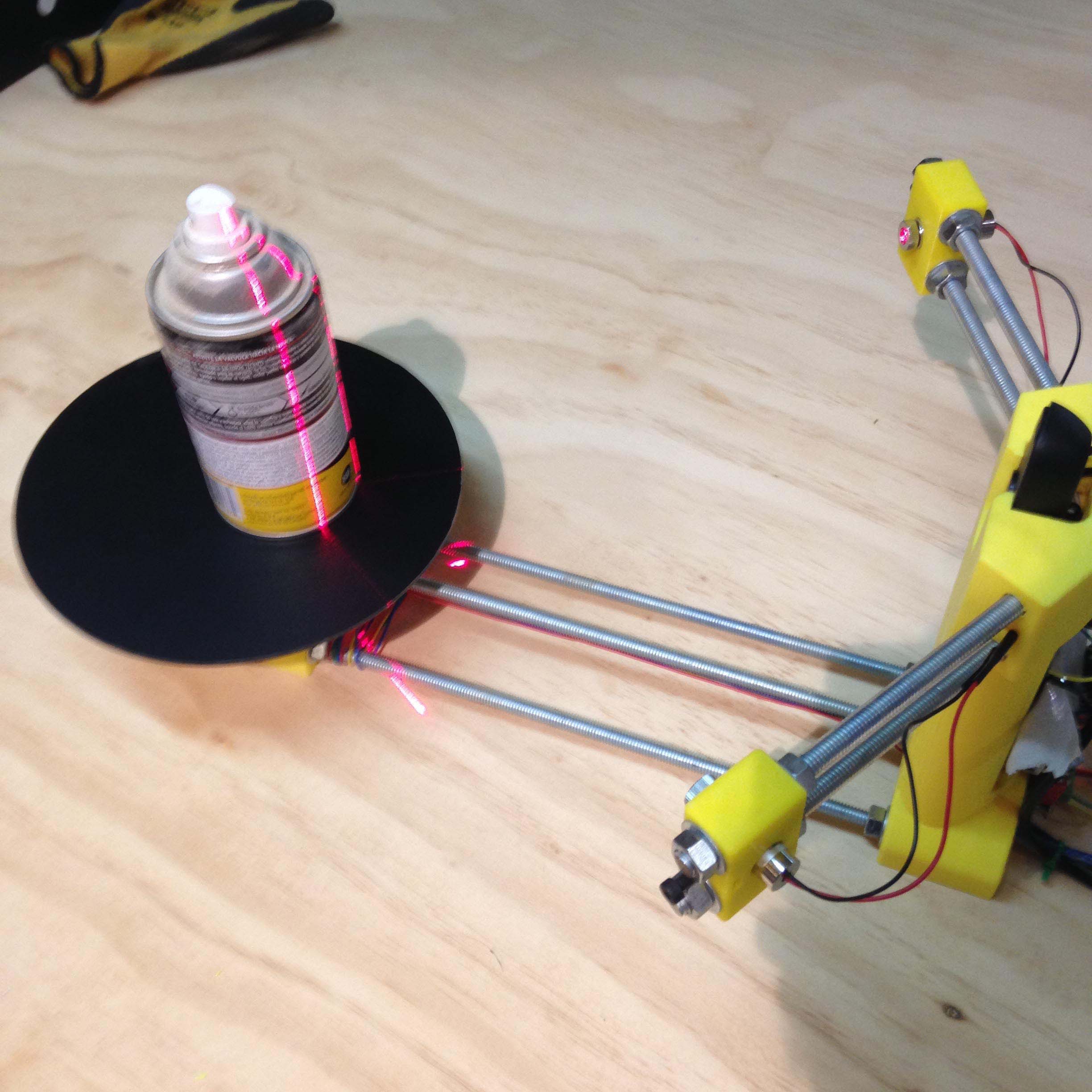

1. Print a functional bearing for the Ciclop 3D scanner

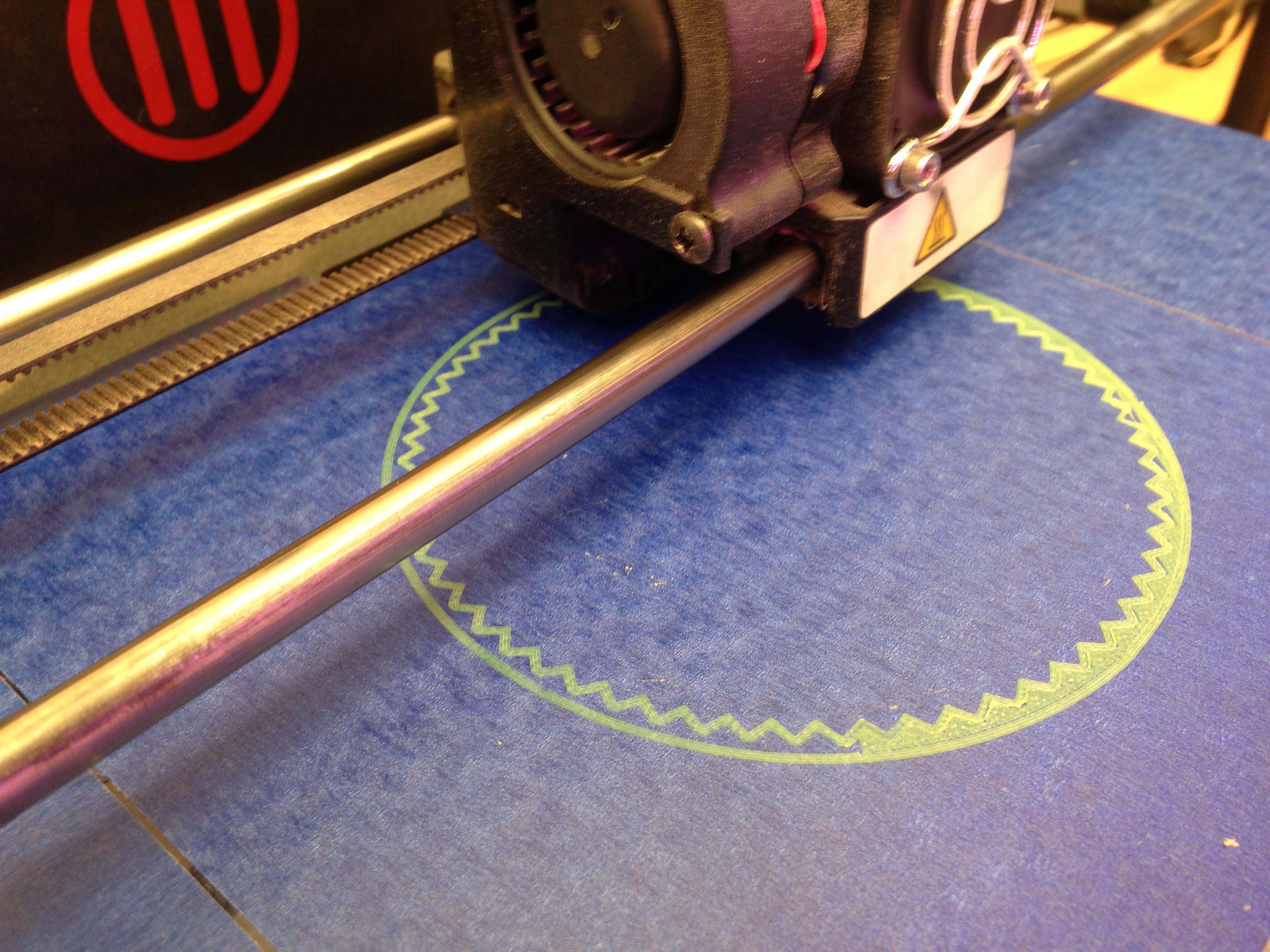

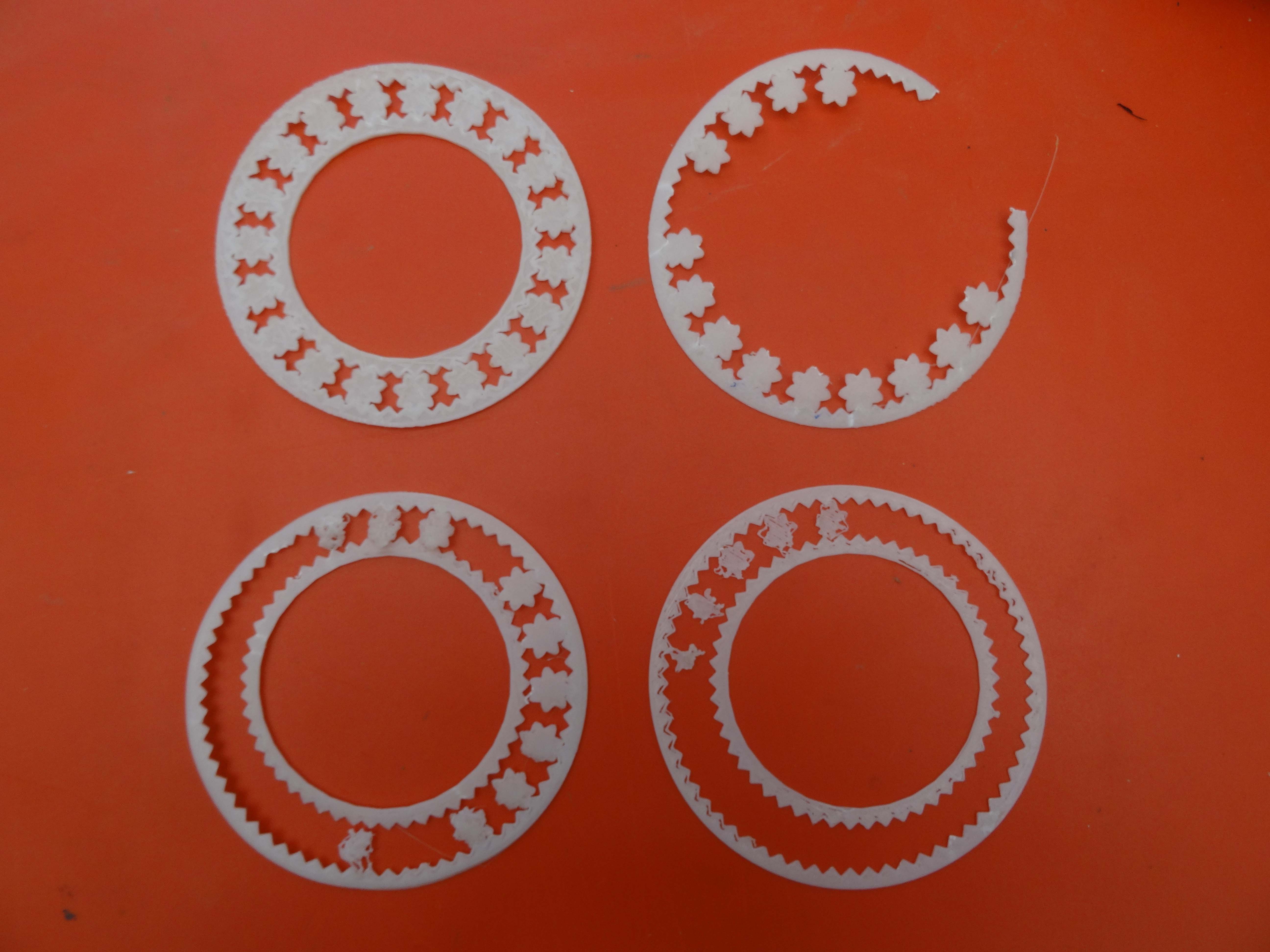

PLA filament

