LESSON TEME: Molding and Casting

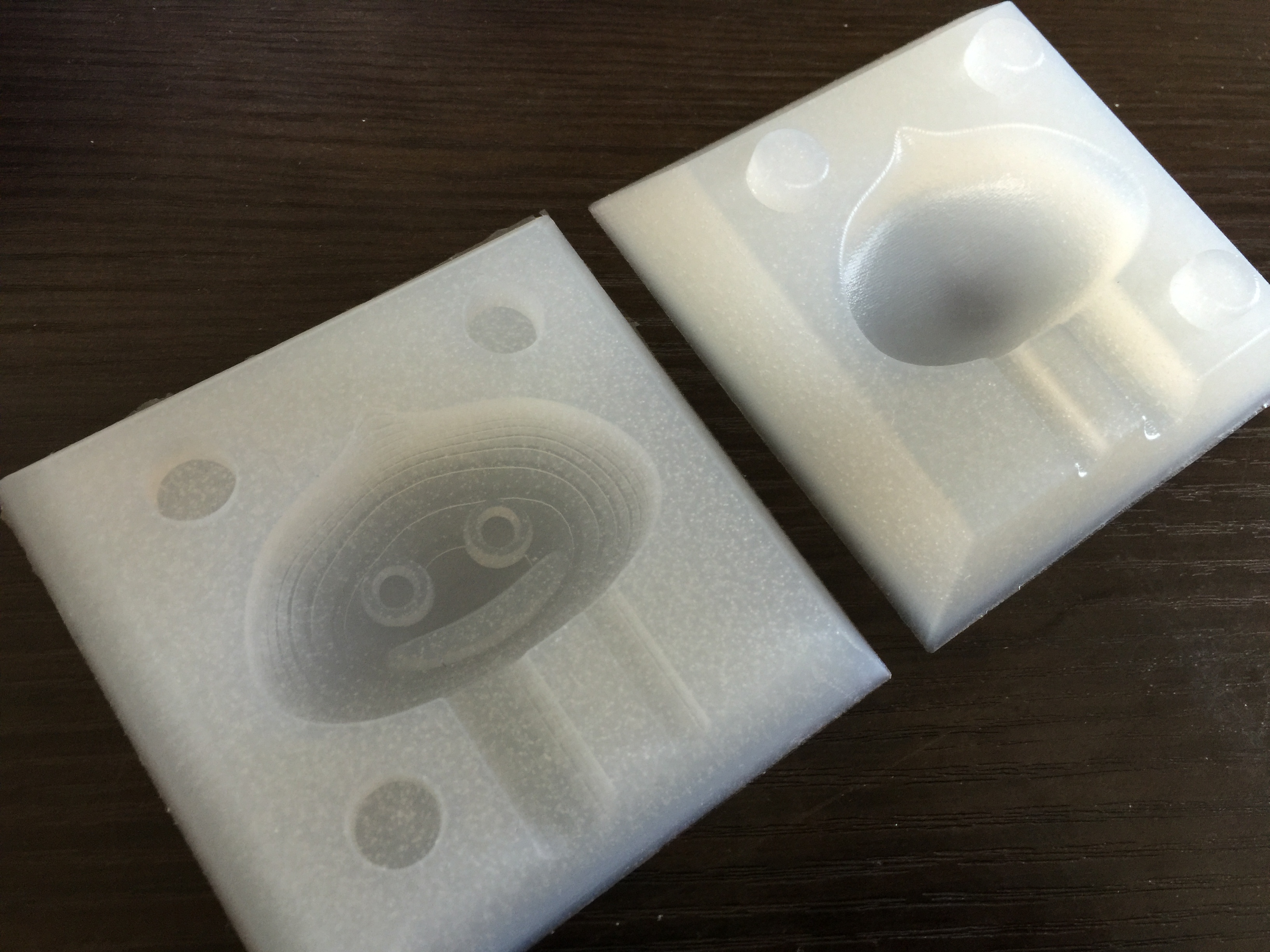

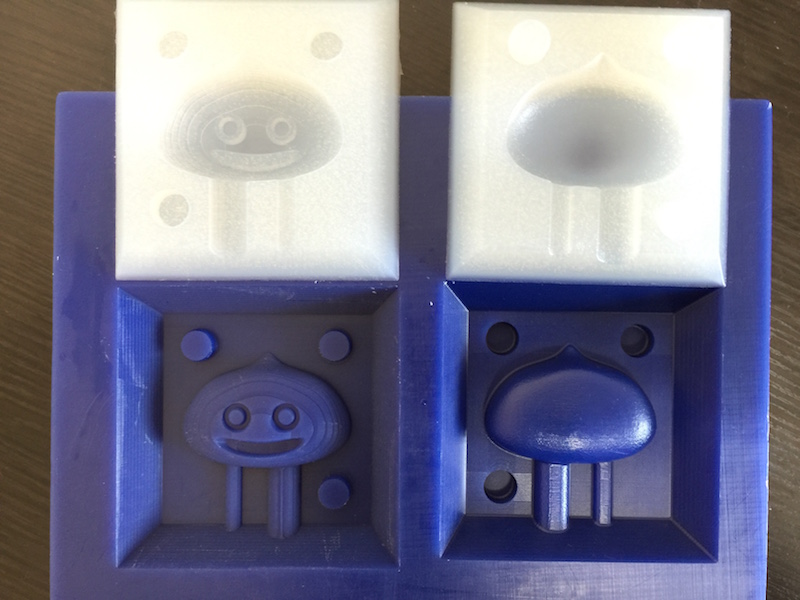

Figure [1] shows a molding shape I made by using silicon for food. This shape is a slime monster which appaers in a TV game "DRAGON QUEST".

