MECHANICAL DESIGN, MACHINE DESIGN

MECHANICAL DESIGN, MACHINE DESIGN

Mc Nulty Machine (link)

INTRODUCTION

This week assignment was about making a machine, including the end effector. First, we had to build the passive parts and operate the machine manually, and then, we had to automate it.

Four different FabLabs decided to get together in Leon in order for us to do the MTM machine. The group members were:

FabLab León: (Borja J. Lanza, Luis Díaz)

FabLab Deusto: (Francisco González-Quintial)

FabLab UE: (Jose Real Cambas, Marta Verde)

FabLab Madrid-CEU: (María Victoria Retana Díaz, María Santisteban)

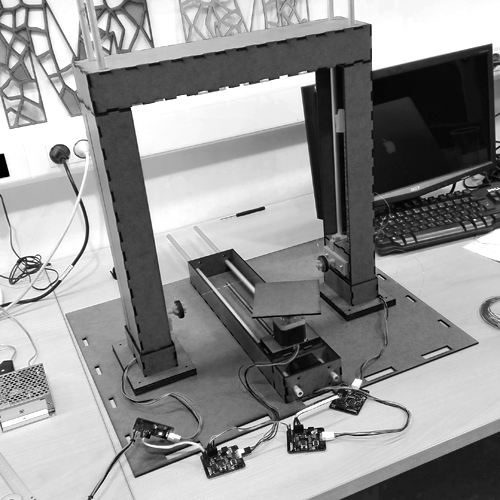

For the machine design we thought about all the different possibilities that we had in terms of building the machine and once we had all the documentation, we decided to build a hotwire cutting machine as it is very useful to have in a FabLab.

We based our work on the information given by Nadya. We also studied how different hotwire cutting machines built last year worked, such as the one made by FabLab Puebla and FabLab Singapore for the purpose of making our very own vision of the machine gathering the best of each one.

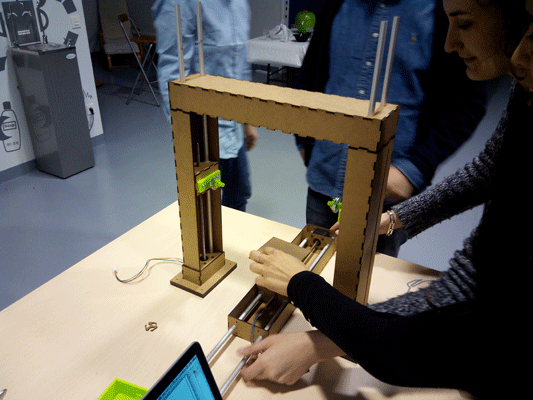

Our machine is designed to work with three axes of motion, one of which can also rotate.

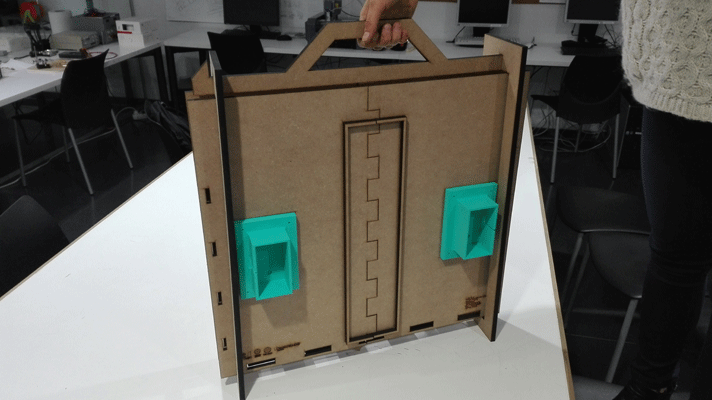

It is also designed to be portable and it can be kept in a suitcase.

We divided the work in two parts:

The construction and assembly of the different parts of the machine made by Francisco González-Quintial, Jose Real Cambas, María Victoria Retana and María Santisteban.

The programming and electronics made by Luis Diaz, Borja J. Lanza and Marta Verde.

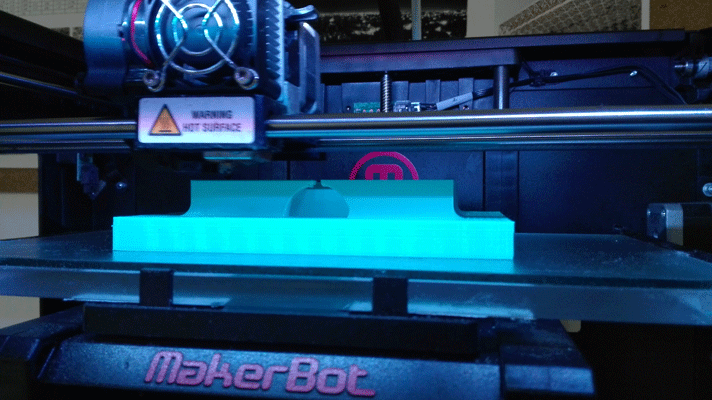

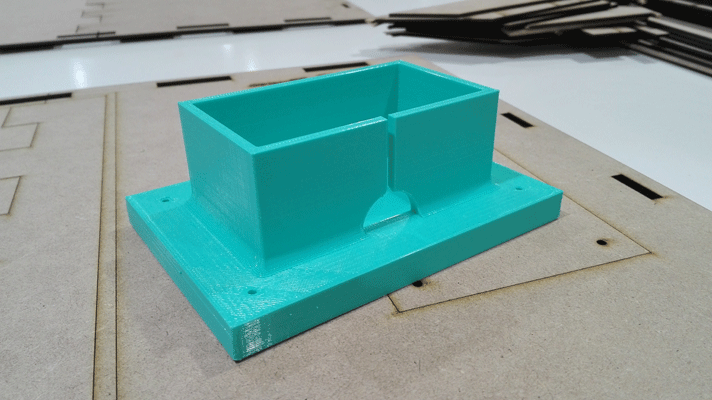

Supports

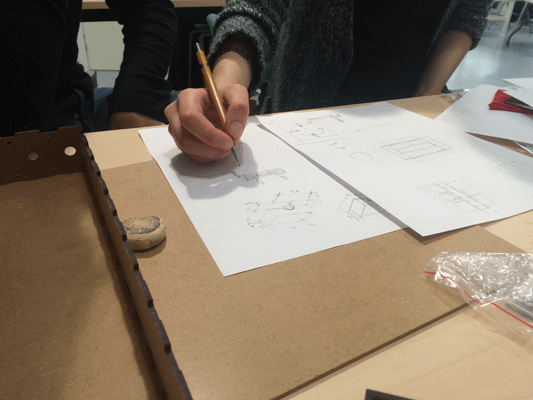

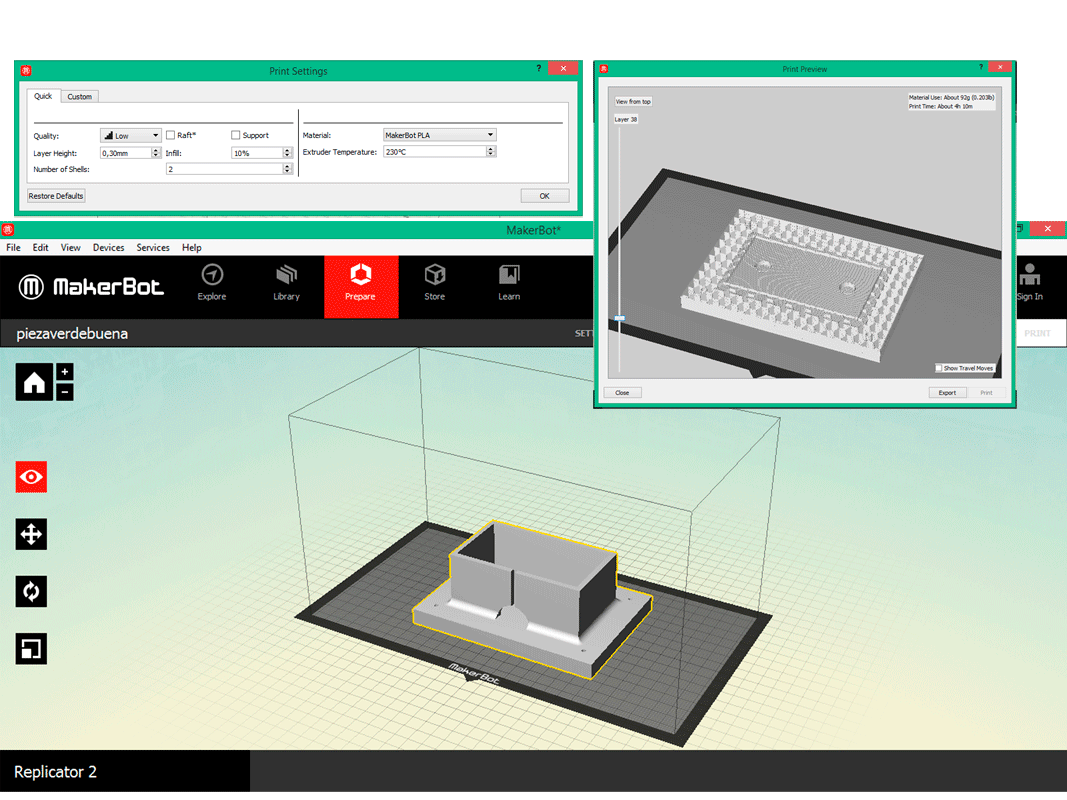

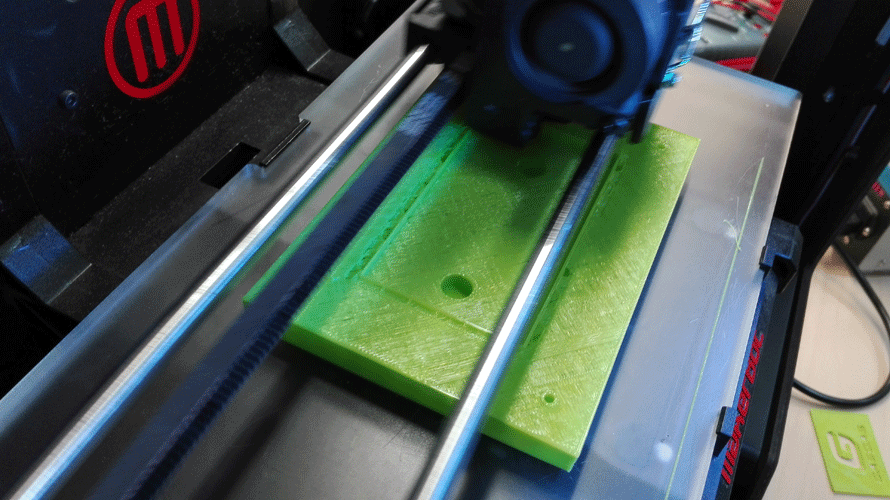

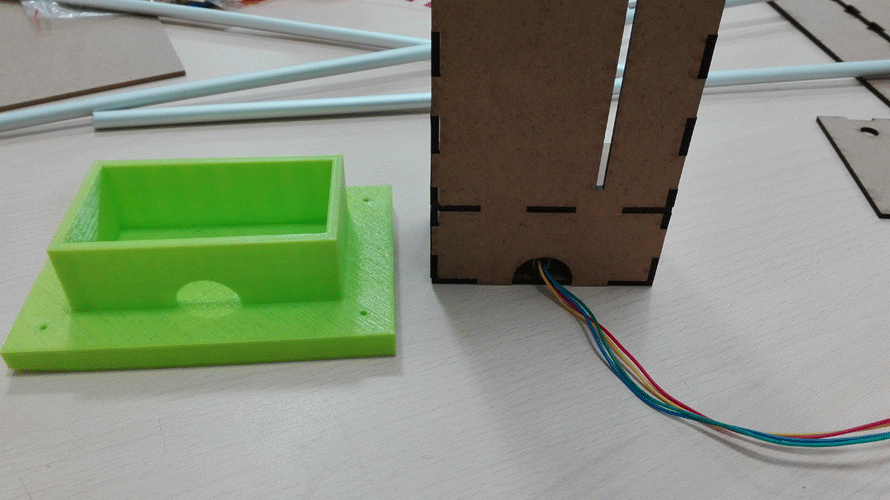

We were designing the supports to the modules. We did two versions of it one in mdf and the other in PLA. We were trying to do the supports in PLA but the printing time was too big to do it, so we did a test and in the future we will change the supports because it will be more rigid, we did the test using 0,3 h in order to know if the piece worked but for the final one we will use 0,2h 220º and without raft nor supports. The piece also has a hole in the back for the motor cables.

By the time the support will be in mdf but in the future we will print it in PLA.

Printing settings: Temperature:220º Infill:10% Layer Height.

Foldable McNulty

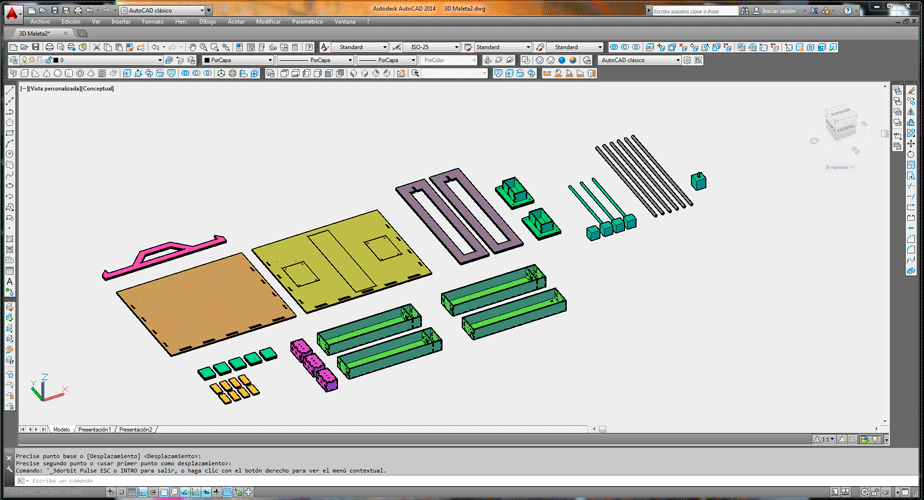

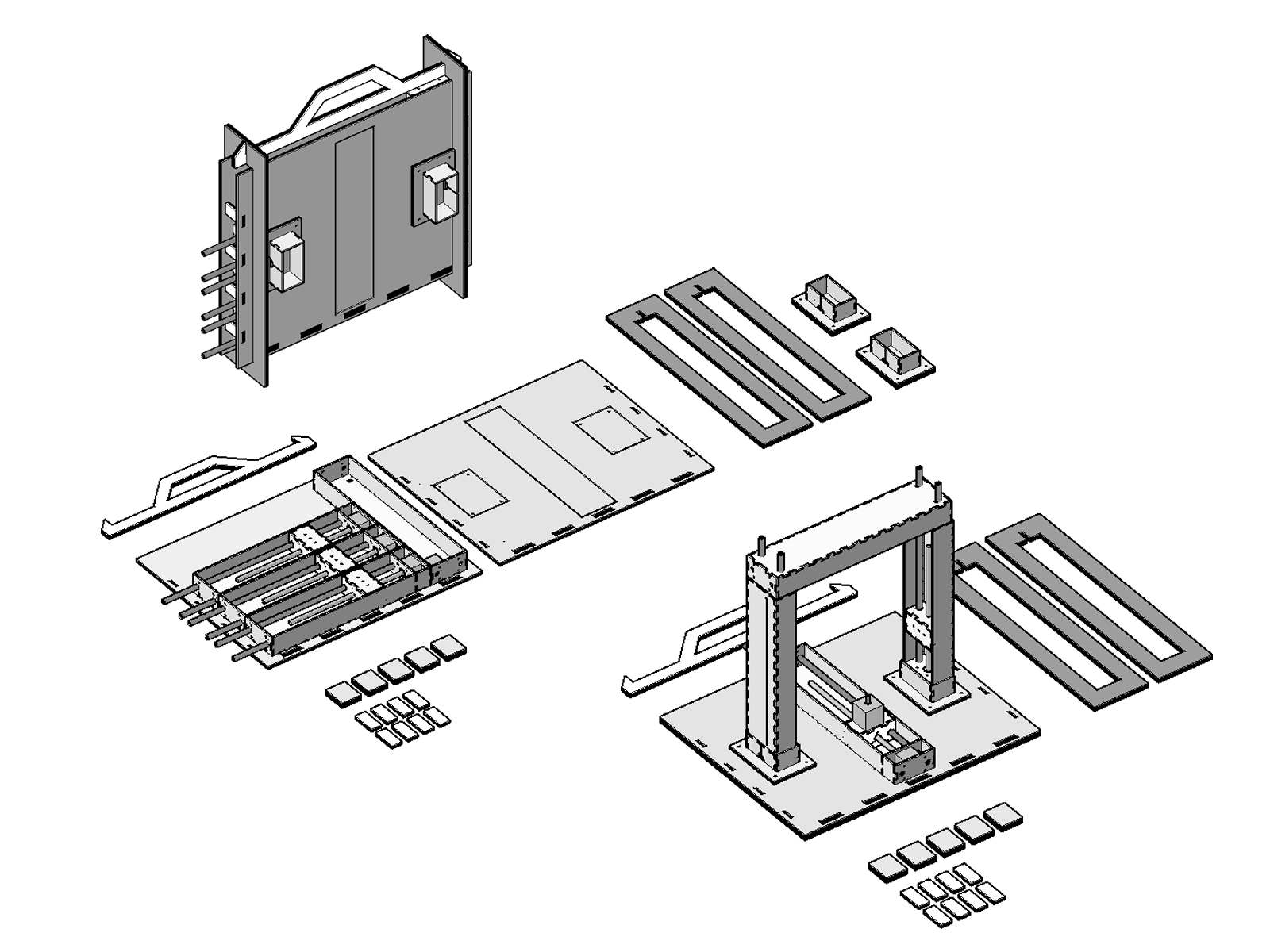

We also wanted the machine to be foldable, so we designed a suitcase that it is a suitcase but also it is the base to the machine, the supports looks like folders and inside the suitcase are the modules, one of them it doesn´t have a motor inside so we can keep the boards and the cables inside this one. We didn't have enough time to finish the suitcase so I draw the 3d modelling in Autocad to show how it works.

As we did't have time to finish the foldable suitcase in Leon, María and me decided to finish it in Madrid and later send it to Leon.

We printed again the Improved version of the supports that have a groove in the back for the cables.

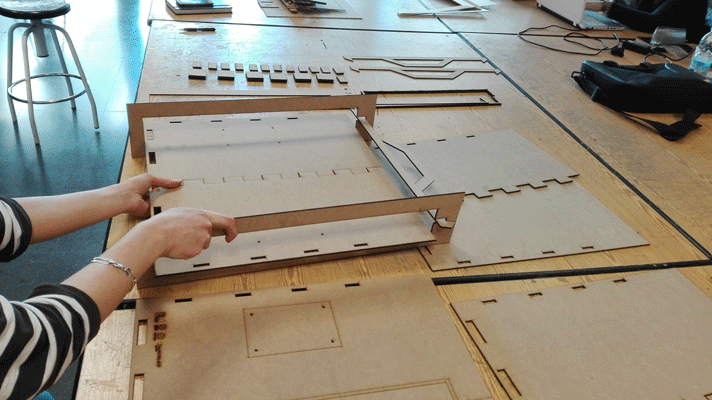

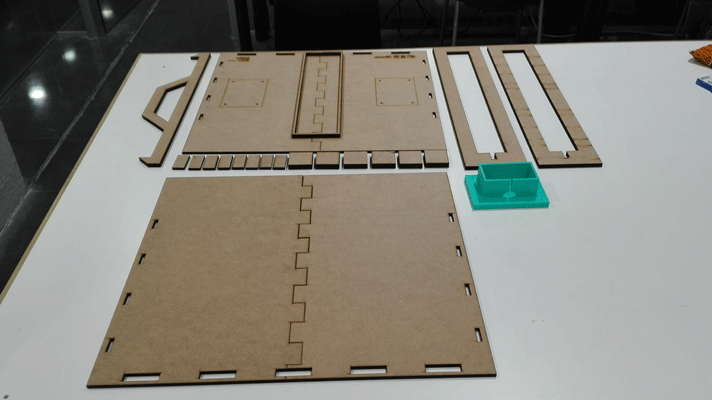

We cut all the pieces in the lasser, we used 3mm mdf.

Laser pieces.

Foldable McNulty Suitcase.

María and I were also in charge of uniting all the team work and make the general web page.

To go to the group web page (here)

Files

Final Result

MachineBuilding_v4 from Marta Verde on Vimeo.