COMPUTER-CONTROLLED MACHINING

COMPUTER-CONTROLLED MACHINING

The assignment for this week was design something was to design something big using the numeric control machine.

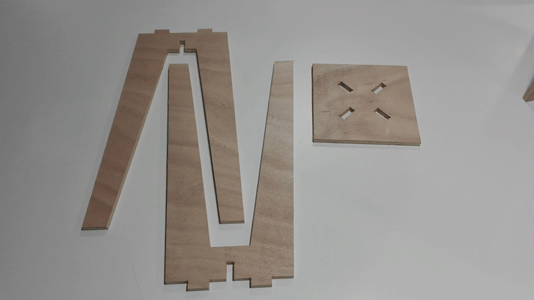

Inspired by the furniture collection "Made in Ch-I-taly" designed by Stefano Pugliese I designed a table and four stools using a press-fit system.

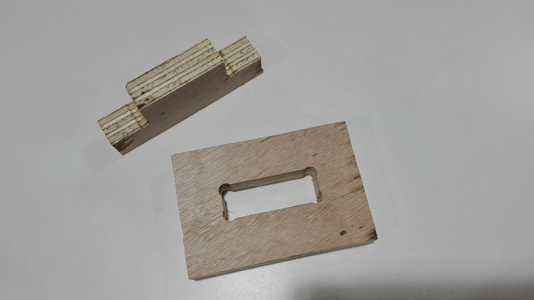

The first thing I did was to cut a few test pieces in order to know what was the clearance between them, using 15mm laminated wood. I decided to cut the pieces with the same size as the hole, because cutting I loosed 0.02 mm and this was enough for the press-fit table.

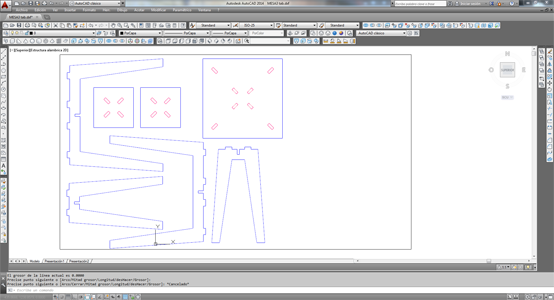

I draw the table and the stools in Autocad and I draw it using just closed polylines and two layers, one for the exterior cut and another for the interior cut.

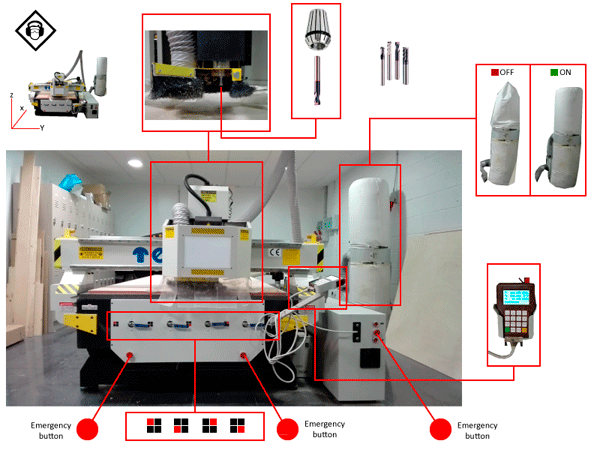

In our fab lab we have the TEC-CAM 1003 CNC, the fixturing system that we use is vacuum, the machine is divided in four quadrants, so depending of how big is the material that you want to cut you open the vacuum quadrants, the maximum size if the machine is 2440x1220 mm, so I used a material of this size and I opened the four quadrants.

The machine has 3 security buttons in the front, so during the cutting we stay just in the front part of the machine. We also have to use visual and hearing protection.