HIPS filament

Flexible filament

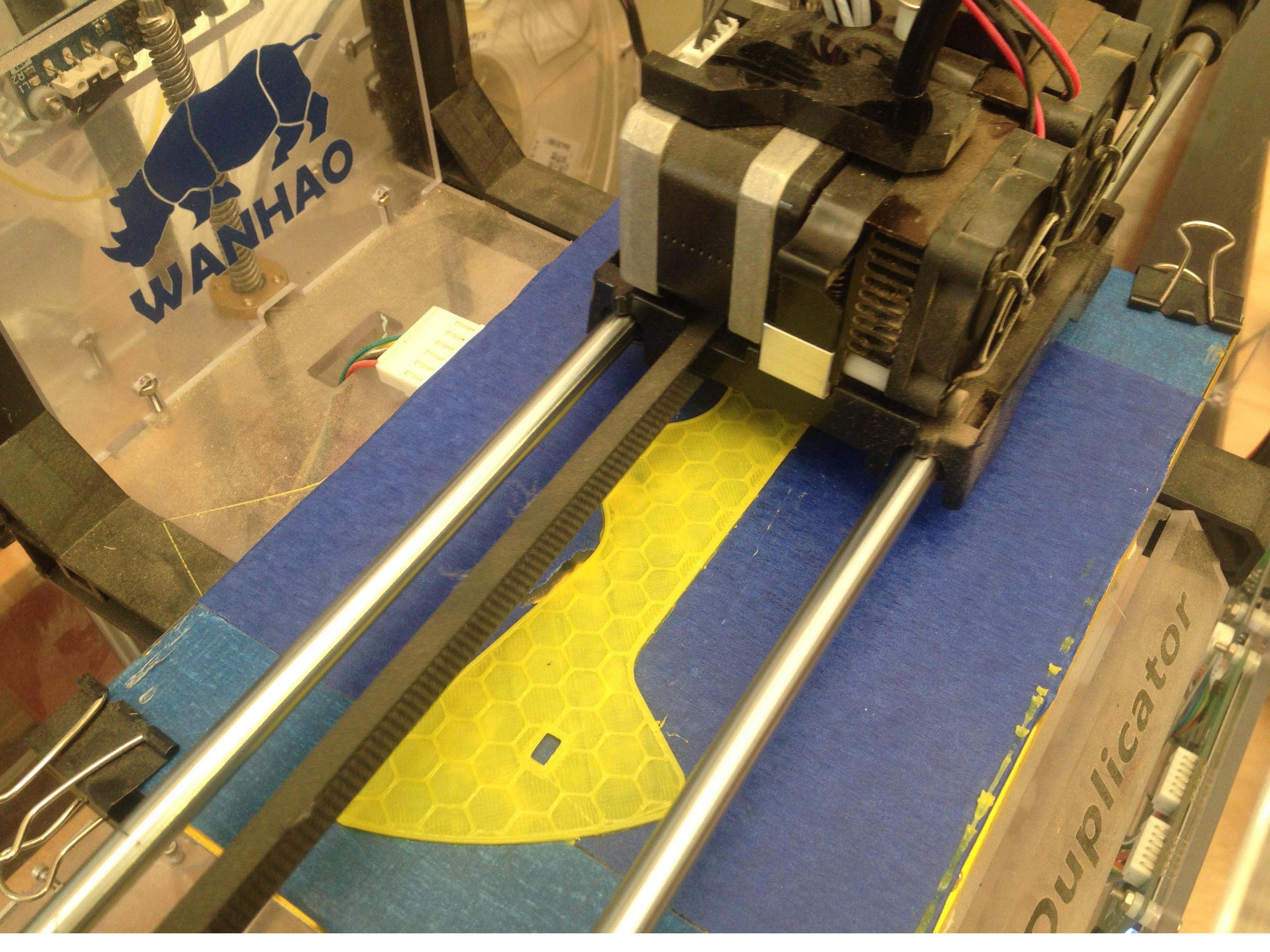

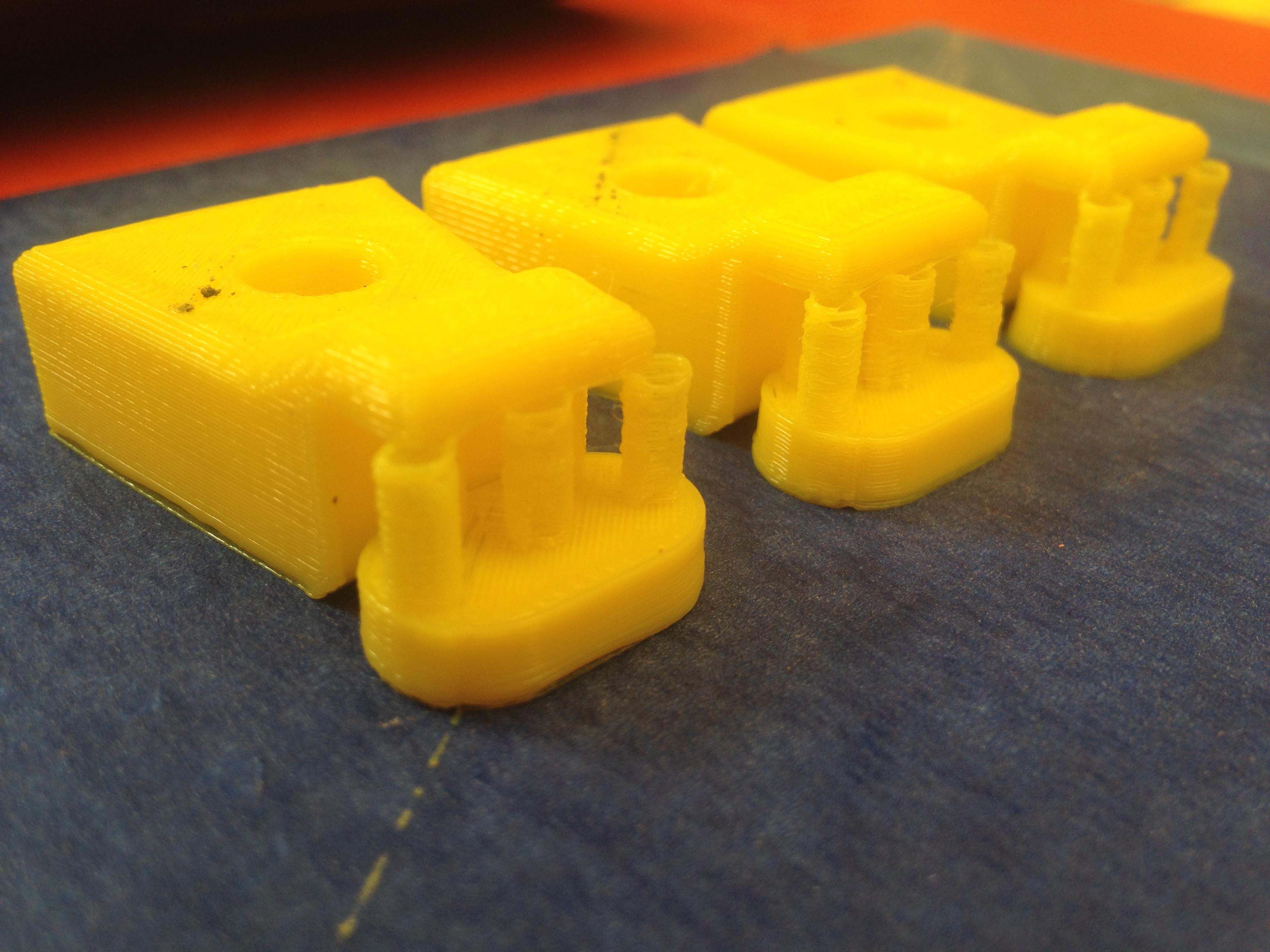

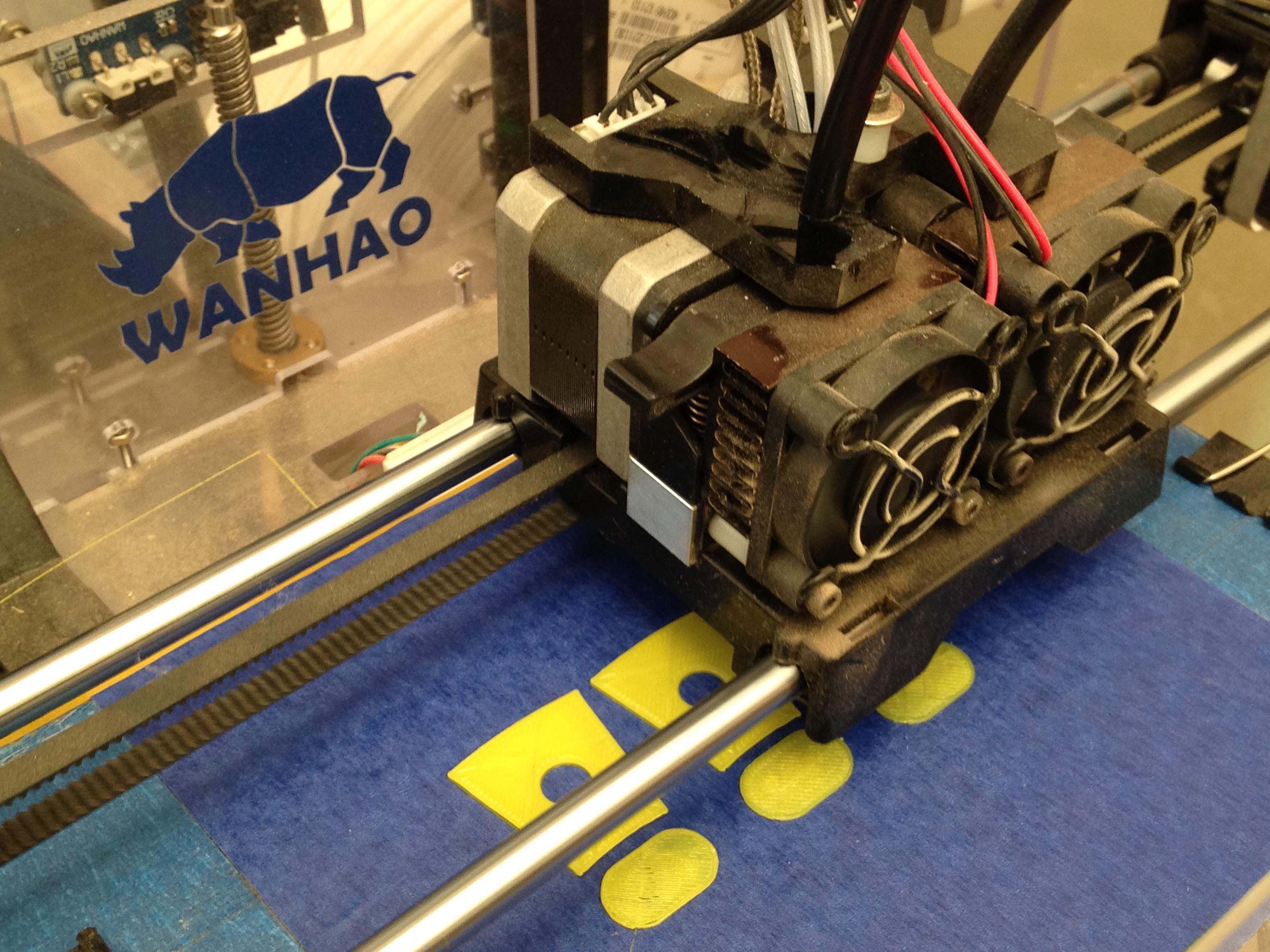

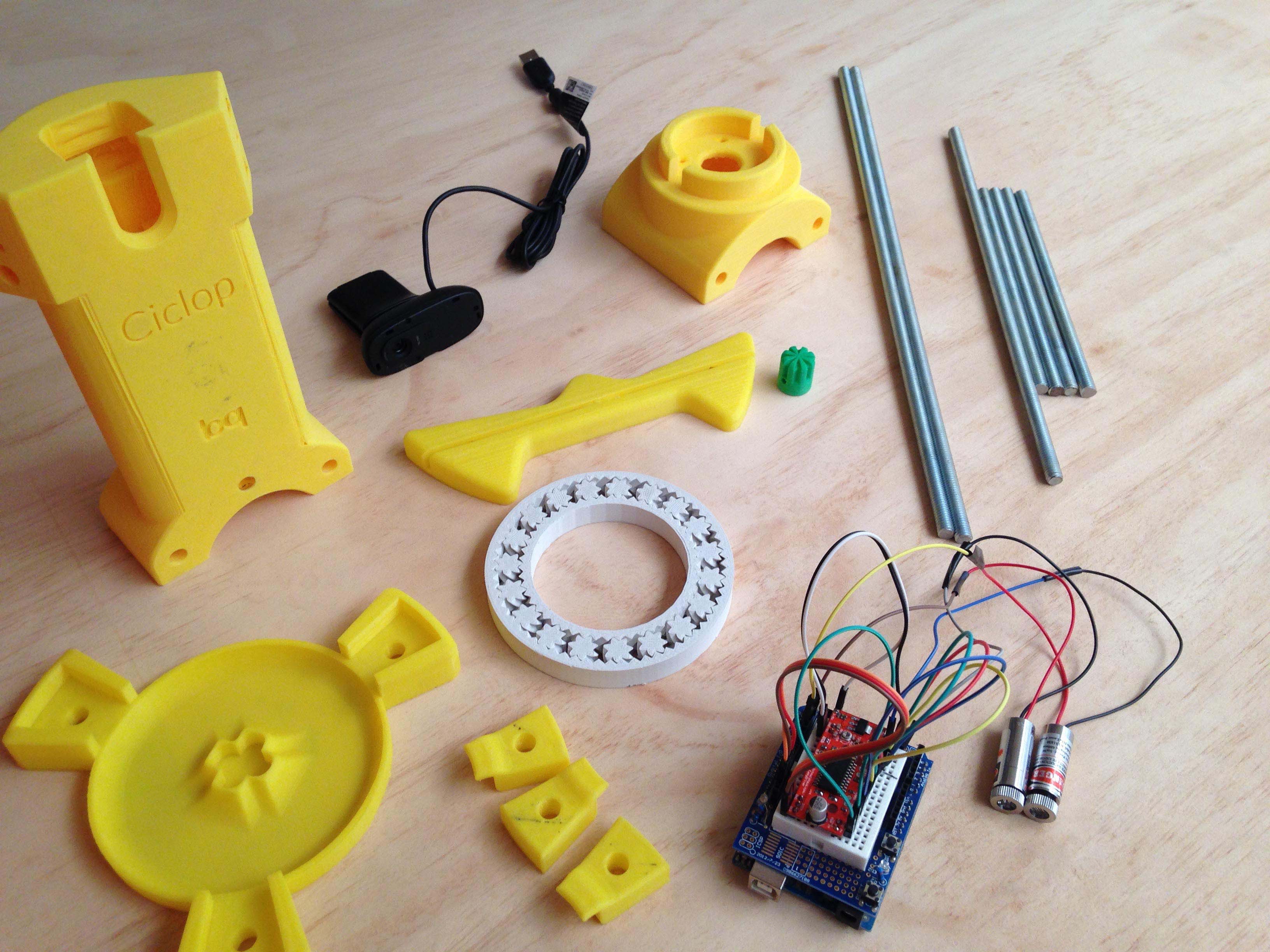

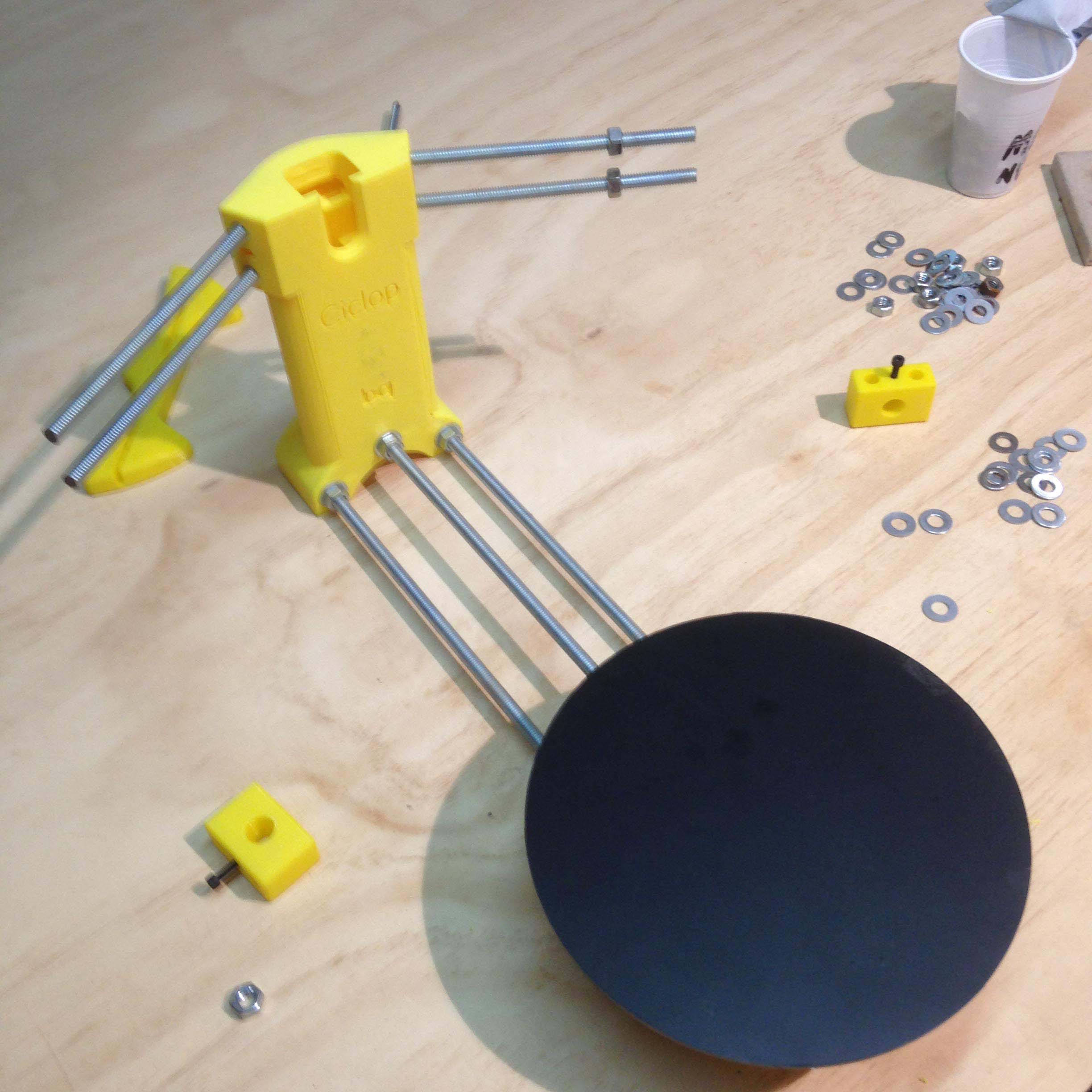

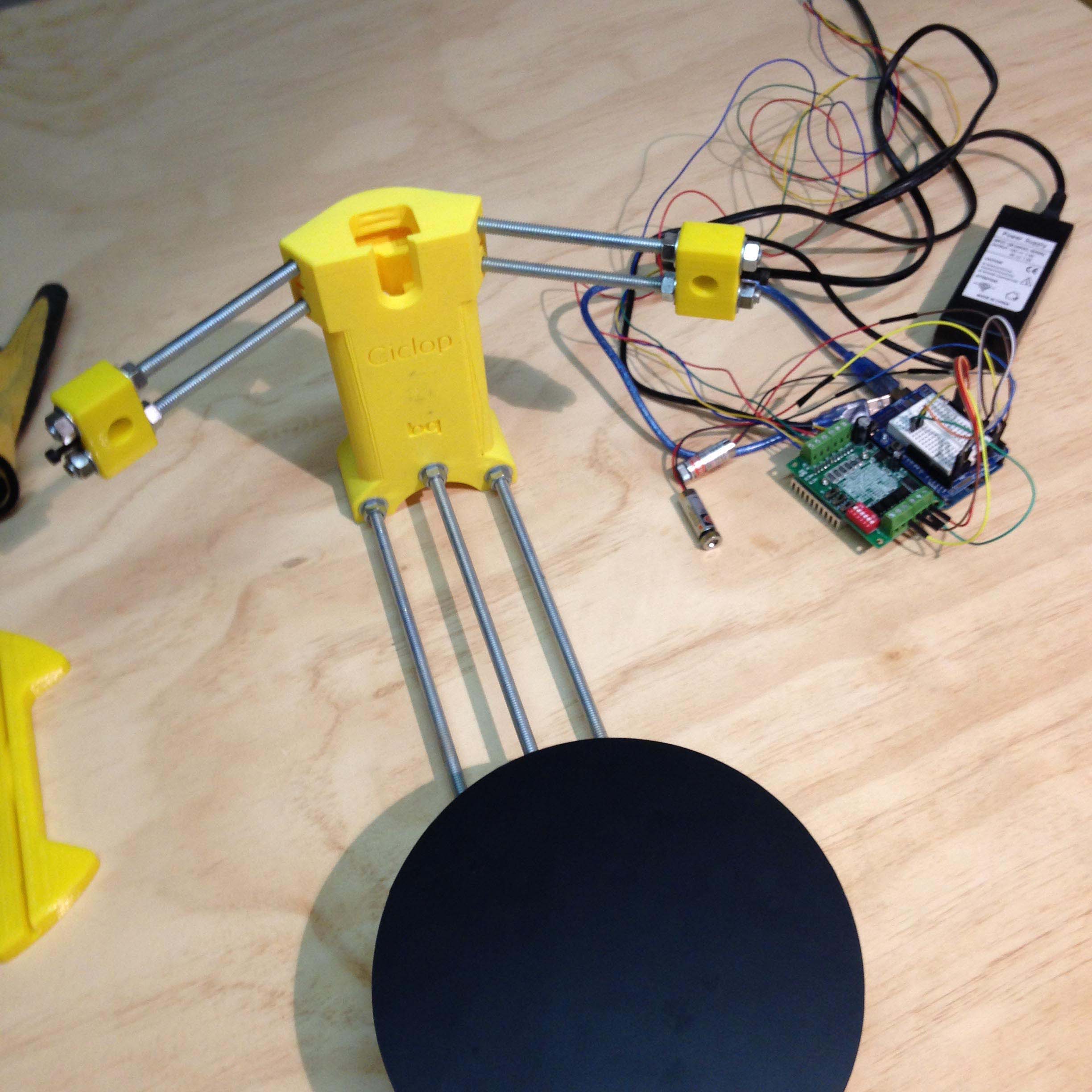

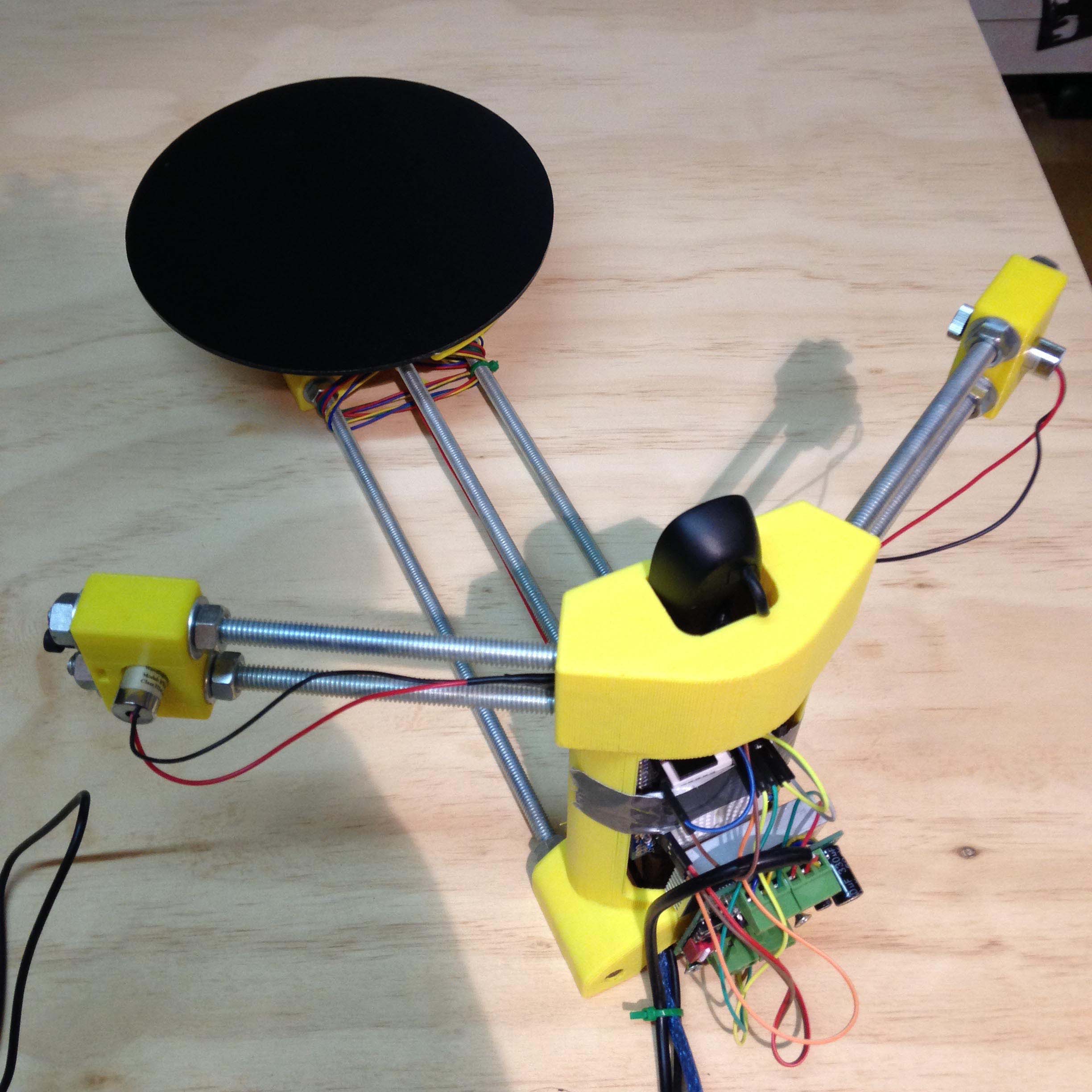

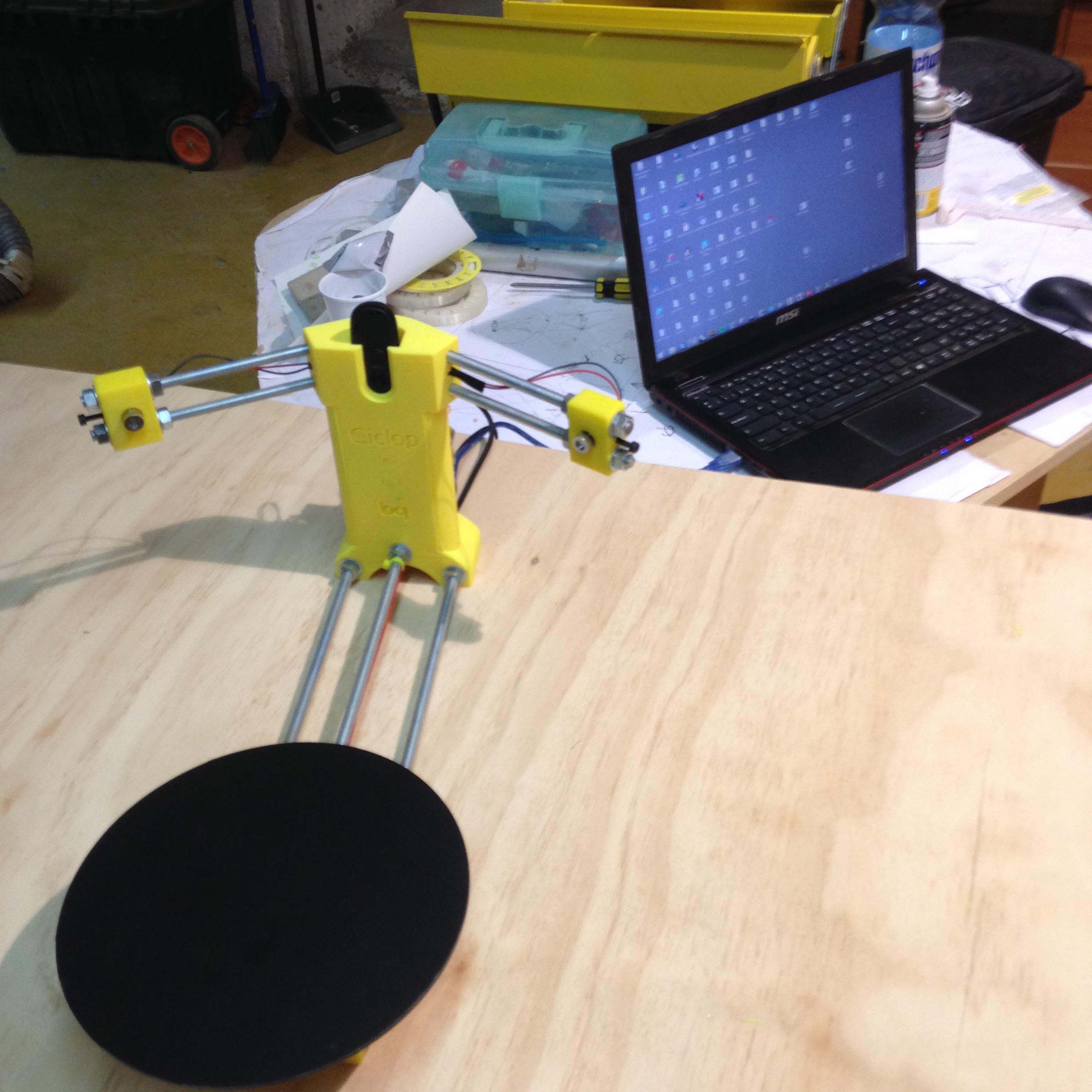

2. 3D Print parts for Ciclop

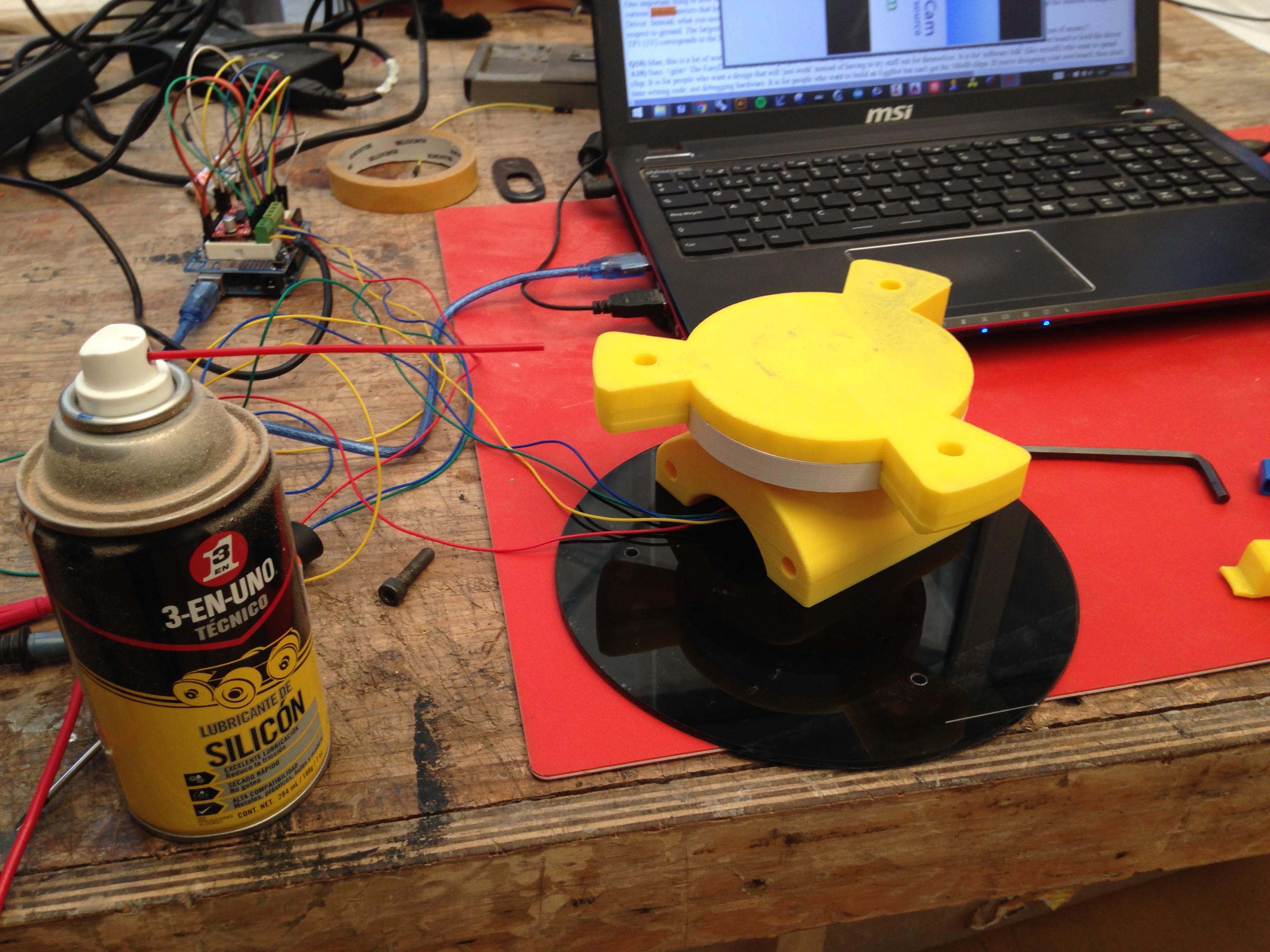

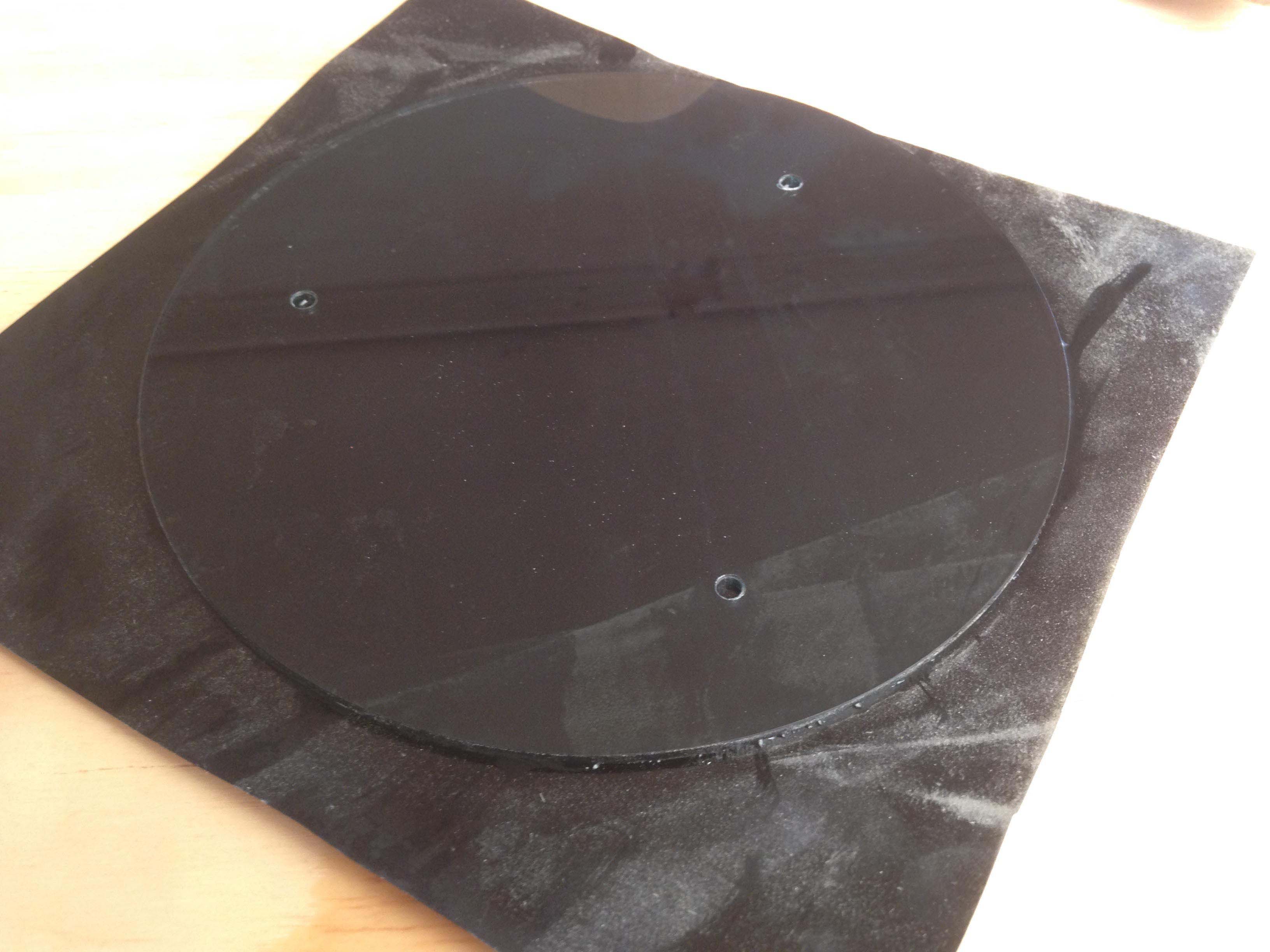

3. Assembly

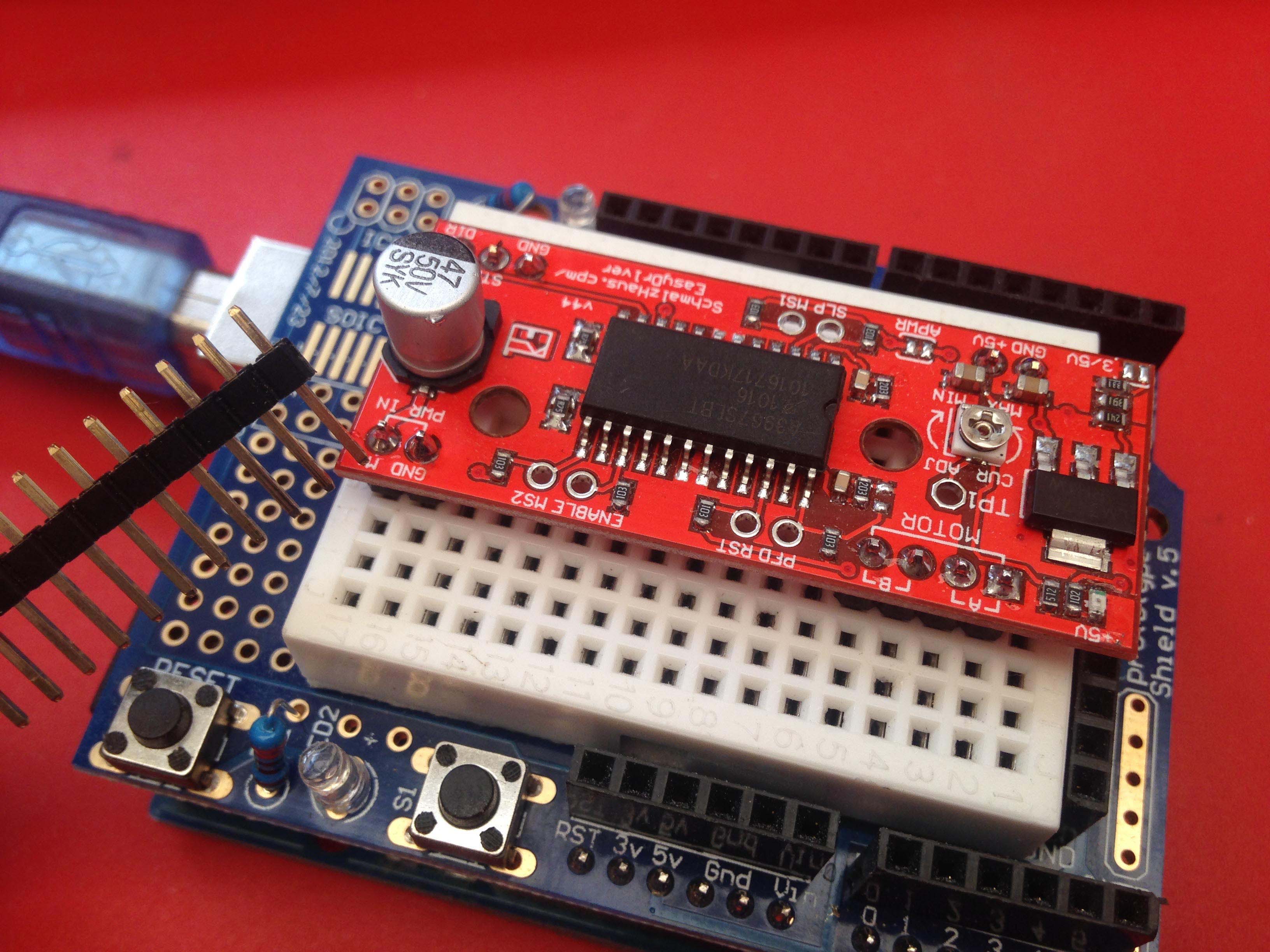

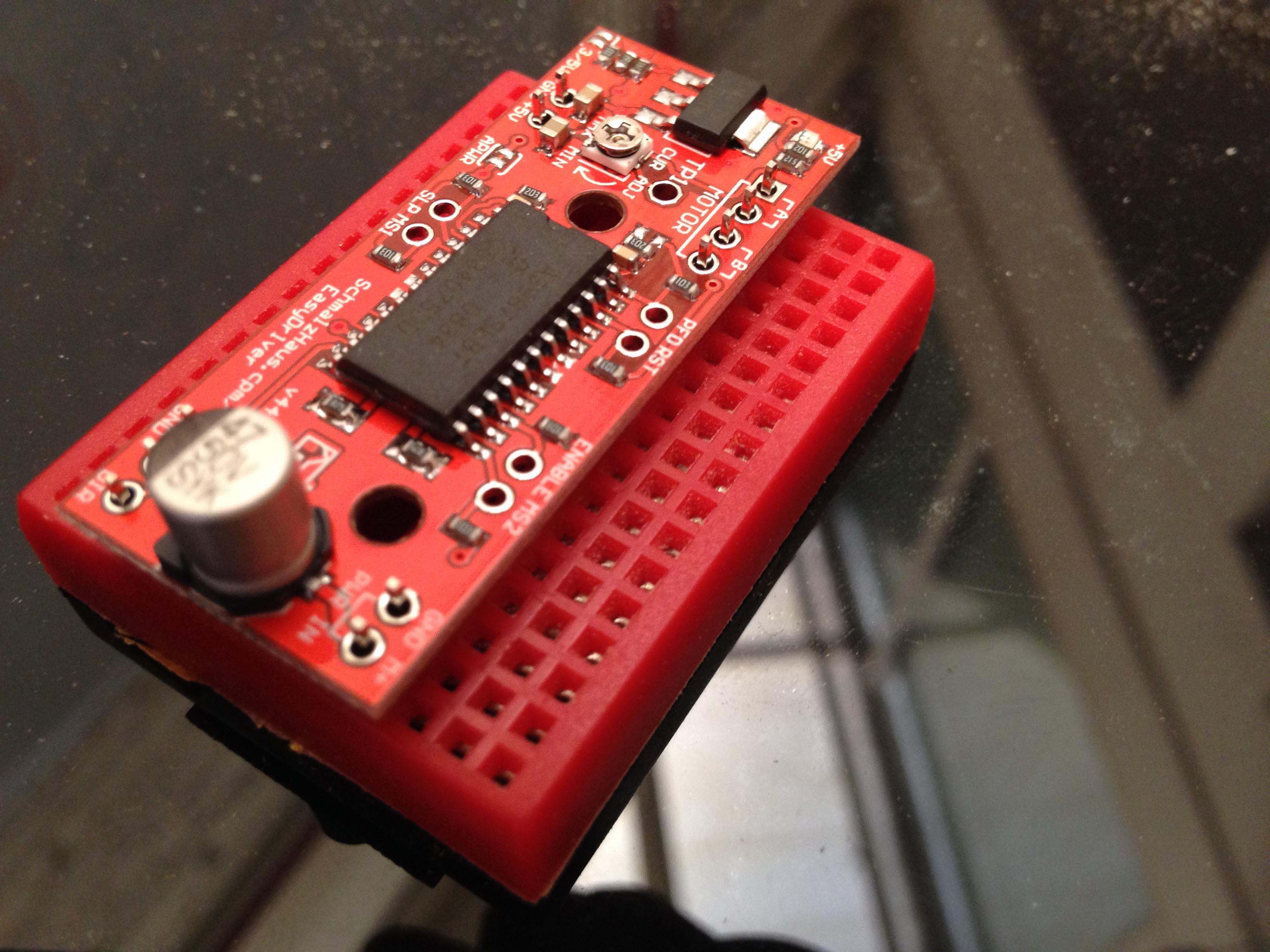

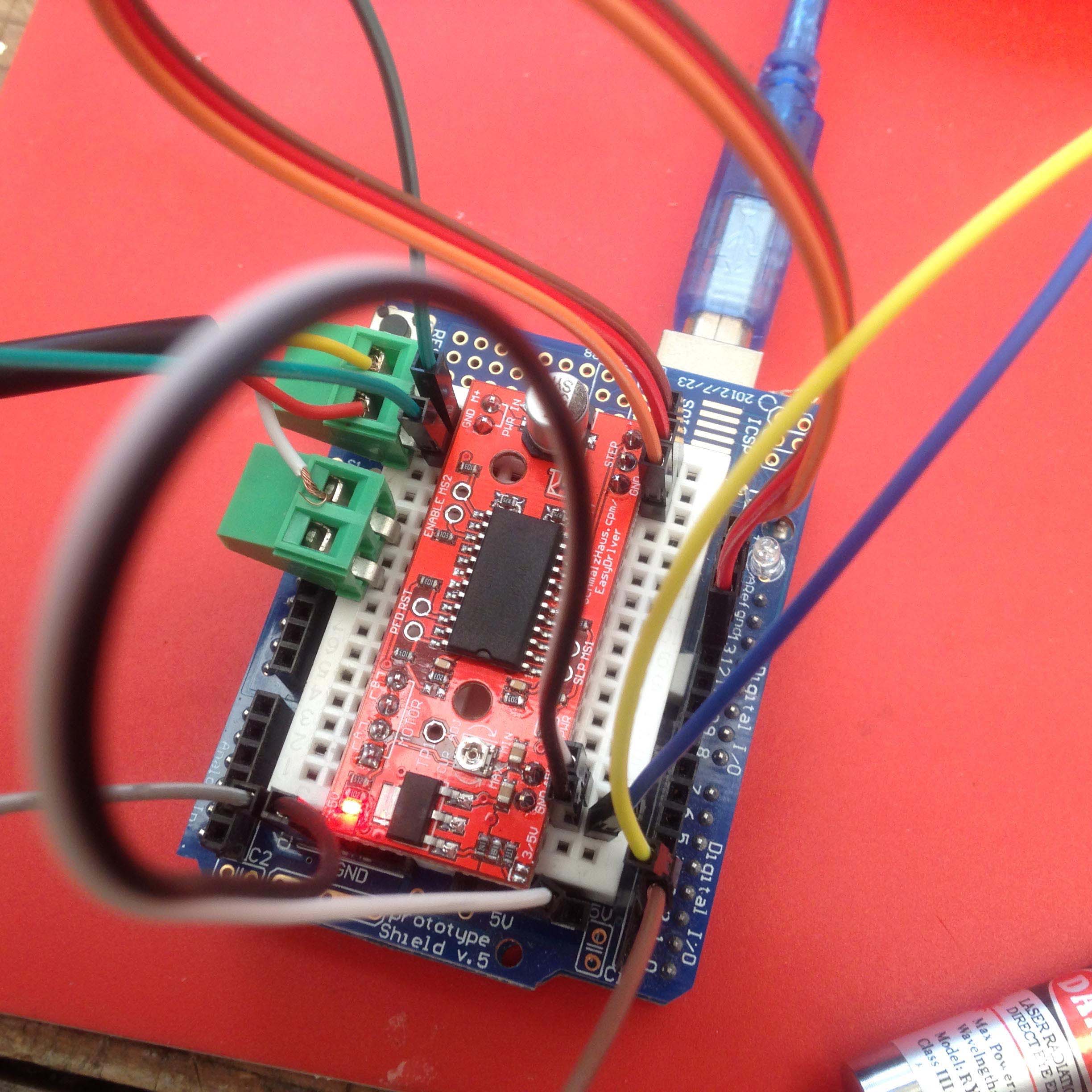

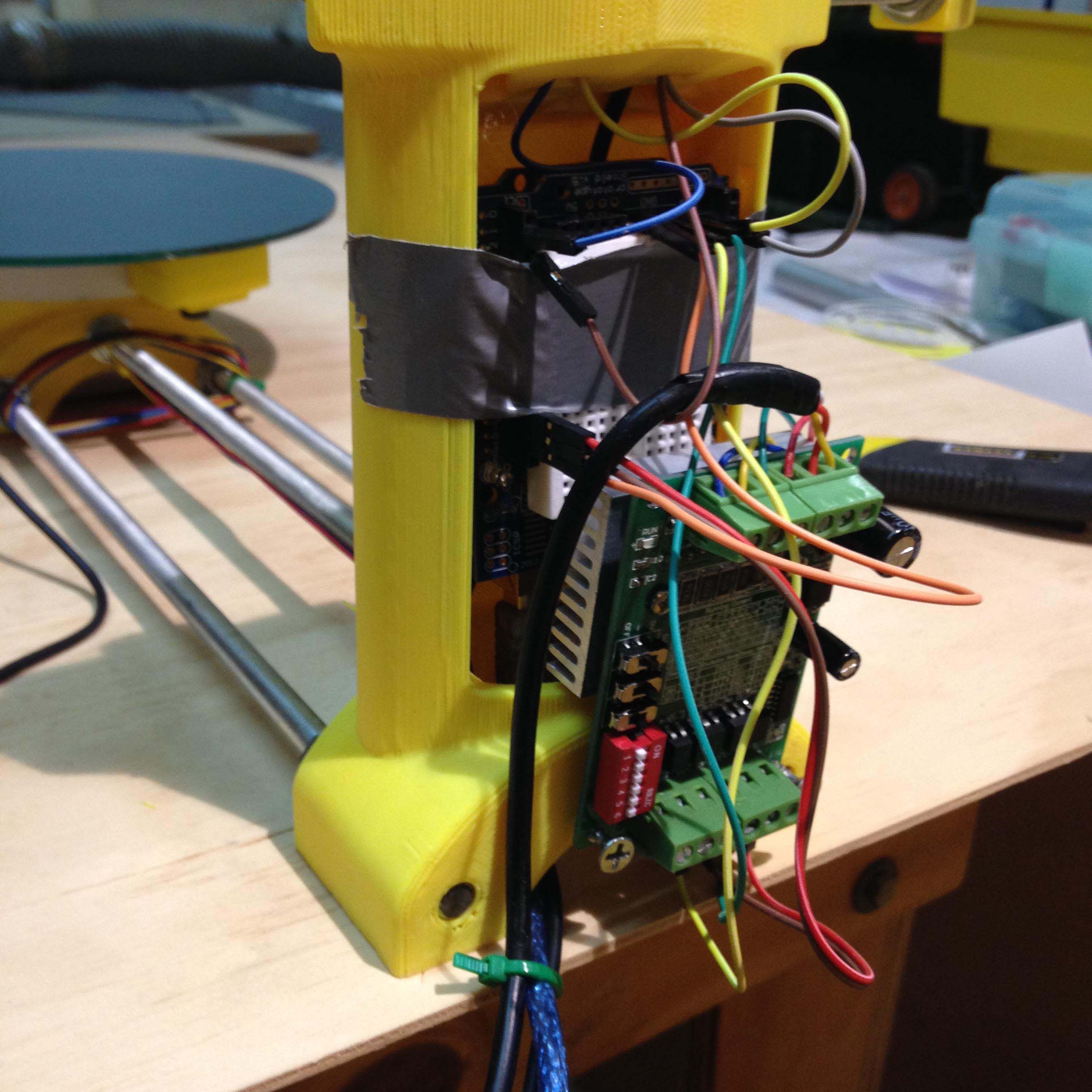

4. Electronics

Cause of the 3D bearing friction, the original driver, the easy driver, I was using for the stepper motor didn`t have enought torque. I have change the driver for a BL-TB6560 runing 1 amp to the motor, it doesn`t sound very well but it works! I think the next step in this proyect is to change the bearing...

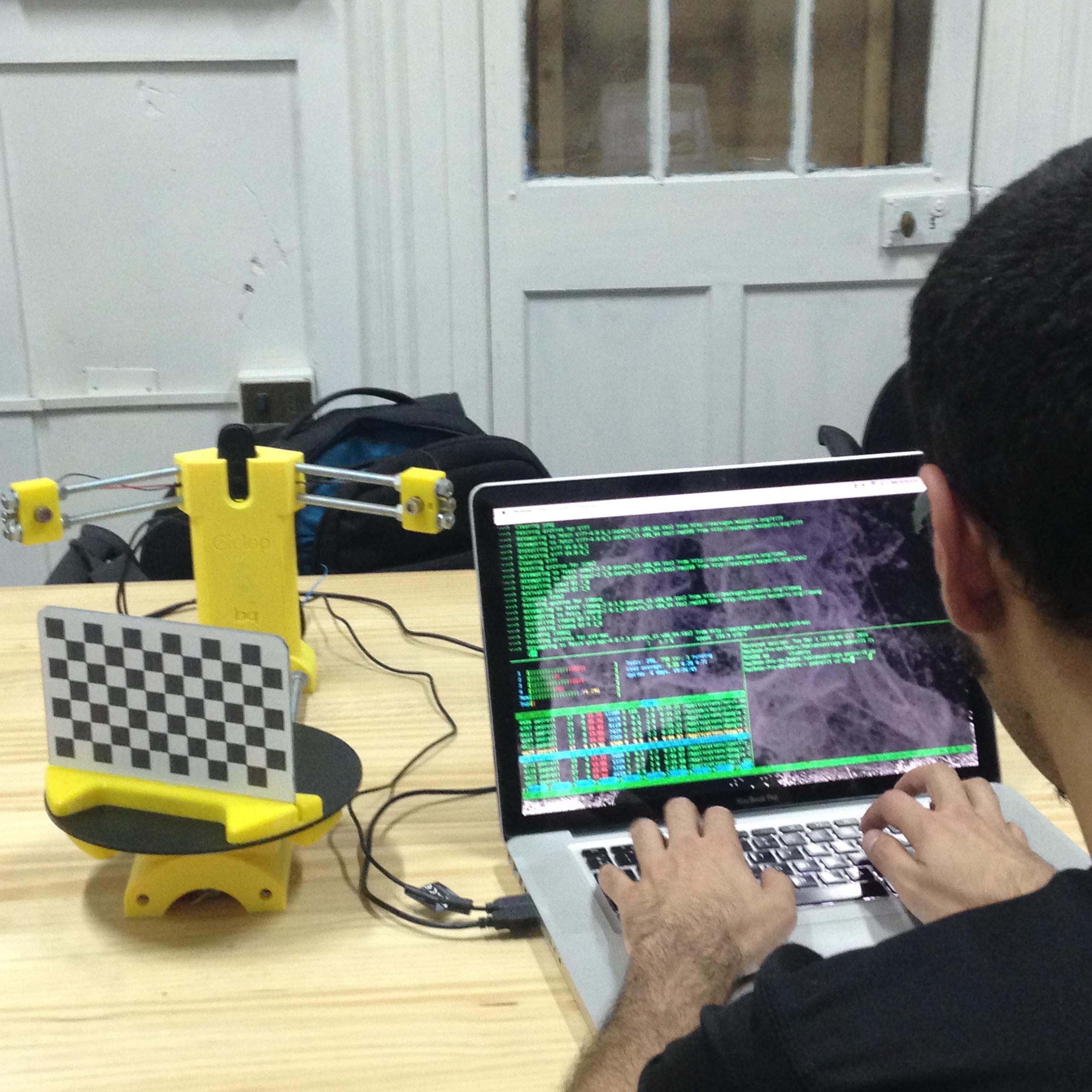

4. Software

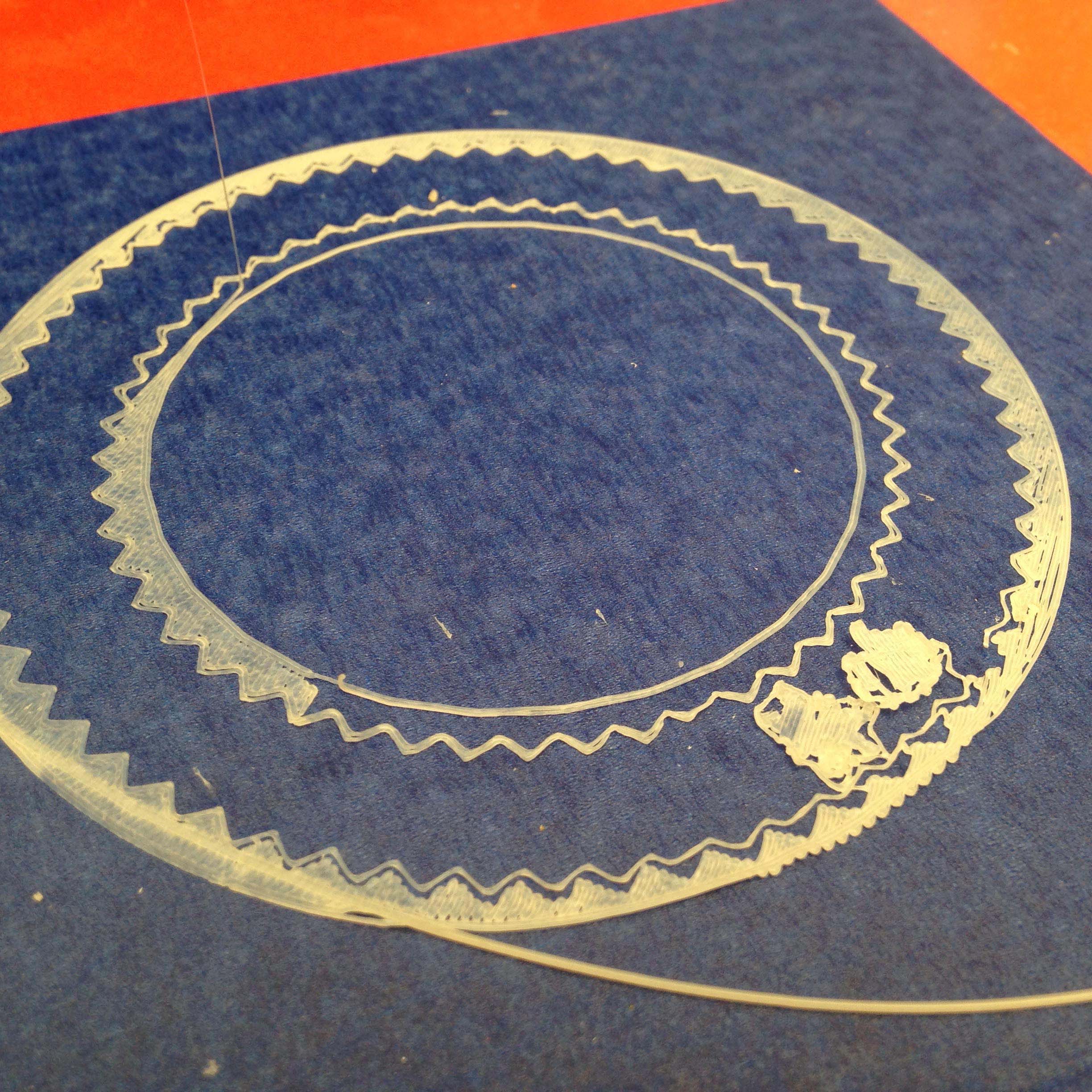

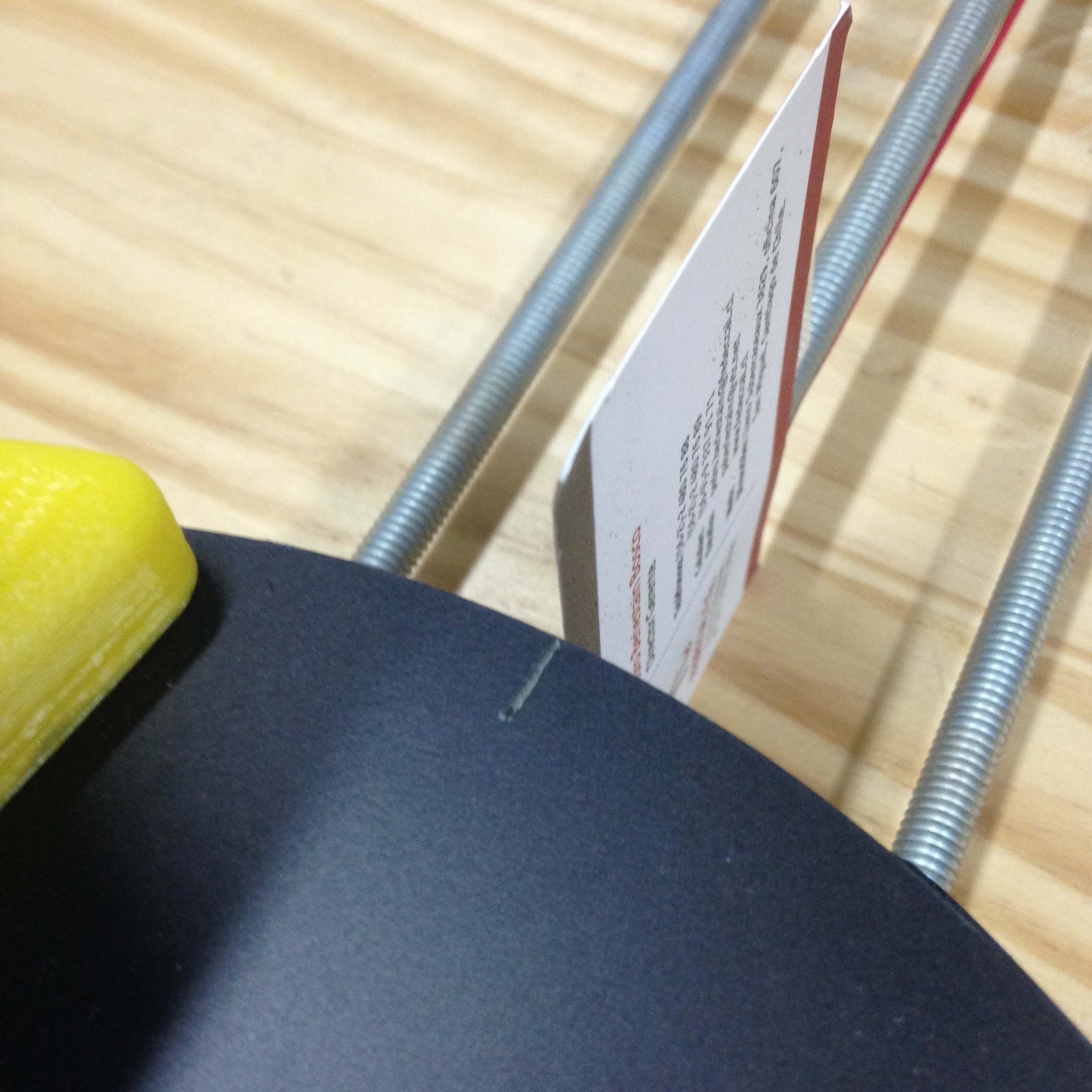

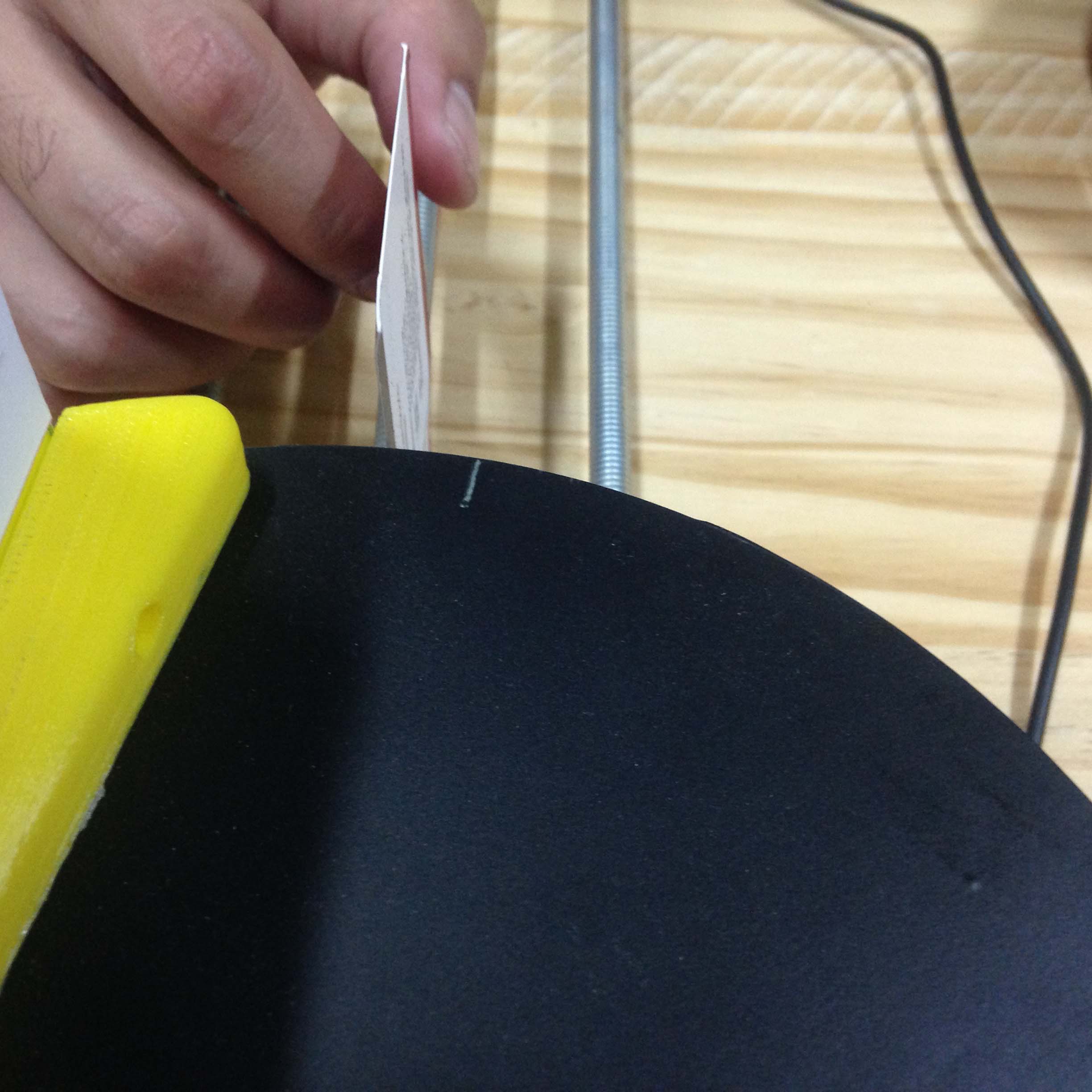

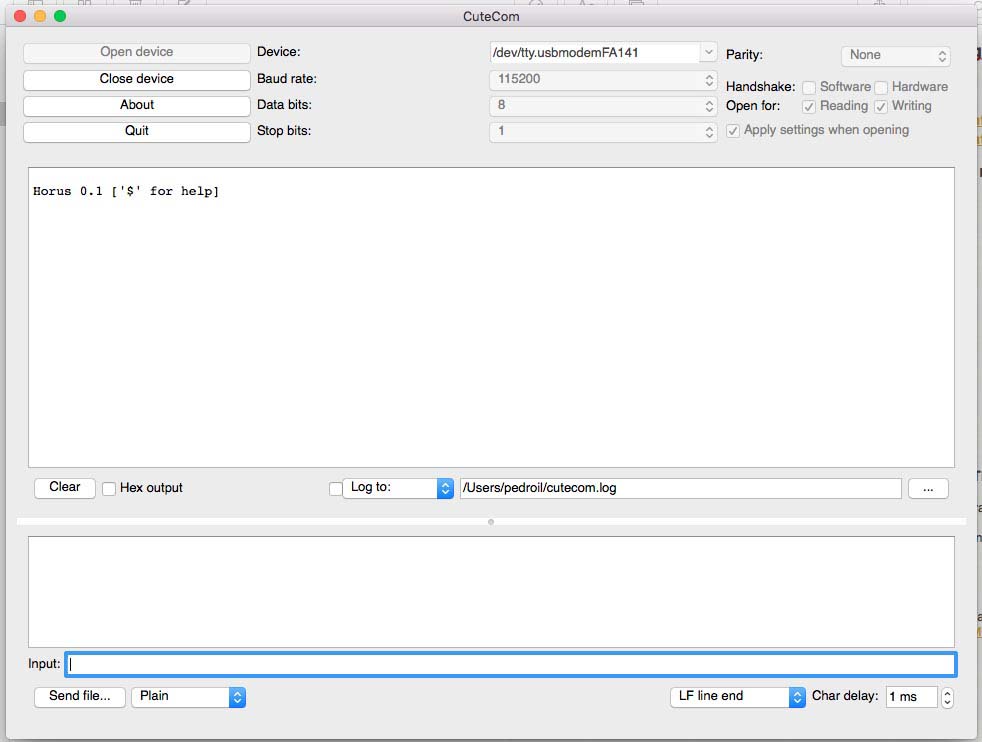

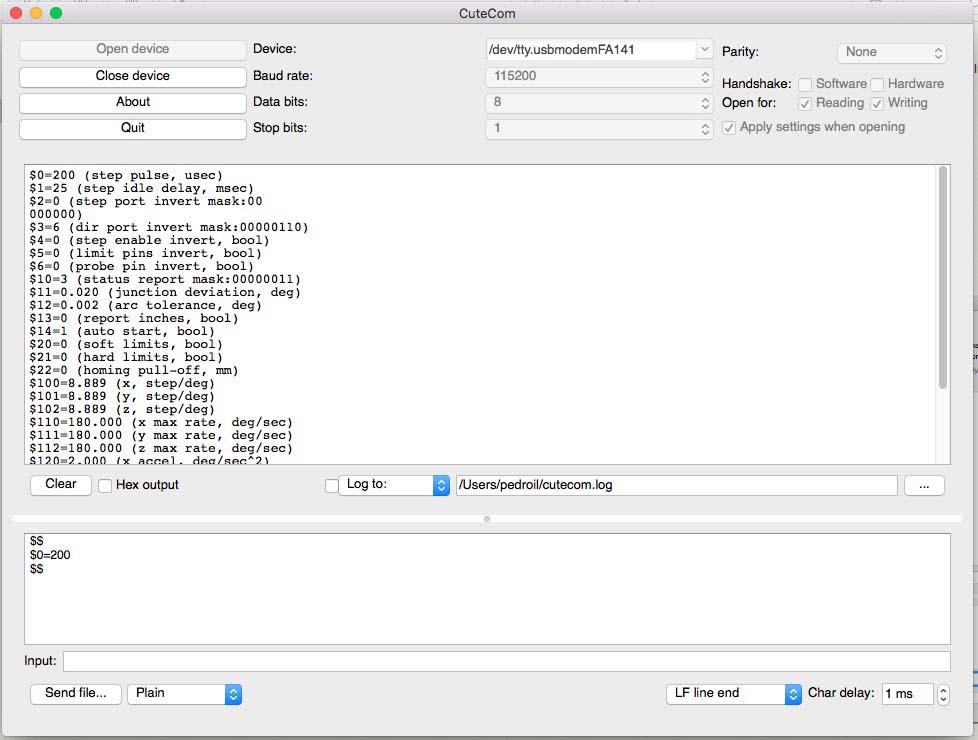

The driver and the motor have to be calibrated in terms of angle/steps, in order to do that, with the help of Fernando (374) we used CuteCom to change this value with the "$100=0.556" comand. So for that you must rotate 360º and verify if the turn is complete, in the pictures I show this method.

5. Calibrating

First Scan with Ciclop by pedroil on Sketchfab

6. First scanning

Taladro by pedroil on Sketchfab

Huincha 1 Laser 0punto5 by pedroil on Sketchfab

Work info:

References:

Ciclop, Horus, Gear Thingiverse,Description:

As the assignment was to print and scan parts, it seems logical to print a scanner, a while ago had seen the open source scanner Ciclop from BQ . I bought the laser and camera, also used a custom electronics with parts I already have. The biggest problem was getting the gear, I couldn´t buy it in my city, so I decided to print it too, this was the most complex part in the assembly. I used 3 types of plastic: PLA, HIPS and Flexible. Finally, the Flexible filament was the solution.