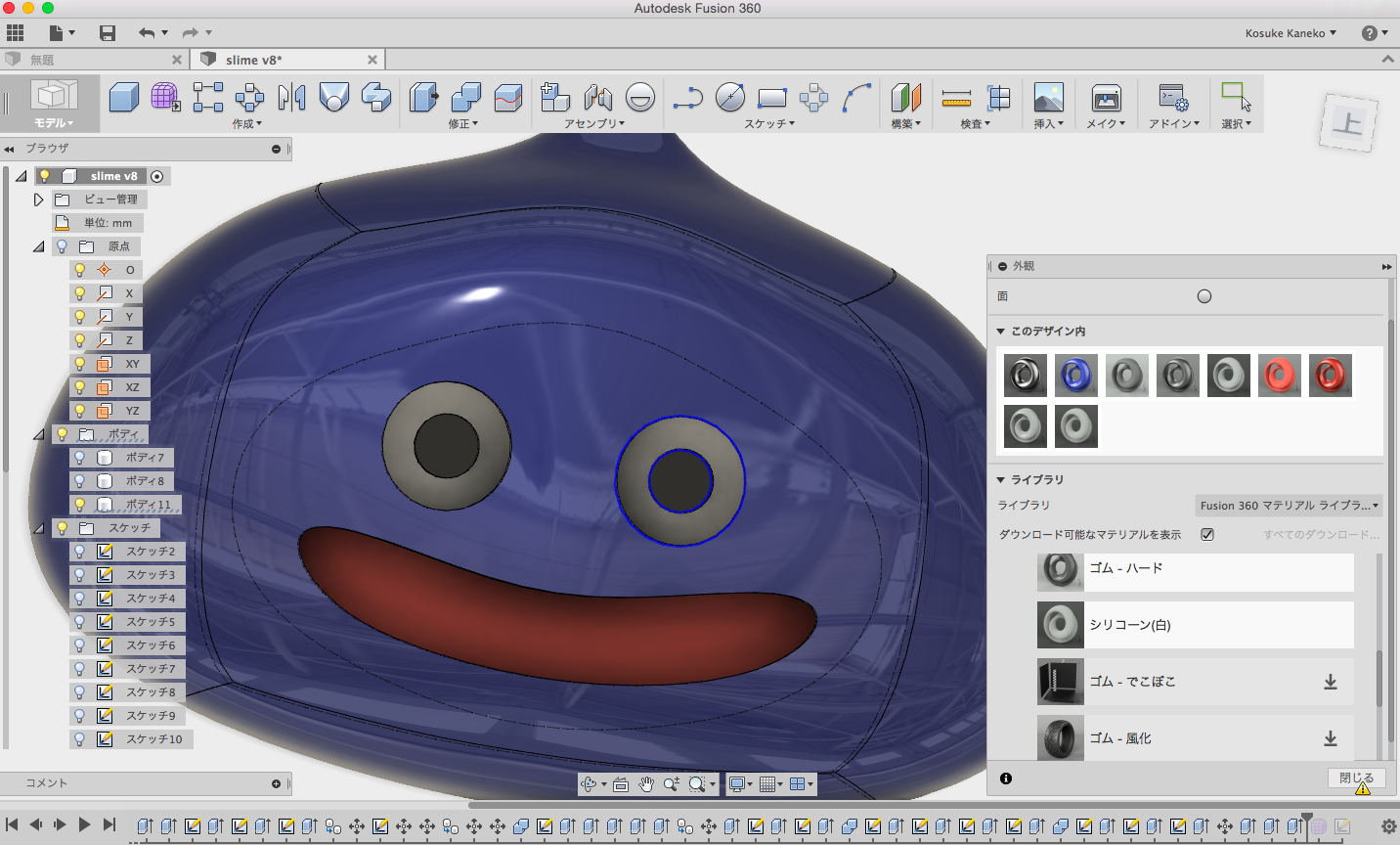

Design for Molding Shapes

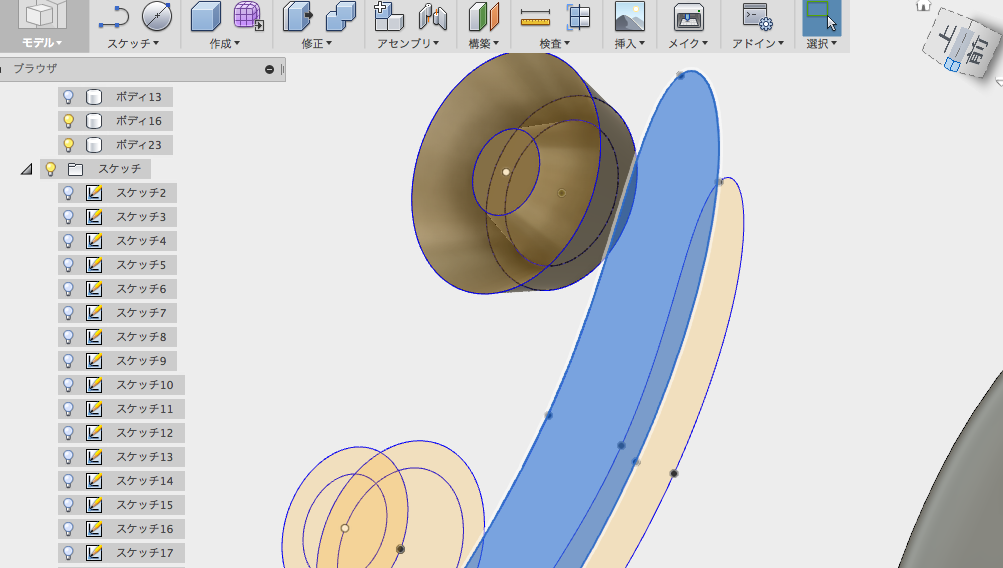

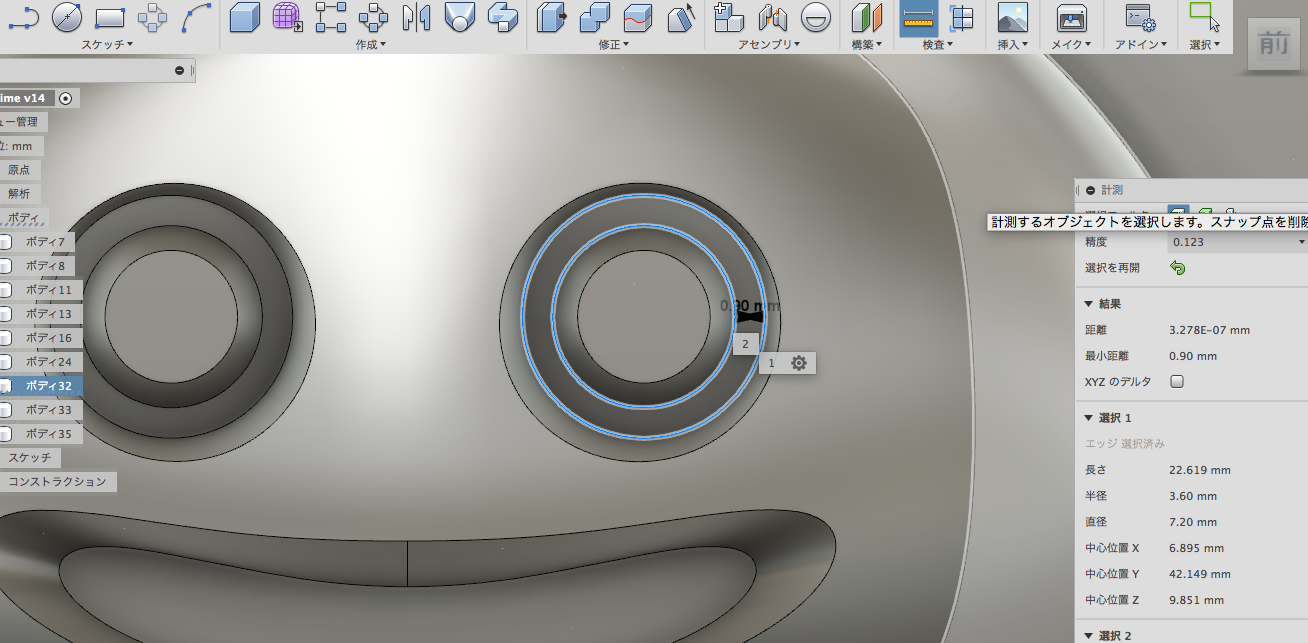

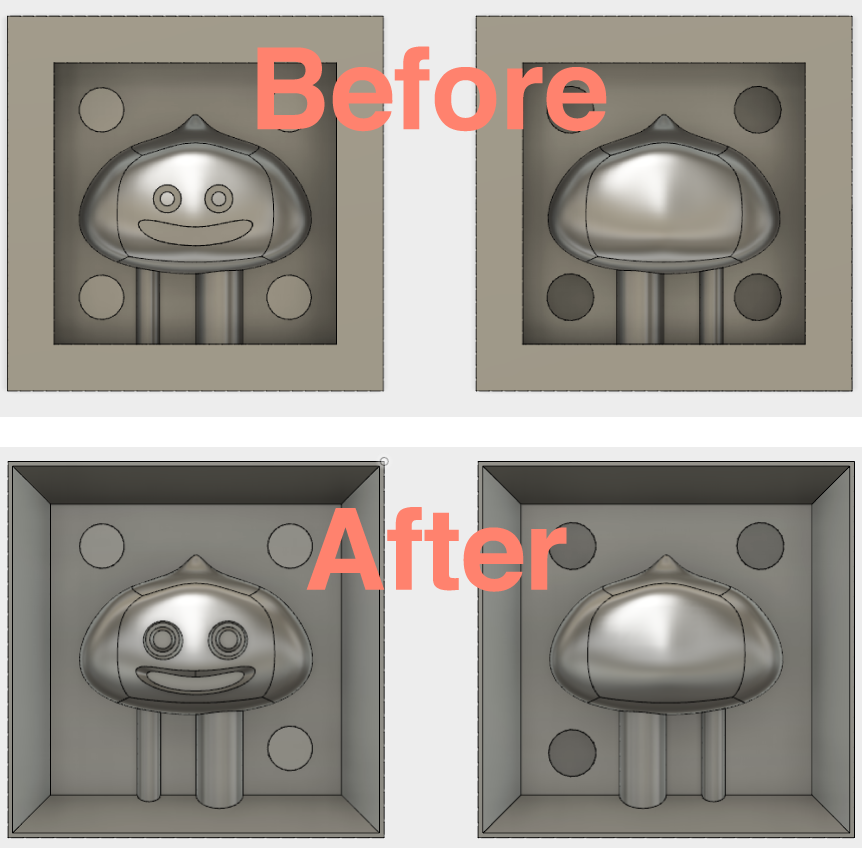

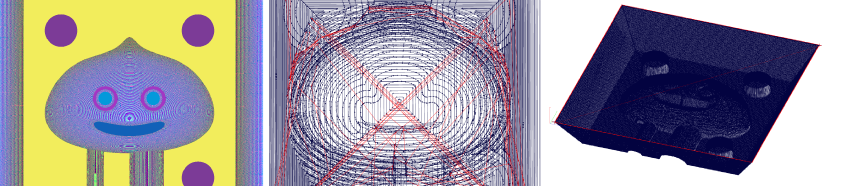

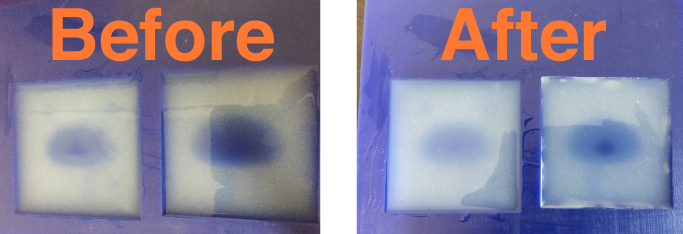

I designed the slime monster for molding shape by using Fusion 360 [2]. The carefully point for designing a molding shape is to make inclination for each edge for milling[3]. And also careful the distance of wide space of each object [4]. Figure [5] shows before/after design for considering the inclination and distance. Figure [6] shows the results of milling data on fabmodules. The right one is the hightmap. The cnter one is raugh cut data. The left one is finish cut data.

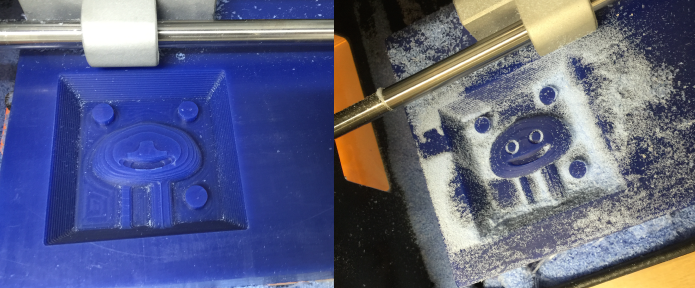

Milling Molding Shape

I milled a wax by using SRM-20, the milling speed is 20 (mm/s). The endmill size is the followings:

| Rough Cut of Front Side | Squared Endmill, 3mm diam. |

| Final Cut of Front Side | Squared Endmill, 0.8mm diam. |

| Rough Cut of Rear Side | Rounded Endmill, 2mm diam. |

| Final Cut of Rear Side | Rounded Endmill, 2mm diam |

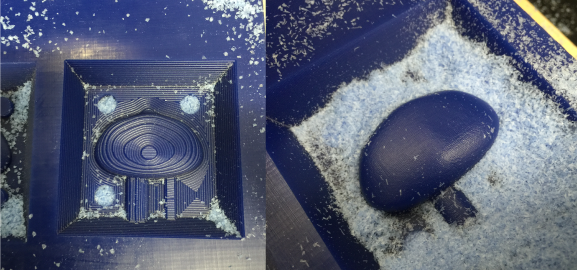

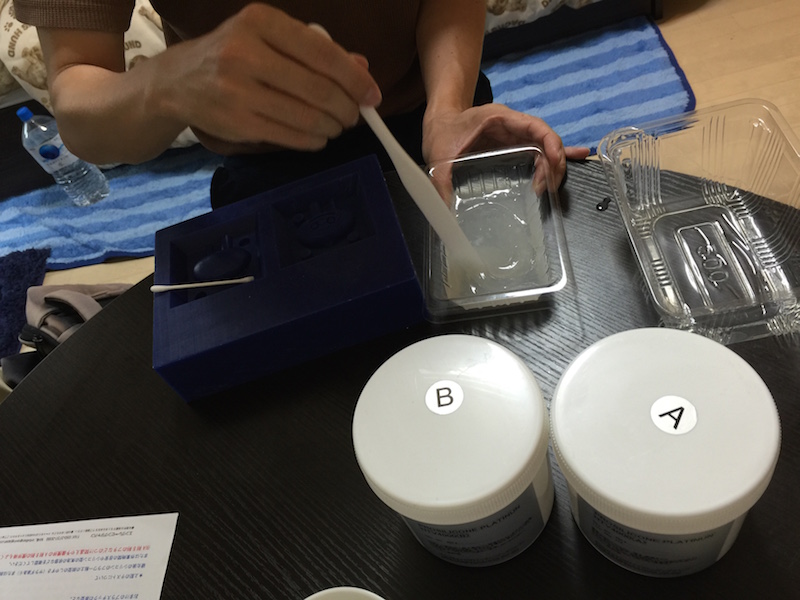

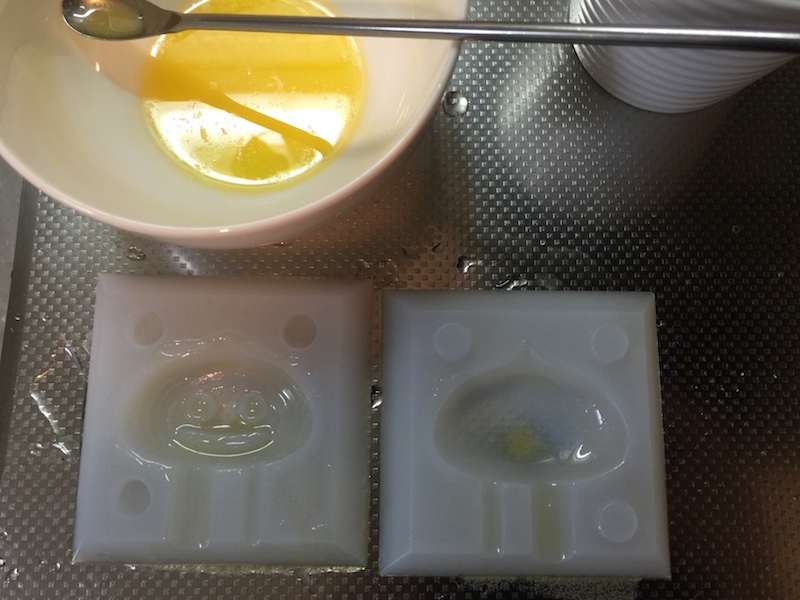

Pour Silicon into Molding Shapes

There are two types of silicon lequid A and B shown in the figure [10]. I pick out the silicon A and B with the same quantity. I stired each silicon for a while and then merged the silicon A and B. I also stired the merged silicon for a while and poured it molding shapes. The left side of figure [11] shows the situlation just when I poured silicon into the molding shape The right side one shows the situation one day after I poured. Finally, I got the casting shapes [12].