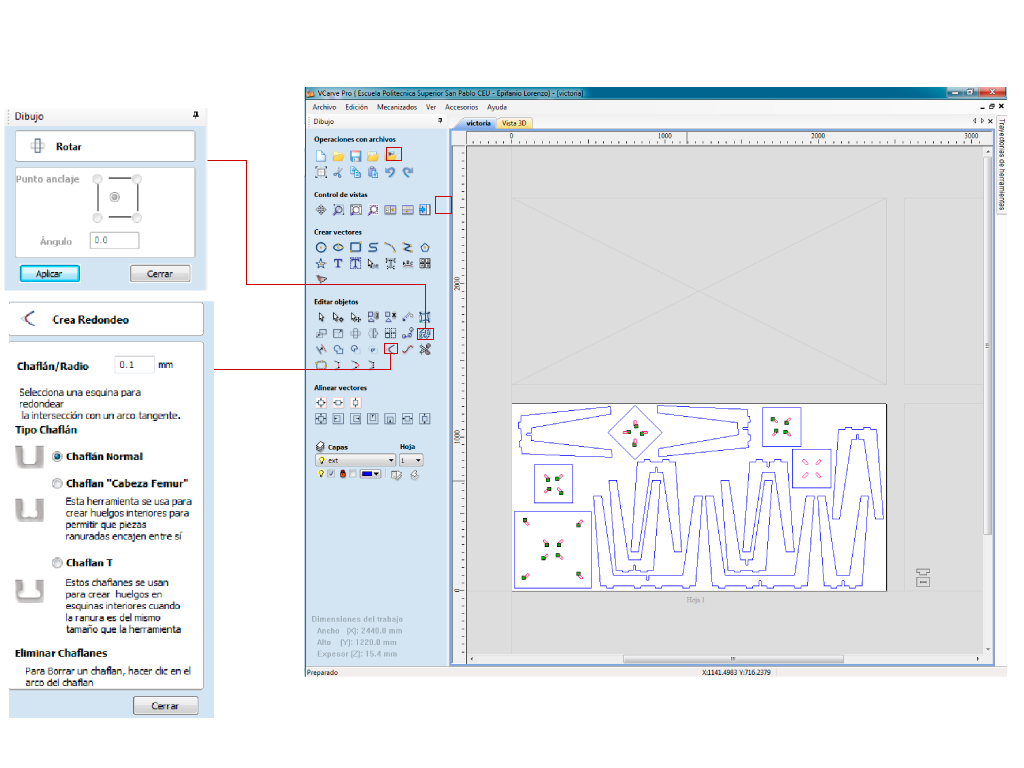

The program that we use is V-carve pro, with this program we can rotate, move, scale and decide how the corners will be cut, I decided to cut the interior corners using femur head and in the exterior corners to use a chamfer.

I cut two layers:

- The interior cut : Conventional cut, interior cut and femur head corners

- The exterior cut : Conventional cut, exterior cut and chamfer corners

We have a sacrificial layer to protect the machine, the thickness of the material was not regular so I decided to cut 0.4 mm deeper than the thickness of the material. I used tongues for the cutting so the elements didn’t move during the cutting.

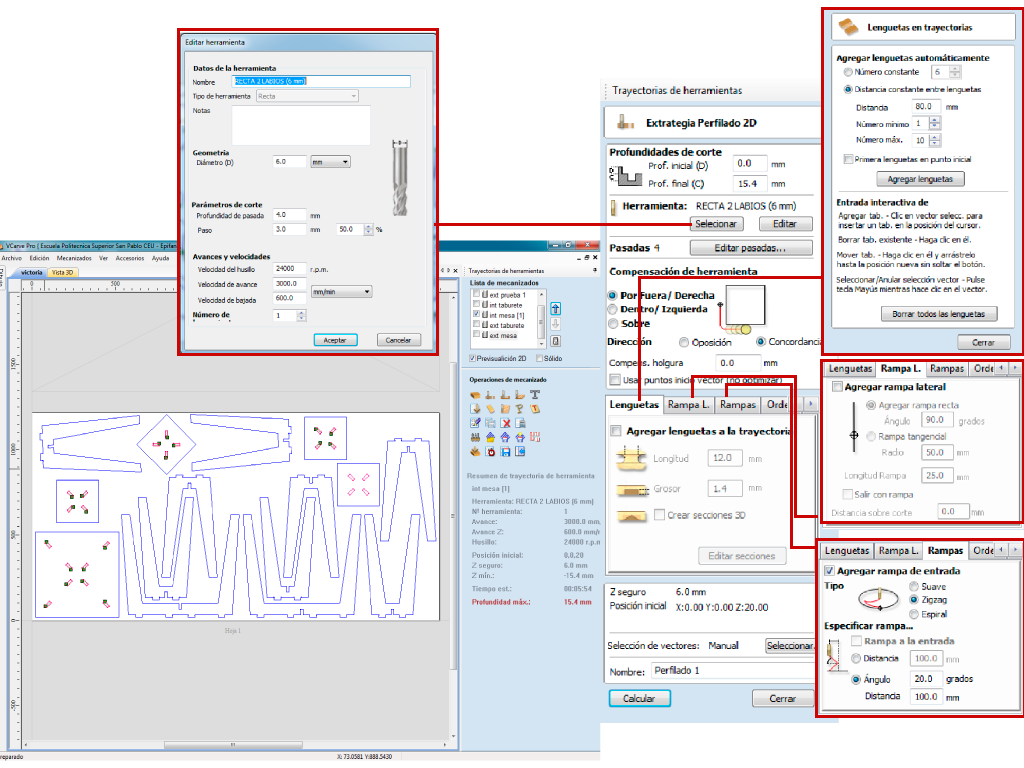

I used a 2 flute 6mm end-mill.

Feeds and Speeds:

- Spindle Speed: 24000 r.p.m

- Feed Rate 3000 mm/min

- Plunge Rate: 600 mm/min

Depth of cut:

- Initial depth :0 mm

- Final depth:15.4mm

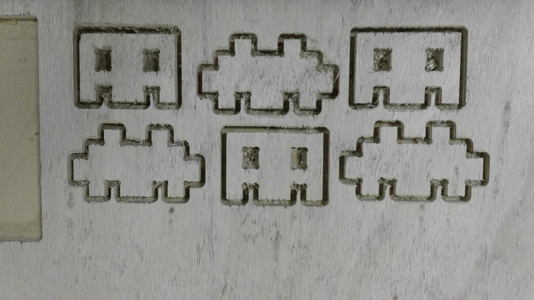

Final result

And that was the final result: