Assignment 2: computer aided design

Our local instructor Jani Ylioja gave a quick tutorial on FreeCAD.

It seemed to be popular and I tried many tutorials available in the

Internet and Youtube. I still don't quite get it. So, I went for

123D Design. I found tutorials

meant for 11 to 13 old kids. I started to like 123D Design already.

A local information science student is a heavy user of 123D, and the

fact that there is help nearby made me select 123D as my 3D design

tool for now. Also these tutorials

helped to make my mind. The problem is: there are so many tools and

so little time. But, I had to choose one.

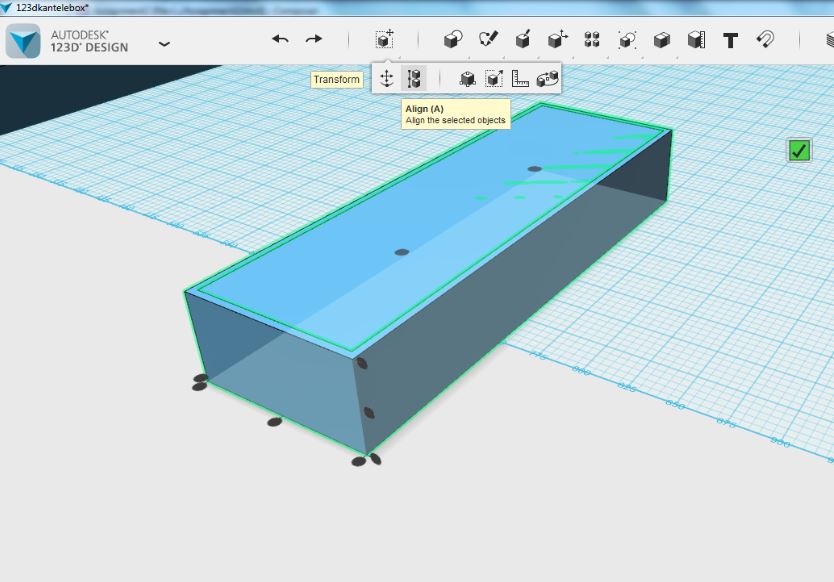

Autodesk 123D Design:

I used Autodesk 123D Design to create the preliminary model for the

Kantele soundbox.

At first I

created a solid box of 300x100x50 mm. Then I made a second solid

box of 292x92x46 to make the first box hollow, by subtracting

the second box from the first one. I aligned the boxes:

and subtracted

the smaller from the bigger.

Then I created the top

of the box as a solid box of 300x100x4 mm, aligned a

cylinder with the radius of 37.5 mm with it, and

subtracted the cylinder from the box. Then I snapped

the top to the body of the Kantele.

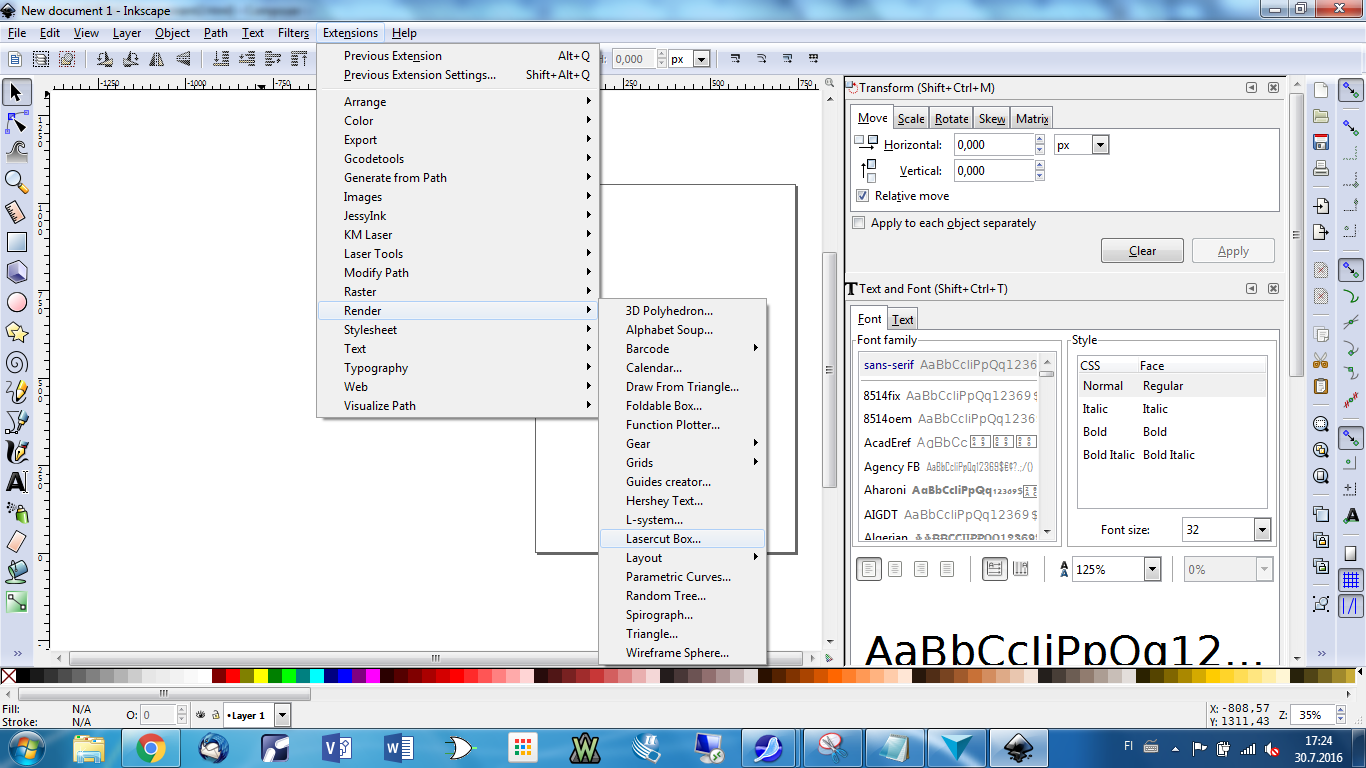

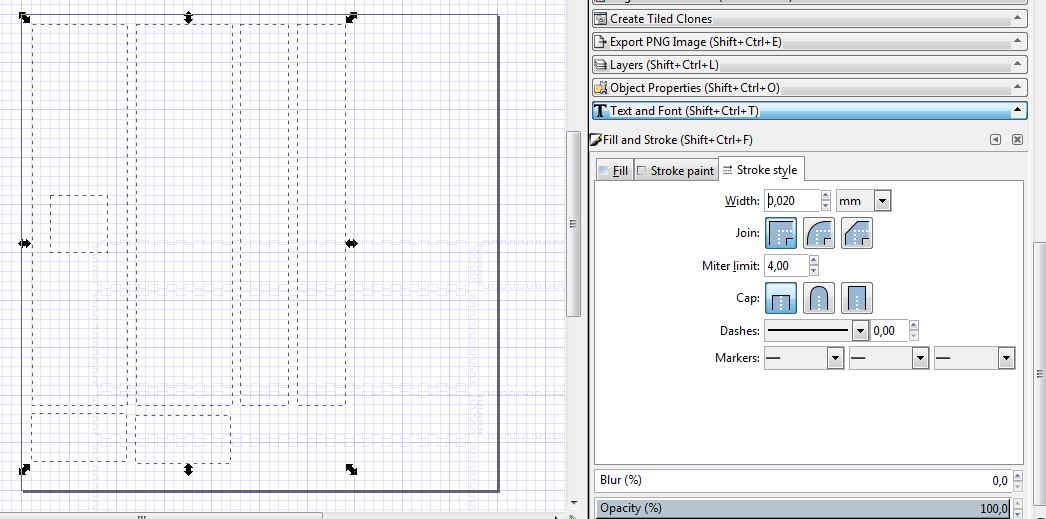

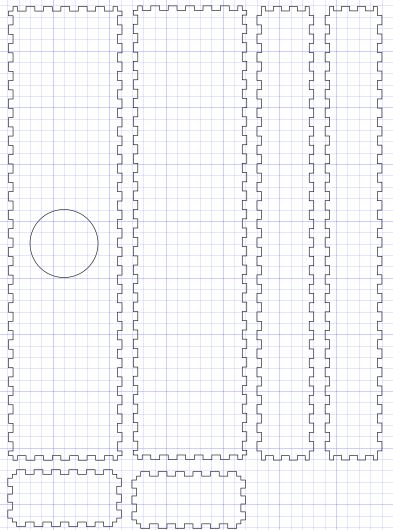

Inkscape:

I also used Inkscape with Lasercut-box

extension to make a tabbed box for the Kantele sound box. I

downloaded the Lasercut-box zip-file, extracted it, and copied the

inx- and py-files to the extensions folder of the Inkscape

installation folder.

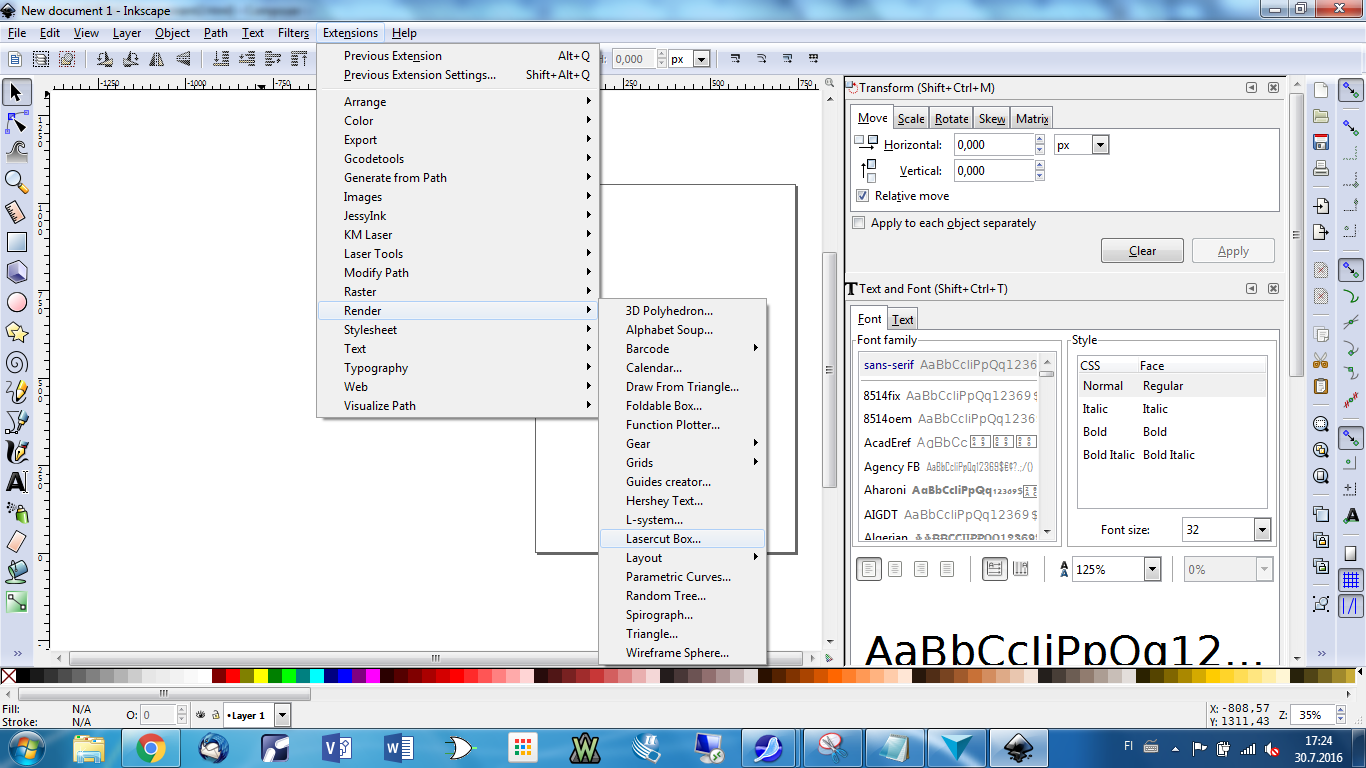

In Inkscape the Lasercut Box extension is found in

Extensions->Render->Lasercut Box.

One can then determine the properties of the box, such as

dimension (External or Internal), material thickness, and tab

count for each dimesion. In the Laser Kerf

menu the amount of material the laser burns away is determined.

This is then taken into account when calculating the actual tab

widths to make precise fit. With soft material dimples can be

used to make press-fit, in which the joints otherwise loose are

made tight with dimples.

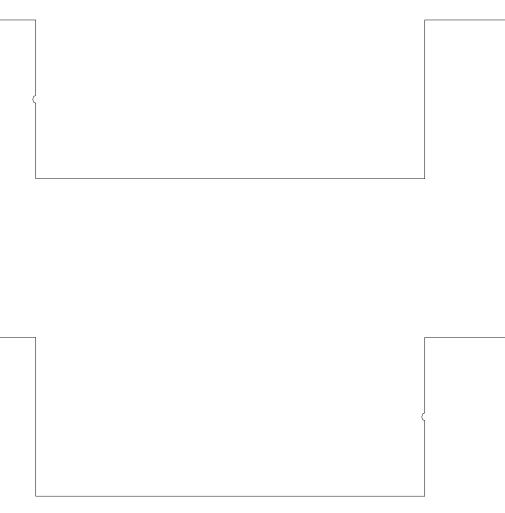

Dimples selected:

I added a sound hole to the top and changed the line width to 0.02

mm for laser cutting:

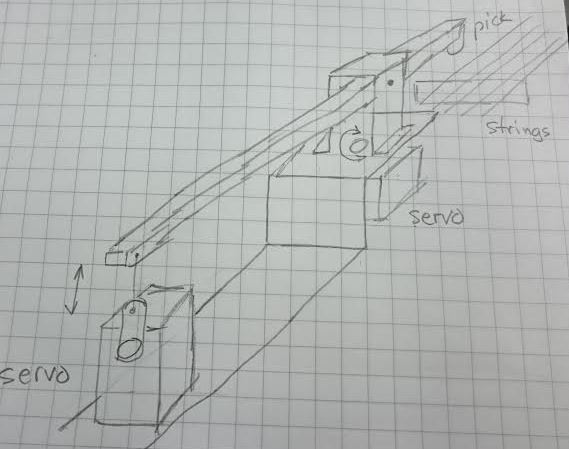

I hand draw a sketch for the

servo mechanics, but I let the mechanics stew in my head for the

final version. I put the design images also to the project page.

It took me a while to twist my brain to 3D design

and perspective drawing, and I have still a lot to learn.

Blender needs more attention still..

Update week 8: Jani gave us a crash course in SolidWorks. It looks

really tempting...

Files:

Kantele 123D Design

Kantele Inkscape

Home